-

iestinstrument

Blade Cell Expansion Testing: Insights for Blade Battery Technology and Design

1. Preface

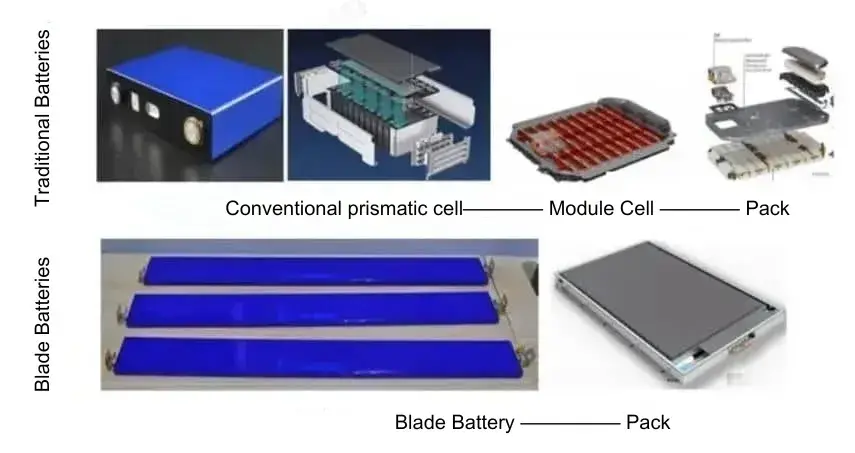

As new energy vehicles demand longer driving range and longer service life, automakers pursue higher volumetric energy density and smarter pack integration. One industrial solution is “removing modules and beams” — using the cell itself as both the energy-storage unit and a structural element. This idea gave rise to the blade cell form factor, and today blade batteries are an important branch of battery innovation.

Most commercial blade batteries use lithium iron phosphate (LFP) chemistry. What sets them apart is not chemistry alone but their long, thin geometry and unique production flow. The blade form — like a long razor blade — enables cells to be embedded directly into the pack without conventional modules, improving pack-level energy density and mechanical stiffness.

Figure 1. Comparison: blade batteries vs. traditional battery assemblies

Blade batteries can be divided roughly into long blades (e.g., BYD’s long blade) and short blades (e.g., Honeycomb Energy’s short designs). According to public specifications, BYD’s Changdao-style long blade is a hard-shell prismatic cell with typical dimensions around 960.0 ±10 mm × 90.0 ±1.0 mm × 13.5 +2.5 / −1.5 mm. Example variations: a 138 Ah blade ≈ 12 mm thick; a 202 Ah blade ≈ 13.5 mm. Electrode sheet sizes after teardown can reach ~944 × 83 mm (cathode) and ~946 × 85 mm (anode). Short blades can still exceed 500 mm in length (e.g., 573 × 117 × 21 mm).

Such large aspect ratios deliver cooling and packaging benefits but create manufacturing and mechanical challenges:

-

Tight dimensional tolerances: even slight deviations can affect performance and safety.

-

High lamination precision: long electrodes require precise layer alignment and flatness control.

-

Mechanical strength and durability: long thin cells experience significant internal stresses during cycling and require sufficiently rigid housing to remain stable.

In short, compared with traditional cylindrical and square batteries, the manufacturing process of blade batteries are more stringent and adopts a multi-layer “sandwich” structure, in which positive and negative electrode plates and separator layers are alternately stacked, however, bubbles are easily generated during the stacking process, and the cell are uneven, causing uneven pressure inside the battery and affecting its strength. Due to its special process and structure, there are currently few mechanical performance characterizations of the expansion of single blade cell. For this reason, IEST has been committed to developing high-precision equipment dedicated to characterizing the expansion performance of blade cell.

2. Equipment Functions and Parameters

IEST’s SWE3500 is engineered to characterize expansion behavior of large-format and short-blade cells in-situ. Its design and capabilities support development and quality control for blade battery technology.

Figure 2. Expansion characterization equipment SWE3500

2.1 Main features:

-

Rugged steel frame for long-term stability and wear resistance.

