-

iestinstrument

In-situ Analysis of The Volume And Thickness Swelling Behavior Of Pouch Cell-LFP/graphite System Cell

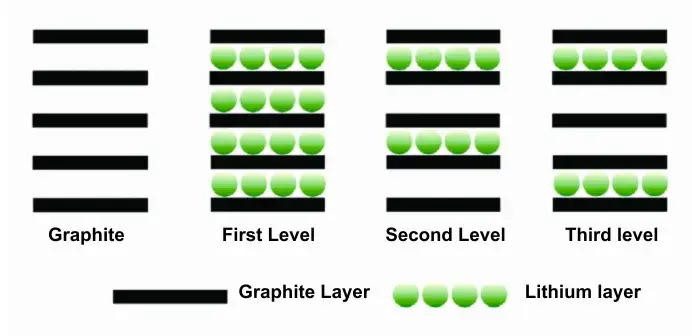

When the cell undergoes de-embedded lithium phase transition during the charging and discharging process, it will cause thickness swelling and volume swelling. This article uses the same test process to perform expansion tests on LFP/graphite battery cells. Since the LFP material is an olivine structure, there is only one very stable platform during the charge and discharge process, and the structural expansion is small. Therefore, the structural expansion of LFP/graphite battery cells are mainly related to the lithium deintercalation platform of the graphite anode. The conversion of different order structures of graphite is shown in Figure 11-2. Comparing the thickness swelling and volume swelling corresponding to each order can guide R&D personnel to further understand the expansion mechanism.

Figure 1. Schematic diagram of graphite stage structure1

1. Experimental Equipment and Test Methods

1.1 Experimental Equipment

1.1.1 In-situ gassing volume monitor

Model GVM2200(IEST) ,The testable temperature range is 20℃~85℃, and it supports dual-channel (2 batteries) simultaneous testing. The appearance of the device is shown in Figure 2.

Figure 2. Appearance of GVM2200 Equipment

1.1.2 In-situ swelling analyzer

Model SWE2110(IEST), the appearance of the equipment is shown in Figure 3.

Figure 3. Appearance of SWE2110 Equipment

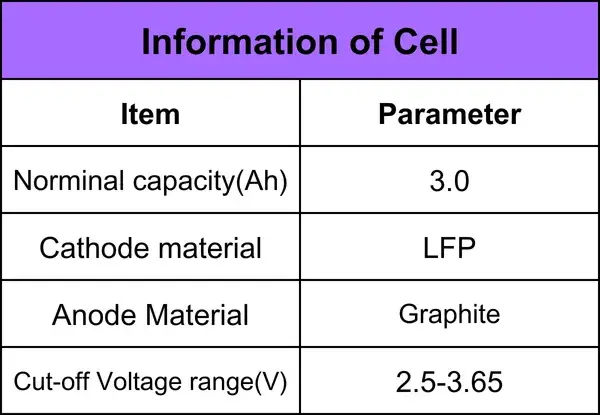

2.1 The Battery Cell Information is Shown in Table 1.

Table 1. Test cells information

2.2 Charging and discharging process:

25℃ Rest 5min; 0.5C CC to 3.65V, CV to 0.025C; rest 5min; 0.5C DC to 2.5V.

2.3 Cell Volume Swelling Test

Initial weighing of the cell m0, put the cell to be tested into the corresponding channel of the equipment, open the MISG software, set the corresponding cell number and sampling frequency parameters of each channel, and the software automatically reads the volume change amount, test temperature, current, voltage, capacity and other data.

2.4 Thickness swelling test of cell

put the cell to be tested into the corresponding channel of the equipment, open MISS software, set the corresponding electric cell number and sampling frequency parameter of each channel, and the software will automatically read the thickness of the cell, the thickness change amount, the test temperature, current, voltage, capacity and other data.

