-

iestinstrument

Analysis of Swelling Thickness and Swelling Force in LiFePO4 Cells

1. Abstract

LiFePO4 cells are widely used in high-power and high-safety applications. As single-cell capacities grow, so does their dimensional response during cycling. This study uses an IEST In-situ swelling analyzer (SWE2110) to compare thickness swelling and swelling force of large-format LFP pouch cells under charge/discharge. We demonstrate that (1) thickness and force traces follow the same trend during cycling, (2) the two measurement modes respond consistently in the 25%–70% SOC phase-change window, and (3) applied external pressure affects the measured maximum thickness. These findings clarify how mechanical boundary conditions influence observed swelling and provide practical guidance for interpreting cell dimensional data in R&D and qualification workflows.

2. Introduction

LiFePO4 cells are often used as power trams or energy storage devices with high power or high security requirements because of their high security and stability. As the capacity of a single cell rises, its expansion during charging and discharging increases. Usually, to analyze the expansion behavior of a cell, the cell expansion thickness or expansion force parameter is used, but the test modes of these two are different, and we have previously analyzed the differences between these two aspects of lithium cobalt oxide system cells1. For more information, please refer to the article, “In-situ Expansion Analysis of Pouch Cell: constant Pressure Vs Constant Gap”.

Figure 1. In-situ XRD characterization of lattice changes in different materials 1

3. Experimental Equipment and Test Methods

3.1 Equipment

The In-situ Swelling Analyzer, model SWE2110 (IEST), was used for this investigation. The equipment is shown in Figure 2. The system supports two measurement modes:

-

Constant-pressure mode: the instrument holds a set compressive load and records thickness changes of the cell.

-

Constant-gap mode: the instrument holds a fixed displacement (gap) and records the force that the cell exerts as it swells.

Figure 2. Appearance of SWE2110 Equipment

3.2 Testing Procedure

-

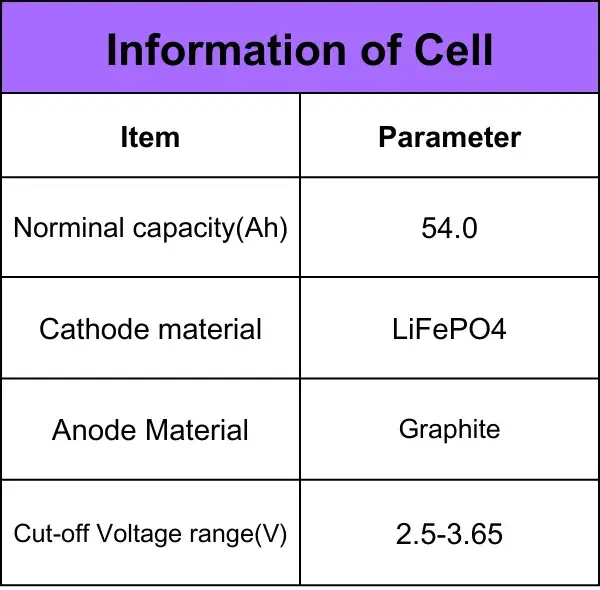

Cell Information: The test cell specifications are summarized in Table 1.

-

Charge-Discharge Protocol: The test was conducted at 25°C using the following sequence: Rest 5 min; 1C constant current (CC) charge to 3.65 V, followed by constant voltage (CV) charge until the current dropped to 0.025C; Rest 5 min; 1C constant current (DC) discharge to 2.5 V.

-

Swelling Measurement: The cell was placed in the corresponding channel of the SWE2110. The MISS software was used to set the cell ID and sampling frequency, automatically recording data for cell thickness, thickness variation, temperature, current, voltage, and capacity.

