-

iestinstrument

Evaluation of Different NCM Materials: Structure, Electrical Properties, and Performance

1. Introduction

The cathode is one of the most critical components in lithium-ion batteries. Common cathode families include layered lithium cobalt oxide (LCO), olivine LiFePO₄ (LFP), spinel LiMn₂O₄ (LMO) and layered nickel–cobalt–manganese ternary materials (collectively referred to as NCM materials). The NCM structure — typically LiNiₓCoᵧMn_zO₂ (x+y+z=1) — combines the strengths of Ni, Co and Mn: nickel increases capacity and lowers cost, cobalt improves electronic conductivity and rate capability, and manganese stabilizes the structure and reduces expense. However, high nickel content can destabilize the layered lattice, and excessive manganese can encourage spinel formation, so optimizing composition is essential for reliable NCM cathode material design.

This study compares three widely used NCM polycrystalline compositions (NCM111, NCM622 and NCM811) to evaluate how NCM materials composition and NCM structure affect morphology, electrical conductivity and compaction behavior — key factors that influence battery material electrical properties and final cell performance.

Figure 1. LiCoxMnyNi1-x-yO2crystal structure4

2. Experimental Methods

2.1 Materials

Three NCM powders with differing nickel contents were selected: NCM111, NCM622, and NCM811. Samples were prepared with identical sampling mass and handling to ensure comparability.

2.2 Morphology Characterization (SEM)

Surface morphology and primary particle structure were examined by scanning electron microscopy (SEM) to visualize the ncm structure and polycrystalline characteristics that affect contact resistance and packing.

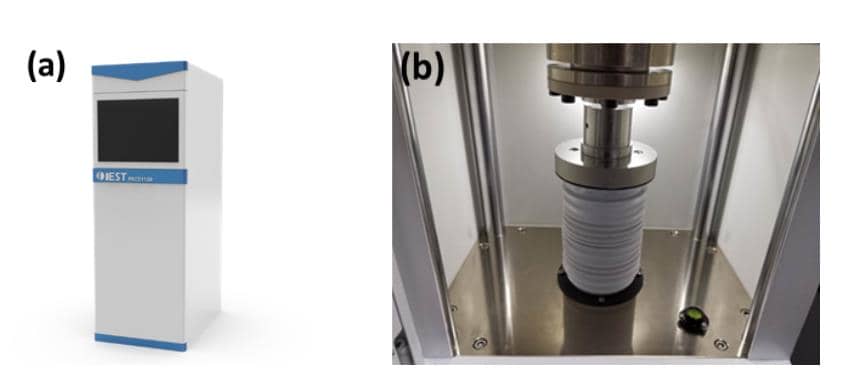

The electrical conductivity and compaction density of the three NCM materials are tested by using PRCD3100(IEST). The test equipment is shown in Figure 2.

Test Parameters: Apply a pressure range of 10-200MPa, with 20MPa interval, and pressure holding for 10s.

2.3 Electrical and Mechanical Property Testing

The battery material electrical properties (conductivity) and compaction density were measured using the PRCD3100 (IEST) powder resistivity and compaction density testing system. This equipment is essential for quantifying key NCM materials characteristics that directly impact electrode processing and cell performance.

-

Test Parameters: A pressure range of 10-200 MPa was applied with intervals of 20 MPa, holding each pressure for 10 seconds to ensure accurate readings.

-

Equipment: Figure 2 shows the PRCD3100, designed for precise measurement of these critical parameters.

Figure 2. (a) PRCD3100 equipment for testing NCM material properties; (b) Schematic diagram of its testing structure.

