-

iestinstrument

Analysis and Characterization of Expansion Force in Cylindrical Lithium Cells

1. Preface

Cylindrical cells (also written in some sources as cylindrical Cell) remain a dominant battery format because of their mature winding process, high automation and consistent quality. Unlike pouch or prismatic formats, steel shell cylindrical cells have rigid metal enclosures that suppress visible diameter change during charge/discharge cycles — which complicates direct expansion measurement. This paper provides a clear explanation of the mechanical origins of expansion in cylindrical lithium cells, derives practical radial expansion estimates from thick-walled cylinder mechanics, and presents an in-situ method (SWE2100 constant-gap mode) to measure the expansion force of cylindrical cells indirectly while preserving the cell core.

2. Why Cylindrical Cell Expansion Matters

Although radial swelling of a shell cylindrical cell is small (microns), internal volume changes still occur from:

-

SEI growth, gas generation and side reactions (irreversible volume increase);

-

Reversible lattice changes during lithiation/delithiation (small elastic volume changes);

-

Mechanical particle fracture and electrode redistribution.

These internal changes affect cell internal stress, contact between jelly-roll and shell, and long-term safety and capacity retention. Quantifying expansion behavior helps manufacturers optimize cell design, pre-loading, and thermal/mechanical management.

3. Test Information

3.1 Experimental equipment

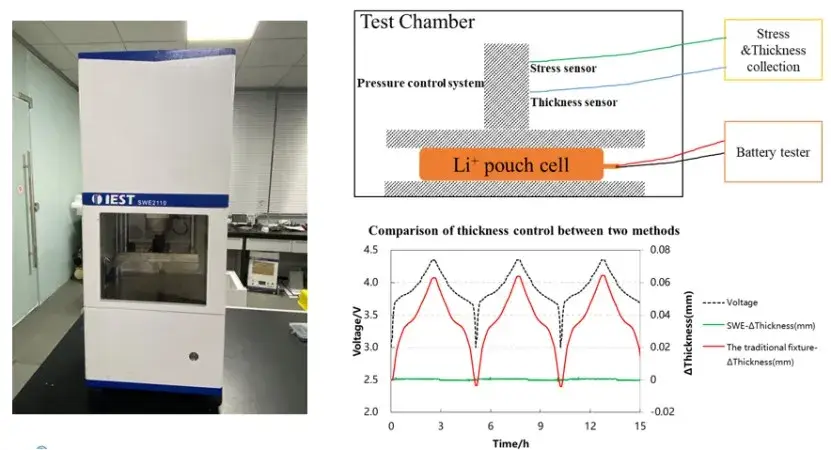

Equipment: IEST SWE2100 in-situ swelling testing system (constant-gap mode), as shown in Figure 1

Procedure overview: remove the metal can in controlled dry conditions, extend tabs, rewrap with flexible film, place the core between ceramic plates, and use SWE2100 to measure expansion force vs state of charge (SOC). This procedure preserves the internal structure while allowing an analog measurement of shell constraints.

Figure 1. Schematic diagram of the in-situ swelling testing system(SWE2100)

3. Result Analysis

3.1 Expansion analysis of cylindrical cell

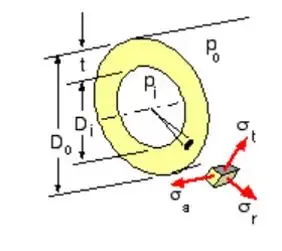

Under the action of internal pressure Pi, the cylindrical cell’s steel shell is subjected to three primary stresses under internal pressure(as shown in Figure 2):

-

σa: Axial stress affecting cell height.

-

σr: Radial stress acting perpendicular to the shell surface.

-

σt: Circumferential stress causing changes in shell perimeter.

