-

iestinstrument

Impact of Battery Cell Consistency on Battery Packs

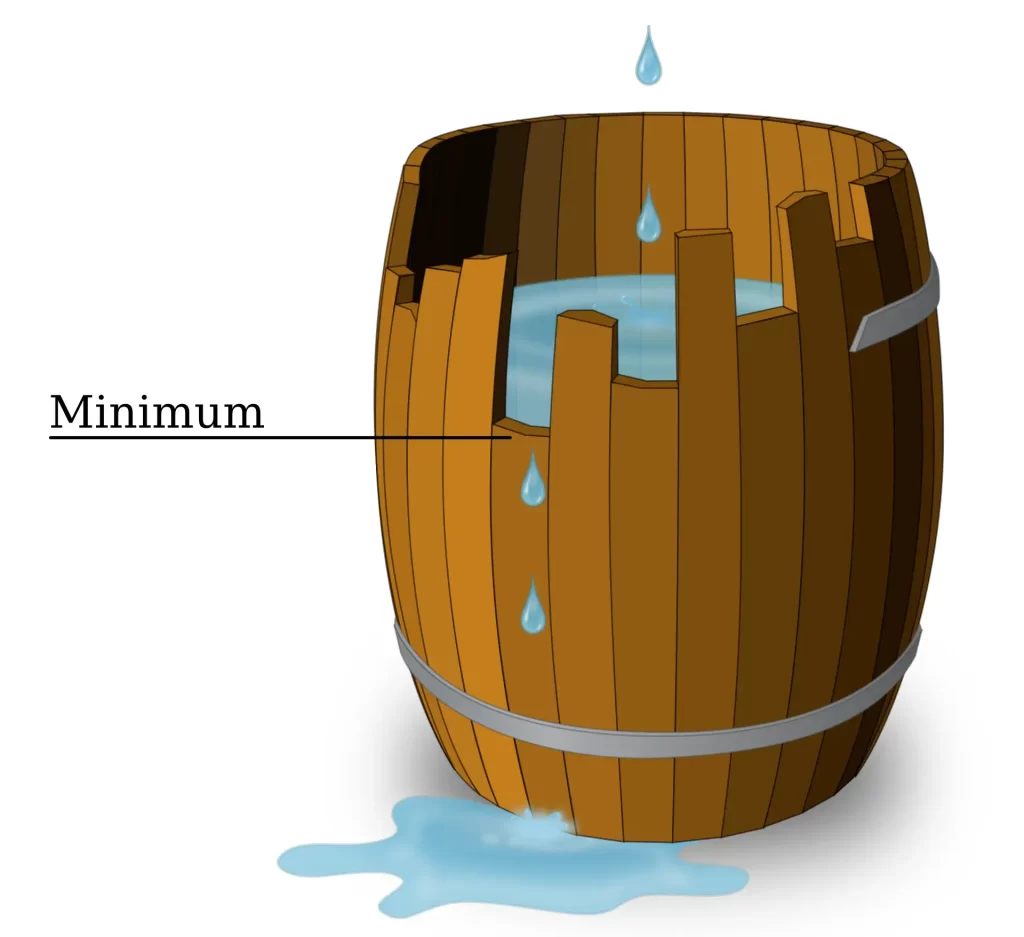

Battery cell consistency is one of the difficulties that the major battery cell manufacturing companies are focusing on. In the manufacturing process of battery cells, due to fluctuations in materials, equipment and environment, there will be minor differences in the produced cells, which will be further amplified after the cells are assembled into battery packs. This small difference will be further magnified when the cells are assembled into a battery pack, which is similar to the “Buckets effect”, in which the cell with the worst performance within the battery pack will directly affect the performance of the whole battery pack, including safety, cycle life, and capacity utilization, etc. [1-2]. In this article, we focus on the effects of inconsistency in voltage, capacity and internal resistance of the cells on the battery pack.

