-

iestinstrument

In-Situ Analysis of Expansion Behavior in Silicon-Carbon Composite Cells

1. Introduction

To enhance the energy density of lithium-ion batteries, advancements in both materials and manufacturing processes are essential. Silicon offers a theoretical specific capacity (~4,200 mAh·g⁻¹ as LixSi, x = 0–4.4) far higher than graphite (372 mAh·g⁻¹), so silicon-based anode electrodes are a leading route to higher cell energy density. However, silicon’s large volumetric change during lithiation/delithiation remains the primary obstacle to practical use. In commercial practice silicon is therefore blended with graphite to form silicon carbon cell; optimizing the Si:carbon ratio is critical because composition strongly influences swelling, cycle life and mechanical integrity.

Currently, most practical silicon-based anodes are composites blending silicon with carbon. Investigating how different mixing ratios affect cell expansion is vital for researchers to deepen their understanding and develop improved material designs, accelerating the adoption of silicon-based technologies. This study employs in-situ expansion analysis to compare the swelling behavior of two pouch cells fabricated with silicon-carbon composites of different specific capacities (450 mAh/g and 800 mAh/g).We synchronize electrochemical data with thickness traces to show how expansion correlates with specific lithiation events identified in the differential capacity curve (dQ/dV).

![]()

Figure 1. Overview of silicon-graphite composite electrodes 1

2. Experimental Setup and Methodology

2.1 Experimental Equipment

The in-situ expansion analysis was performed using an SWE2110 battery expansion analyzer (IEST), shown in Figure 2.

Figure 2. SWE2110 Equipment Appearance

2.2 Test Methods

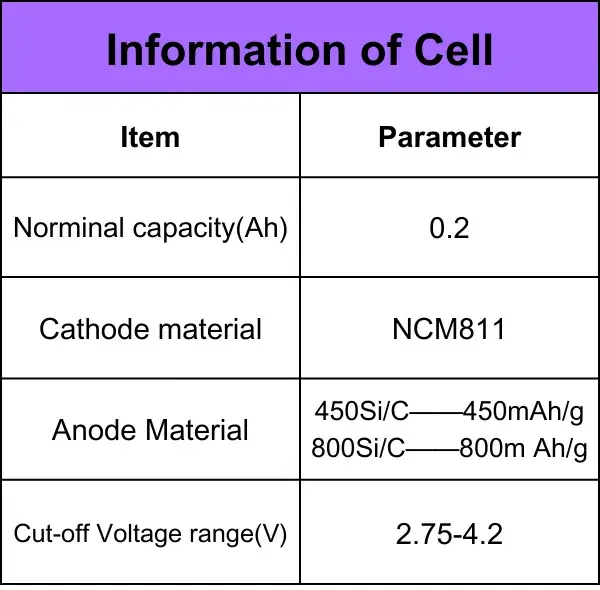

2.2.1 The cell information is shown in Table 1.

Table 1. information of cell

2.2.2 Charging and Discharge Process

The testing protocol consisted of: Rest at 25°C for 5 min; Charge at 0.5C constant current (CC) to 4.2V, followed by constant voltage (CV) charge until the current dropped to 0.025C; Rest for 5 min; Discharge at 1C CC to 2.75V.

2.3 Thickness Expansion Measurement

Each cell was placed into the corresponding channel of the SWE2110 system. Using the MISS software, parameters such as cell ID and sampling frequency were configured. The software automatically recorded real-time data including cell thickness, thickness change, temperature, current, voltage, and capacity.