Figure 2. Cylindrical cell shell stress decomposition

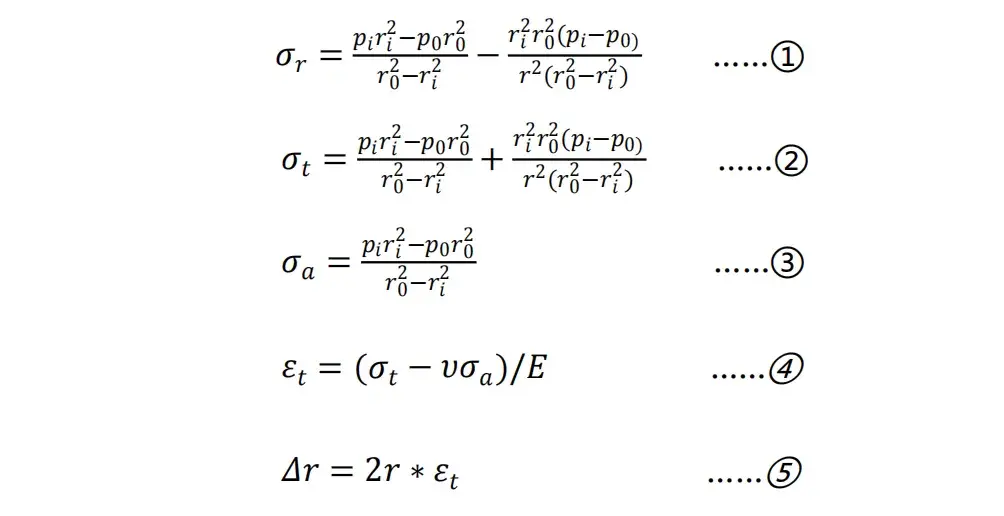

In accordance with the thick-walled cylinder shear stress theory to derive the three stresses expressed as follows ① ② ③, stresses were calculated for a sample 3665 cylindrical lithium cell (inner diameter = 17.7 mm, outer diameter = 18.0 mm). Under an assumed internal pressure of 1.0 MPa, results showed:

-

σr = -0.1 MPa

-

σt = 52.6 MPa

-

σa = 26.2 MPa

Figure 3. Calculation Formula

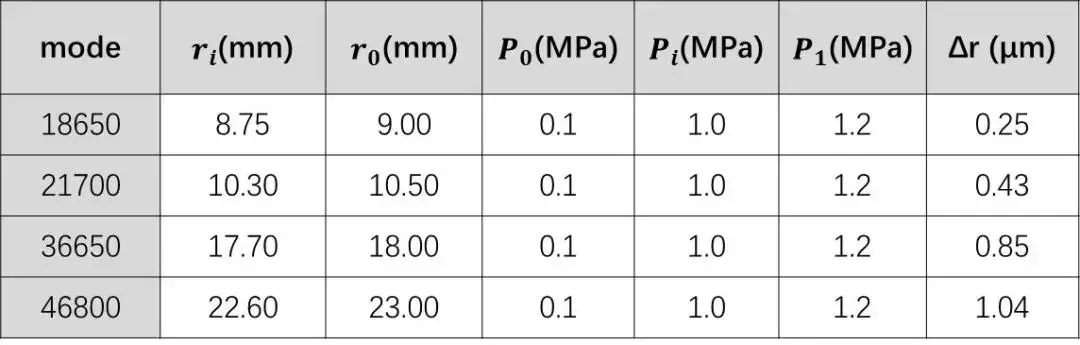

Ignoring the influence of σr, the change in shell diameter can be obtained by further combining the stress-strain law of the steel shell (Formula ④) and the circumference formula (Formula ⑤). Assuming that the elastic modulus E of the steel material is 210GPa and the Poisson’s ratio υ is 0.3, it is calculated that the radial expansion is about 9.4μm when fully charged (assuming that the internal pressure Pi is 1.2MPa at this time). If it returns to the state after being fully discharged, that is, the internal pressure is 1.0MPa, the radial expansion is 7.7μm at this time, and the radial expansion thickness during the charging and discharging of the battery cell is about 1.7μm. The calculation of the charging and discharging deformation of different types of battery cells under this condition and this method is shown in Table 1 below. It can be obtained that there is basically no radial expansion of the cylindrical battery cell during the charging and discharging process. In practice, the internal pressure after formation may not reach 1.0MPa, and some processes are formed first and then sealed, which also shows that the actual deformation will be smaller than the calculated value in Table 1.