Figure 1. The Buckets effect

1. The effect of cell inconsistency on battery packs

1.1 Voltage inconsistency

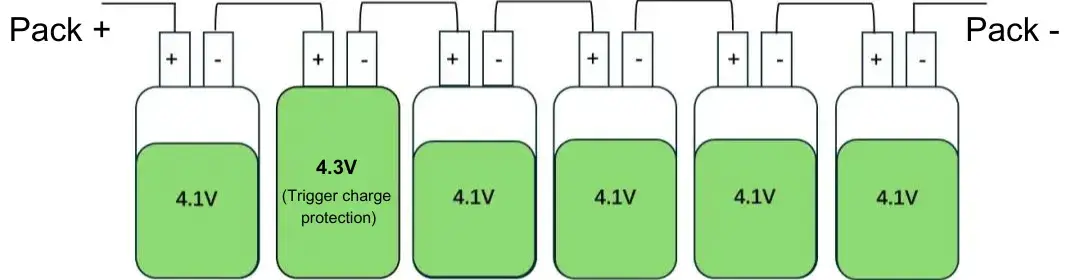

Take a battery pack with 6 cells in series as an example (Figure 2), assuming that during the charging process, 5 cells have a voltage of 4.1V, while 1 cell has reached the full charging voltage of 4.3V, at this time, the BMS will activate the overcharge protection to stop charging, which directly results in the rest of the cells not being full of power, thus reducing the battery pack’s power storage capacity. In the discharge process is also the same reason, the lower voltage of the cell will be prioritized to reach the over-discharge protection voltage, resulting in the battery pack early end of the discharge, affecting the range. Voltage inconsistency will not only affect the capacity of the battery pack, but will also cause part of the battery cells to be frequently overcharged and over-discharged, which will lead to accelerated cyclic degradation of that part of the battery cells and create a certain degree of safety risk.

Figure 2. Series connection of cells with inconsistent voltage

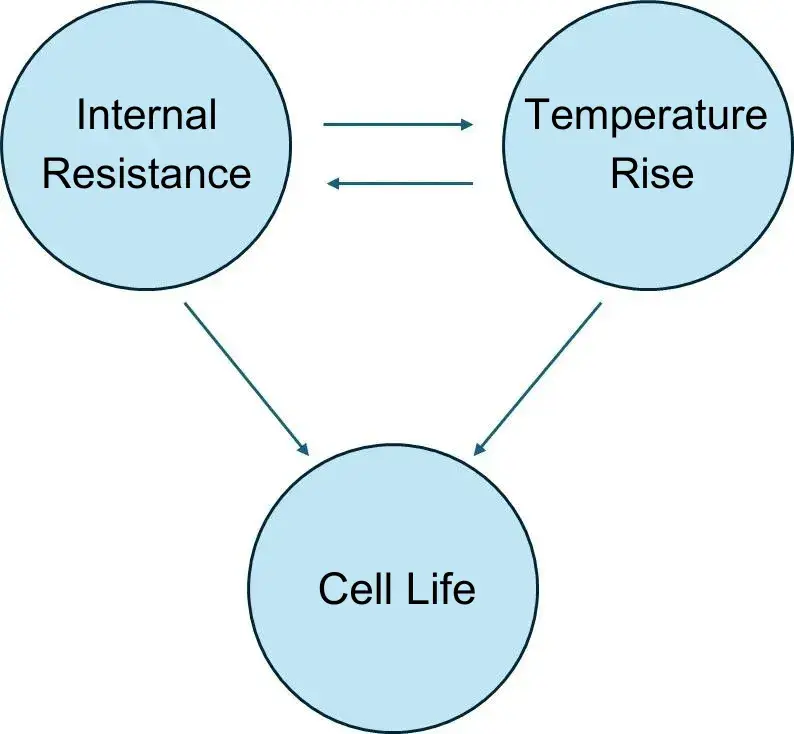

2.2 Inconsistent internal resistance

During the manufacturing process of the battery cell, the uniformity of the slurry/coating/cold pressing and the welding effect of the pole lugs will affect the internal resistance of the finished battery cell. Large internal resistance of the battery cell in the charge and discharge process will generate more heat leading to the rise in temperature of the battery cell, and high temperature will accelerate the aging of the battery cell and further increase the internal resistance, then the internal resistance and temperature form a pair of negative feedback, resulting in rapid degradation of the performance of the battery cell, and the performance of the fastest decay of the battery cell and directly determines the life of the battery pack.

Figure 3. Impact of internal resistance and temperature rise on the life of the battery cell