-

Insulating high-hardness pressure plates to prevent deformation and provide electrical isolation.

-

Servo-driven power system with closed-loop control for precise actuation.

-

High-resolution displacement sensors (0.1 µm) and pressure sensors (accuracy 0.3% F.S.).

-

Integrated charge/discharge interface for synchronized electro-mechanical testing.

-

Built-in environmental chamber: −20 °C to 80 °C to simulate operating conditions.

-

Maximum test pressure: 5 t.

-

System footprint: approximately 1500 × 1700 × 2000 mm.

2.2 Supported test modes

-

Constant Pressure Mode: Hold an applied pressure while monitoring expansion thickness during cycling.

-

Constant Gap Mode: Maintain a fixed gap and record the evolving expansion force.

-

Steady-State Compression: Quasi-static stress–strain characterization for mechanical property mapping.

3. Application Cases

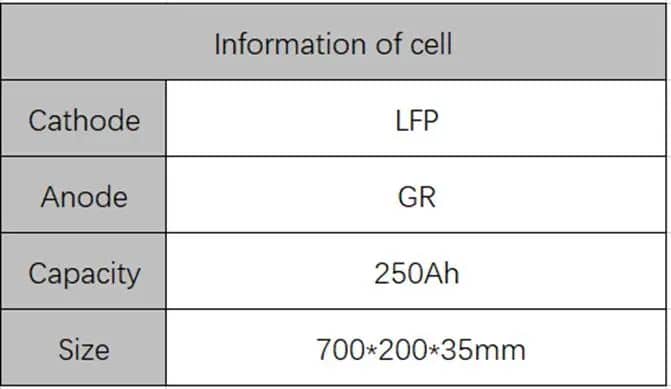

3.1 Cell Information

3.2 Charge and Discharge Process

3.3 Characterization of Expansion Performance

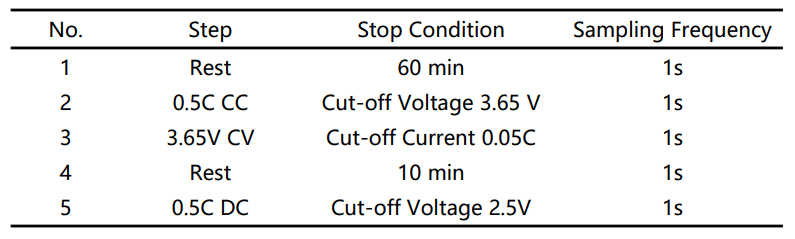

Set a constant pressure of 1000kg and a constant gap of 1000kg to test the expansion thickness and expansion force of the balde cell, as shown in Figure 3 below: the thickness and expansion force change curves show regular changes with the cell voltage curve, and the trends of the two curves are similar, and both have the unique “hump” phenomenon of the LFP/Gr system.

Figure 3. Cell expansion thickness and expansion force change curves with voltage