Table 1. Radial calculation of charge and discharge of different types of batteries

Thickness variations are particularly pronounced in flexible cells with flexible aluminum-plastic films, and measurements are easily achieved. However, due to the structural rigidity of the hardshell body, cylindrical cells exhibit much smaller diameter expansion (~0.1%), making it difficult to observe reversible and irreversible cell diameter changes. However, due to the growth of irreversible layer thicknesses such as the solid electrolyte interface (SEI) layer and Li plating, which can lead to volume changes, and gassing due to side reactions, which can also lead to an increase in pressure inside the shell, the cells inside the shell will definitely expand and contract during charging and discharging. In order to understand what potential mechanical processes are occurring inside the battery, suitable measurements are needed to record and analyze parameters such as electrode thickness and volume changes of the cell components. Evaluating the structural characteristics of a cell typically uses methods such as X-rays, computed tomography, neutron and ultrasound imaging to obtain comprehensive information on strain, stress distribution and structural strength. While these techniques are powerful, they are often used as offline diagnostic techniques due to the need for special equipment, high cost, and the inevitable interference these high energy sources cause during battery operation.

3.2 Characterization of the expansion force of cylindrical cells

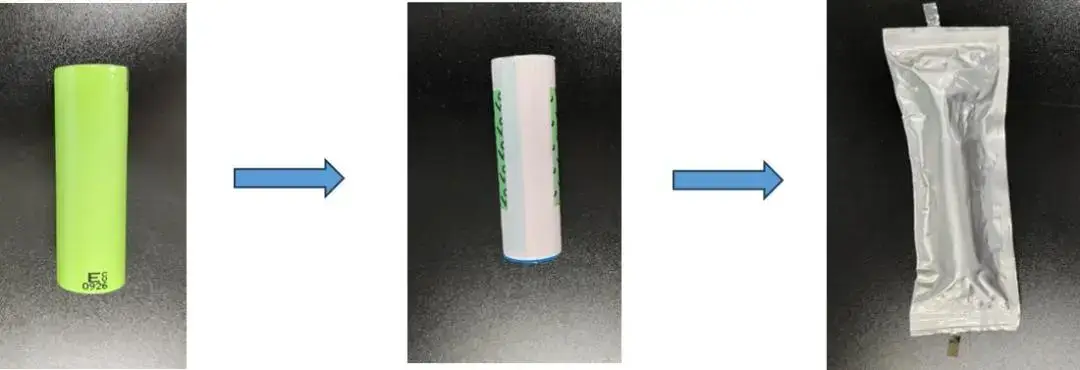

Given that cylindrical cells are essentially non-expanding in the radial direction, they cannot be monitored directly from the outside of the cell. The expansion changes in Table 1 are comparable to the controlled fluctuations of ±1μm in the constant gap mode of IEST in-situ swelling analysis system (SWE2100), so the SWE2100 equipment can be used to simulate the binding of the cylindrical cell shell on the core, thus realizing the characterization of the expansion force of the cylindrical cell. The pre-testing process is shown in Figure 4 below: in a glove box or dry room, the outer package (steel shell) is removed, then the tabs are extended, and finally the package is re-encapsulated with aluminum-plastic film.

