-

iestinstrument

Single Battery Cells and Module Cells’ Swelling Performance Correlation Analysis

1. Preface

With the rapid advancement of the new energy sector, lithium-ion batteries are now extensively used in electric vehicles (EVs). As a result, the safety performance of these batteries has become a major focal point. During long-term cycling, battery module cell configurations—composed of multiple cells in series or parallel—commonly experience swelling due to lithium intercalation/deintercalation and gas generation. This swelling can compromise the structural integrity of the module casing and even lead to safety hazards. It is therefore essential to monitor battery cell swelling throughout its lifecycle.

Different module designs involve varying numbers of cells, electrical configurations, and pre-tightening forces, each influencing swelling behavior. Experimental analysis of these factors helps reveal how swelling evolves from single cells to full modules. Combining physical tests with simulation allows for better module design and safer EV batteries. This study provides fundamental data on the correlation between swelling thickness and swelling force in single cells and multi-cell modules, supporting predictive modeling for ev battery cell swelling compensation.

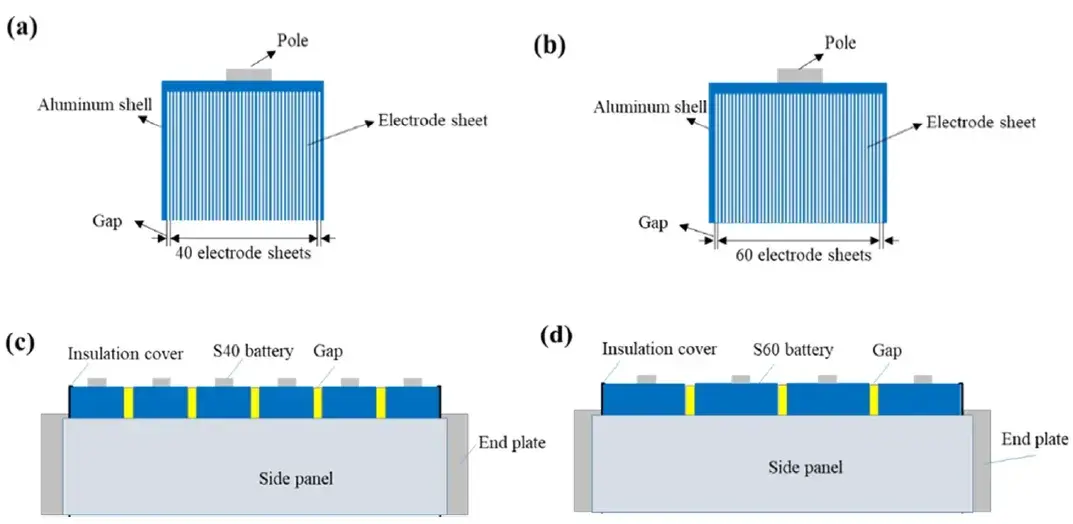

Figure 1. Schematic diagram of single cell and module cell

2. Experimental Equipment and Test Methods

2.1 Experimental Equipment

The tests were conducted using the In-situ Swelling Analyzer, model SWE2110 (IEST), shown in Figure 2. This system enables high-precision measurement of thickness and force changes in real time during battery cycling.

Figure 2. Appearance of SWE2110 Equipment

2.2 Test Procedure

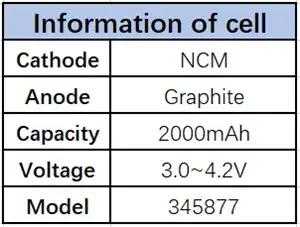

2.2.1 The Cell Information is Shown in Table 1

Table 1. Test cell information

2.2.2 Charge–Discharge Protocol

-

Temperature: 25°C

-

Rest: 60 min

-

Charge: 0.5C CC to 4.35V, then CV until current ≤ 0.05C

-

Rest: 30 min

-

Discharge: 1.0C to 3.0V

2.3 Cell Thickness Swelling Test

Each cell or module was placed in the SWE2110 chamber. Using MISS software, parameters such as cell ID and sampling frequency were configured. The system automatically recorded real-time thickness change, temperature, current, voltage, and capacity.

