-

iestinstrument

Charge/Discharge Efficiency and Expansion Thickness of Model Coin Cell Performance Evaluation

1. Background

Lithium-ion batteries have been widely used in all aspects of life, such as mobile phones, cars or household energy storage, etc. Therefore, it is particularly important to evaluate various performances of lithium-ion batteries. We know that lithium batteries will expand or shrink during charging and discharging, so when designing lithium battery modules, the expansion parameter is one of the important parameters that must be considered. In addition, with the emergence of a new generation of anode electrodes with high specific capacity (such as silicon-based anodes or lithium metal anode electrodes), their structural expansion is much more obvious than that of traditional graphite anode electrodes [1,2], therefore, more and more companies are focusing on the evaluation of the expansion performance of lithium batteries.(Model Coin Cell)

Usually, researchers have to prepare electrode into single-layer or multi-layer finished batteries to evaluate the expansion. This method has a long testing cycle, low evaluation efficiency, and consumes a lot of resources, which seriously affects the development process of new materials. IEST has recently innovatively used the model coin cell to evaluate the expansion behavior of the battery electrode, which greatly shortens the evaluation cycle of the material expansion performance, and can save a lot of manpower and material resources for preparing batteries for universities or enterprises. For this model coin cell battery, users are most concerned about whether its cycle efficiency is comparable to that of a traditional steel shell battery pack, and whether the expansion thickness change measured by the model coin cell battery is comparable to that of the finished battery. For this concern, this article provides corresponding comparison data based on these two aspects, which is convenient for users to evaluate and choose.

2. Testing Condition

2.1 Testing Equipment

This article uses the model coin cell of IEST and cooperates with the Silicon-Based Anode Swelling In-Situ Screening System(RSS1400, IEST) to carry out the charging and discharging test and expansion test of model coin cell and pouch cells.

Figure 1. Silicon-based anode swelling in-situ rapid screening system (RSS1400)

2.2 Charge and Discharge Test Conditions

①Use IEST’s model coin cell battery to assemble NCM/Li coin cell half-cell and NCM/SiC coin cell full battery, and perform 3-cycle charge and discharge at a rate of 01C, which is convenient for subsequent comparison between commercial steel shell button batteries and performance of single-layer pouch cell stacked cells.

②Use the commercial 2032 steel shell to assemble the button half battery of NCM//Li, and perform 3 rounds of cycle charge and discharge at the rate of 01C.

③Assemble NCM/SiC single-layer pouch cell laminated batteries, and perform 3 cycles of charge and discharge at a rate of 01C.

2.3 Cell Expansion Test Conditions

The NCM/SiC model Button-type full battery and single-layer pouch cell laminated battery are placed in the silicon-based anode swelling in-situ rapid screening system (RSS1400, IEST). After applying an initial preload of 5 kg, the expansion thickness changes of the two were monitored in real time during the charge and discharge process of 01C.

3. Result Analysis

3.1 Comparison of charging and discharging efficiency between the IEST model coin cell battery and the commercial 2032 steel shell coin cell.

