-

iestinstrument

Analysis of Electrode Sheet AB Side Resistance: Measuring Surface Resistance to Assess Coating Uniformity

1. Introduction: The Critical Role of Electrode Coating Uniformity

In lithium-ion battery manufacturing, the two sides of an electrode sheet – Side A (first-coated) and Side B (second-coated) – are as crucial as vital pathways. Their performance uniformity directly dictates key cell metrics: energy density, rate capability, and cycle life. During coating and subsequent calendering processes, subtle differences in equipment, slurry state, and applied pressure can lead to variations in pore structure and particle contact between Side A and Side B.

One of the most direct manifestations of this variation is surface resistance (or area resistance). The difference in surface resistance between the two sides serves as a key indicator for assessing coating uniformity, calendering effectiveness, and predicting overall cell consistency. An optimal electrode manufacturing process should strive to minimize the resistance gap between Side A and Side B.

2. Measurement Equipment and Experimental Setup

2.1 Measurement Equipment

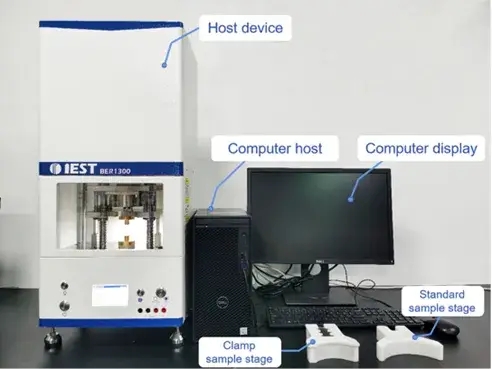

To quantify AB-surface resistance differences, we used the BER-series electrode sheet resistance tester from IEST Battery Electrode Sheet Resistance Tester (BER series). The instrument operates on a two-probe principle and supports both a folded (ex-situ) test and an in-situ three-electrode method for AB measurement.

Figure 1. IEST Electrode Sheet Resistivity Measurement System(BER Series)

