-

iestinstrument

How Conductive Agent Addition Affects NCM Powder Compaction and Compression Performance

Abstract

This study evaluates how premixing conductive agent and binder alters the compaction density and compression behavior of NCM powder. Using the PRCD series compression tester, we compared pure NCM powder with NCM+PVDF and NCM+PVDF+SP (where SP is a carbon-black conductive agent) across a broad pressure range (10–350 MPa). Results show that adding PVDF and especially nanoscale SP increases reversible and irreversible deformation, lowers compacted density at a given pressure, and substantially changes stress–strain response. These powder-level changes explain, in part, why electrode coating, drying and calendering processes must be optimized when conductive agents are introduced.

1. Preface

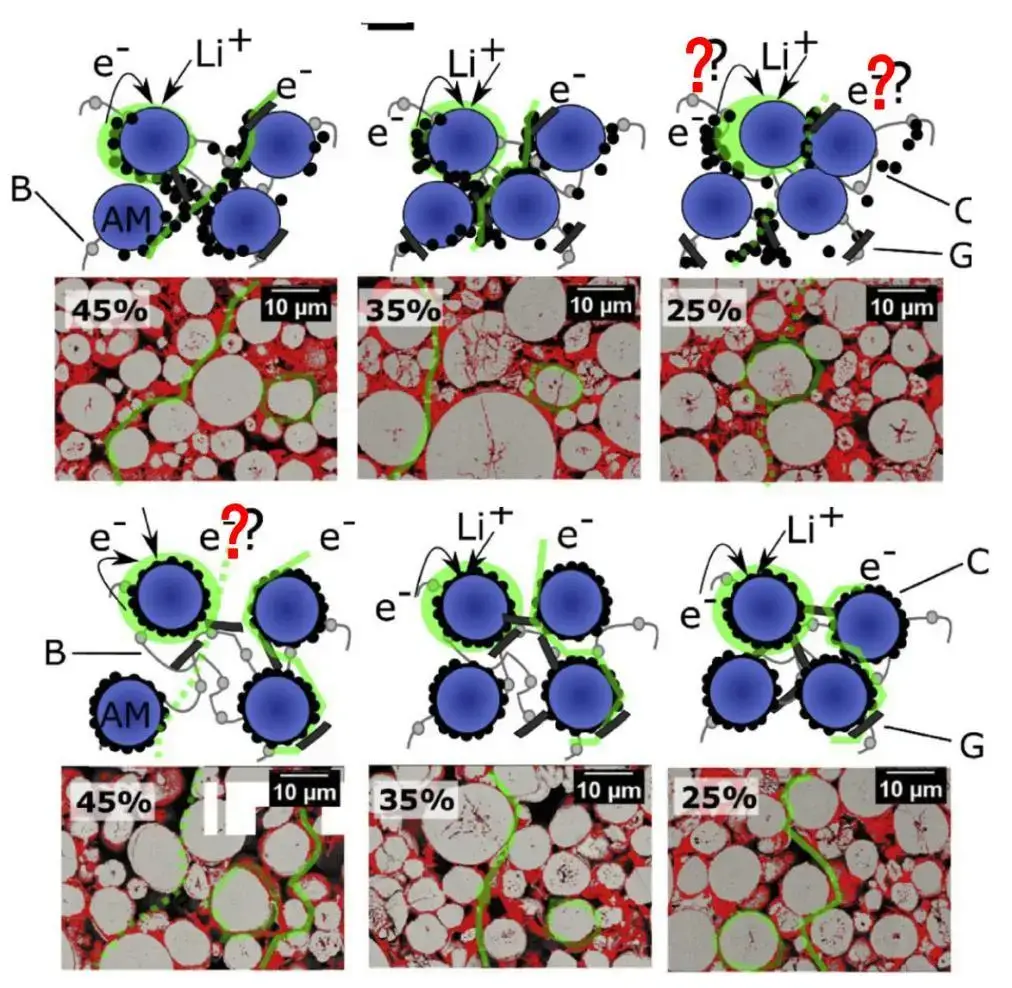

Lithium-ion battery R&D production process found that the conductivity of the cathode and anode active material particles can not meet the requirements of the electron migration rate, so the battery manufacturing process needs to add a conductive agent, the main role is to enhance the electronic conductivity. Conductive agent between the active substance particles, active substance particles and collector play a role in conducting electrons, collect micro-current, thereby reducing the contact resistance of the electrode, effectively reducing the polarization phenomenon of the battery. Commonly used conductive agents in lithium batteries can be divided into traditional conductive agents (such as carbon black, conductive graphite, carbon fiber, etc.) and new conductive agents (such as carbon nanotubes, graphene and its hybrid conductive slurry, etc.) , such as Figure 1 for the lithium-ion battery electrode sheet in the distribution of the distribution of conductive agents schematic diagram.