3. In-Situ Analysis of Expansion in Silicon Carbon Cells

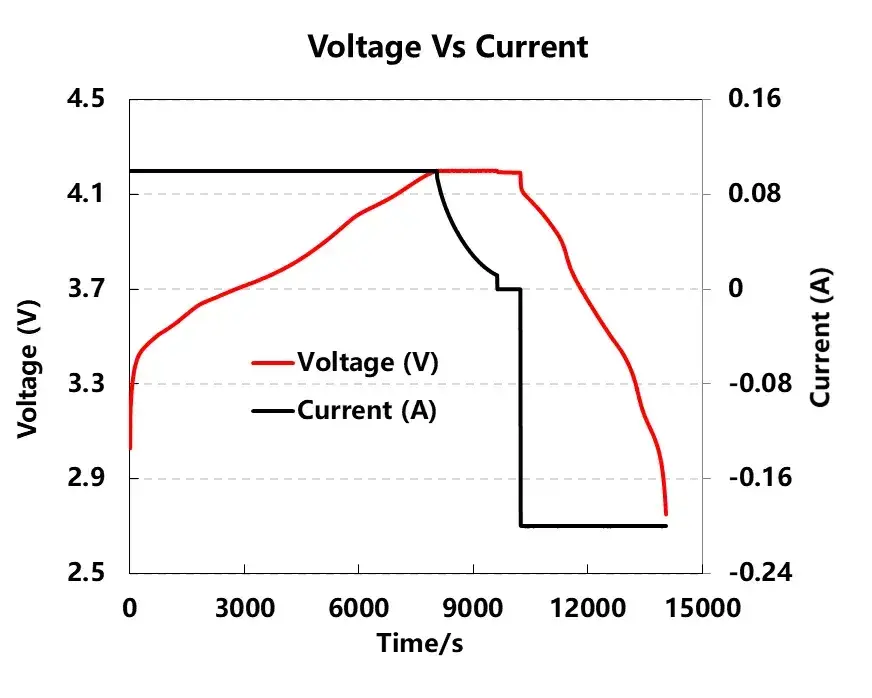

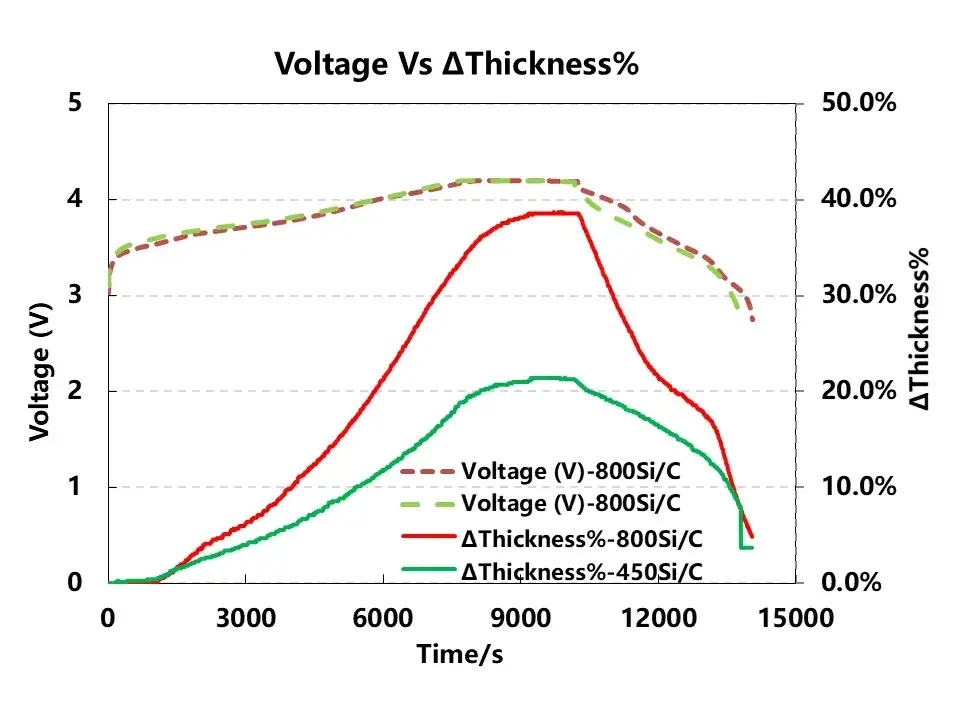

Figure 3 displays the charge-discharge voltage profiles alongside the corresponding thickness change curves. During cycling, cell thickness increases initially and then decreases. This behavior is directly linked to structural phase transformations within the silicon-carbon anode during lithiation/delithiation. As lithium ions migrate from the cathode and incorporate into the anode, they form LixSi alloys with silicon and LiCx intercalation compounds with graphite, both contributing to anode expansion. Further insight can be gained by correlating this data with differential capacity analysis.

