-

iestinstrument

Stabilizing Lithium Metal Anodes by Leveraging Inherent Stress Variations via an Adaptive Piezoelectric Effect

1. Article Abstract

Volume change of lithium metal anodes (LMAs) during plating/stripping produces evolving mechanical stress that drives SEI fracture, particle detachment and dendrite growth. This study proposes and validates an alternative approach: convert the unavoidable stress variations during cycling into a beneficial, adaptive piezoelectric effect that generates a local internal electric field. That field guides Li⁺ migration toward regions with deficient deposition, thereby homogenizing local current density and relieving stress concentrations. Finite-element simulations coupled with in-situ stress mapping and experiments using piezoelectric polymer coatings (PLA and PVDF) demonstrate the mechanism and its practical benefit: PLA-protected LMAs show dramatically improved morphology and electrochemical stability (symmetric-cell lifetimes exceeding 6000 h at 10 mA·cm⁻² in the reported tests).

2. Concept — How an Adaptive Piezoelectric Effect Stabilizes a Lithium Metal Anode

Rather than opposing stress, the method leverages it. A high-sensitivity piezoelectric polymer layer (applied directly to the Li surface) converts local mechanical stress — which increases where Li deposition is excessive — into a local electric potential. That built-in field accelerates Li⁺ migration away from overloaded regions and toward less-deposited areas, flattening concentration gradients and evening out local current density. As a result, regions that would otherwise develop dendritic protrusions experience reduced polarization and lower probability of SEI rupture. Finite-element modeling (FEM) shows this electromechanical coupling decouples and stabilizes the electrochemical–mechanical evolution during charge.

3. In Situ Stress Monitoring & Finite Element Analysis

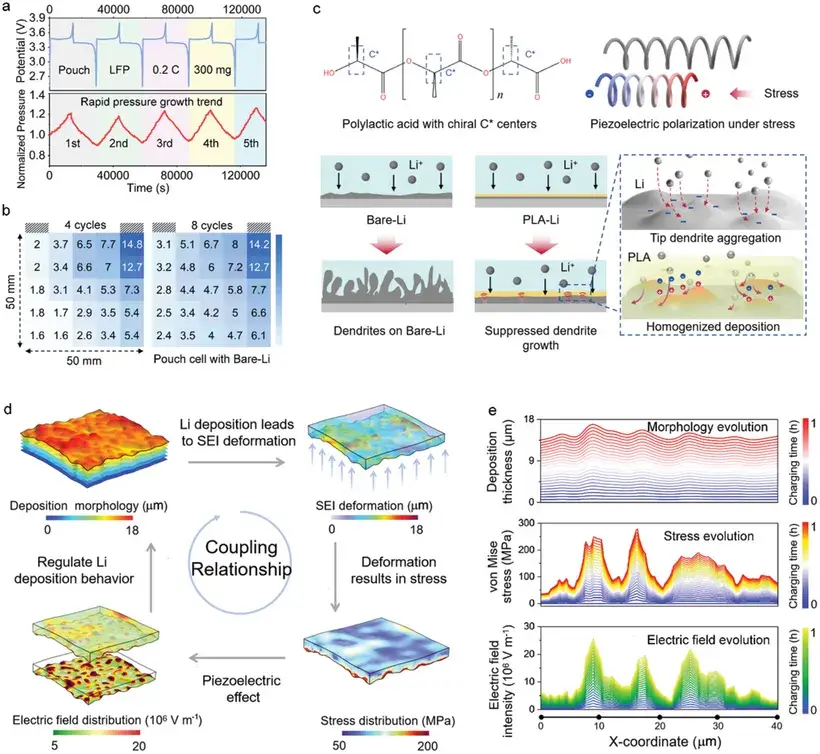

This paper combines sensing technology with finite element simulation to study the stress evolution of lithium metal anodes during battery cycling, and on-site monitoring of stress growth and distribution during battery cycling.

