-

iestinstrument

How to Balance Design Gaps and Swelling Force to Mitigate Battery Capacity Fade

1. Abstract

A 2020 collaborative study by Central South University and CATL investigated the cyclic swelling force evolution in NCM (Nickel Manganese Cobalt) lithium-ion power batteries under different design and assembly conditions. By combining experimental measurements with 3D simulation, the research analyzed the swelling force exerted on a module casing at the end of battery life, providing critical insights for optimized battery design.

2. Experimental Setup

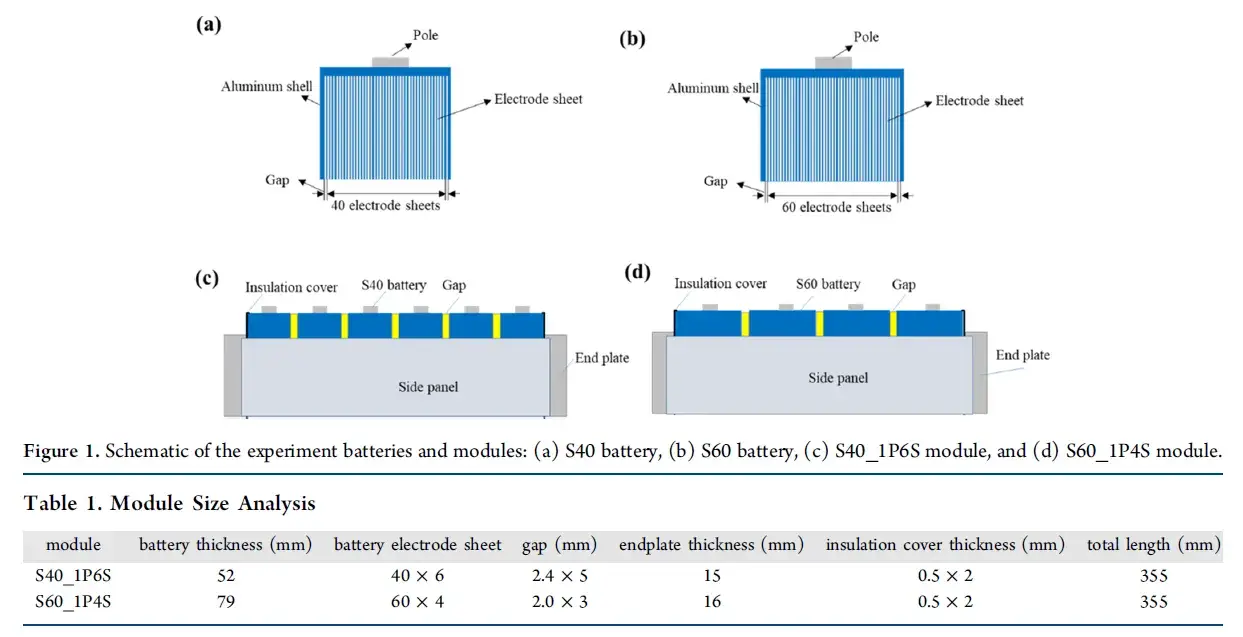

The study compared different cell and module configurations:

-

Single Cells: S40 (containing 40 electrode sheets) and S60 (containing 60 electrode sheets). The gap between the electrode stack and the aluminum casing was identical for both types.

-

Module Assemblies: S40_1P6S (6 S40 cells in series) and S60_1P4S (4 S60 cells in series).

-

Test Conditions: 25°C, 1C charge/1C discharge rate.