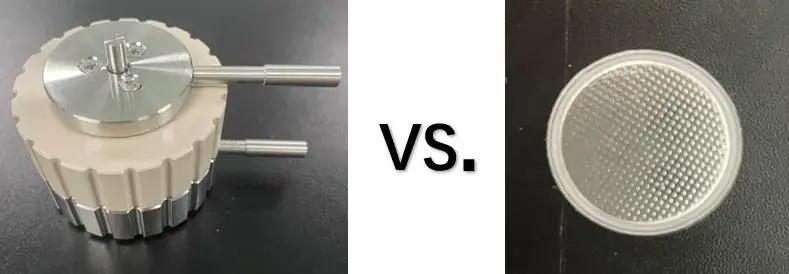

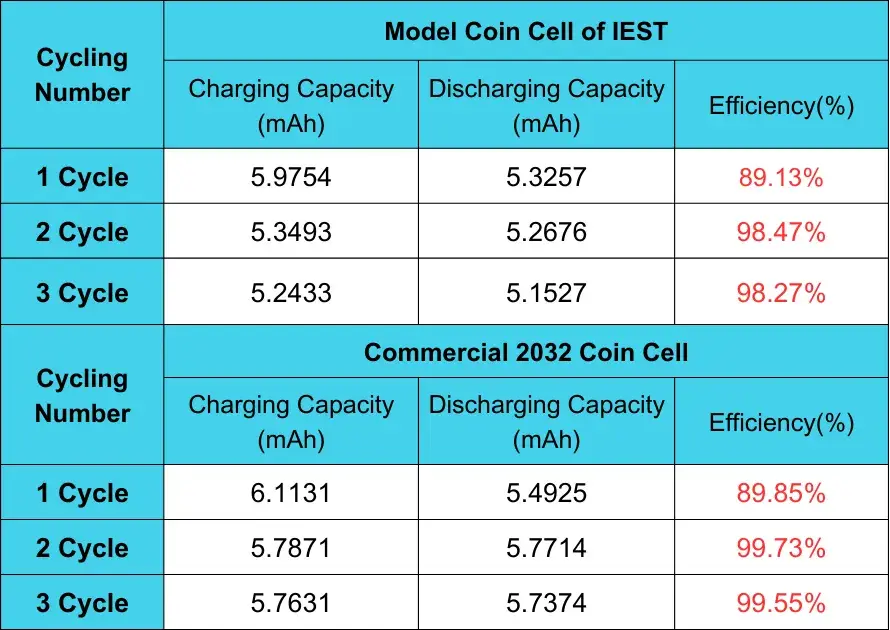

The left picture of Figure 2 is the IEST model coin cell, and the right picture is the commercial 2032 steel shell coin cell. We used ternary positive electrodes of the same size and composition to assemble a pair of lithium-sheet coin half-cells, and compared the Coulombic efficiencies of the two at 01C charge and discharge rates, the results are shown in Table 1. It can be seen from the figure that the first effect of the model coin cell is about 89.13%, which is only about 0.718% lower than the commercial steel coin cell, the maximum cycle efficiency of the second and third laps is only about 1.28% lower than that of the commercial steel shell button. In addition, the maximum cycle efficiency COV of the model button and the steel case button for three cycles is only 0.65% (where COV=standard deviation/average*100, in general, if COV<5%, it indicates the repeatability of the two The reproducibility is relatively good), so it can be considered that the IEST model coin cell battery has similar cycle charge and discharge performance to the commercial steel shell coin cell battery!

Figure 2. The left picture is the model coin cell of IEST; the right picture is the commercial 2032 steel shell cell.

Table 1. Comparison of cycle efficiency between NCM/Li model coin half-cells and commercial steel-shell cells