Figure 3. Cell Voltage Profiles and Thickness Expansion Curves

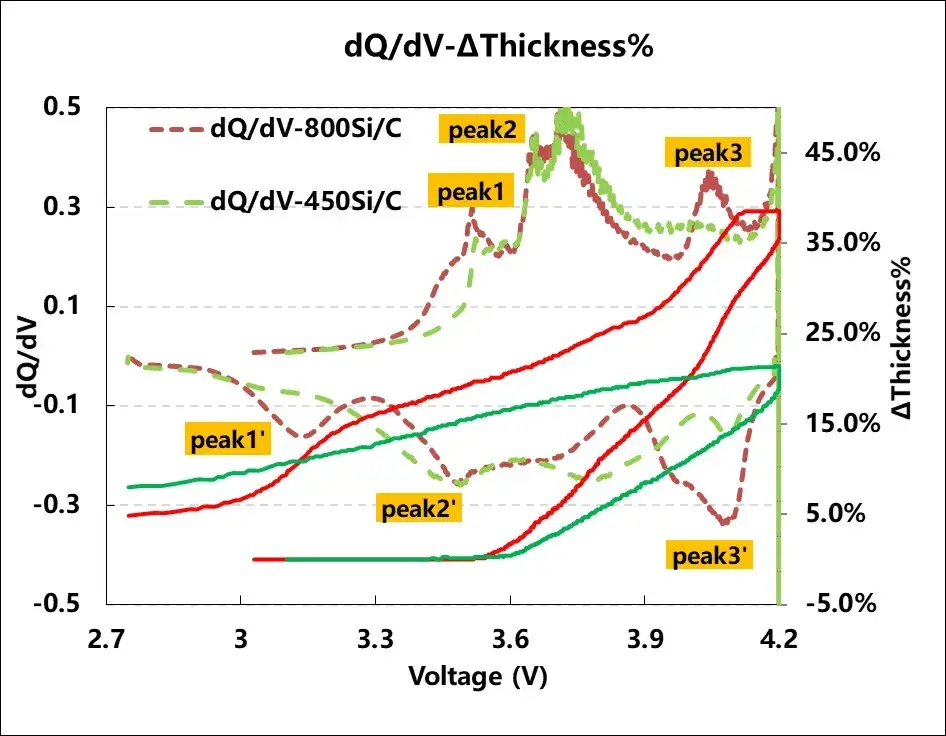

Figure 4 compares the differential capacity curves (dQ/dV) with the thickness change curves. The dQ/dV plots for both cells show three distinct peak pairs during charge and discharge. Notably, both cells used an NCM811 cathode paired with silicon-carbon anodes of different capacities. The intensities of peaks labeled peak2 and peak2′ are similar for both cells, indicating these features primarily correspond to phase transitions in the NCM811 cathode.

However, significant differences are observed in peak1 and peak3. The intensities for these peaks are markedly stronger in the 800 mAh/g silicon carbon cell compared to the 450 mAh/g cell. This indicates that the higher-capacity anode, containing more silicon, undergoes more extensive alloying reactions (LixSi formation). Consequently, this leads to greater thickness expansion during charging, as clearly reflected in the expansion curve.

Figure 4. Differential Capacity Curves vs. Thickness Expansion

4. Interpretation and Design Implications

Our results demonstrate a clear, practical linkage:

-

Higher Si fraction → larger expansion thickness. The 800 mAh·g⁻¹ silicon carbon cell expands more during charging because more Si participates in LixSi formation.

-

dQ/dV features identify the expansion drivers. Peaks that scale with Si content mark voltage windows where silicon alloying dominates and where most of the thickness increase occurs.

-

Design levers. To limit macroscopic swelling while retaining energy benefits, developers should consider: (a) limiting Si content or distributing Si as nano-sized domains, (b) engineering porosity to accommodate expansion internally, and (c) applying surface modifications or binders that mitigate fracture and SEI growth. These measures reduce irreversible thickness gain and improve cycle life.

Additionally, when reporting expansion thickness one must explicitly state test boundary conditions (pressure, cell stack fixture, sampling frequency) because absolute thickness numbers depend strongly on the mechanical test setup.

5. Summary

In this paper, an in-situ swelling analyzer (SWE Series) is used to analyze the thickness expansion of silicon carbon cells with different gram capacity, and it is found that with the increase of the gram capacity of silicon carbon anode, the expansion thickness of the silicon carbon cells increases, which is mainly related to the expansion of the silicon structure during the formation of silicon carbon alloys, and the R&D personnel should rationally control the ratio of silicon to carbon and modify the structure of silicon-based materials to inhibit the expansion of the structure, so as to ensure that the battery has good cycling stability.

6. References

[1] Peng Li, Hun Kim, Seung-Taek Myung, Yang-Kook Sun Diverting Exploration of Silicon Anode into Practical Way: A Review Focused on Silicon-Graphite Composite for Lithium Ion Batteries .Energy Storage Materials , 35(2021) 550-576.

[2] Andressa Y.R.Prado, Marco-Tulio F.Rodrigues, Stephen E.Trask, Leon Shaw and Daniel P.Abraham.Electrochemical Dilatometry of Si-bearing Electrodes: Dimensional Changes and Experiment Design, J.Electrochem.Soc.167 160551.

[3] Sujong Chae, Minseong Ko,Kyungho Kim, Kihong Ahn and Jaephil Cho.Confronting Issues of the Practical Implementation of Si Anode in High-Energy Lithium-Ion Batteries .Joule 1, 47–60, September 6, 2017.

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.