3. Results

3.1 SEM Morphology — NCM Structure Observations

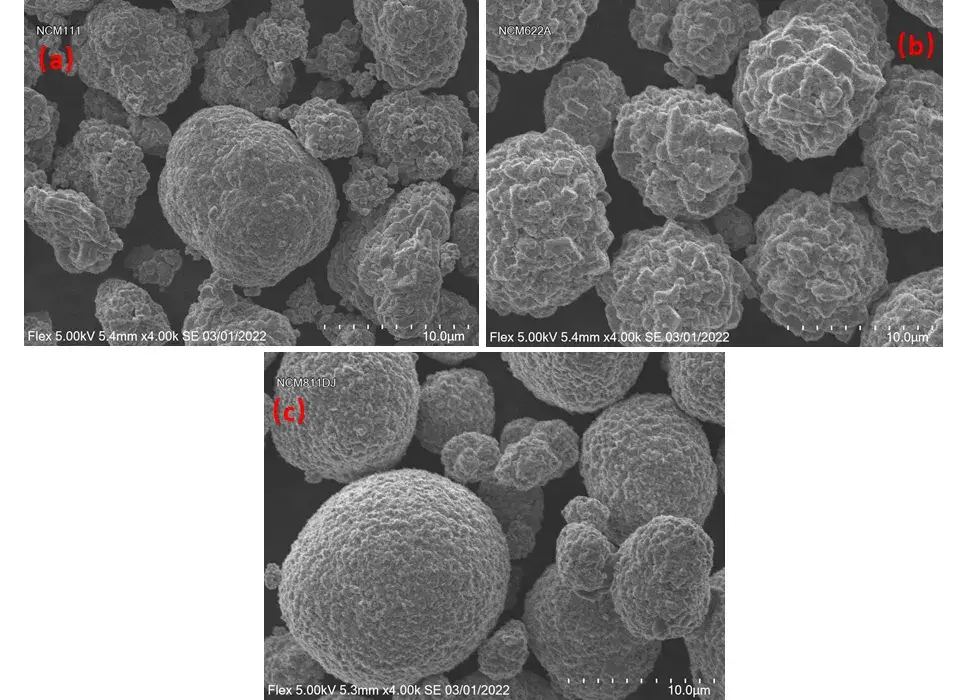

SEM images (Figure 3) show distinct morphology across compositions:

-

NCM811: Higher surface packing density and more spherical polycrystalline agglomerates — favorable for particle contact and intrinsic conductivity.

-

NCM622 & NCM111: More pronounced layered primary particles and lower apparent surface packing density; grain boundaries and plate-like features are clearer.

These morphological differences reflect how ncm structure and grain aggregation influence interparticle contact, porosity, and thus the battery material electrical properties.

Figure 3. SEM topography of the three NCM cathode materials: (a) NCM111, (b) NCM622, (c) NCM811.

3.2 Electrical Conductivity and Compaction Density

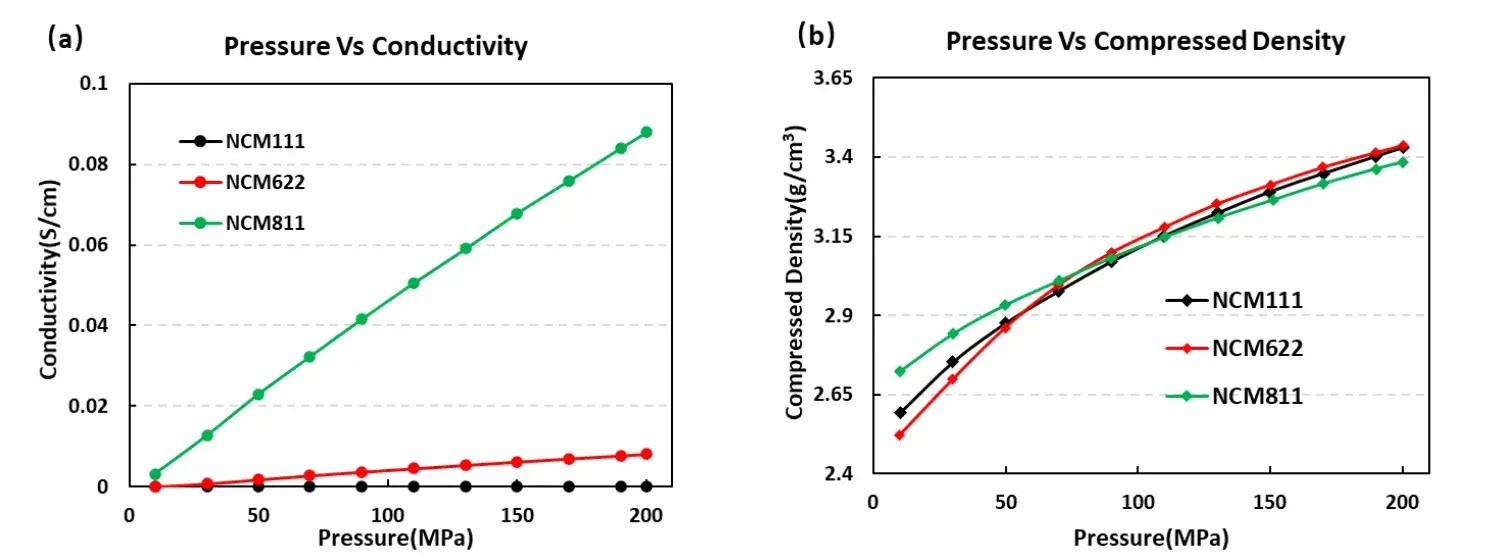

The battery material electrical properties, specifically conductivity, are crucial for cell rate performance. As shown in Figure 4(a), the ranking of conductivity is NCM811 > NCM622 > NCM111. This is directly correlated with the increasing nickel and cobalt content, which improve electronic conduction.

