-

iestinstrument

Analysis of Model Coin Cell Performance: Charge/Discharge Efficiency & Thickness Expansion

1. Abstract

Silicon-containing anodes exhibit substantially larger volume changes during (de-)lithiation than conventional graphite. As a result, rapid and reliable screening methods for thickness expansion and electrochemical performance are essential for material development. This report compares the model coin cell against (a) a commercial 2032 steel-cased coin cell and (b) a single-layer pouch cell, focusing on reproducibility and how well the model coin cell predicts full-cell behavior for lithium-ion battery charge/discharge efficiency assessments.

2. Introduction

Lithium-ion batteries have become ubiquitous in modern life, powering devices from smartphones to electric vehicles and home energy storage systems. Consequently, comprehensive performance evaluation of these batteries is critically important. During charge and discharge cycles, lithium batteries undergo expansion and contraction, making expansion parameters essential considerations in battery module design. The emergence of next-generation high-capacity anode materials—such as silicon-based anodes or lithium metal anodes—has further intensified focus on expansion assessment, as these materials exhibit significantly greater structural expansion than conventional graphite anodes [1,2].

Traditional expansion evaluation methods require researchers to fabricate electrodes into single or multi-layer finished cells, leading to extended testing cycles, low assessment efficiency, and substantial resource consumption that severely hinders new material development. IEST has innovatively addressed this challenge by utilizing model coin cells to evaluate electrode expansion behavior, dramatically shortening assessment timelines while saving significant manpower and material resources for universities and enterprises. For this model button cell, users primarily concern themselves with two key questions: whether its cycling efficiency is comparable to conventional stainless steel coin cells, and how its measured thickness expansion compares with data from finished cells. This article presents comparative data addressing both aspects to facilitate user evaluation and selection.

2. Experimental Setup: Equipment and Testing Parameters

2.1 Testing Equipment

This study employed IEST’s model coin cells alongside the Silicon-based Anode Expansion In-situ Rapid Screening System (RSS1400) for conducting charge-discharge tests and expansion measurements on both coin cells and pouch cells.

Figure 1. Silicon-based Anode Expansion In-situ Rapid Screening System (RSS1400)

2.2 Charge and Discharge Test Conditions

-

Assembled NCM//Li coin half-cells and NCM//SiC coin full-cells using IEST’s model button cells, conducting 3 cycles at 0.1C rate for subsequent comparison with commercial stainless steel coin cells and single-layer stacked pouch cells

-

Assembled NCM//Li coin half-cells using commercial 2032 stainless steel coin cells, conducting 3 cycles at 0.1C rate

-

Assembled single-layer stacked NCM//SiC pouch cells, conducting 3 cycles at 0.1C rate

2.3 Cell Expansion Test Conditions

Placed NCM//SiC model coin full-cells and single-layer stacked pouch cells in the RSS1400 system, applying 5 kg initial preload force while monitoring real-time thickness expansion changes during 0.1C charge-discharge cycles.

