-

iestinstrument

How to Choose the Right Battery Test Equipment? 5 Essential Tips

1. Overview

As the core of the modern energy system, batteries are widely used in various critical fields such as consumer electronics, power batteries, and energy storage systems. A reliable battery test system is not only the foundation of R&D and quality control but also directly affects product performance, safety, and lifecycle management. For research institutions and industrial users, selecting a test system that truly meets their needs is a crucial and complex decision.

IEST specializes in the R&D and manufacturing of high-precision battery test equipment and electrochemical analysis equipment. We have a deep understanding of the practical challenges users face in material research, cell development, module integration, and failure analysis. Our product design consistently revolves around three core principles: ultra-high precision measurement, system-level stability, and comprehensive safety protection. Based on solid industry experience and continuous customer feedback, we continuously optimize device architecture and functional systems, committed to providing users with reliable testing solutions.

So, how should one systematically evaluate and select among the many battery test equipment available on the market? IEST recommends considering the following 5 dimensions in depth.

Figure 1. IEST Electrochemical Product Family

2. Five Critical Dimensions for Evaluating Battery Test Equipment

2.1 Hardware Performance — Accuracy, Range, and Reliability

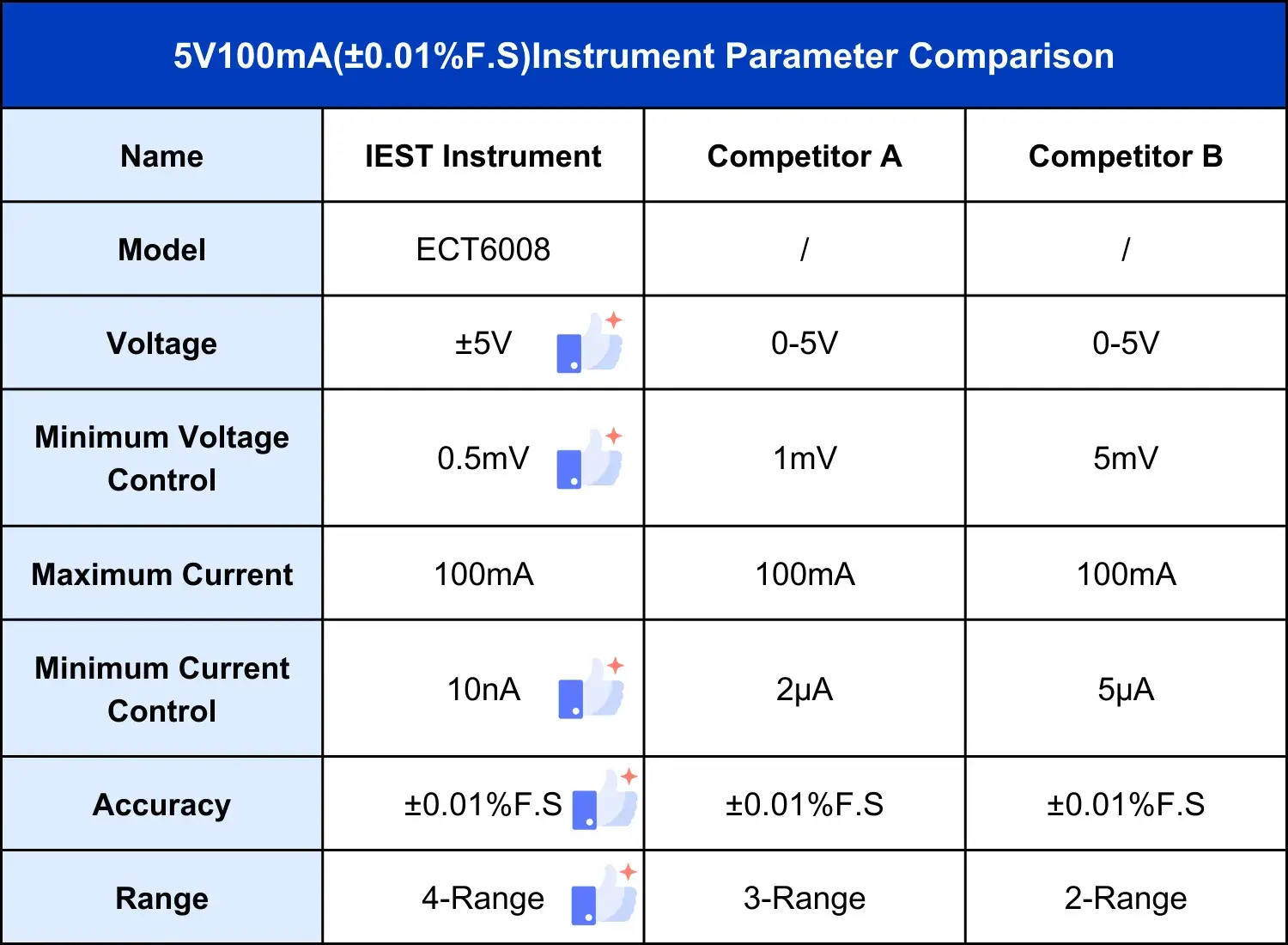

The essence of battery testing lies in the high-precision control and measurement of voltage and current. Excellent battery test equipment should feature automatic multi-range switching capability, supporting both high-rate charge-discharge tests and precise control at nanoampere-level currents, while ensuring linear accuracy and stability across the entire range. Key component selection, low-noise circuit design, and regular calibration mechanisms directly impact data credibility.

IEST’s Advantages:

Our ECT Series High-Precision Charge-Discharge Battery Test Systems and ERT Series Electrochemical Performance Analyzers offer voltage and current control accuracy as high as 0.01%, supporting a wide current output range from nanoamperes to amperes. The industry-leading 4-range current design meets diverse testing scenarios. Each device is verified for accuracy via CNAS certification and comes with IEST calibration reports, ensuring authentic and reliable data. Additionally, the equipment integrates triple protection mechanisms across hardware, software, and firmware, supporting one-click test resumption to ensure continuity and integrity in long-term testing.