Figure 1. In-Situ Cell Swelling Analyzer(SWE2110)& Battery Pressure Mapping System(BPD1000)

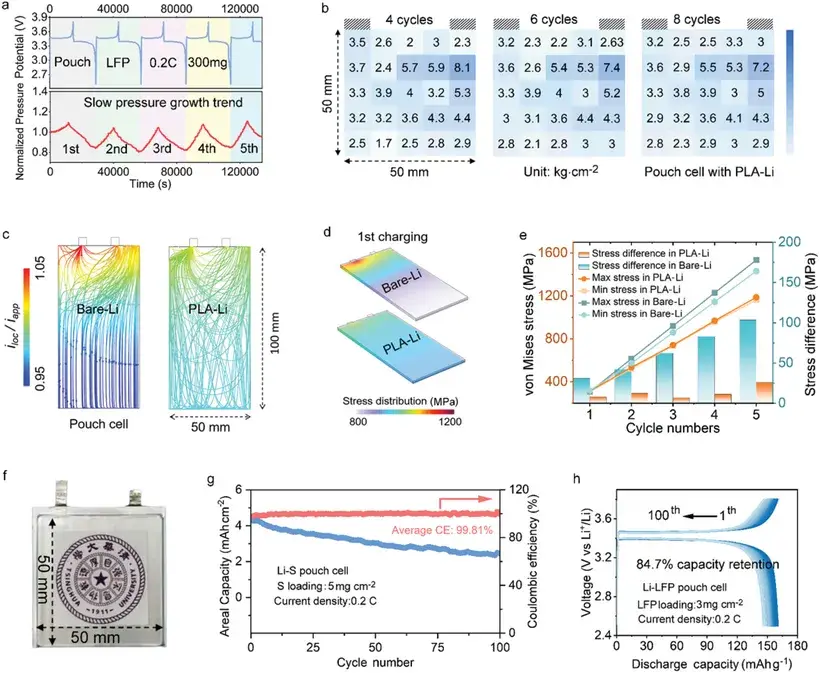

The authors combined sensor-based monitoring with finite element simulation (FES) to investigate stress evolution in lithium metal anodes during cycling. An in-situ expansion analysis system (SWE2110) and a Battery Pressure Mapping Testing system (BPD1000) were employed to track real-time stress changes in a 50 × 50 mm² pouch cell using a Bare-Li anode and a low-volume-change LFP cathode.

Results revealed pronounced stress fluctuations and uneven stress distribution, with notable stress concentration near tab regions. These localized stress hotspots accumulate over cycles, ultimately accelerating cell failure.

The authors propose a method to convert inherent stress variations into an internal electric field through adaptive piezoelectric effect. Utilizing finite element simulation, they elucidate in detail the modulation and evolution mechanism of the electrochemical-mechanical-field coupling relationship by the piezoelectric effect during the charging process of lithium metal anode.

During charging, the deposition of lithium ions leads to variations in the anode thickness. Additionally, the internal stress within the piezoelectric film and the magnitude of the generated electric field adaptively change with the deposition thickness during charging. It is noteworthy that areas with more lithium deposition on the anode surface spontaneously generate higher stress and adjust the electric field. This phenomenon demonstrates the adaptability of the piezoelectric film to automatically adjust the internal electric field intensity based on the amount of lithium deposition at different charge states (SOC) and different positions on the anode surface.

Figure 2. Stress related issues visualization and piezoelectric effect-harnessing stress variation