Figure 1. Schematic representation of conductive agent distribution in lithium-ion battery electrodes[1]

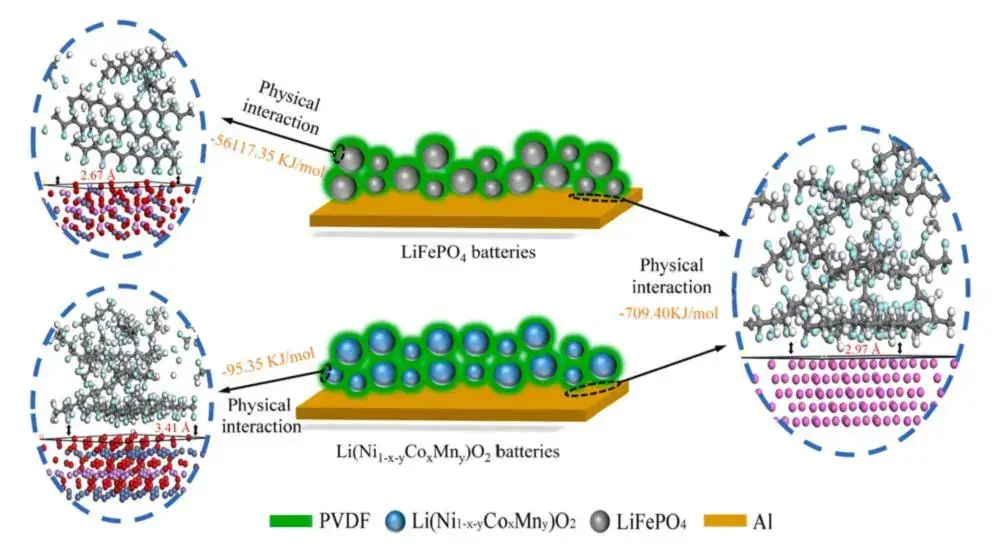

The main function of lithium-ion battery binders is to bind the active material powders. Binders can tightly attach the active material and the conductive agent to the current collector to form a complete electrode, prevent the active material from falling off and peeling off during the charge and discharge process, and can evenly disperse the active material and the conductive agent, thereby forming a good electron and ion transmission network and achieving efficient transmission of electrons and lithium ions. Commonly used binders include polyvinylidene fluoride (PVDF), carboxymethyl cellulose (CMC), styrene-butadiene rubber (SBR), polyvinyl pyrrolidone (PVP), polymethyl methacrylate (PMMA), polyacrylonitrile (PAN), polyacrylic acid (PAA), etc. The mechanism of action of binders in lithium-ion battery research has always been the focus of attention. Zhong et al.[3] analyzed the binding effect between active particles and binders through density functional theory (DFT) simulation calculations and explored the binding mechanism. The results of process simulation and theoretical calculation show that in the LFP system, the binding effect between LFP and PVDF is much greater than that between PVDF and Al, while in the NCM system, the binding effect between NCM and PVDF is weaker than that between PVDF and Al; scanning electron microscopy and Auger electron spectroscopy (AES) analysis also show that PVDF has good bonding properties in NCM batteries. Figure 2 shows the possible binding mechanism of PVDF in different battery systems.

Figure 2. Schematic representation of possible binding mechanisms of PVDF in Li-ion batteries[2]

In electrode manufacturing, conductive agents (e.g., carbon black, conductive graphite, CNTs, graphene) are added to active powders to build electronic percolation networks and reduce contact resistance. Binders (PVDF, CMC/SBR, PAA, etc.) hold particles together and affect powder flow and mechanical response. The combined influence of conductive agent plus binder on NCM powder compaction behavior is crucial because powder compaction correlates with electrode areal density, porosity, and ultimately cell energy density and rate performance.

This work models the dry mixing/premixing step used in electrode processing by blending NCM with PVDF and with both PVDF+SP, then quantifying compaction, rebound, and steady-state stress–strain using the PRCD3100 series instrument.

2. Experimental Methods

2.1 Test equipment

The PRCD3100 (IEST) system was used to evaluate powder compaction density, unloading rebound, and stress-strain behavior under pressures ranging from 10 to 350 MPa.