Table 1. LiFePO4 Cells Information

4. In-situ Analysis of Swelling Behavior of LiFePO4 Cell

4.1 Equipment Stability Verification

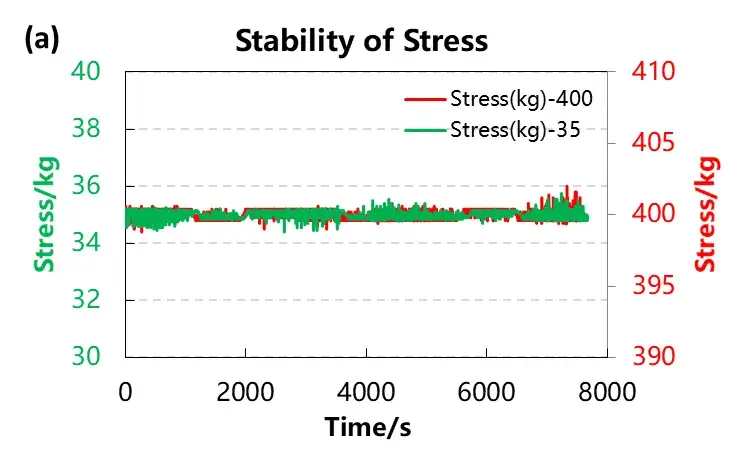

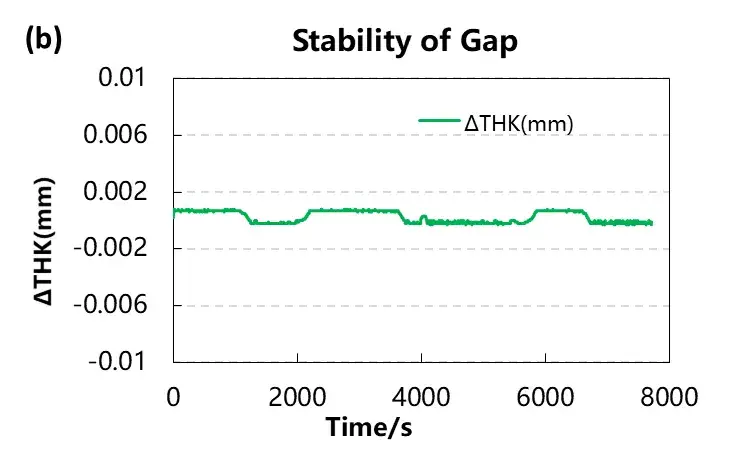

In this paper, two different test modes of the In-situ swelling analyzer(SWE2110) are used to test the variation of the expansion thickness of the LiFePO4 cell under constant pressure conditions and the variation of the expansion force of the LiFePO4 cell under constant gap conditions. The verification about the control stability of the equipment is shown in Figure 3. When the constant pressure is set to 35 kg and 400 kg, respectively, the fluctuation of the pressure during the whole testing process is ±1 kg, and when the constant gap is set, the variation of the gap during the whole testing process is within ±1 µm, which indicates that the control accuracy and stability of the equipment itself is very good.

Figure 3. (a) Control stability curves for constant force and constant gap modes

Figure 3. (b) Stability curve of gap under constant pressure and constant gap

4.2 Swelling Thickness Curve Under Two Different Pressure Conditions

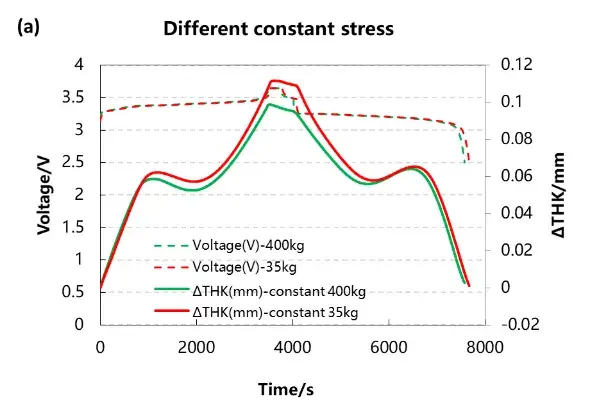

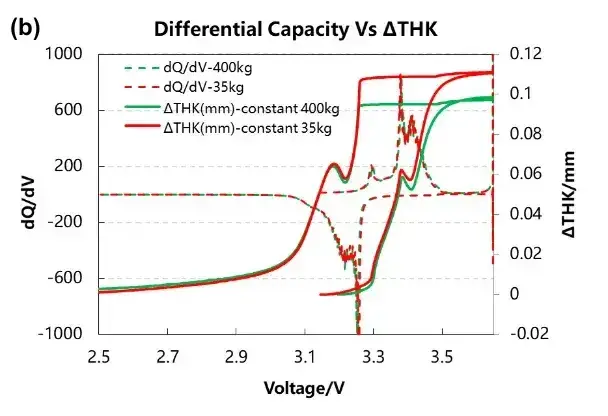

Figure 4 shows the cell’s charge-discharge curves, differential capacity (dQ/dV) curve, and thickness expansion curve. A notable observation for this LFP/Graphite system is a slight decrease in thickness during the charging process. This thickness decrease coincides with the second lithium intercalation stage of graphite. A plausible explanation is that lithium extraction from the olivine-structured LiFePO₄ cathode causes a contraction on the cathode side, which partially offsets the expansion from lithium intercalation into the graphite anode. This results in a net decrease in overall cell thickness, a phenomenon that could be further investigated using techniques like in-situ XRD. Furthermore, the maximum swelling thickness observed during the cycle increased when a higher constant pressure was applied to the cell.