3. Analysis of Results

3.1 Measured Swelling Force in Single Cells and Modules

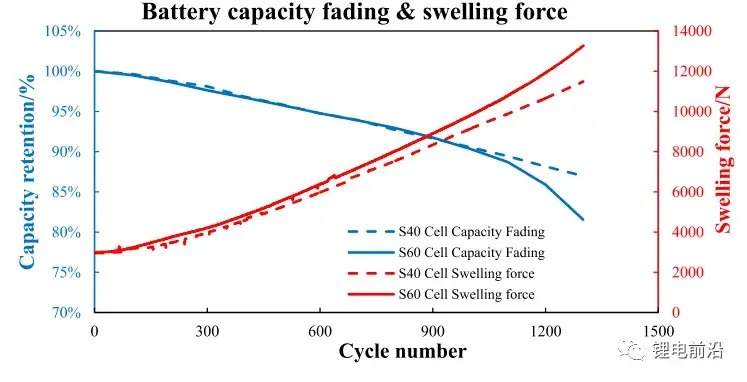

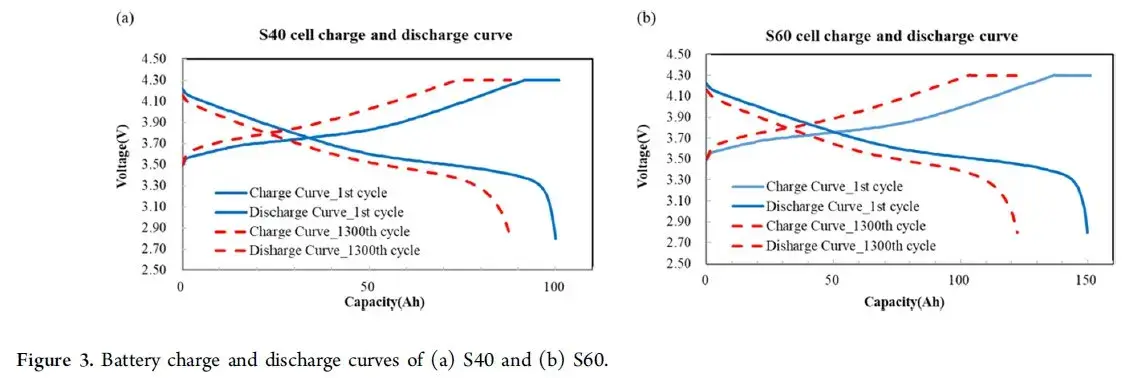

The capacity retention and swelling force curves for single cells revealed that S40 and S60 performed similarly for the first 1000 cycles. This indicates the initial gap between the electrodes and the aluminum casing was sufficient to accommodate expansion during this period.

Beyond 1000 cycles, particularly up to 1300 cycles, the S60 cell exhibited a faster rate of capacity fade and a more rapid increase in swelling force compared to the S40. This demonstrates that for prismatic aluminum cells with a fixed internal gap, cells with a higher number of electrode sheets (greater stack height) generate swelling force more rapidly in later cycle life, accelerating capacity degradation.

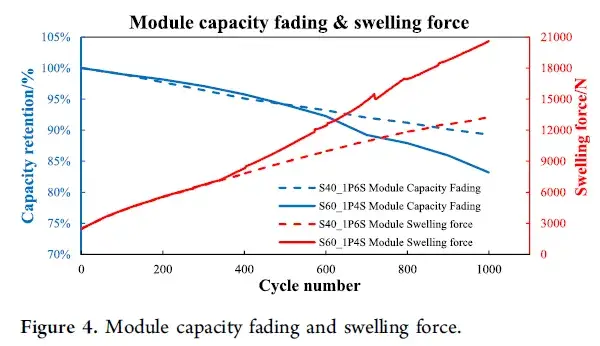

For the modules, the inter-cell gap was 2.4 mm for S40_1P6S and 2.0 mm for S60_1P4S. Similar to the single cells, both modules showed comparable performance for the first 400 cycles. After 400 cycles, the S60_1P4S module degraded faster in both capacity and swelling force.

Two modular batteries, the gap between the single cells of S40_1P6S is 2.4mm, and the gap between the single cells of S60_1P4S is 2.0mm. Judging from the capacity retention rate and swelling force curves of the two modular batteries, there is no significant difference between the S40 and S60 cells in the first 400 cycles. Explain that before this, the gap reserved between the battery cell and the module housing is still enough to support the swelling of the battery cell. When the cycle continues to 1000 cycles, the capacity decay rate of the S60_1P4S module is significantly greater than that of the S40_1P6S module, and the increase rate of the swelling force of the S60 is also greater than that of the S40. There are two main reasons:

-

The S60_1P4S module had less internal free space (2.0 mm gap) than the S40_1P6S module (2.4 mm gap), causing the module casing to constrain cell expansion earlier.

-

The S60 single cell inherently produces greater swelling force due to its larger electrode count, which translates to higher force on the module structure.

So the swelling force fed back to the module housing is also greater. Therefore, in the module design, the influence of the reserved gap and the swelling force on the attenuation of the battery capacity should be considered in a balanced manner.