Figure 3. Appearance & Structure Schematic of PRCD Series

2.2 Sample preparation and testing protocol

Two mixtures were prepared:

-

NCM : PVDF = 19 : 1

-

NCM : PVDF : SP = 18 : 1 : 1

Protocol: Powder samples were compacted between 10 and 350 MPa. We recorded thickness under pressurized and unpressurized conditions (to compute rebound), measured compaction density, and ran steady-state press/depress cycles to extract stress–strain curves, maximum deformation, reversible deformation and irreversible deformation.

3. Key Results and Discussion

3.1 Thickness rebound and elastic recovery

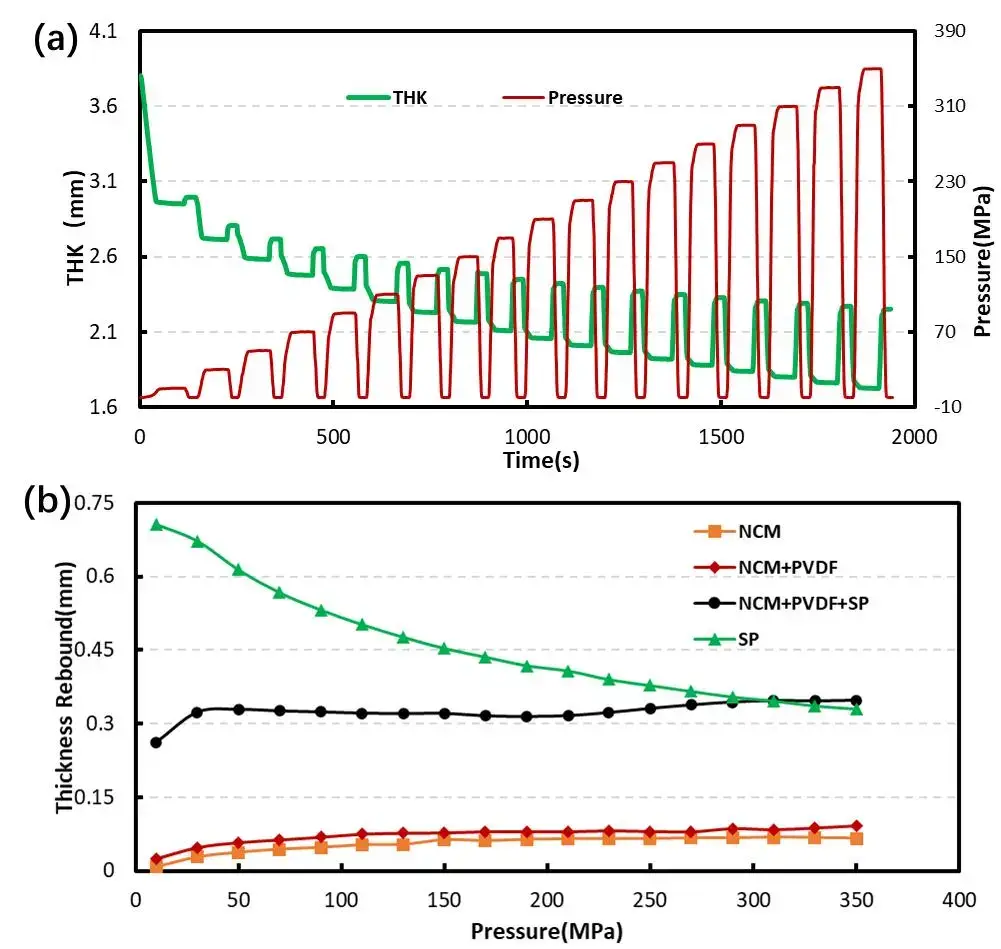

The thickness monitoring of different powders was carried out under the pressurized and unpressurized mode as in Figure 4(a), and the absolute value of the unpressurized thickness minus the pressurized thickness was defined as the thickness rebound of the material, and Figure 4(b) shows the comparison of the rebound of different materials under the pressurized and unpressurized conditions.

From the test results:

-

SP alone exhibited the largest thickness rebound after unloading, reflecting large elastic strain from its nanoscale, branched aggregate morphology.

-

NCM and NCM+PVDF had much smaller rebound; adding PVDF slightly increased rebound, while adding SP (NCM+PVDF+SP) produced a larger rebound intermediate between SP and pure NCM.

-

With increasing maximum pressure, SP’s rebound decreased (progressive particle rearrangement/crushing), whereas NCM and hybrid powders showed rebound increases—indicating different deformation regimes.