2.2 Methodology I: The Ex-situ Folded Electrode Method

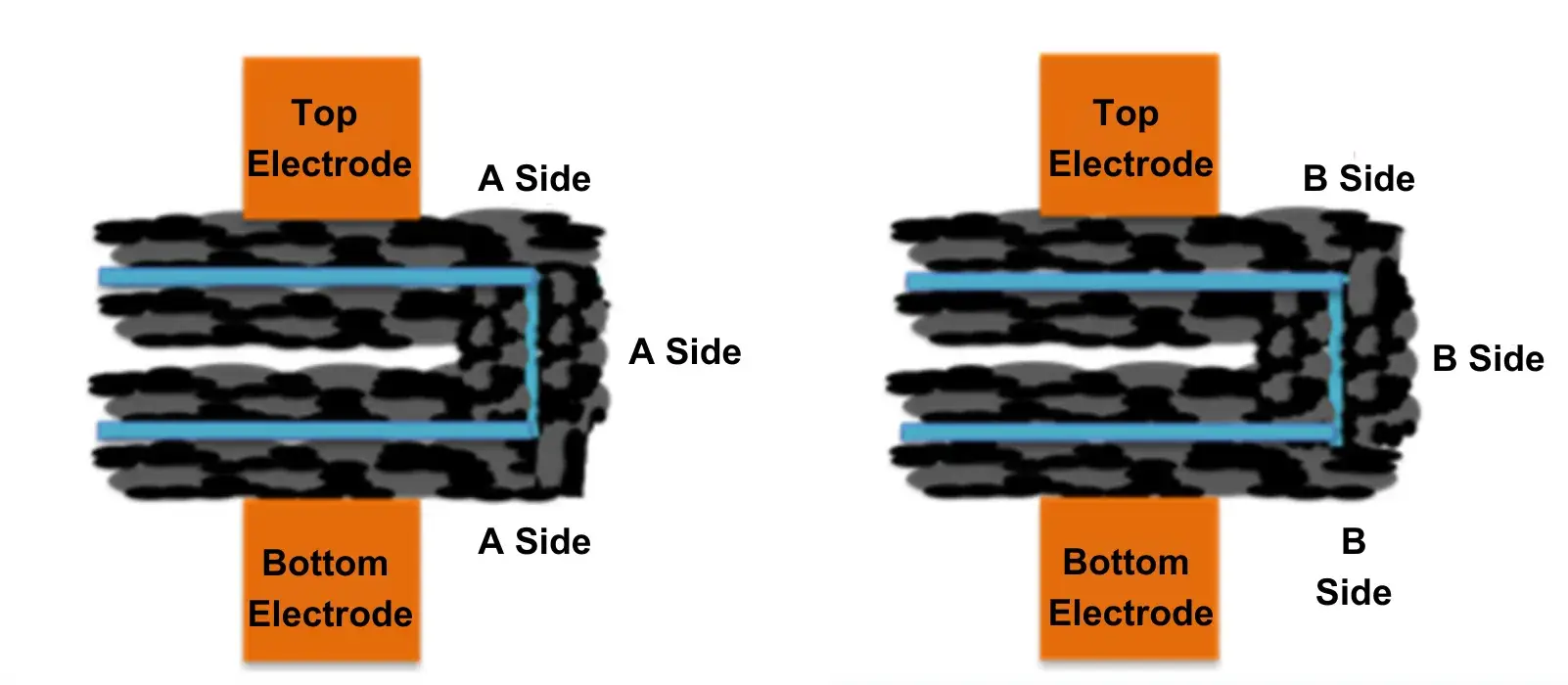

This procedure involves folding the electrode sheet and placing it between the instrument’s two terminals. The system then applies a standardized pressure and conducts the measurement.

Figure 2. Schematic diagram of the ex-situ folded electrode test method.

