-

iestinstrument

Entering Electrochemistry | The Critical Role of High Precision in Battery Test Equipment

1. Abstract

High precision battery test equipment is central to credible electrochemical research and to quality-controlled production of lithium-ion cells. Precise control and measurement of current and voltage reveal small but consequential phenomena—micro-voltage drift, subtle capacity loss and early signs of degradation—that lower-precision systems can miss. This guide explains why precision matters, how control precision differs from measurement precision, which hardware and software design choices deliver stable long-term accuracy, and how integrated electrochemical modules (CV, EIS) and calibration practices support robust battery cycle tester workflows.

2. Why is High Precision Battery Test Equipment Essential?

Research and development decisions rely on trustworthy data. When you measure capacity, voltage plateaus or small impedance changes, even tiny measurement errors translate into incorrect conclusions about material performance. High precision battery test equipment provides exact electrochemical parameters, enabling researchers to probe subtle physical and chemical changes within a cell. These changes are often minute and can only be captured accurately by high-precision instrumentation. In production, better test fidelity supports quality control and helps shift competition from scale to product quality.

3. The Need for Accurate Current & Voltage Measurement

Current and voltage are fundamental parameters characterizing battery performance during cycling. Precise measurement not only ensures data integrity but also helps identify potential issues—for instance, minor voltage fluctuations can be early indicators of cycle life degradation.

Mass-produced equipment typically offers accuracies of 0.1% (1/1000) or 0.05% (5/10,000), suitable for general cycle life validation. For charge-discharge equipment, precision involves two distinct yet related aspects: Control Accuracy and Measurement Accuracy.

Fundamentally, equipment is an assembly of components controlled by specific logic. Selecting superior components enhances both precision and long-term stability. Significant investment in component selection is why Ultra-High Precision Charge-discharge (UHPC) systems can cost orders of magnitude more than standard units.

4. Understanding Control Accuracy vs. Measurement Accuracy

-

Control Accuracy refers to a device’s ability to precisely regulate and maintain a target voltage or current. It determines whether the equipment can operate according to setpoints without deviation. This capability hinges on hardware control, utilizing high-precision Digital Signal Processors (DSPs) or microcontrollers. Key design elements include precision power supplies and control loops that minimize noise and interference, ensuring a fast, stable response to the target value. Furthermore, using high-quality components like low temperature-drift and low time-drift resistors and precision capacitors reduces errors caused by temperature changes and aging—factors often referred to by R&D engineers as “temperature drift and time drift.”

-

Measurement Accuracy indicates how closely the device’s reported voltage or current values reflect the true values. It reflects the accuracy and stability of the device’s measurement system—the data users see on the control software. The process involves high-precision Analog-to-Digital Converters (ADCs) transforming analog signals into digital data for software interpretation. Achieving high measurement accuracy requires optimized measurement circuits to reduce noise and error. Techniques like 4-wire (Kelvin) measurement eliminate lead resistance effects. Crucially, regular channel calibration is necessary for users to verify and adjust for hardware drift, thereby maintaining specified measurement accuracy over time.

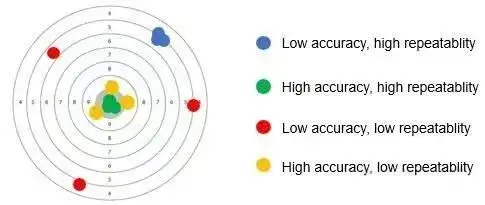

Figure 1. Accuracy and Repeatability Target Diagram

In practice, both control and measurement accuracy are vital. Control accuracy ensures precise operation, while measurement accuracy provides reliable feedback data for process control and analysis.

When reviewing equipment specifications, definitions of “accuracy” can vary by manufacturer. Often, a single accuracy parameter is listed, which typically refers to measurement accuracy, as this is the parameter users can directly observe and verify.

5. A hHigh Precision Battery Test Equipment for Demanding R&D

As a professional supplier of lithium battery testing equipment, IEST has been deeply involved in equipment development for many years, accumulating extensive experience with customer needs and pain points. The development of battery cycle tester products aims to meet customers’ increasingly stringent standards and provide customized services. Our currently developed equipment is equipped with 8 test channels with 1 in 10,000 accuracy. The system integrates electrochemical modules for Cyclic Voltammetry (CV) and Electrochemical Impedance Spectroscopy (EIS). This integration allows CV or EIS test steps to be seamlessly programmed within long-term cycle test protocols, enabling convenient in-situ monitoring of electrochemical properties over hundreds or thousands of cycles.

Figure 3. IEST Electrochemical testing system

Figure 4. IEST Battery Cycle Tester Electrochemical Tester-ECT Series(8 Channels)

6. How Can High-Precision Testing Assist Battery Research?

The application scenarios for high-precision charge-discharge equipment are diverse. It’s not an exaggeration to say that “a thousand users have a thousand Hamlets” in mind. Ultimately, the goal is to address three key issues:

6.1 Enhancing Energy Density

By precisely testing the capacity, voltage plateau, and cycle life of new materials, researchers can identify optimal formulas and designs to develop batteries with higher energy density, driving progress toward more efficient and longer-lasting energy storage.

6.2 Improving Safety

High precision battery test equipment can detect subtle signs of potential safety hazards, such as conditions leading to overcharge, over-discharge, or thermal runaway. Detailed analysis of this data informs better battery design, enhancing safety and preventing failures.

6.3 Extending Lifespan

Battery degradation mechanisms are complex and varied. Through high-precision long-term cycle testing and impedance analysis, researchers gain deeper insights into aging processes, enabling the development of effective strategies to prolong battery lifespan.

We have previously explored these applications in detail; interested readers can refer to our article: Entering Electrochemistry | The Significance of High-Precision Charge/Discharge Testing for Predicting the Lithium ion Battery Lifespan

7. Software and Workflow Features That Improve Data Utility

Precision hardware requires matching software capabilities to extract value:

-

Flexible step editors that allow CV and EIS steps to be embedded in cycle sequences.

-

Automated calibration routines and per-channel validation reports.

-

Synchronized logging of environmental parameters (temperature, humidity, box pressure) and metadata (cell ID, electrode formulation) to support traceability.

Integrated software reduces operator error and enables repeatable, auditable test campaigns for battery cycle testers used in regulated or standards-driven environments.

8. Conclusion

High precision battery test equipment and well-configured battery cycle testers enable more reliable research and stronger quality control in battery development. By separating control precision from measurement precision, investing in low-drift hardware, embedding CV/EIS capability and adopting disciplined calibration and data workflows, teams can detect subtle phenomena, accelerate material qualification and produce defensible lifetime estimates. These capabilities ultimately support safer, higher-energy and longer-lived batteries.

Subscribe Us

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.