Figure 4. Pressure relief test: (a) pressure change in unloading mode; (b) thickness rebound curve

3.2 Stress–strain behavior and compaction density

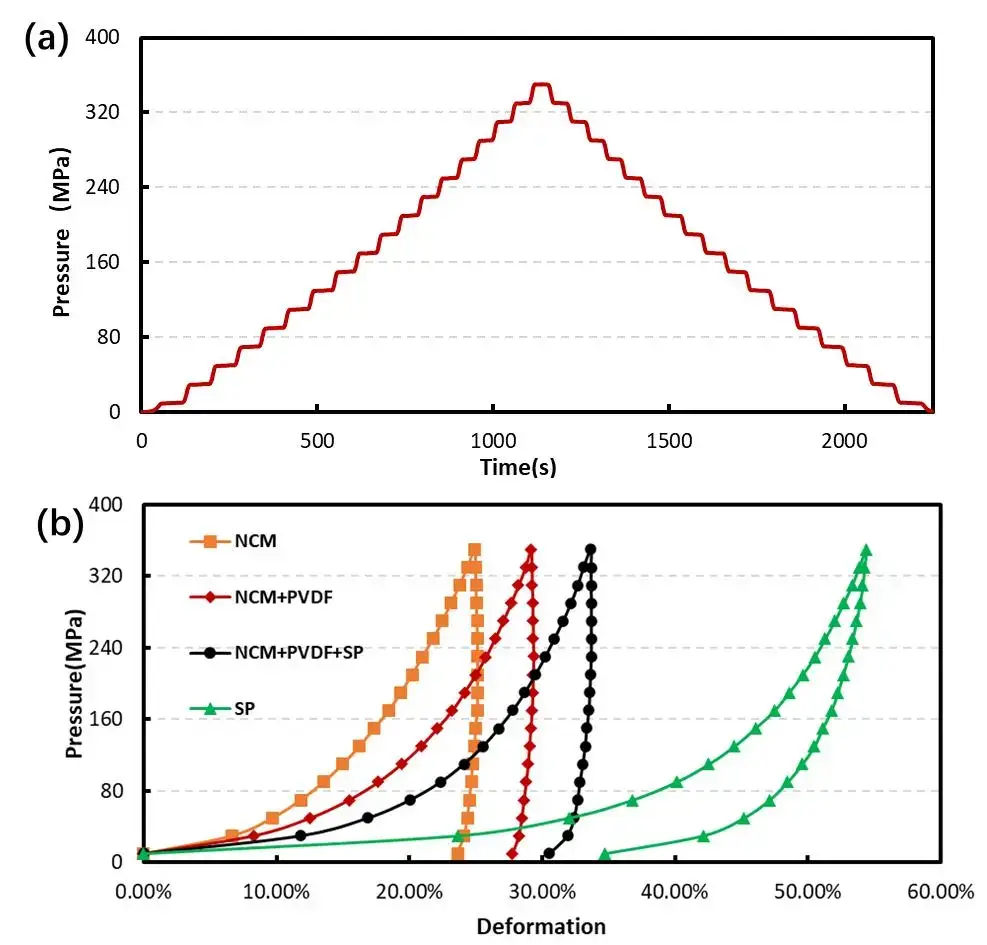

To further explore the possible correlations, the stress-strain and compaction density properties of different powder materials are further tested in this paper in conjunction with the steady-state experimental model. As shown in Figure 5(a), pressurization and depressurization were carried out under steady state pressure to monitor the thickness of different powders. Taking the thickness under initial pressure of 10 MPa as the base thickness, the thickness deformation of different powders under pressurized or unpressurized conditions was calculated to obtain the stress-strain curves of different powder materials shown in Figure 5(b).

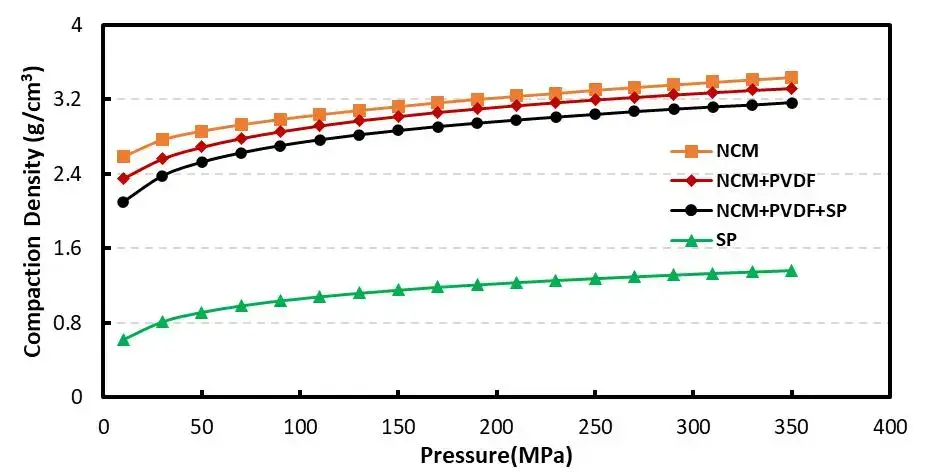

From the test results:

-

Under steady-state press conditions, maximum deformation ranked:

SP > NCM+PVDF+SP > NCM+PVDF > NCM. -

Both reversible and irreversible strains followed the same ordering, meaning conductive-agent-rich mixes deform more and leave greater residual porosity after unloading.