Figure 2. IEST ECT6008-5V100mA High-Precision Charge-Discharge System

Table 1. Parameter comparison of IEST battery test equipment and other equipment

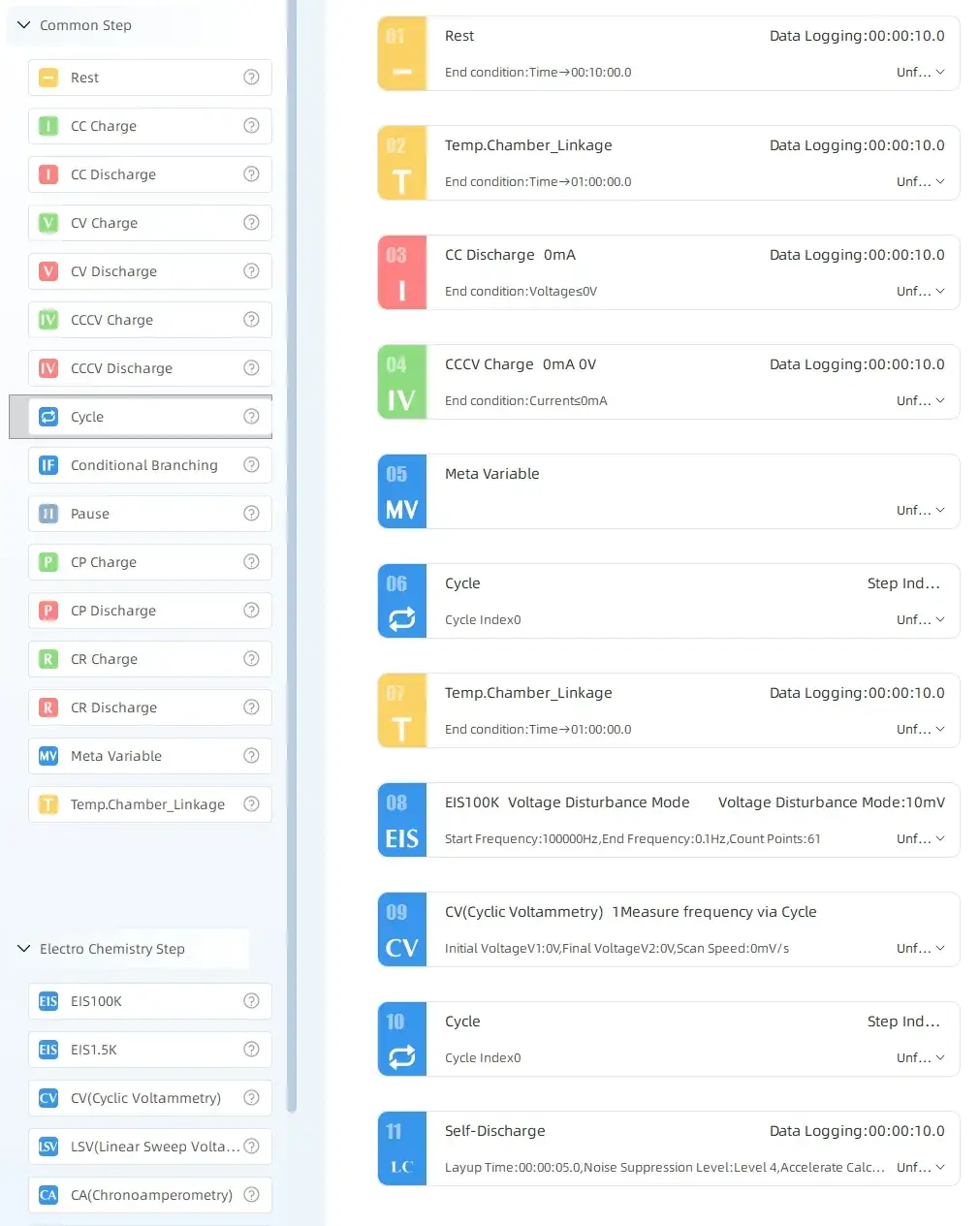

2.2 Software Capabilities — Rich Protocols and Flexible Workflows

Test software should not only serve as an operation interface but also empower experimental processes. It must support multiple electrochemical test methods, such as Cyclic Voltammetry (CV), Electrochemical Impedance Spectroscopy (EIS), Galvanostatic Intermittent Titration Technique (GITT), and Potentiostatic Intermittent Titration Technique (PITT), while allowing users to flexibly design complex sequences for automated and batch testing.

IEST’s Advantages:

IEST provides self-developed test software that supports multi-step sequence design, real-time data visualization, and script-based control. Whether for material-specific capacity analysis, Coulombic efficiency tests, or dynamic EIS and cycling impedance monitoring, all can be efficiently completed on a unified platform, significantly improving R&D efficiency.

Figure 3. IEST Software Step Sequence Interface

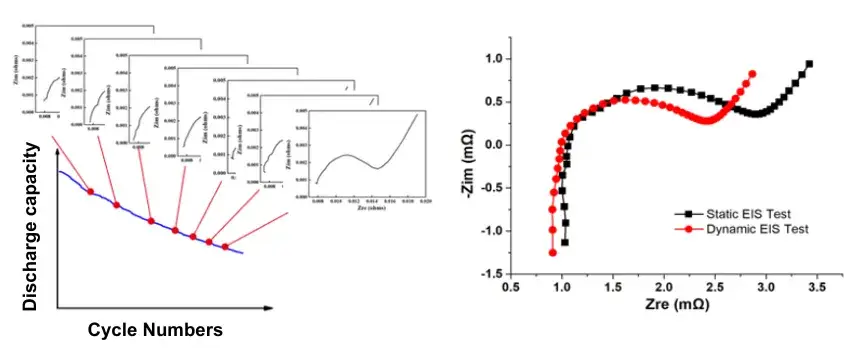