3. In-situ analysis of the expansion behavior of pouch cell

3.1 Thickness and force curves of cell swelling during charging and discharging processes

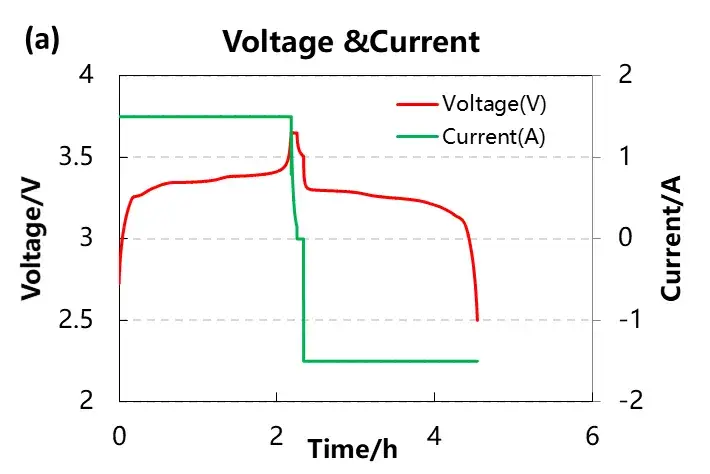

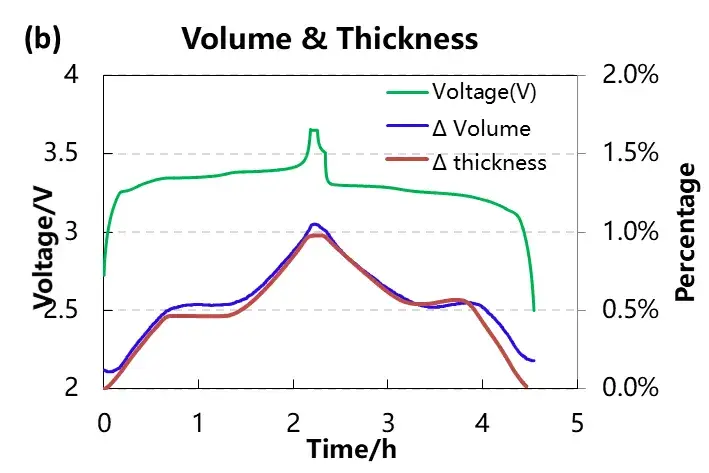

Figure. 4(a) and (b) show the charging and discharging curves as well as the thickness and volume change curves of the cell. When fully charged, both the volume and thickness of the cell increase by about 1%, and there is a plateau at the corresponding charge/discharge voltage plateau where the thickness and volume are basically unchanged. After one round of charging and discharging, the thickness and volume of the cell remain basically unchanged, indicating that there is no obvious irreversible expansion phenomenon of the cell at this time.

Figure 4. (a) Voltage and volume changes during charging and discharging.

Figure 4. (b) Thickness swelling and volume swelling changes during charging and discharging.

3.2 Swelling volume and thickness of the cell during charging and discharging with differential capacity curve analysis

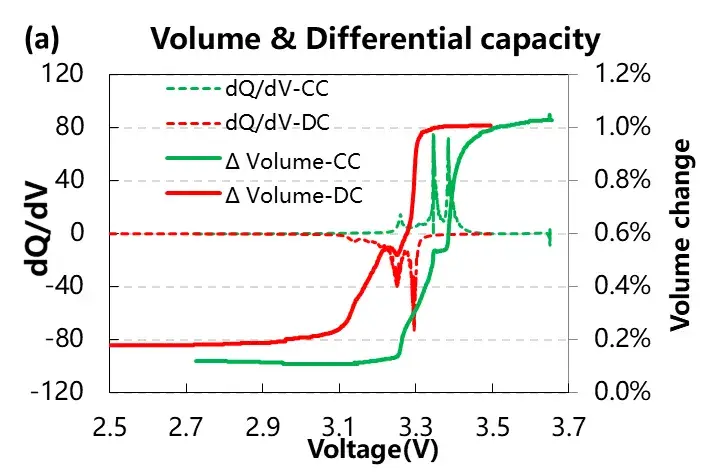

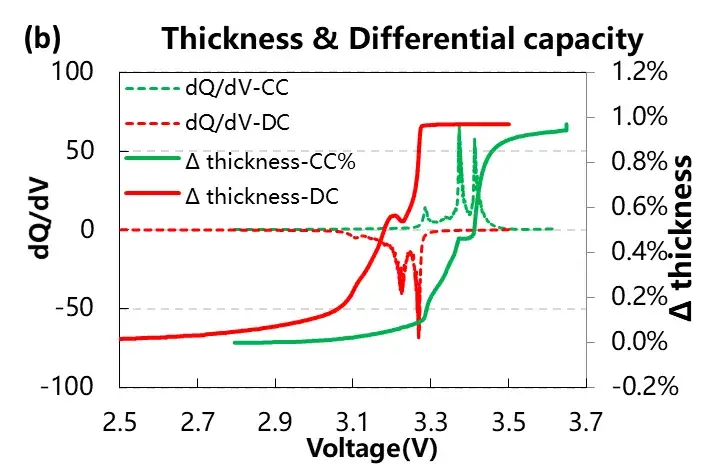

Figure 5 shows the volume swelling and thickness swelling of the cell and the differential capacity curve. Each peak of the differential capacity curve corresponds to the phase change of lithium insertion and extraction. Since the LFP material has only one voltage platform during the entire lithium insertion and extraction process, the three peaks seen on the differential capacity curve of the battery cell are all lithium insertion and extraction peaks of three different orders of graphite. It can be seen from the figure that when charging, at the first lithium insertion peak LiC24 phase change and the third LiC6 of graphite, the corresponding slope of the volume and thickness curve is larger, indicating that the phase change at this time causes a larger swelling of the graphite structure.