3.2 Comparison of the expansion thickness of the IEST model coin cell and pouch cell

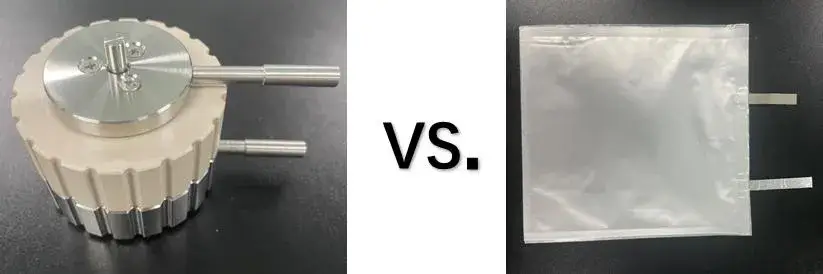

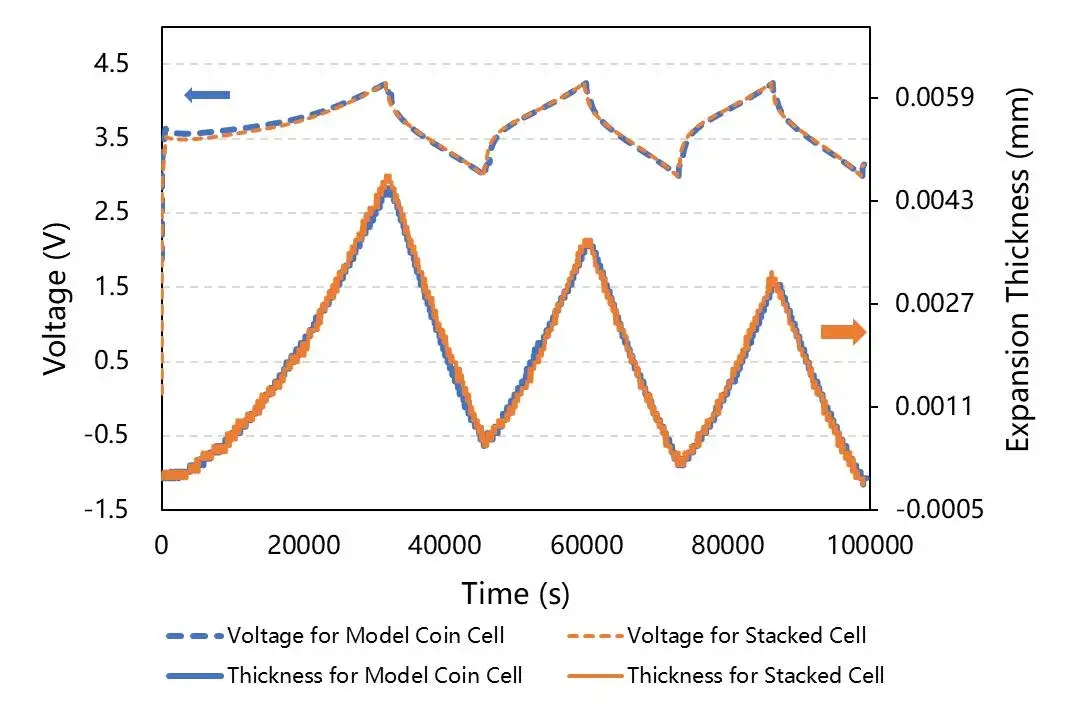

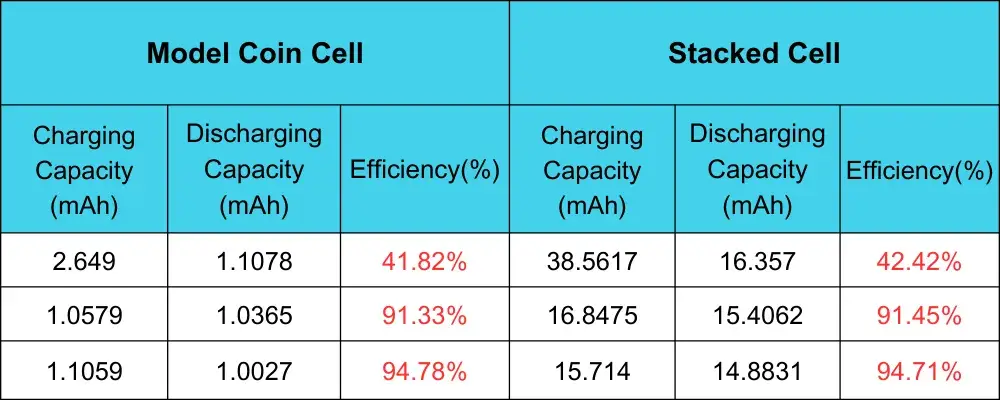

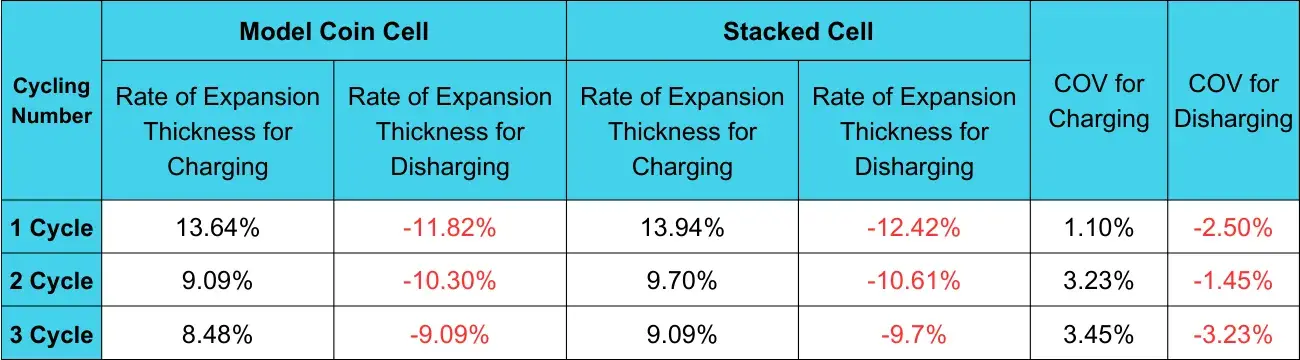

The left picture of Figure 3 is the IEST model coin cell battery, and the right picture is a single-layer pouch cell laminated battery. The two use the same composition of ternary positive electrode and silicon carbon negative electrode to assemble a full battery, and monitor the expansion thickness change of the two during the charge and discharge process of 01C in real time. The voltage curve and thickness expansion curve of the two are shown in Figure 4, the specific full battery cycle efficiency and expansion thickness comparison are shown in Table 2 and Table 3, respectively. It can be seen from Figure 4 that, whether it is the voltage curve during the charge and discharge process or the thickness expansion curve, the model coin cell battery and the pouch cell laminated battery all show good consistency. It can be seen from Table 2 that, the first efficiency of the model coin cell battery and the pouch cell laminated battery are 41.82% and 42.42%, respectively, and the cycle efficiency of the last two cycles is only 0.12% different; However, it can be seen from Table 3 that the thickness expansion rate COV of the two circles is also within 3.5%, indicating that the thickness expansion rate of the two also has a good consistency.

Figure 3. The left picture is the IEST model button battery; the right picture is the single-layer pouch Sstacked cell.

Figure 4. The blue dashed and solid lines are the voltage profile and thickness expansion profile of the model coin cell, respectively;

Orange dashed and solid lines are the voltage profile and thickness expansion curve of single-layer pouch stacked cell, respectively