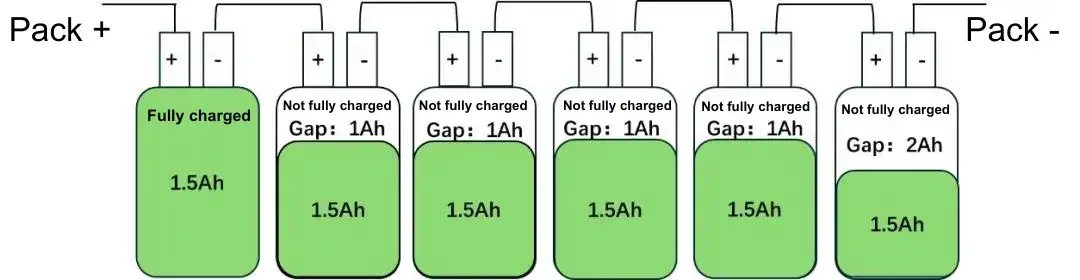

2.3 Inconsistent capacity

In a series circuit, the capacity of the battery pack is determined by the cell with the smallest capacity. As shown in Figure 4, assuming that in a battery pack with 6 cells connected in series, the average capacity of the cells is 2.5Ah, and the smallest capacity is 1.5Ah. The capacity obtained by charging and discharging the 6 cells individually totals 2.5*6=15Ah, while in a battery pack, the actual capacity can only be exerted as 1.5*6=9Ah, which is mainly due to the fact that the voltage of the cells with small capacity will reach the full charging voltage earlier, making the battery stop charging earlier, which results in each cell only being able to exert 1.5Ah of capacity. This is mainly because the voltage of the small capacity cell will reach the full charge voltage earlier, causing the battery to stop charging earlier, which leads to the capacity of each cell can only play 1.5Ah.

Figure 4. Series connection of cells with inconsistent capacity

3. Solutions for cell inconsistency

The inconsistency of battery cells will lead to the degradation of battery pack performance and certain safety risks, IEST Company has developed a series of products from different dimensions to monitor the consistency of the production process & shipment of battery cells, to ensure the high consistency of the battery cells in the battery pack.

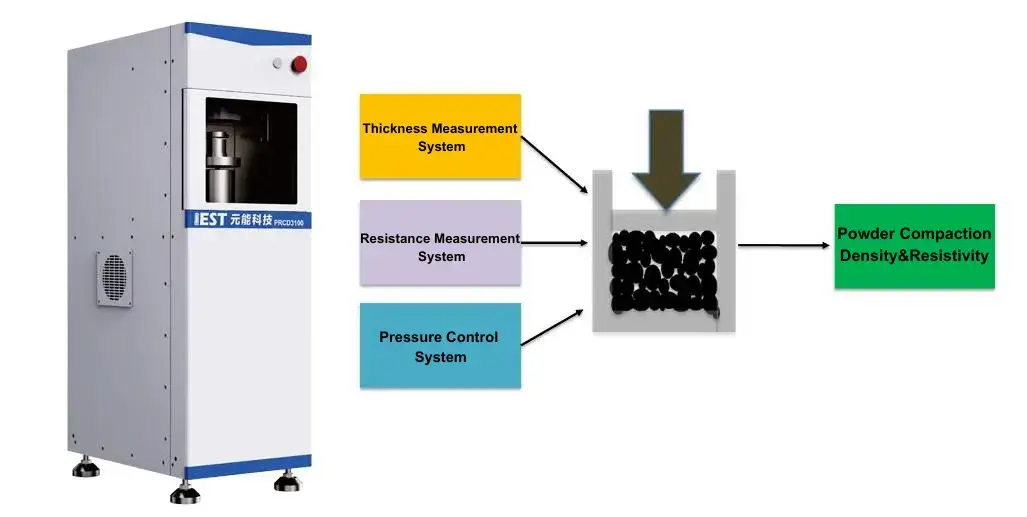

3.1 Incoming Material Inspection: Powder Resistivity & Compaction Density Measurement System(PRCD)

The cathode and anode powder will also be different during the manufacturing process due to the fluctuation of equipment and environment, which will further affect the capacity and internal resistance of the battery cells. IEST introduces Powder Resistivity & Compaction Density Measurement System(PRCD), which can be applied to incoming material inspection to monitor the resistance and compaction ability of the powder to ensure that the quality of the powder used in the production of the battery cell is at the same level, and thus improve the consistency of the finished battery cell.

Figure 5. IEST Powder Resistivity & Compaction Density Measurement System (PRCD3100)