-

Compacted density results showed: SP < NCM+PVDF+SP < NCM+PVDF < NCM at equivalent pressures — i.e., adding PVDF and especially SP reduces the powder’s ability to reach the same bulk density under the same compaction load.

Figure 5. Steady state test: (a) Steady state mode pressure variation; (b) Stress-strain curves for different powders

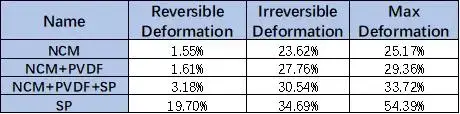

Table 1. Comparison of deformation data for different powders

Figure 6. Compacted density measurement results of different powders

3.3 Mechanistic interpretation

-

SP (carbon black) consists of primary nanoparticles (~40 nm) that form complex agglomerates and multibranched chain structures. These aggregates generate large internal elastic strains and resist densification until higher pressures, producing high rebound.

-

PVDF particulates introduce elastic binder domains that increase the material’s overall deformability and limit close particle packing, so mixed powders require higher pressure to reach target electrode densities.

-

Micrometer-scale NCM particles have higher modulus and compact more readily, explaining their superior densification when used alone.

4. Practical implications for electrode processing

-

Formulation trade-offs: Adding conductive agent and binder improves electronic connectivity and coating integrity but reduces achievable powder layer density for a given calendering schedule. A higher calender load or adjusted calender roll temperature may be required to reach target electrode porosity.

-

Calendering & roll-press settings: Because conductive-agent-containing mixes deform differently, optimize calender nip pressure and roll gap specifically for NCM+PVDF+SP formulations rather than using settings derived from pure NCM.

-

Slurry & drying effects: This dry-mix study highlights powder-level tendencies but electrodes made from slurries may behave differently (binder redistribution, solvent effects). Correlate powder PRCD data with coated-and-dried electrode compaction testing to close the prediction loop.

-

Quality control: Use PRCD compressibility metrics (maximum deformation, irreversible strain, rebound) as quick QC indicators for premix batches: large variability in rebound or lower compaction density signals inconsistent conductive-agent dispersion or moisture content issues.

-

Conductive agent selection: If target areal density is high, consider alternative conductive agents (graphite blends, CNT networks) or hybrid carbon systems that achieve electrical percolation with less impact on compaction.

5. Recommendations for further work

-

Extend testing to slurry-coated, dried and calendered electrodes to quantify transfer functions from powder behavior to electrode density and through-plane resistivity.

-

Evaluate alternate conductive agents (graphitic carbon, CNTs, graphene hybrids) using the same PRCD protocol to identify low-impact, high-conductivity additives.

-

Study the influence of particle size distribution and surface treatments on the compaction trade-off between conductivity and density.

6. Conclusion

Premixing a conductive agent (SP) and PVDF binder with NCM powder significantly modifies powder compaction and compression behavior: conductive agent increases elastic rebound and reduces compacted density at given pressures, while PVDF adds elasticity and increases irreversible deformation. These powder-level effects must be considered during electrode formulation, calendering setup, and process control to meet both electrical and packing density targets.

5. References

[1] mikoWoo @ Ideal Life. Theory and Process Basis of Lithium-ion Battery Electrodes.

[2] Zhong X , Han J , Chen L, et al. Binding mechanisms of PVDF in lithium ion batteries [J]. Applied Surface Science, 2021, 553(4):149564.

[3] BRUCE P G,SCROSATI B,TARASCON J M. Nanomaterials for Rechargeable lithium batteries[J]. Angew Chem Int Ed Engl,2008,47(16):2930-2946.

[4] Kazuaki Kisu, Shintaro Aoyagi, et al. Internal resistance mapping preparation to optimize electrode thickness and density using symmetric cell for high-performance lithium-ion batteries and capacitors[J]. Journal of Power Sources, 2018, 396:207-212.

[5] Yang Shaobin, Liang Zheng. Principles and applications of lithium-ion battery manufacturing process.

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.