The compaction density curves in Figure 4(b) show that above 80 MPa, NCM622 achieves a slightly higher density than NCM111 and NCM811, though the overall difference is minor. Compaction density is influenced by particle shape, size distribution, and mechanical strength. The process involves particles rearranging into a densest packing under pressure, followed by elastic and plastic deformation at higher pressures.

Figure 4. Electrical conductivity and compaction density curves of the three NCM materials

3.3 Deformation and Rebound Behavior

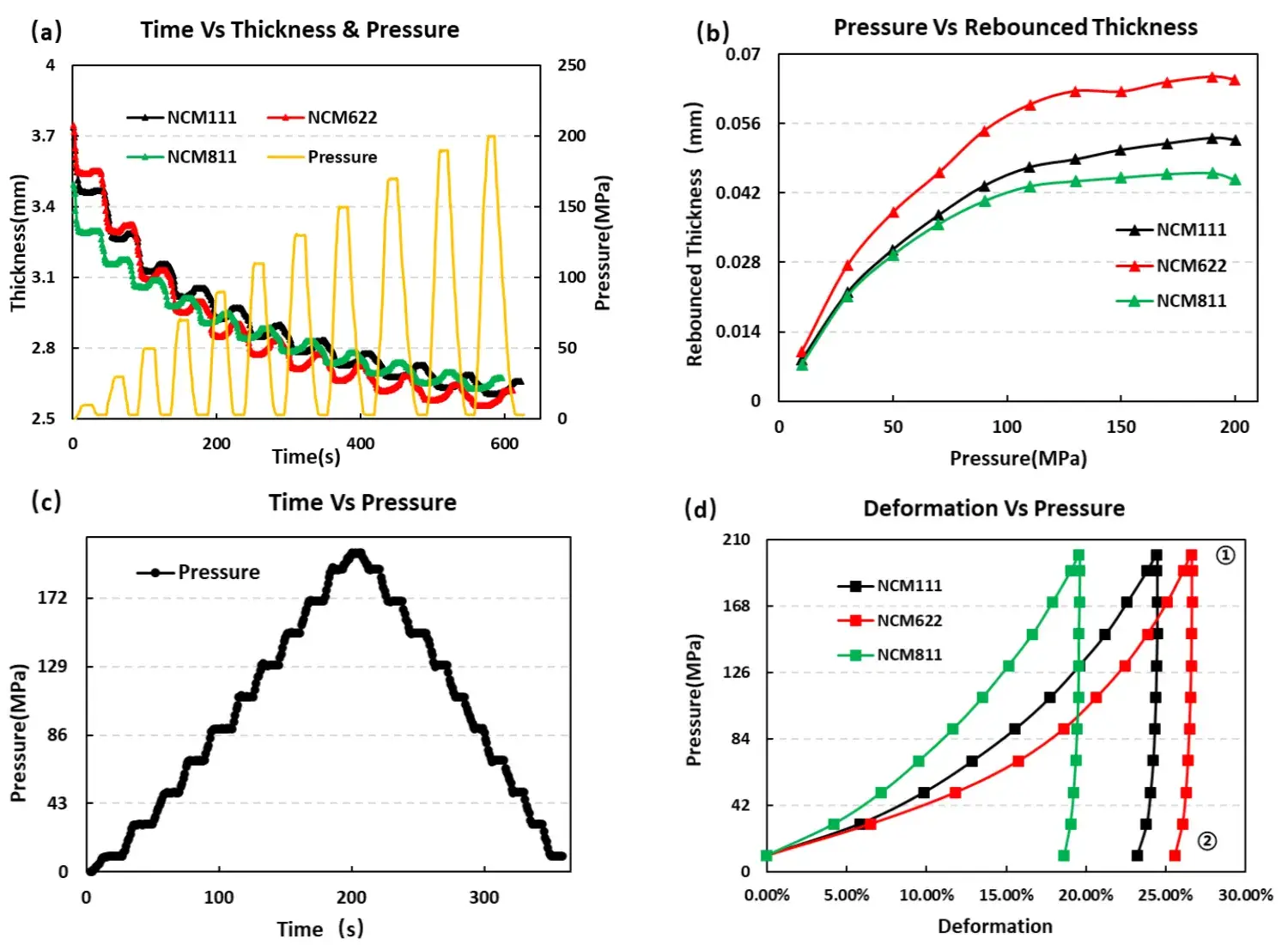

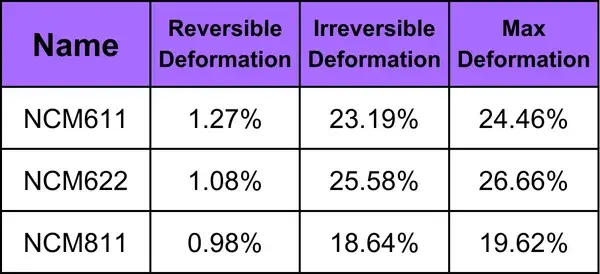

To further understand the mechanical behavior of the NCM cathode material, pressure release and rebound tests were conducted. The results, shown in Figure 5 and summarized in Table 1, indicate that:

-

NCM622 exhibits a greater thickness rebound upon pressure release, suggesting significant elastic recovery.

-

At approximately 110 MPa, the rebound stabilizes, indicating that inter-particle pores are largely eliminated and the rebound is due to the inherent elasticity of the particles themselves.

-

Analysis of reversible and irreversible deformation shows that NCM111 has slightly more reversible deformation, but the overall differences are small. The stress-strain curve slope indicates that NCM622 has a lower compression modulus, meaning it is more easily compressed under force.

These results demonstrate that the specific NCM structure and morphology of NCM622 allow it to achieve a favorable combination of high compaction density and manageable elastic rebound, which is critical for manufacturing dense, stable electrodes.

Figure 5. Stress and strain curves during the pressurization and pressure relief of the three NCM materials.

Table 1. Summary of deformation data for the three NCM materials.

4. Discussion — Linking NCM Structure to Battery Material Electrical Properties

-

Microstructure vs. Conductivity: NCM811’s higher apparent conductivity is linked to denser polycrystalline agglomerates and better contact networks after compaction. This improves electron percolation in the electrode, benefiting rate performance.

-

Compaction trade-offs: While increasing nickel content raises capacity and intrinsic conductivity, it may also increase brittleness and sensitivity to mechanical stress; careful control of calendering pressure and electrode formulation is needed to avoid particle fracture.

-