3. Experimental Process and Data Analysis

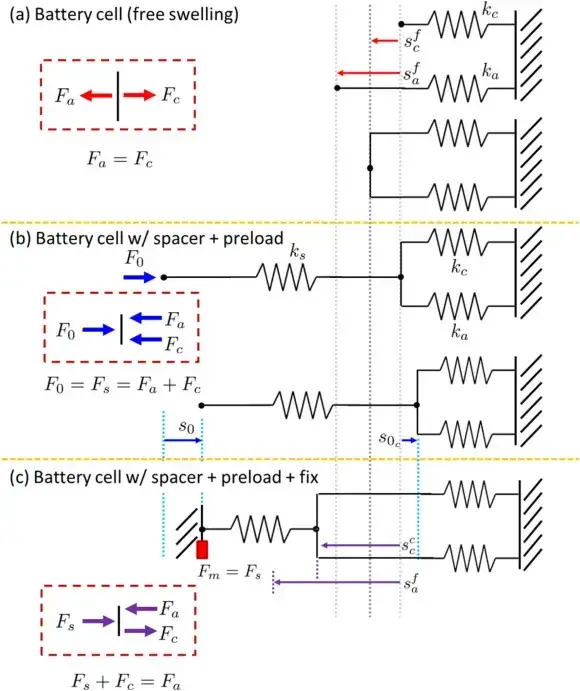

Battery swelling can be evaluated under three test modes (Figure 3):

-

Free swelling: Cell expands without mechanical constraint; useful for fundamental material expansion characterization.

-

Constant preload: A pre-tightening force (F₀) approximates module clamping conditions and allows observation of how preload redistributes during cycling.

-

Constant gap: Simulates rigid module housings with fixed clearance; cell expansion is resisted, producing internal forces that a pack must accommodate or compensate.

Each mode imposes different boundary conditions and mechanical interactions. In module configurations, the presence of a pouch cell swelling pad or other interstitial materials adds complexity to force distribution. Under constant-pressure or constant-gap conditions, the role of the pouch cell swelling pad becomes critical in managing mechanical stress and supporting ev battery cell swelling compensation.

Figure 3. Three modes of cell and module cell unit swelling test.