4. Material Selection: PLA vs. PVDF

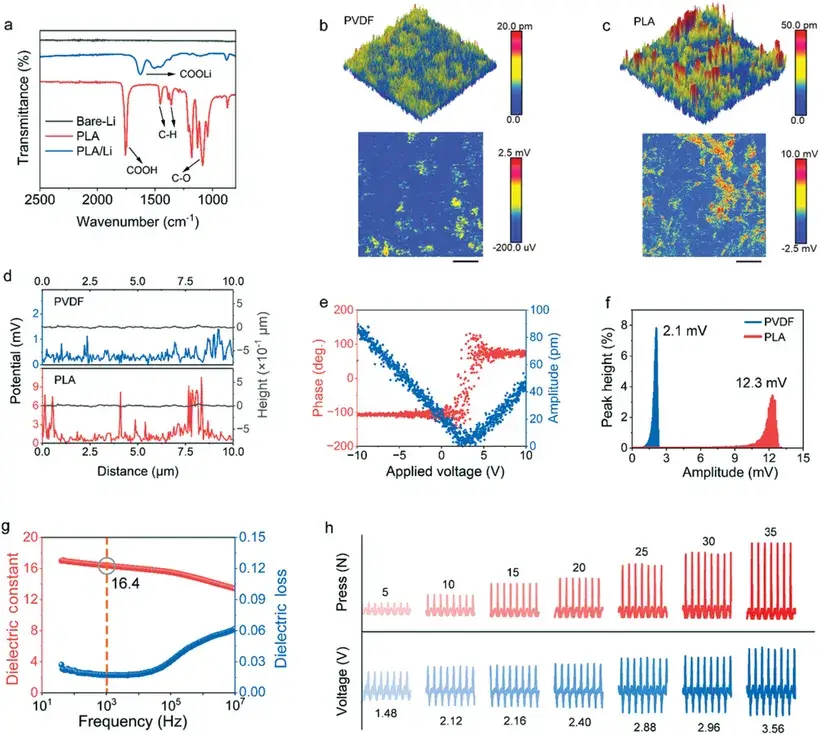

To validate the impact of piezoelectric effect and multiphysical field response, the authors prepared two polymer materials, PLA and PVDF, with piezoelectric properties for comparison. Piezoresponse force microscopy (PFM) characterization showed that PLA exhibits stronger and more uniform piezoelectric activity, with displacement amplitudes of 0–85 pm, significantly higher than PVDF (0–20 pm).

Voltage output tests under applied forces (5–35 N) confirmed that PLA generates a measurable built-in electric field even under minimal stress (5 N), demonstrating high pressure sensitivity and rapid response.

Figure 3. Piezoelectric properties of PLA and its generated built in electric field a Fourier

5. Mechanism of Homogeneous Li Deposition

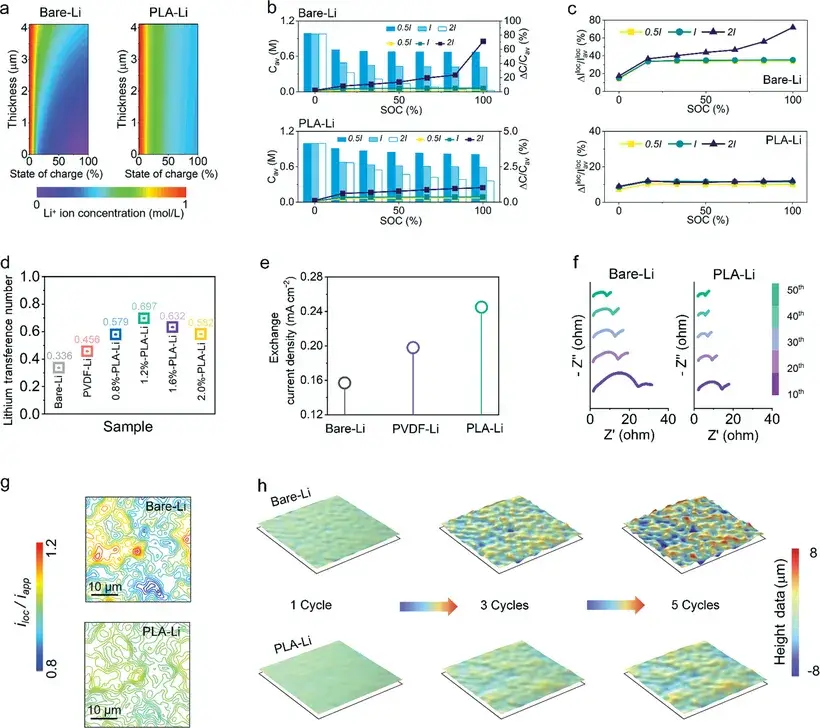

The inherent electric field exhibits a unique electromechanical coupling effect, and the authors validate its protective mechanism on LMA through a combination of theoretical simulation and experimental results. The authors employed finite element simulation to investigate the influence of the internal electric field of piezoelectric films on the electrochemical behavior of Li+ ions. Compared to Bare-Li, the Li+ ion concentration gradient within the PLA-Li film was significantly reduced, thereby weakening concentration polarization and markedly decreasing the likelihood of dendrite formation.

In addition to the concentration gradient of Li+ ions perpendicular to the anode surface typically studied, simulations of the concentration gradient within the anode surface during charging were conducted to explore the relationship between local current density and Li+ ion concentration distribution in depth. Compared to Bare-Li, there were notable differences in the Li+ ion concentration distribution on the anode surface during charging, leading to significant unevenness in the local current density distribution as depicted in the figure.

In contrast, the electric field generated internally by PLA-Li ensured that the concentration difference of Li+ ions within the anode surface remained at an extremely low level, achieving uniform distribution of local current density. These results indicate that the inherent electric field not only alleviates the concentration gradient of Li+ ions in the vertical direction but also reduces the difference in lithium-ion concentration within the plane, thereby synergistically promoting uniform distribution of local current density.

Electrochemical impedance spectroscopy (EIS) further revealed that PLA-Li maintains lower SEI resistance (R_SEI) over cycles. Morphology analysis after cycling showed that PLA-Li retains a smooth surface, whereas Bare-Li develops rough, dendritic structures that lead to stress concentration, SEI fracture, and capacity fade.