2.3 Data Processing — High Sampling, Deep Analysis, Easy Export

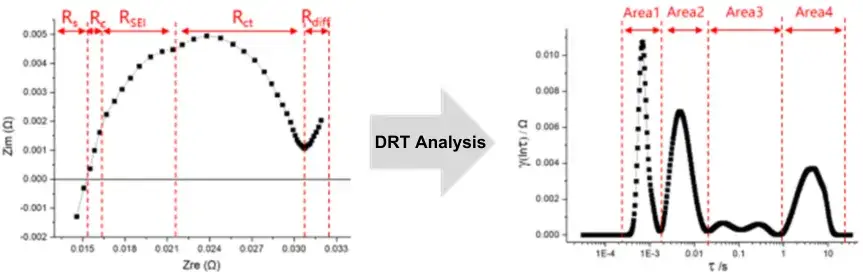

Battery test equipment must possess high sampling rates and large storage capacity to capture subtle features during transient responses. More importantly, the system should offer professional data processing tools, such as dQ/dV differential capacity analysis, Distribution of Relaxation Times (DRT) analysis, and EIS fitting, to help users extract key insights from vast datasets.

![]()

Figure 4. IEST Multi-functional Data Analysis Software

Figure 5. Cycling EIS and Dynamic EIS Testing

Figure 6. DRT Analysis of IEST EIS Curves

IEST’s Advantages:

Our systems support high-speed sampling at 0.01s intervals and enable real-time data backup and multi-layer storage. The accompanying analysis software includes modules for CV, EIS, dQ/dV, and more, helping identify key behaviors such as material phase transitions, side reactions, and impedance evolution, while exporting publication-ready charts and graphs. And consider how easily the data can be exported for reporting or further analysis. Compatibility with various formats (CSV, Excel, etc.) is beneficial.