3.1 Correlation Between Single Cell and Module Cell Swelling Thickness

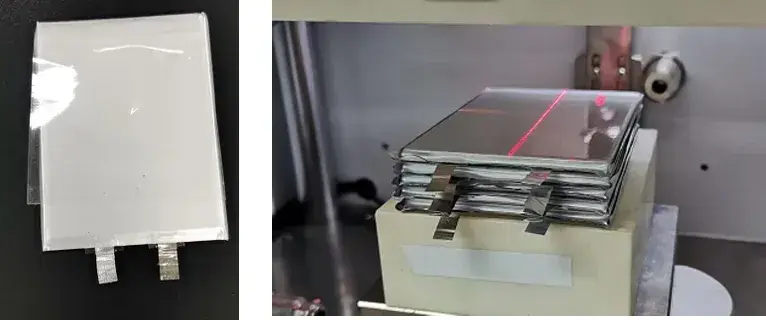

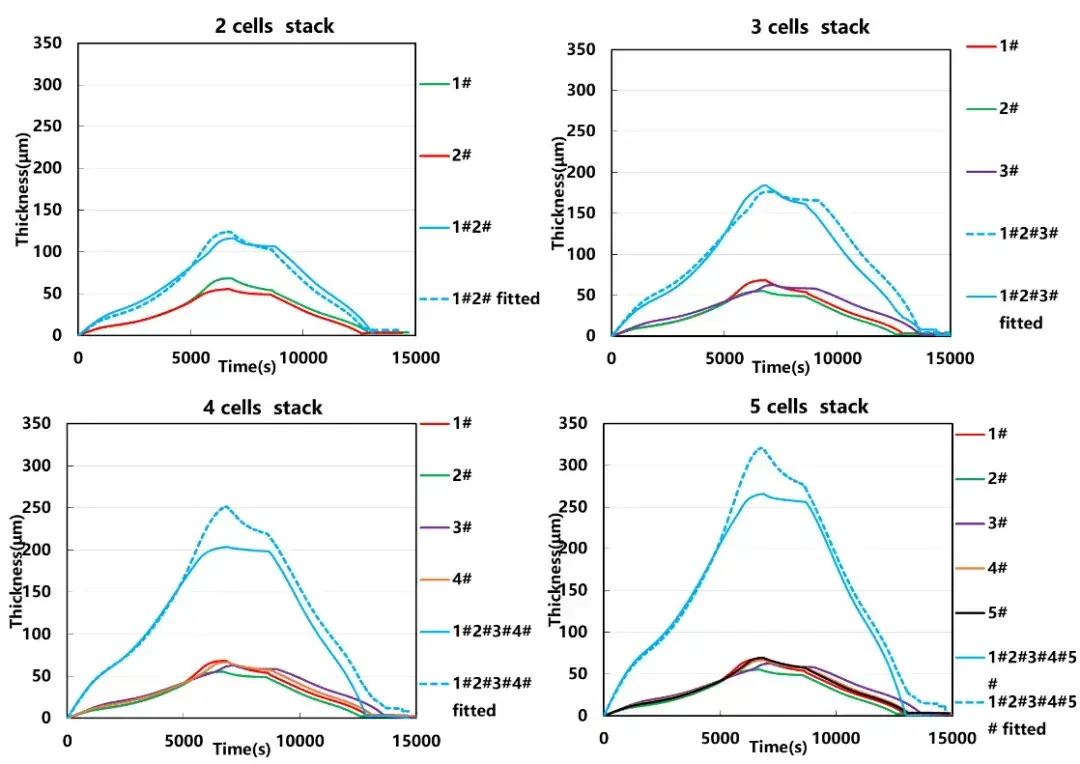

To simulate inter-cell layers in a module, a PET film was applied to individual cells (Figure 4). Cells were then stacked and tested under a 200 kg constant-pressure mode. Figure 5 shows the swelling thickness of individual cells and stacked modules during cycling.

Both single and multi-cell setups exhibited swelling during charging and contraction during discharging, consistent with Li-ion intercalation and deintercalation in graphite and ternary materials. The measured module swelling (solid line) closely matched the arithmetic sum of individual cell swelling (dotted line), though minor deviations occurred at end-of-cycle points, likely due to cell-to-cell inconsistency. These results emphasize the importance of cell consistency in multi-cell modules.

Figure 4. Schematic diagram of battery with PET film and Schematic diagram of cell superposition

Figure 5. Variation curves of swelling thickness of each battery cell and after superimposition

3.2 Correlation Between Single Cell and Module Cell Swelling Force

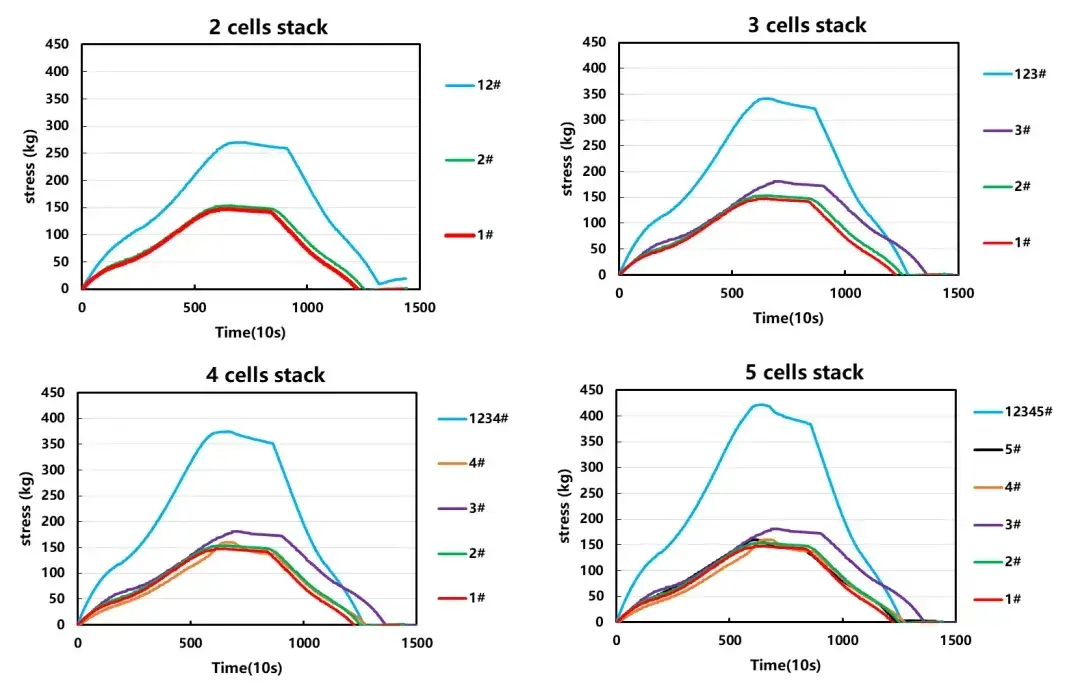

Under constant-gap mode, the swelling force was measured for single cells and stacked modules (Figure 6). As the number of cells increased, the total swelling force of the module also increased—but not linearly. The total force was less than the arithmetic sum of individual cell forces. This suggests that constraining the gap alters the internal mechanical and electrochemical state of cells, affecting their swelling behavior. Further studies incorporating capacity measurements before and after grouping may clarify this phenomenon.

