-

iestinstrument

Understanding Single-Particle Mechanical Properties: Compression and Crushing Behavior of Hollow Spheres

1. Background

With the continuous development of science and technology, research in the field of materials science is becoming increasingly in-depth. Among them, hollow sphere materials have shown broad application prospects in many fields due to their unique structure and performance. The mechanical properties of hollow sphere materials are closely related to their internal structure and composition. The SPFT (single-particle mechanical properties test) equipment of IEST can deeply understand the mechanical response of hollow sphere materials when compressed, including the crushing force, brittle characteristics, internal microstructure and other information of particles, providing a scientific basis for further optimization and application of materials.

2. Test Equipment and Methods

2.1 Test Instrument

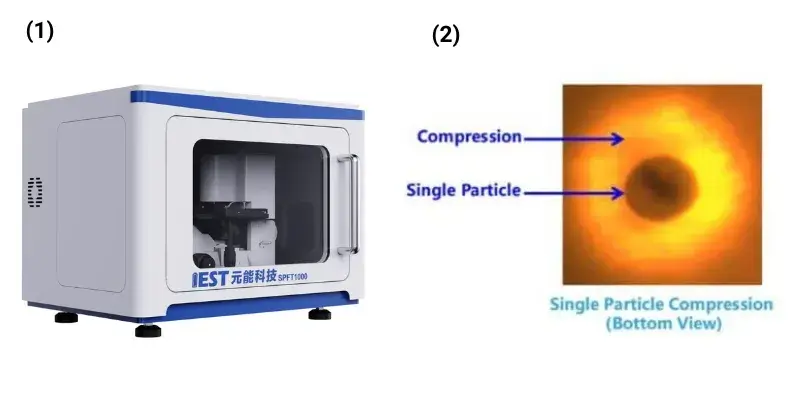

The Single-Particle Force Test (SPFT) system developed by IEST enables high-precision displacement control and force measurement during particle compression. Equipped with a bottom-mounted optical imaging system, the SPFT captures real-time deformation and particle crushing events, making it ideal for evaluating the mechanical properties of micron-sized hollow spheres.

Figure 1. (a)Single Particle Force Properties Test System; (2) Bottom view of optical system

2.2 Samples and preparation.

Two rare-earth oxide hollow sphere grades (XT-1, XT-2) and two fly-ash hollow sphere grades (FM-1, FM-2) were studied. Samples were dispersed in ethanol to minimize agglomeration, and individual particles were located under the optical microscope prior to testing. For statistical reliability, each grade was tested on >5 isolated particles and many particles were tested repeatedly (10–15 repeat compressions per grade) to evaluate reproducibility and population scatter.

2.3 Test protocol

Single particles were centrally aligned beneath a flat, rigid indenter. Compression proceeded under displacement control at a constant approach rate until particle failure. The system recorded load and displacement continuously; high-speed images captured the onset of cracking, progressive fragmentation and final crushing morphology.

2.4 Data analysis.

From each test we extracted: (1) peak crushing force, (2) displacement at peak force, (3) the full force-displacement curve shape, and (4) post-failure fragment behavior. Where particle geometry was measurable, compressive strength was calculated using standard powder test methods (force normalized by contact area or characteristic diameter) to facilitate cross-sample comparison.

3. Results Analysis

3.1 Single particle compression curve and dynamic image display

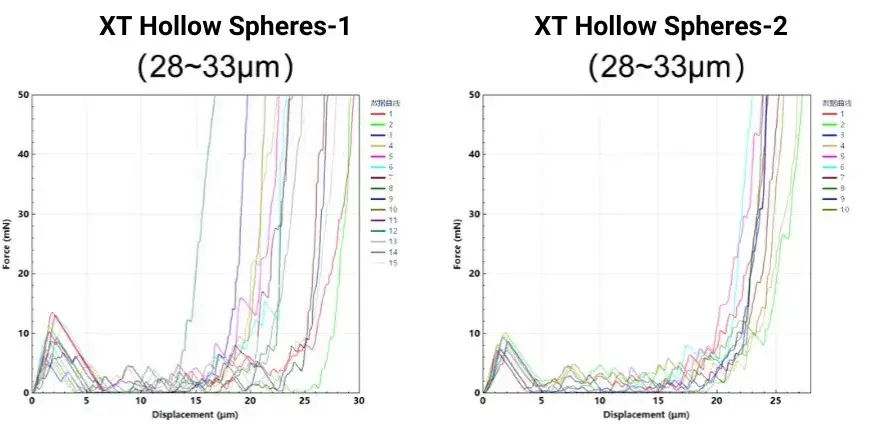

Figure 2. Single particle compression curves of two different XT hollow spheres

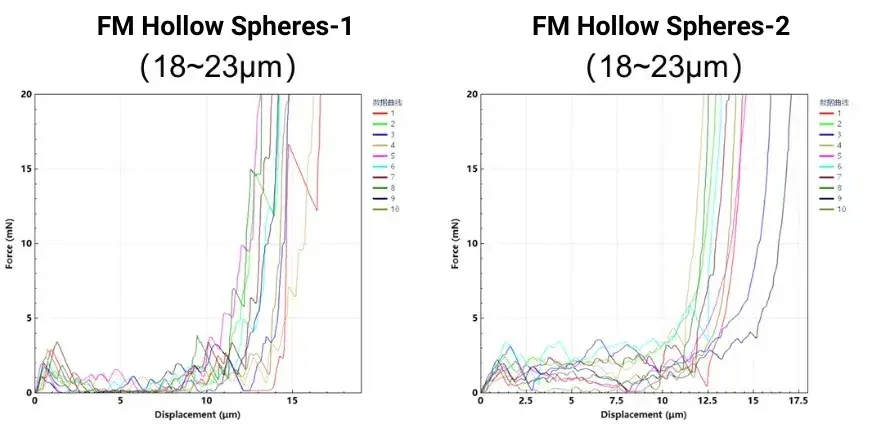

Figure 3. Single particle compression curves of two different FM hollow spheres

Figure 4. Animation of the single particle compression process of XT hollow sphere (left) and FM hollow sphere (right) (excerpt)