Table 2. Comparison of cycle efficiency between NCM/SiC model coin cell and single-layer pouch stacked cell

Table 3. Comparison of expansion thickness of NCM/SiC model coin cell y and single-layer pouch stacked cell

4. Summary

This paper evaluates the charging and discharging performance and expansion thickness of the model coin cell of IEST. It can be seen from the results that the cycling charging and discharging efficiency of the model coin cell is basically the same as that of the commercial 2032 steel case button cell, and the thickness expansion rate during the 3-turn cycling process is basically the same as that of the test results of the single-layer stacked cell, which indicates that IEST model button cell has good cycling charging and discharging efficiency and expansion evaluation results. This indicates that IEST model coin cell has good cycle charging and discharging efficiency and expansion evaluation effect. In this paper, it is recommended to use the silicon-based anode swelling in-situ rapid screening system (RSS1400) for silicon-based anode expansion with the model coin cell, which has a thickness expansion test accuracy of 0.1 μm and a resolution of up to 0.01 μm, and has a good ability to detect and discriminate subtle thickness changes caused by the de-embedded lithium phase change, which can help the development of new low expansion and high capacity anode materials!

5. References

[1] J. Lin, L. Wang, Q.S. Xie, Q. Luo, D.L. Peng, C. B. Mullins and A. Heller, Stainless Steel-Like Passivation Inspires Persistent Silicon Anodes for Lithium-Ion Batteries. Angew. Chem. 135 (2023) e202216557.

[2] M. Ashuri, Q.R. He and L.L. Shaw, Silicon as a potential anode material for Li-ion batteries: where size, geometry and structure matter. Nanoscale 8 (2016) 74–103.

Subscribe Us

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.