Figure 5. (a) Swelling volume and differential capacity curve.

Figure 5. (b) Swelling thickness and differential capacity curve.

3.3 Analysis of irreversible swelling during charging and discharging processes

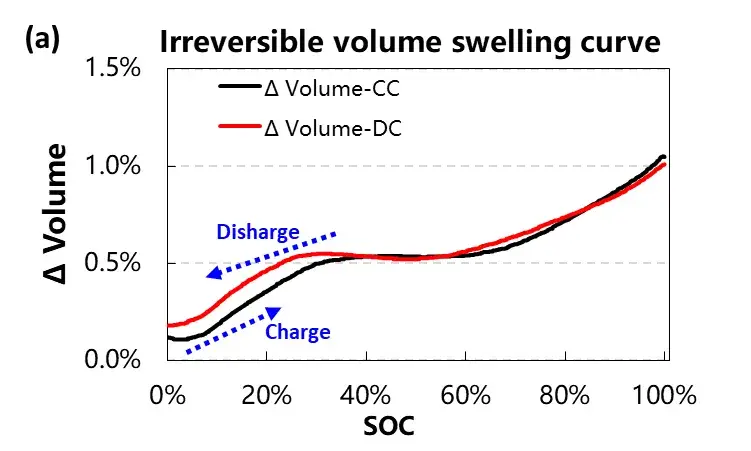

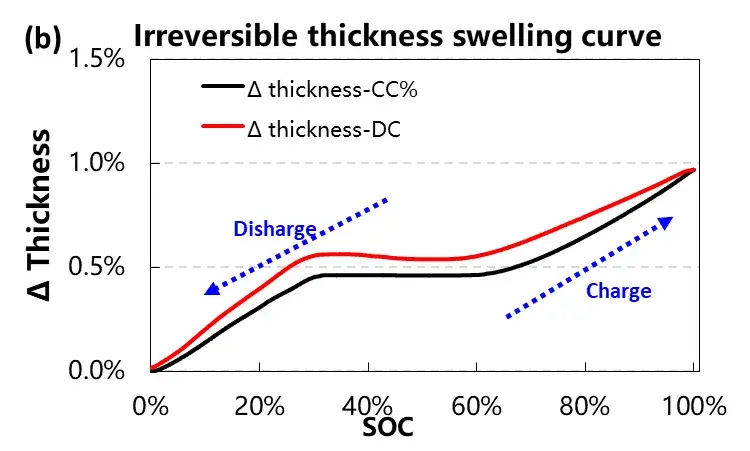

The volume and thickness swelling curves under different SOC conditions are shown in Figure. 6 (a) and (b). The spacing of the expansion curves corresponding to charging and discharging represents the irreversible expansion. The thickness swelling of both the discharge process is larger than that of the charging process, and the volume expansion curves of the two processes are in agreement with the thickness swelling curve pattern in the low SOC interval, while there is no significant difference in the high SOC interval, which may be due to the Archimedes’ law of buoyancy used in the testing of the volume expansion, and if some slight gas production occurs in the high SOC condition, it will also be monitored. Therefore, if researchers only want to study the structural expansion of the cell, they can prioritize the thickness swelling measurement method, and if they want to study some gas production reactions, they can prioritize the volume expansion measurement method.

Figure 6. (a) Volume swelling curve under different SOC conditions.

Figure 6. (b) Thickness swelling curve under different SOC conditions.

4. Summary

In this paper, an in-situ volume monitor (GVM) and an in-situ swelling analyzer (SWE) are used to analyze the volume and thickness swelling during the charging and discharging process of the pouch cell, which can characterize the reversible swelling and irreversible swelling in real time, and help R&D personnel from analysis of cell swelling behavior in different dimensions.

5. Reference

[1] Nalamova V,Guerard D,Lelaurain M,et al. X-ray investigation of highly saturated Li-graphite intercalation compound[J]. Carbon ,1995,33(2):177-181.

Subscribe Us

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.