The deterioration of Bare-Li morphology led to internal stress concentration in the SEI, making it prone to failure and crack formation, resulting in increased electrolyte consumption, decreased Coulombic efficiency, accumulation of “dead” lithium, and premature battery failure. Both simulation results and experimental evidence confirm the critical role of PLA in facilitating uniform deposition of Li+ ions, thereby reducing dendrite formation and improving the lifespan and safety of lithium batteries.

Figure 4. Regulating mechanism of the built in electric field a Li-ion concentration evolution

6. Electrochemical Performance Validation

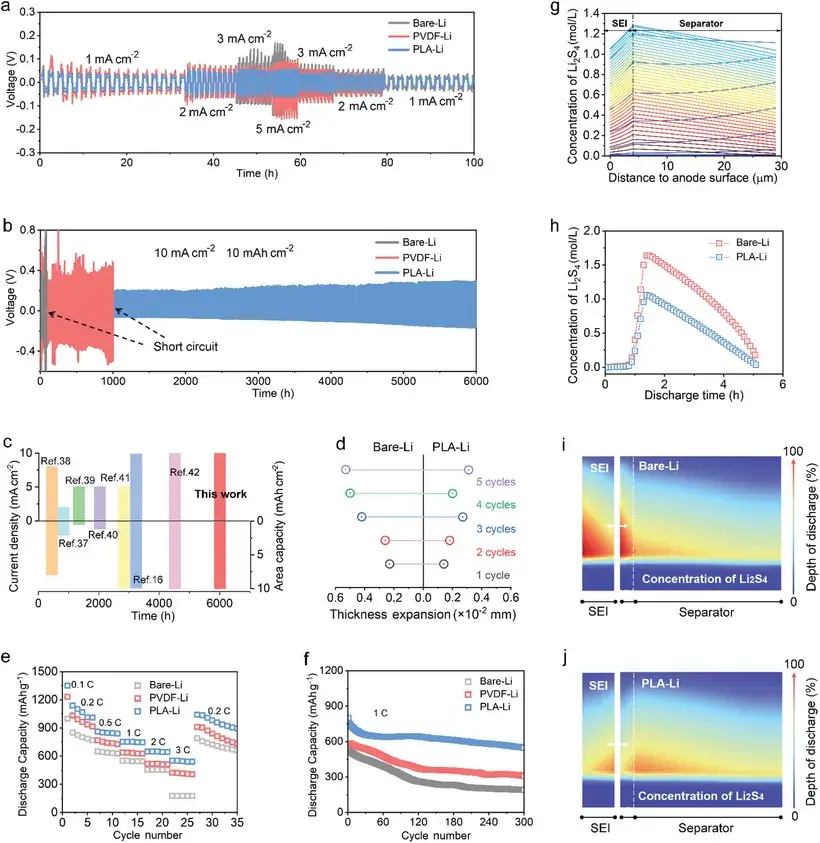

To further confirm the influence of the inherent electric field on stress modulation, we assembled lithium metal anodes into symmetric cells and evaluated their electrochemical performance. The interface stability of lithium metal anodes with Bare-Li, PVDF-Li, and PLA-Li was studied using constant current cycling of symmetric cells. The rate performance of symmetric cells was tested at current densities ranging from 1 to 5 mA/cm². As the applied current density increased, Bare-Li anodes exhibited significant voltage fluctuations, indicating the formation of severe side reactions and unstable electrode interfaces.

In contrast, the cycling stability of PLA-Li anodes was greatly improved, with negligible voltage changes. Meanwhile, the polarization voltage of PLA-Li cells was significantly lower than that of PVDF-Li cells. This finding highlights the adaptability of the internal inherent electric field of PLA, which can effectively modulate lithium deposition in response to dynamic changes in current density. It can be observed that batteries using PLA-Li anodes exhibit excellent cycling stability, exceeding 6000 hours, with polarization voltage as low as 300 mV. In comparison, the enhancement performance of PVDF coating on lithium metal anodes is limited to within 1000 hours of cycling lifespan. It can be inferred that the conversion of stress into electric field effectively enhances the electrochemical performance of lithium metal anodes.

Pairs of metallic lithium coated with various protective layers were paired with LFP and lithium-sulfur (Li-S) batteries to test their applicability and suitability. To study the influence of the inherent electric field on Li+ ion transport and deposition, the assembled LFP batteries were evaluated for thickness variation during cycling using an in-situ battery expansion analyzer. Due to the significant stability of the LFP electrode, the change in the entire battery thickness was attributed to deposition and stripping on the lithium metal side.