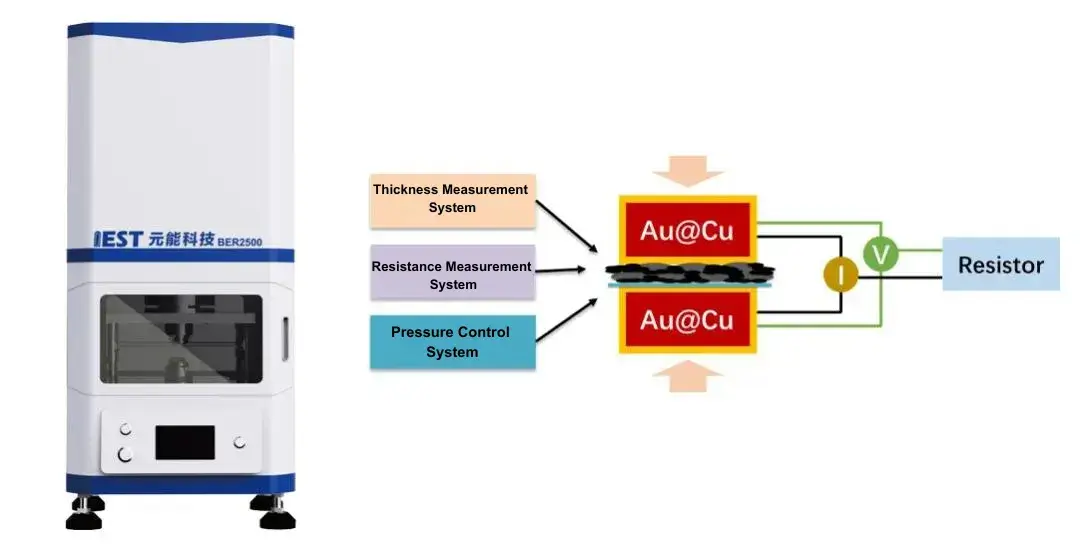

3.2 Manufacturing end of cell production: Electrode Sheet Resistance Tester(BER)

The pre-processes (mixing, coating, cold pressing, etc.) of core production directly determine the final performance of the cell, so it is necessary to set up a barrier before the end of the pre-processes. IEST self-developed Electrode Sheet Resistance Tester(BER) can measure the body resistance of the electrode as well as the corresponding thickness of the electrode, and monitor the stability and uniformity of the electrode production process through the distribution and fluctuation of the electrode’s resistance/thickness.

Figure 6. IEST Lithium Battery Electrode Sheet Resistance Tester(BER2500)

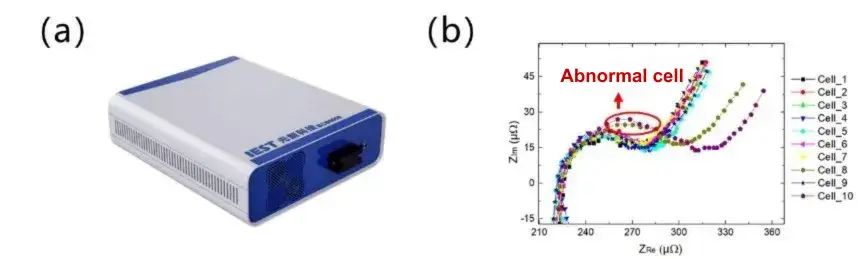

3.3 Battery cell shipment: Battery cell consistency screening instrument(BCS)

After battery cells are produced, they are usually screened for consistency before being assembled into battery packs. Generally, they are grouped by voltage, capacity and internal resistance. However, the above conventional test data basically monitors the electronic impedance of the battery cells, and there is almost no evaluation of the ionic impedance of the battery cells, which undoubtedly increases the probability of the appearance of short-board batteries in the battery pack. Ionic impedance is one of the important indicators of battery cell performance, which directly affects the efficiency, aging rate and safety of the battery cells. However, the current battery cell production line does not include ionic impedance as one of the shipment evaluation parameters. This is mainly because conventional EIS testers (electrochemical workstations) are expensive and have a long test cycle. IEST has innovatively developed an industrial-grade EIS rapid testing equipment –Battery Cell Consistency Screening Instrument(BCS), as shown in Figure 7-a. The equipment can perform EIS rapid testing on large quantities of battery cells, identify battery cell interface resistance, lithium ion diffusion capacity, etc.[3-4]. Battery cell manufacturers can finely group battery cell consistency based on EIS data to ensure high consistency of grouped batteries (Figure 7-b).

Figure 7. (a)Battery cell consistency screening instrument(BCS); (b) EIS distribution diagram of 10 340Ah batteries

4. Summary

The importance of cell consistency to battery packs is self-evident, as it is directly related to the performance, life and safety of battery packs. The control of cell consistency and the screening of cells into groups are both systematic projects, which require consideration of multiple dimensions such as cell design, production, quality control, cell grouping parameters and their specifications.

5. References

[1] Li Xiangzhe, Pan Hongbin. Discussion on battery cell consistency [J]. Battery Industry, 2005, 10 (5): 285-289.

[2] Wang Jiayuan, Sun Zechang, Wei Xuezhe, et al. Research on sorting methods of electric vehicle power batteries [J]. Power Technology, 2012, 36 (1): 94-98.

[3] W.X. Hu, Y.F. Peng, Y.M. Wei and Y. Yang, Application of Electrochemical Impedance Spectroscopy to Degradation and Aging Research of Lithium-Ion Batteries. The Journal of Physical Chemistry C[J], 127 (2023) 4465-4495.

[4] Zhang S S, Xu K, Jow T R. Electrochemical Impedance Study on the Low Temperature of Li-ion batteries[J]. Electrochimica Acta, 2004, 49 ( 7) : 1057-1061.

Subscribe Us

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.