Figure 4. Pre-treatment flow of cylindrical cell

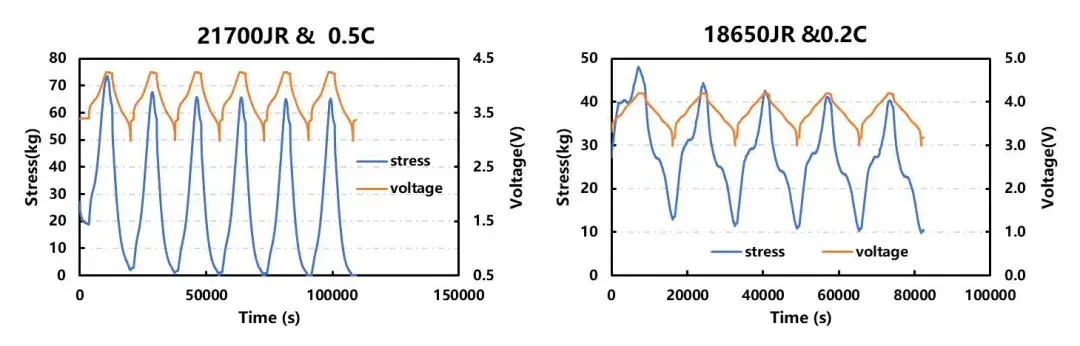

During the test, the cell was directly placed in the test chamber (between two ceramic plates), and the test software (MISS2.1) was turned on, and the constant gap mode was selected to monitor the expansion force with the change of SOC in situ, as shown in Figure 5 below.

Figure 5. Expansion force of cylindrical cells of different models

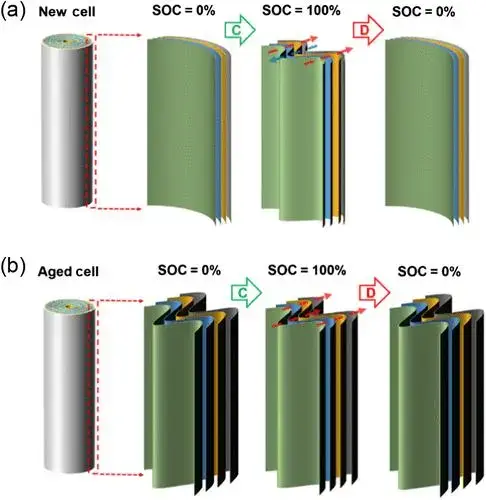

The main thing that this method monitors is the deformation process of the cylindrical cell during the charging and discharging process. As shown in Figure 6, cylindrical cells, unlike flexible aluminum-plastic film shells of soft-pack batteries, have rigid metal shells, which can impede the release of stresses generated by internal expansion. The non-uniform contact between the metal shell and the internal film in the tested battery leads to tiny loose contacts, which results in uneven stress distribution. In the early stages of cycling (i.e., new batteries), the volume expansion mechanism is shown in Figure 6a. The surface of the cell is initially relatively circular, and the stress distribution inside the cell is transferred to the metal case when the cell is fully charged, thus creating a non-uniform expansion distribution. Due to the structure of the cell roll, the radially protruding expansion results in shrinkage depressions on the metal case. As cycling proceeds, the increase in irreversible expansion causes this peak-valley structure to be permanently fixed and accumulated, bringing the case into closer contact with the interior, as shown in Figure 6b.

Figure 56. Schematic diagram of the mechanism of volume change of new (a) and aged (b) cylindrical cells

4. Recommendations for manufacturers & test labs

-

Use IEST SWE2100 constant-gap testing to quantify cylindrical cell expansion force during development and incoming quality checks.

-

Combine mechanical force measurements with imaging (X-ray CT, ultrasonic) for a full picture of internal evolution.

-

When designing can thickness/geometry for a steel shell cylindrical cell, consider not only peak internal pressure but also cumulative irreversible expansion over life.

-

For high-expansion chemistries (e.g., silicon-rich anodes), exploit the cylindrical can’s constraint and use expansion force data to select appropriate preloads and venting strategies.

5. Summary

This study demonstrates that the SWE2100 in-situ swelling analysis system, operating in constant-gap mode, offers an effective solution for characterizing expansion forces in cylindrical lithium cells. By simulating the mechanical binding effect of the steel shell, this approach enables accurate assessment of internal stresses and deformation behavior during cycling.

The methodology provides valuable insights for the development and optimization of cylindrical cells, particularly for applications involving high-expansion materials. It also supports safety evaluations and enhances our understanding of mechanical processes within rigid shell cylindrical cell configurations.

6. References

W.X. Jiang, H.R. Li, S.C. Wang, S.S. Wang, W. Wang, Dynamic Volume Imaging by Observing the Breathing of Cylindrical Lithium-Ion Batteries during Cycling,

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.