3.2 Simulation for Module Design Assessment

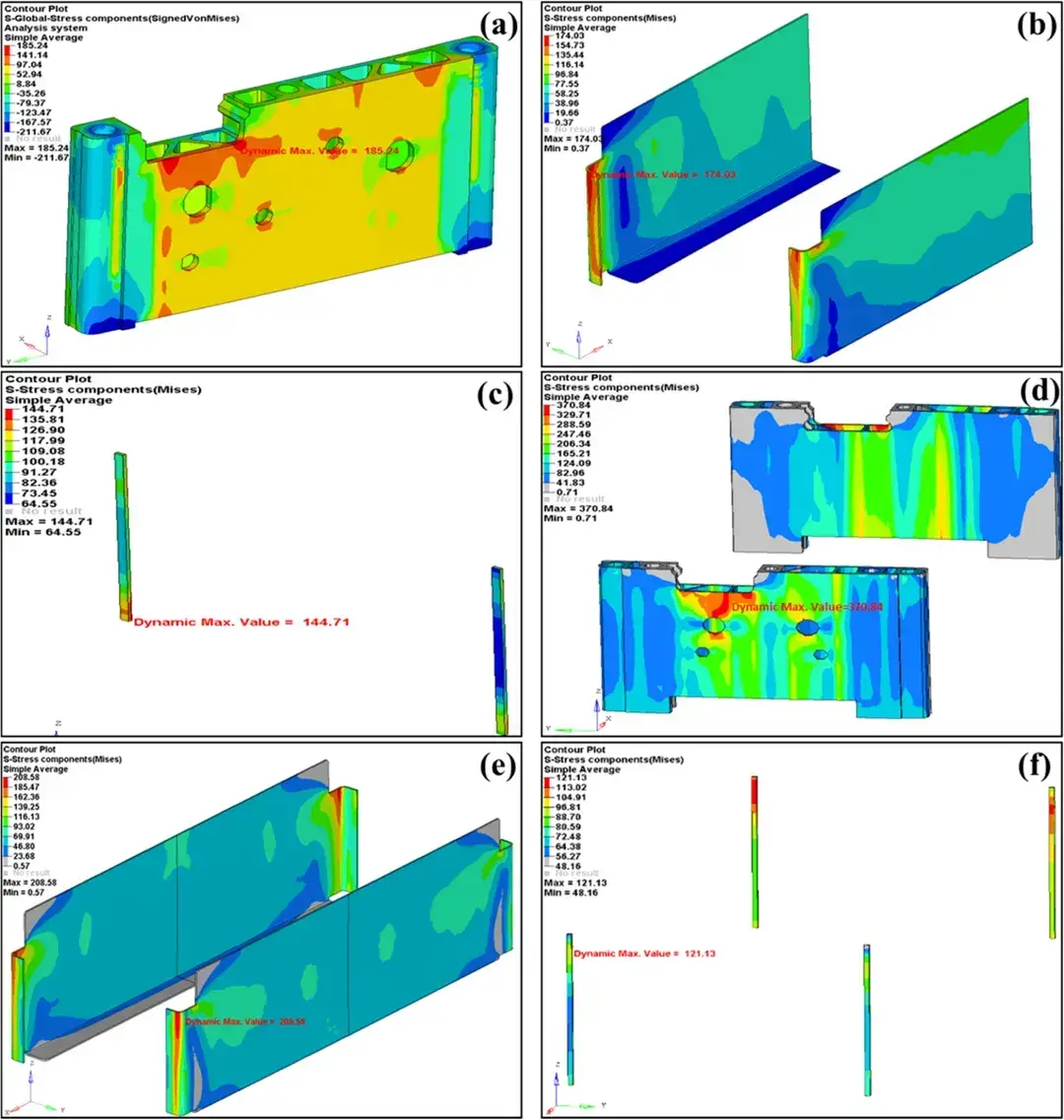

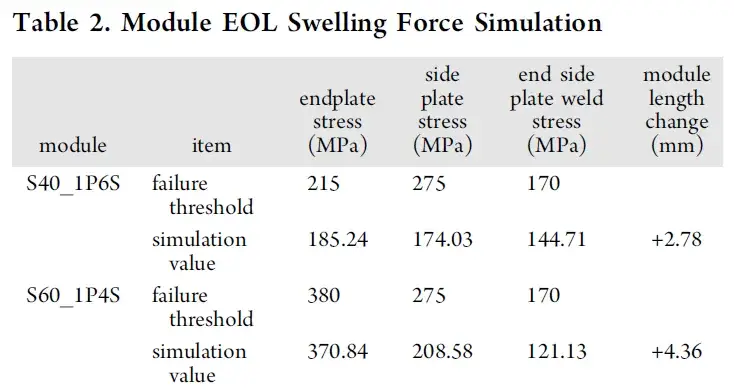

Based on the previous actual swelling force test of single cell and modular battery, the simulation method is used to analyze the maximum swelling force that the three main structural parts of the module (top cover, side plate, top side plate welding point) can withstand, in advance evaluate the reliability of the module structure. Using about simulation software, input some measured cell expansion force and material characteristics and other parameters, and finally output the stress that the structural components of the module bear, as shown in Figure 5 and Table 2. Comparing the simulated stress values and failure thresholds of different components given in Table 2, the swelling force of each component of the S60_1P4S module is greater than that of the S40_1P6S module. If the failure threshold of the component is less than the simulated value, it means that the structural component does not meet the design requirements.