2.4 System Expandability — Multi-Parameter Coupling and External Integration

Battery testing often requires synchronous monitoring of multi-physics signals such as temperature, pressure, and volume change, or integration with peripheral devices like environmental chambers and glove boxes. Therefore, modular expandability and external communication compatibility are critical.

Figure 7. IEST High-Precision Auxiliary Module: Temperature, Voltage, Pressure

IEST’s Advantages:

We offer the Aux_Module series of high-precision auxiliary modules, supporting the acquisition of various signals including temperature (T-type thermocouples, PT100), voltage, and pressure. Customized integration solutions with environmental chambers are also available. Communication between the main unit and auxiliary modules is via Ethernet, ensuring stable and flexible configuration to fully support multi-scenario testing from material to cell level.

2.5 Application Support — Product Safety Mechanisms and Professional Services

Battery testing involves high-energy samples, requiring equipment with dual hardware and software protection mechanisms, such as real-time monitoring and shutdown for over-voltage, over-current, over-temperature, and short-circuit events. Additionally, the supplier’s technical support and service capabilities directly impact the long-term user experience.

IEST’s Advantages:

We incorporate multiple safety protection strategies and provide remote monitoring and fault warning capabilities. Backed by a comprehensive customer service system and rapid response mechanism, we offer full-cycle support from solution design and equipment training to data analysis. We have extensive project experience in advanced applications such as impedance modeling, life prediction, and consistency screening.

3. Matching equipment to use cases

-

Materials R&D / lab screening: Prioritize precision at low currents, high sampling rates and EIS capability.

-

Cell engineering & formation: Focus on multi-channel cyclers with robust long-term stability, automated formation scripts and thermal control integration.

-

Production QA & sorting: Throughput, repeatability, and automated report generation matter most—select multi-channel systems with easy-to-deploy templates.

-

Safety testing / abuse protocols: Ensure compatibility with fixturery for nail penetration, overcharge, thermal ramping, and venting capture systems.

4. A Guide to Avoiding Common Pitfalls: 3 Mistakes Beginners Often Make

4.1 Overlooking Scalability — a Costly Shortfall

One of the most common mistakes when procuring battery test equipment is neglecting scalability. Early-stage projects may only require a handful of channels or basic sensors, but research programs and production lines typically expand. Choose systems with a modular architecture (expandable channel counts, add-on temperature/pressure/thickness sensors, and remote I/O) and open software APIs so you can scale functionality without replacing core hardware. Failing to plan for growth often forces a costly, disruptive equipment refresh later, hurting both productivity and total cost of ownership.

4.2 Underestimating After-Sales Service and Support

After-sales support is often underestimated, yet it is a crucial factor when purchasing a battery test equipment. Brands that offer technical guidance, troubleshooting, and ongoing maintenance can save significant time and prevent potential issues. At IEST, we have established a comprehensive customer service system with a rapid response mechanism, providing full-cycle support from system design and equipment training to data analysis. A reliable after-sales team can also offer valuable technical advice to help you get the most out of your battery test equipment.

4.3 Chasing Low Price — Hidden Costs Add Up

Buying the low-price battery test equipment can be a false economy. Low-cost battery test equipments often sacrifice measurement precision, thermal stability, sampling rate, or safety interlocks—issues that produce unreliable data, scrap materials, and potential safety risks. Evaluate battery test equipment on total cost of ownership: include calibration, downtime, consumables, and risk mitigation. Investing in robust, traceably-calibrated equipment typically reduces test error margins (often to <1%) and delivers superior ROI through reproducible data and fewer failed experiments.

5. Battery Test Equipment Procurement checklist (quick reference)

-

Does the unit meet required voltage/current precision across the full range?

-

Is the sampling cadence adequate for the transient tests you run?

-

Are EIS, GITT, PITT and scripting supported natively?

-

Are auxiliary channels (T, P, force, thickness) available and integrable?

-

Is the system traceably calibrated (CNAS or equivalent) and documented?

-

What is the vendor’s service response time and training capability?

-

Are data export formats compatible with your data pipeline and LIMS?

6. Conclusion

Selecting the right battery test equipment is a complex decision that requires a comprehensive consideration of experimental needs, equipment parameters, and brand services, It is essentially about choosing a reliable technical partner. It must not only excel in specifications but also demonstrate stability, flexibility, and safety in practical applications. IEST adheres to the product philosophy of “Precise Measurement, Reliable Operation, and Intelligent Analysis,” committed to providing high-performance and highly usable test solutions for the battery R&D and manufacturing industry. Don’t make hasty decisions. Reach out to a professional supplier today for a tailored solution.

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.