Porosity and packing: NCM622’s favorable compaction density suggests that intermediate Ni content can deliver a practical balance between packability and mechanical resilience, which is useful when optimizing battery material electrical properties at the electrode level.

-

Practical implication for electrode manufacture: Beyond material selection (Ni/Co/Mn ratio), electrode processing — slurry formulation, coating and calendering parameters — must be tuned for each NCM composition to maximize volumetric energy while minimizing contact resistance and particle breakage.

5. Conclusions

This study utilized the PRCD3100 to comprehensively evaluate the battery material electrical properties and mechanical characteristics of NCM111, NCM622, and NCM811, demonstrates that:

-

NCM structure strongly influences morphology, compaction behavior and electrical conductivity.

-

NCM811 exhibits the highest measured conductivity due to denser particle packing and favorable microstructure.

-

NCM622 offers advantageous compaction density above ~80 MPa and is easier to compact (lower compression modulus), providing a practical compromise between energy density and mechanical robustness.

-

Optimizing ncm cathode material performance requires coupling composition selection with tailored electrode processing to control particle fracture, interparticle contact, and final electrode porosity — all of which govern battery material electrical properties and cell-level performance.

Material developers and process engineers should evaluate composition, microstructure and mechanical response together rather than in isolation to achieve the best trade-offs for energy density, rate capability and long-term durability.

4. References

[1] Zhang R, Meng Z, Ma X, et al. Understanding fundamental effects of Cu impurity in different forms for recovered LiNi0.6Co0.2Mn0.2O2 cathode materials[J].Nano Energy, 2020:105214.

[2] Guangshun Xiao. Recent Development on Ni-Co-Mn Ternary Cathode Material for Lithium-Ion Batteries[J].Material Sciences, 2020, 10(4):201-215.

[3] Zhaoguo Wu. Synthesis, characterization and modification of high nickel ternary cathode materials for lithium-ion batteries [D]: [Doctoral dissertation]. Hefei: University of Science and Technology of China, 2018.

[4] Meng Y S, Arroyo-De Dompablo M E. Recent advances in first principles computational research of cathode materials for lithium-ion batteries[J].Accounts of Chemical Research, 2013, 46(5):1171-80.

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.