Non-linear force increase may also indicate that beyond a certain stacking pressure, cell components such as electrodes and separators undergo microstructural compression, influencing overall performance.

Figure 6. Swelling force variation in single and stacked cells

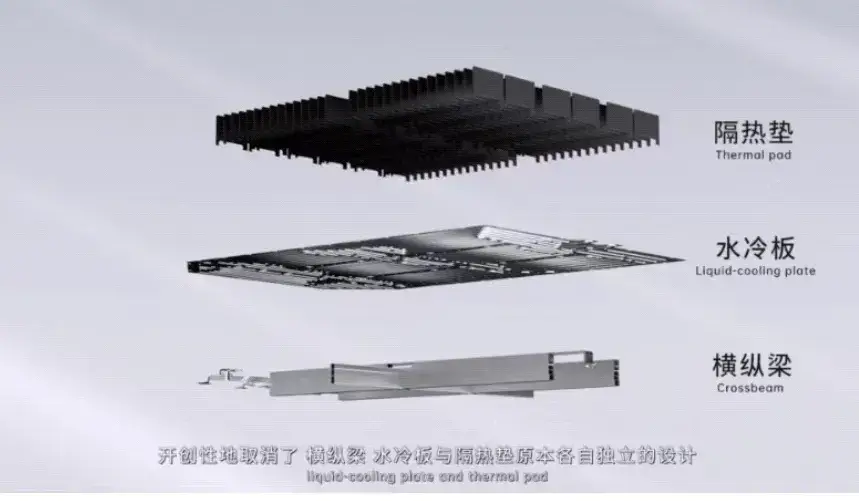

These findings indicate that in a fixed module or pack, the design and material of inter-cell pads—such as a pouch cell swelling pad—significantly influence overall swelling and force distribution. For example, CATL’s Kirin battery incorporates a multi-functional elastic interlayer that accommodates cell swelling and contraction, thereby enhancing cycle life and safety.

Figure 8. Multi-functional elastic interlayer in CATL’s Kirin battery

4. Summary of Implications for pack design and EV battery cell swelling compensation

-

Preload design matters: Under preload (constant pressure) conditions, thickness behavior is predictable and additive—making engineering allowances easier. However, the preload level itself affects how cells share load and thus their electrochemical behavior.

-

Gap-limited designs require caution: Rigid module designs that rely on a fixed gap to control expansion can create uneven stress distributions and non-intuitive force accumulation—potentially shortening cell life or damaging casings.

-

Consistency is critical: As stack size grows, monomer (single-cell) consistency becomes increasingly important. Small variations in cell capacity, internal resistance, or initial thickness amplify module-level discrepancies.

-

Compensation strategies: Effective EV battery cell swelling compensation should combine mechanical design (elastic interlayers, compliant gaskets, multi-functional pads) with thermal and electrochemical management. Solutions such as CATL’s “Kirin” elastic interlayer—integrating beams, thermal plates and breathing-friendly micro-bridges—illustrate industrial approaches to accommodating breathing cells.

-

Measurement best practice: Use in-situ swelling analyzers with multi-channel capability and pouch cell swelling pads to obtain spatially resolved force and thickness maps during cycling.

5. Conclusion

This study used an in-situ swelling analyzer (SWE2110) to evaluate swelling thickness and force in single cells and multi-cell modules. Under constant pressure, the swelling thickness of a module closely followed the arithmetic sum of individual cell swelling. However, under constant gap conditions, the swelling force did not scale linearly, highlighting the effect of mechanical constraints on cell behavior.

These insights are valuable for designing better module cell systems and effective ev battery cell swelling compensation strategies. Future work will focus on modeling mechanical behavior under different boundary conditions and elucidating electrode-level swelling mechanisms.

5. References

[1] Yongkun Li, Chuang Wei, Yumao Sheng, Feipeng Jiao, and Kai Wu. Swelling Force in Lithium-Ion Power Batteries,Ind. Eng.Chem. Res,2020, 59, 27, 12313–12318.

[2] Oh K Y, Epureanu B I , Siegel J B , et al. Phenomenological force and swelling models for rechargeable lithium-ion battery cells[J]. Journal of Power Sources, 2016, 310(Apr.1):118-129.

[3] Martin Wünscha,Kaufmana, Dirk Uwe Sauer. Investigation of the influence of different bracing of automotive pouch cells on cyclic liefetime and impedance spectra. Journal of Energy Storage 21 (2019) 149–155.

[4] Qiu Shitao, Chen Chaohai, Jiang Jibing. Effect of foam performance on module cell swelling force. Guangdong Chemical Industry, 2020, 47(22): 1-3d

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.