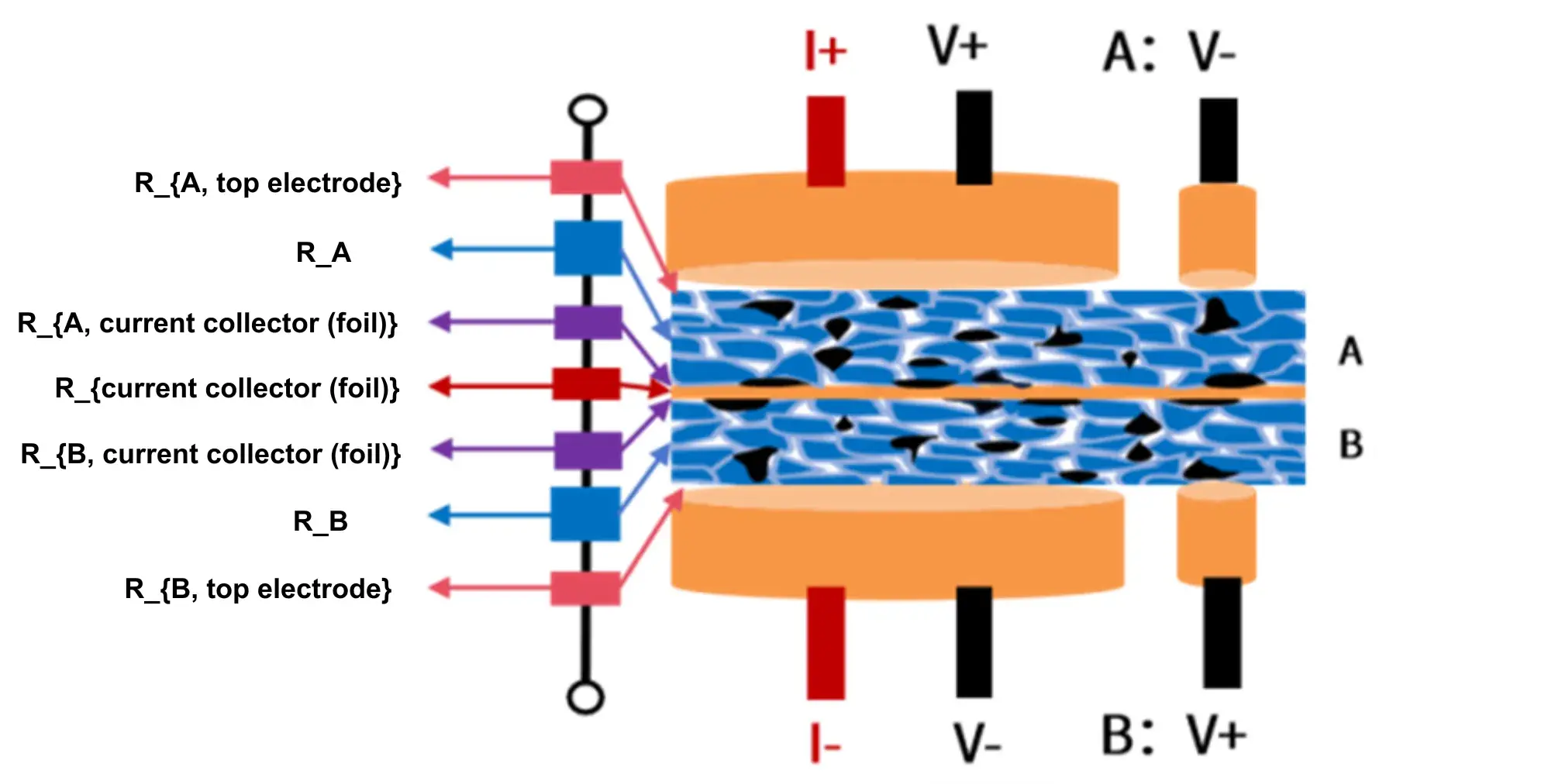

2.3 Methodology II: The In-situ Three-Electrode Method

To individually and in-situ extract the resistance of either Side A or Side B, we introduced a third electrode. This approach offers a simpler and faster testing workflow.

-

System Setup: A standard two-electrode system is augmented with an independent third electrode acting as a probe.

-

Testing Process: After installing the third probe, the electrode sheet is laid flat in contact with the main test stage. The instrument applies standardized pressure and performs the measurement.

Figure 3. Schematic diagram of the In-situ Three-Electrode test method.

3. Test Data and Comparative Analysis

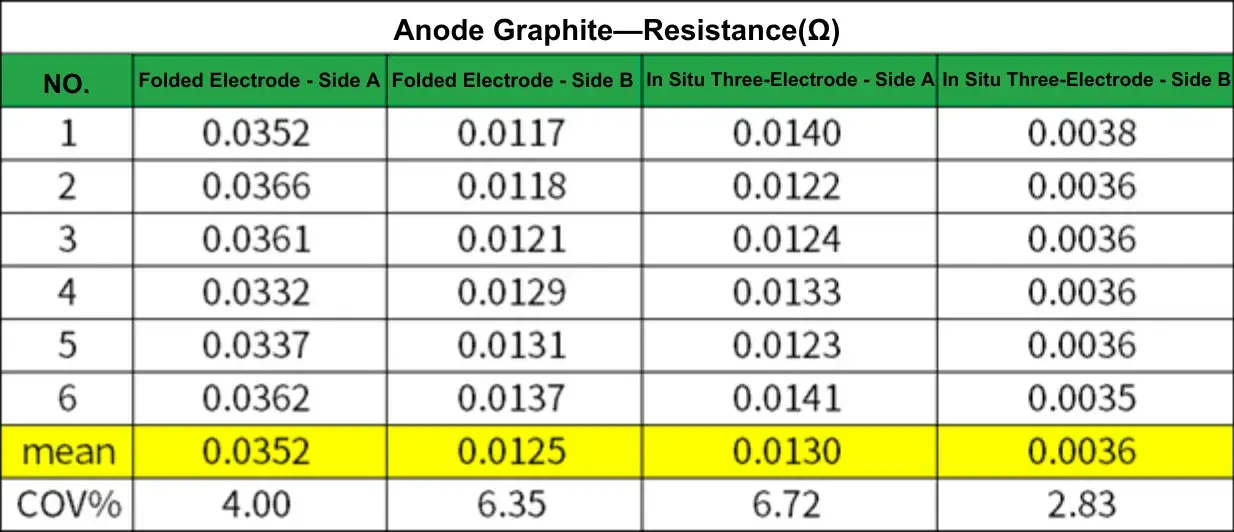

We applied both methods to evaluate cathode (LFP) and anode (Graphite) electrode sheets from the same production batch.

-

Cathode (LFP): Test conditions: 25 MPa pressure, 15-second hold time. (Data presented in Table 1).

-

Anode (Graphite): Test conditions: 5 MPa pressure, 15-second hold time. (Data presented in Table 2).