3.2 Comparison of crushing force and compressive strength

From the results, it can be seen that the curve consistency of each sample tested 10-15 times in parallel is relatively good. The overall crushing force of the single particle of the two XT hollow spheres tested is much greater than that of the other two FM hollow spheres. Due to similar composition and particle size, there is little difference between different styles of XT hollow spheres/FM hollow spheres-1/-2.

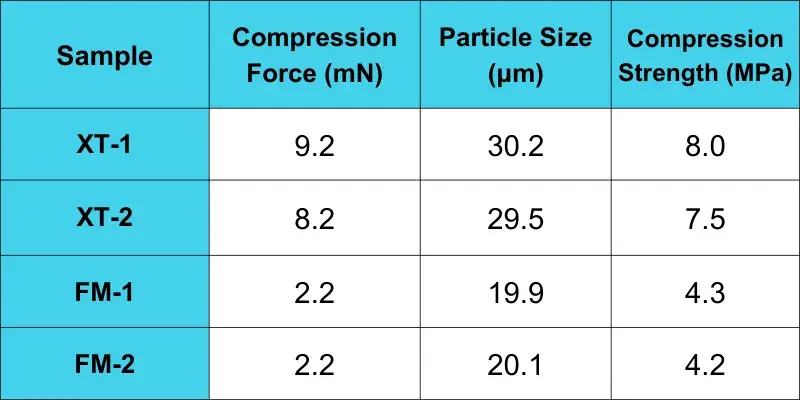

According to the national standard GB/T 43091-2023 on the test method of powder compressive strength, the compressive strength of the particles can be calculated by the crushing force of a single particle and the particle size. The average results are shown in Table 1. The compressive strength of the two XT hollow spheres is about twice that of the two FM hollow spheres, and the compressive strength of XT-1 is slightly greater than that of XT-2. This may be because the rare earth material itself has a higher strength and hardness, which enables it to better resist deformation and damage when subjected to external forces. It can also be seen from the animated image in Figure 4 that the XT hollow sphere is relatively hard when broken, while the FM hollow sphere appears relatively soft.

Table 1. Single particle compressive strength of different XT hollow spheres and FM hollow spheres

3.3 Wave-shaped characteristics of force-displacement curve

On the single-particle compression curve, we can also see the special force-displacement curve characteristics of the hollow sphere after crushing. Their force-displacement curves all show a wavy shape after crushing, similar to the shape of a wave. This wavy shape may be caused by the complexity of the internal structure of the hollow sphere and the expansion and intersection of cracks during the crushing process. Specifically, in the early stage of compression, as the pressure head gradually presses down, the particles begin to deform elastically. When the stress reaches a certain level, cracks begin to appear in the particles and plastic deformation occurs. As the cracks expand and converge, the particles gradually break, and the force-displacement curve also fluctuates.

4. Discussion — Mechanisms Underpinning Wavy Force-Displacement Behavior

The observed wavy force-displacement response after shell collapse can be attributed to a combination of factors:

-

Multi-crack nucleation and interaction. Multiple cracks nucleate at different sites and propagate at varying rates. Their interactions produce alternating load relief and transient re-engagement of remaining shell segments, yielding force oscillations.

-

Fragment interaction and mechanical interlock. As the shell fragments, pieces may temporarily jam, rub or reassemble under the indenter, causing local increases and decreases in measured load.

-

Internal heterogeneity. Variations in shell thickness, porosity, inclusions or reinforcement phases lead to spatially varying strength; localized failure events produce abrupt load changes visible as waves.

-

Energy dissipation mechanics. The forms of energy absorption — brittle fracture versus plastic deformation or microcracking — differ between XT and FM materials, altering both peak force and post-peak waviness.

Understanding these mechanisms at the single-particle level is critical for designing hollow spheres with targeted crushability, impact resistance or controlled fragmentation behavior tailored to downstream processing or functional performance.

5. Practical Implications & Applications

-

Material selection: For load-bearing filler or structural uses, XT-type hollow spheres provide superior mechanical integrity; FM-type may be preferable where controlled breakage or lower density is prioritized.

-

Process design: Knowledge of particle crushing thresholds informs compaction and pressing parameters in manufacturing, reducing damage and yield loss.

-

Product reliability: Single-particle metrics (crushing force distribution and compressive strength) can be integrated into quality control acceptance criteria to ensure batch consistency.

-

Model development: Force-displacement signatures and synchronized imagery enable calibration of numerical models (DEM, finite element shell models) to predict aggregate behavior under processing loads.

6. Summary

This paper evaluates the mechanical properties of rare earth oxide hollow spheres and fly ash hollow spheres by comparing their force-displacement curves and compressive strength data. The curves of the two tested rare earth oxide hollow spheres and two fly ash hollow spheres are consistent, and the overall crushing force and compressive strength of the rare earth oxide hollow spheres are higher.

In addition, the undulating morphology of the force-displacement curve also provides us with valuable information about the internal structure and mechanical response mechanism of the material. By analyzing these undulating characteristics, we can have a deeper understanding of the material’s damage mechanism and failure mode, thereby providing a theoretical basis for its performance optimization and improvement in practical applications.

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.