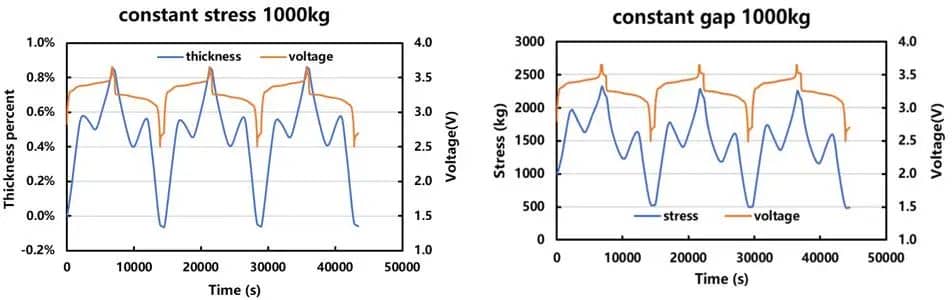

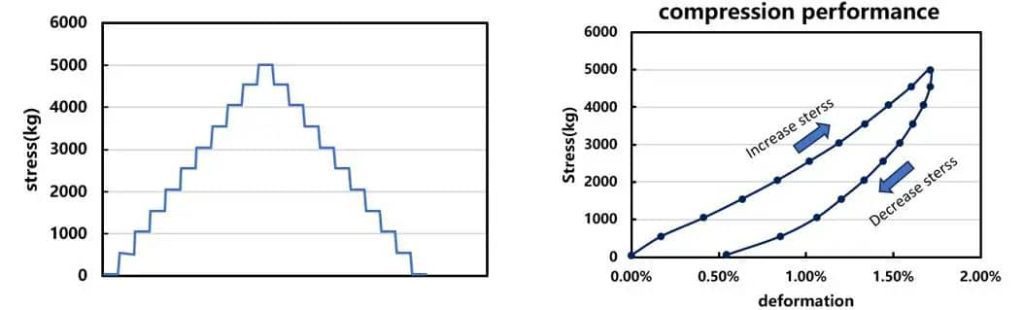

A static compression sequence was applied (start 50 kg, step increments of 500 kg to 5,000 kg, then unload back to 50 kg). The resulting stress–strain loop enabled quantification of reversible and irreversible deformation:

-

Max deformation at 5,000 kg: 1.71% thickness reduction.

-

Irreversible rebound after unloading: 0.54%.

-

Reversible component: 1.17%.

These metrics support design limits for casing stiffness, pre-load strategies, and safety margins.

Figure 4. Pressure control curve (left picture) cell stress-strain curve (right picture)

4. Design & Manufacturing Considerations for Blade Batteries

Although blade batteries bring clear pack-level benefits (improved cooling channels, higher volumetric density, simpler pack structure), their unique geometry requires process and design adaptations:

-

Strict dimensional control: enforce tight tolerances on electrode sheet cutting, coating, and calendering.

-

Precise lamination: improve roll-to-roll alignment and tension control to prevent trapped voids and bubbles.

-

Housing design: select casing materials and cross-sections that provide adequate stiffness while allowing controlled strain relief.

-

Pre-load distribution: apply uniform pre-pressure during assembly to compensate expected swelling and reduce stress concentration.

-

Electrolyte filling & SEI control: develop filling protocols and electrolyte solvent formulations that minimize solvent-driven swelling and inconsistent SEI formation across long electrodes.

-

In-line inspection: adopt optical flatness metrology and acoustic/ultrasonic checks to detect defects early.

5. Why In-Situ Expansion Testing Accelerates Blade Battery Technology

Quantitative, synchronized electro-mechanical testing provides actionable insights:

-

Material screening: compare binders, active-material formulations, and coating stacks for lower swelling signatures.

-

Process tuning: optimize compaction pressures, lamination parameters, and filling temperatures with direct feedback.

-

Lifetime modeling: correlate reversible vs. irreversible deformation with cycle life and mechanical fatigue predictions.

-

Safety validation: detect conditions leading to excessive deformation that could compromise mechanical or electrical safety.

IEST’s SWE3500 enables manufacturers and R&D teams to iterate faster on blade cell designs and makes the transition to mass production safer and more predictable.

6. Conclusion

Blade cell form factors are a strategic evolution in pack-level design — delivering higher volumetric energy density and improved thermal management while simplifying assembly. However, the long thin geometry of blade batteries brings new mechanical and manufacturing risks. Systematic in-situ expansion testing (thickness, force, stress–strain) across SOC and temperature is indispensable for robust blade battery technology development. IEST has launched a large-size cell expansion force characterization equipment that can accurately characterize the expansion thickness, expansion force, stress-strain and other related properties of large-size cells in-situ. It helps engineers to screen the modification process of positive and negative electrode materials and determine the best modification process; accelerate the progress of cell research and development, and develop safer and more reliable cell. At the same time, you can also explore the best usage conditions and extend the service life of the cell.

5. References

[1] “New Energy Battery Pack Technology” public account: [The Origin of the Blade Battery Storm] BYD Blade Batteries Analysis 3.0.

[2] The Analysis on the Principle and Advantages of Blade Battery of BYD — A Domestic New Energy Manufacturer, DOI: 10.1051/shsconf/202214402003.

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.