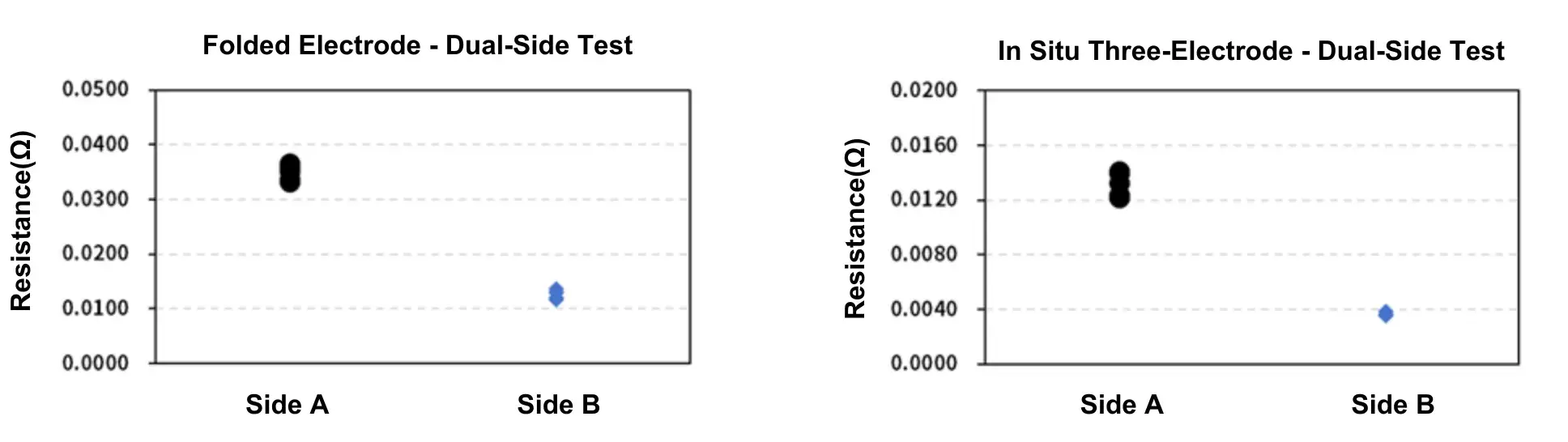

For each group, six different spots were measured. Results from both the folded method and the three-electrode method consistently showed that the surface resistance of Side A was higher than that of Side B for both cathode and anode sheets. This clearly indicates a measurable difference in coating uniformity between the two sides.

Figure 4. Side A/Side B surface resistance comparison data for Cathode (LFP).

Figure 5. Side A/Side B surface resistance comparison data for Anode (Graphite).

4. Comparison of the Two Testing Methods

-

The two methods measure different electrical pathways, leading to variations in absolute resistance values.

Figure 6. Comparison of the Two Testing Methods: In Situ Three-Electrode Method Vs Ex-situ Folded Electrode Method

-

The Ex-situ Folded Electrode Method requires no additional hardware and is straightforward. However, it measures Side A and Side B resistance from different physical spots on the folded sheet, introducing potential positional error.

-

The In-situ Three-Electrode Method can output resistance for both Side A and Side B from the exact same spot. This approach offers shorter test cycles, higher efficiency, and eliminates error from measuring different locations.

5. Practical Implications for Process Engineers

Surface resistance asymmetry between A and B surfaces can reveal upstream process issues:

-

Variation in slurry rheology or solid loading during the first vs. second coating pass.

-

Uneven nip roll pressure during calendaring or inconsistent edge effects.

-

Local differences in binder or conductive additive distribution that reduce particle contact.

Addressing such issues typically involves root-cause steps: tightening coating process control, revalidating calendaring pressures, and sampling at multiple transverse and longitudinal locations to confirm improvements.

6. Conclusion: Enabling Precision in Process Optimization

Measuring AB-surface surface resistance provides a robust, practical metric for assessing coating uniformity and identifying process deviations early. While the folded (non-in-situ) approach is convenient for quick checks, the Three-Electrode Method offers superior local accuracy and repeatability. Adopting the Three-Electrode Method in routine QA/QC enables engineers to pinpoint coating inconsistencies and to optimize manufacturing parameters for higher cell performance and consistency.

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.