Figure 5. Module swelling force simulation (a-c) S40 1P6S module simulation and (d-f) S60 1P4S module simulation.

4. How Swelling Force Translates Into Capacity Fade — Mechanistic linkage

The measured relationship between swelling force and capacity fade can be summarized mechanistically:

-

Mechanical constraint reduces electrode porosity or alters contact pressure. When cells press against the enclosure or against neighboring cells, local mechanical compression can change electrode microstructure, impede ionic transport, or alter SEI formation dynamics.

-

Thermo-mechanical effects accelerate side reactions. Confinement can shift local temperature and stress distributions, promoting parasitic reactions that consume active lithium or increase impedance.

-

Accelerated impedance rise and loss of active material manifest as capacity fade. As swelling force grows and the module enclosure begins to bear load, these coupled effects appear as faster capacity decline in the affected cells.

5. Summary

This study, employing both experimental testing and 3D simulation, analyzes the swelling force in NMC cells and modules up to their end-of-life (EOL). It highlights several crucial design parameters that influence cycle life: the internal gap within a cell, the number of electrode sheets (affecting stack pressure), and the failure stress thresholds of module components. A successful design must carefully balance these factors to manage swelling force and mitigate capacity fade.

6. Reference

Yongkun Li, Chuang Wei, Yumao Sheng, Feipeng Jiao, and Kai Wu. Swelling Force in Lithium-Ion Power Batteries,Ind. Eng.Chem. Res,2020, 59, 27, 12313–12318.

7. IEST Related Test Instruments Recommendations

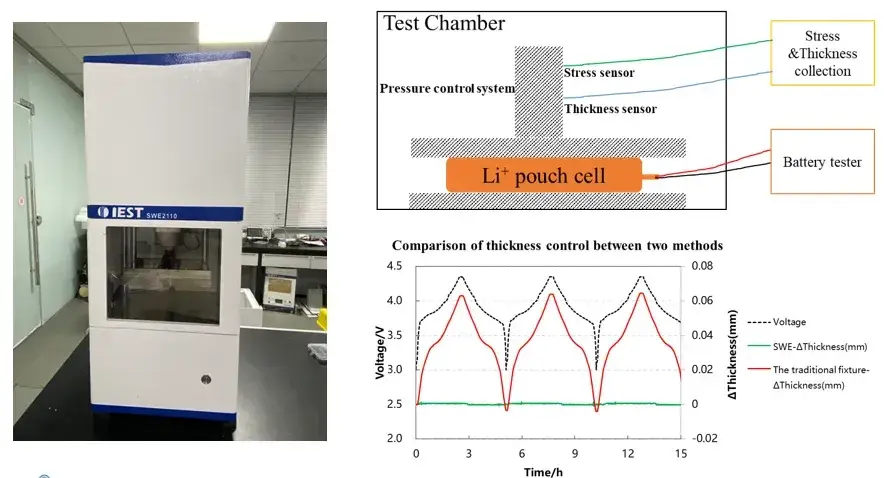

Accurate characterization of swelling force and thickness requires high-stability, glovebox-compatible instruments that can record long-term trends. The SWE-series in-situ expansion analysis systems (IEST Instrument) used in the referenced study provide synchronized thickness and swelling-force measurement during charge/discharge, enabling direct correlation between electrochemistry and mechanical response. Consider test systems that capture both metrics simultaneously for highest fidelity. The main features of this system are as follows:

1. Integration of multiple in-situ cell characterization methods (stress & swelling thickness): Measure the swelling thickness and swelling force during the charging and discharging process of the cell at the same time, and quantify the changes in the swelling thickness and swelling force of the cell;

2. More detailed and stable testing system: utilizing a highly stable and reliable automated regulation platform, equipped with high precision thickness measurement sensors and pressure regulation system, the relative thickness measurement resolution is 0.1µm, realizing the long cycle monitoring of the long-term charging and discharging process of the battery cell;

3. Diversified environmental control and testing functions: SWE series equipment can adjust the temperature of the charging and discharging environment, which is helpful for the study of the swelling behavior of the electric core under high and low temperature conditions; in addition to the conventional thickness and pressure testing, it can also realize the testing of parameters such as the swelling force of the electric core, the compression modulus, and the compression rate.

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.