During the first five cycles of charge and discharge, Bare-Li exhibited a faster rate of thickness expansion, with an expansion of up to 0.53 × 10−2 mm after five cycles, while PLA-Li showed a slower rate of thickness expansion, at 0.31 × 10−2 mm. This reduction in volume expansion is attributed to the decrease in lithium dendrite and “dead” lithium layer thickness. Finite element simulations further verified the effective application of the piezoelectric effect in lithium-sulfur batteries. When negatively charged polysulfides shuttle to the piezoelectric film, they are repelled by the electric field force, thereby hindering their corrosion of the anode. Compared to Bare-Li, PLA-Li significantly reduced the shuttle effect of polysulfides, which is beneficial for the cycling stability of the anode and improves the utilization of the sulfur cathode.

Figure 5. Electrochemical performance in coin cells.

7. Practical Demonstration in Pouch Cells

To demonstrate the practical application of PLA, which would experience more pronounced stress variations in real-world scenarios, the authors assembled a PLA-Li/LFP pouch cell with the same electrode dimensions and active material loading as the Bare-Li/LFP pouch cell. The stress changes and distribution in the protected pouch cell were studied, and a comparative analysis was conducted on the influence of the PLA protective layer on the electrochemical performance of the battery.

Compared to the Bare-Li/LFP pouch cell, the growth of expansion force per cycle is relatively slow in PLA-Li. The lithium deposition on the PLA-Li anode is very uniform, and dendritic growth behavior is suppressed. This can be attributed to the inherent electric field generated by the piezoelectric effect of the PLA layer, guiding the formation of a uniform pattern of local current density distribution.

Further explanation of the superiority of the piezoelectric effect in practical pouch cells was provided through finite element simulation. Unlike prismatic cells, pouch cells accommodate higher cathode active material loading, higher current densities, and correspondingly larger volume changes in the lithium metal anode. After coating the anode with a PLA film, the higher stress generated at locally deposited sites can be converted into an in-plane electric field within the anode. Therefore, the uneven distribution of local current density and deposition sites caused by variations in pouch cell size and manufacturing processes is eliminated.

This helps to achieve uniform stress distribution throughout the entire cell, avoiding the pronounced stress concentrations observed in Bare-Li. Meanwhile, during cycling, the accumulation of “dead” lithium not only gradually exacerbates the pressure throughout the entire cell but also amplifies the stress differences within the Bare-Li anode due to preferential deposition of Li+ ions. Local stress concentrations further affect subsequent Li+ ion deposition behavior, reinforcing the unevenness of local current density distribution and achieving positive feedback regulation.

This positive feedback regulation exacerbates stress-related issues, accelerating the occurrence of problems such as SEI fracture, electrode cracking, and localized dendrite growth. In contrast, PLA-Li, due to the unique protective mechanism of the piezoelectric effect, maintains a lower level of stress difference within the cell during cycling, indicating uniform lithium deposition on the anode side, ensuring the cycling stability of PLA-Li in practical pouch cells.

To validate the practical application effectiveness of the inherent electric field, the authors assembled pouch cells sized 50 × 50 mm² for Li-S and LFP batteries and observed their cycling stability. When LFP was used as the positive electrode, the capacity retention rate reached 84.7% after 100 cycles, extending the cycle life of the lithium metal battery. Moreover, the protected pouch cells successfully charged a mobile phone after cycling. In practical pouch cells, PLA improved stability and extended long-cycle life, indicating the feasibility of obtaining a stable lithium metal anode through leveraging inevitable stress changes in the adaptive piezoelectric effect.

Figure 6. Application of PLA in practical application scenarios a In-situ evolution of internal

8. Summary

The authors present a stress-adaptive strategy for stabilizing lithium metal anodes by converting cyclic mechanical stress into a tunable built-in electric field via the piezoelectric effect. This field enhances Li-ion transport, ensures uniform deposition, suppresses dendrites, and mitigates stress concentration. Through finite element modeling, material characterization, and multi-scale validation from coin to pouch cells, we demonstrate that a high-sensitivity piezoelectric polymer (PLA) can extend cycle life beyond 6000 hours and improve safety in various battery systems. This work provides a new pathway to decouple electrochemical-mechanical interactions in battery electrodes and offers a scalable approach toward durable lithium metal batteries.

9. Original Article

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.

-Battery-Pressure-Distribution-Measure-System(BPD1000).webp)