Figure 4. Charge-discharge curves, differential capacity curve, and thickness swelling curves

4.3 Comparative Analysis of Swelling Force vs. Swelling Thickness

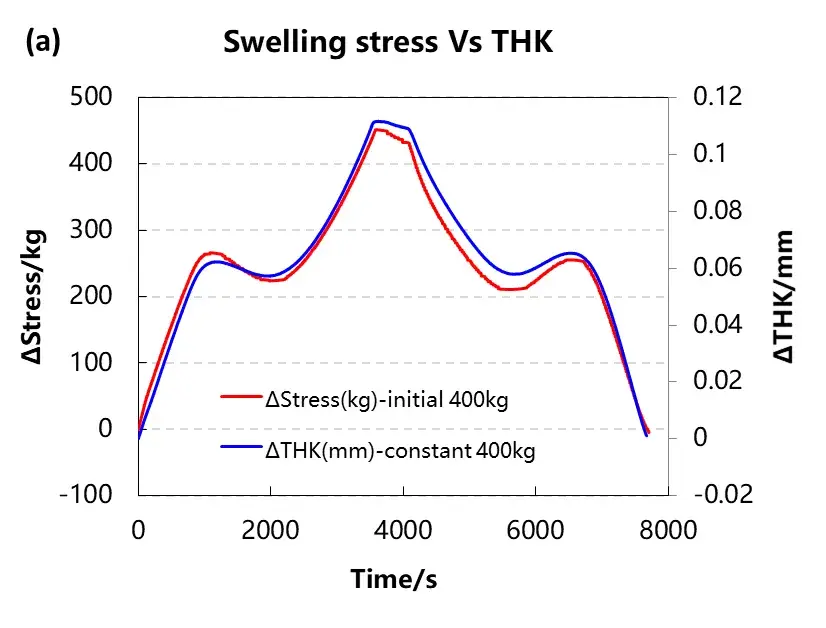

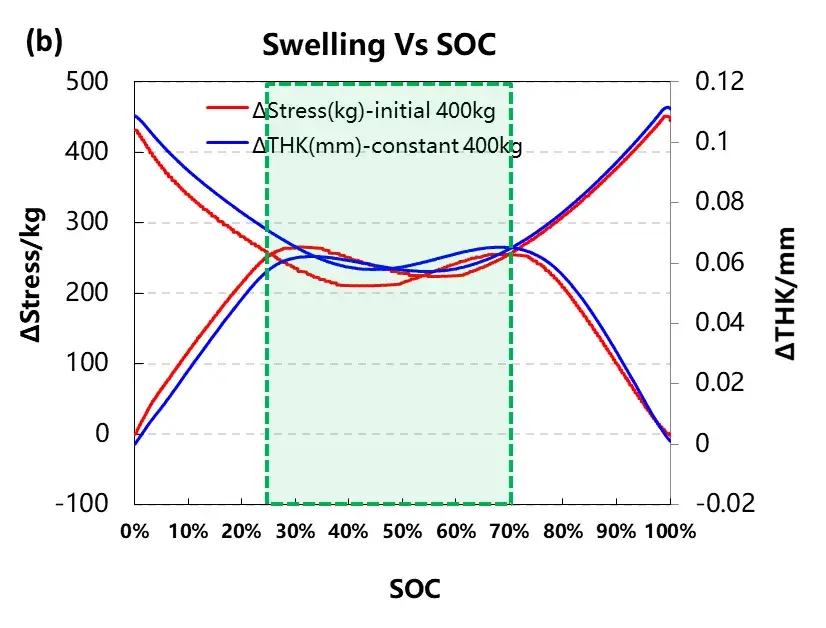

Figure 5 presents a direct comparison of the swelling force and swelling thickness curves obtained from the two different testing modes. The general swelling trends for both force and thickness are consistent throughout the charge-discharge cycle. Notably, within the 25% to 70% State of Charge (SOC) range—a key phase transition region for lithium (de)intercalation and an interval with relatively low cell impedance—the thickness decreases during charging and increases during discharging. This complex behavior, involving opposing expansion and contraction mechanisms from the anode and cathode, necessitates further investigation using complementary characterization techniques to fully deconvolute the individual electrode contributions.

Figure 5. Comparison of swelling force and swelling thickness curves under two different test modes

5. Summary

In this paper, an in-situ swelling analyzer (SWE) is used to perform a comparative analysis of swelling thickness and swelling force on a high-capacity LiFePO4 cell. The results demonstrate that the general swelling trends for force and thickness are consistent during cycling. A distinct thickness decrease during charging and increase during discharging was observed within the 25%-70% SOC range. Further analysis, combining this method with other characterization techniques, is required to fully elucidate the intricate expansion/contraction mechanisms of the positive and negative electrodes in this system.

6. References

[1] Xiujuan Wei, Xuanpeng Wang, Qinyou An, Chunhua Han, and Liqiang Mai. Operando X-ray Diffraction Characterization for Understanding the Intrinsic Electrochemical Mechanism in Rechargeable Battery Materials Small Methods 2017, 1700083.

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.