3. Results Analysis: Efficiency and Expansion Comparison

3.1 Charge/Discharge Efficiency: Model Coin Cell vs. Commercial 2032 Cell

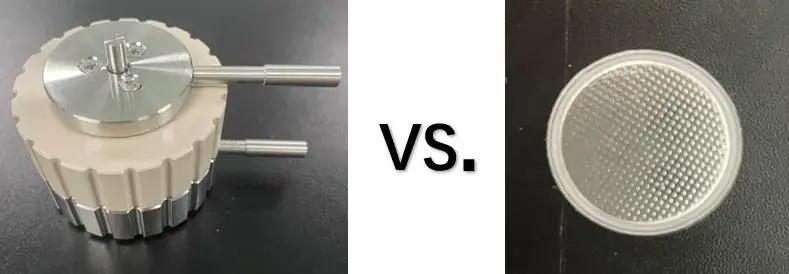

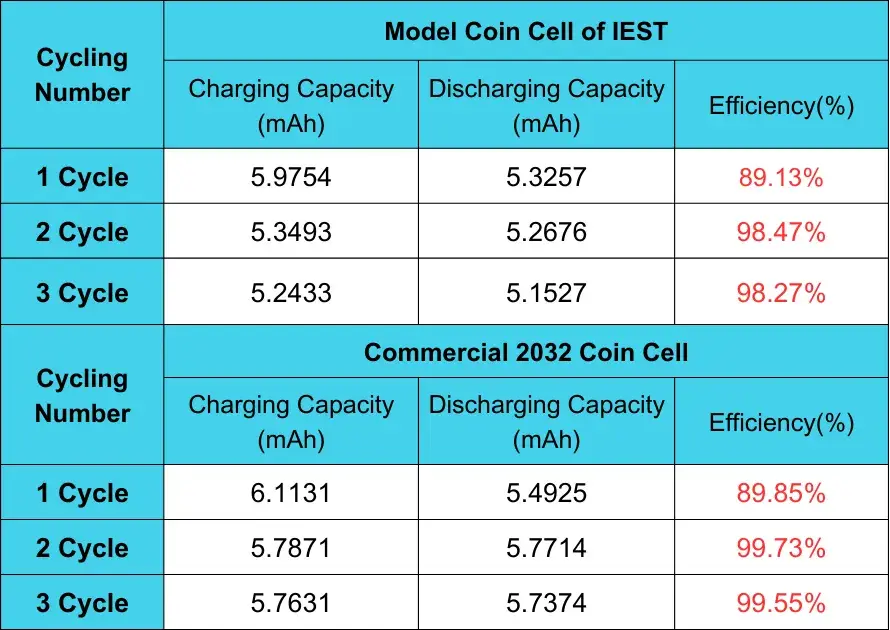

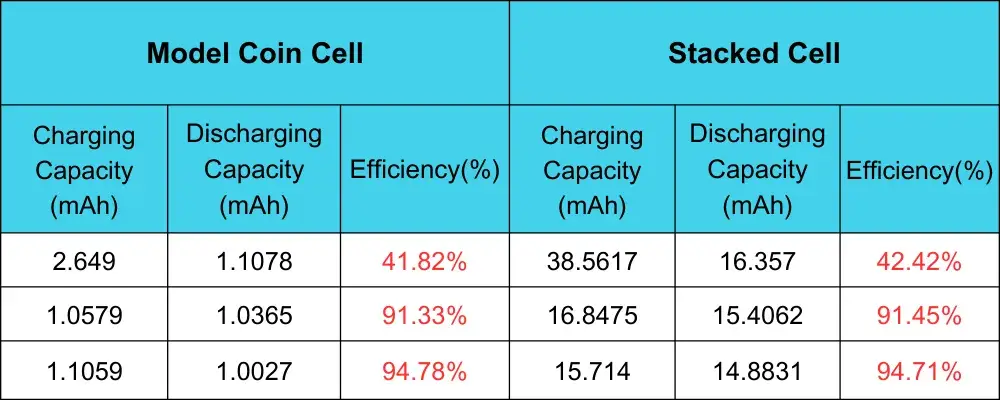

Figure 2 shows IEST’s model coin cell (left) and the commercial 2032 stainless steel coin cell (right). We assembled coin half-cells using NCM cathodes of identical dimensions and composition, comparing their coulombic efficiency at 0.1C charge-discharge rate (Table 1):

-

The coin cell exhibited a first-cycle Coulombic efficiency of ~89.13%, which is ~0.718% lower than the commercial 2032 steel-cased coin cell (i.e., the difference between the two first-cycle values was ~0.718%).

-

Differences in the second and third cycles were also small; the maximum cycle-to-cycle efficiency gap between model button cell and 2032 coin cell did not exceed ~1.28%.

-

Statistical reproducibility (3-cycle COV of Coulombic efficiency) for the two formats showed a maximum COV of 0.65%, indicating good repeatability and reproducibility (COV defined as standard deviation / mean × 100).

These results demonstrate that IEST‘s model button cells deliver comparable cycling performance to commercial stainless steel coin cells.

Figure 2. Left: IEST’s model coin cell; Right: Commercial 2032 stainless steel coin cell

Table 1. Cycling efficiency comparison between NCM//Li model coin half-cells and commercial coin cells

3.2 Thickness Expansion: Model Coin Cell vs. Single-Layer Pouch Cell

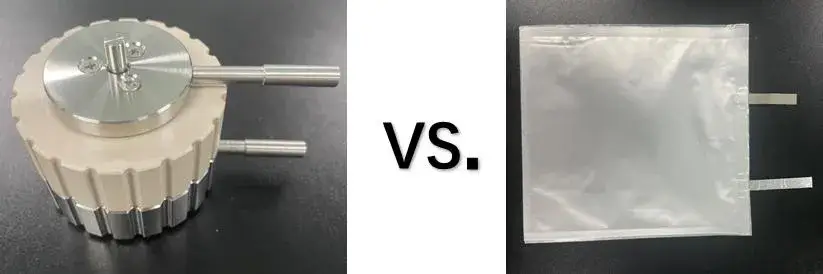

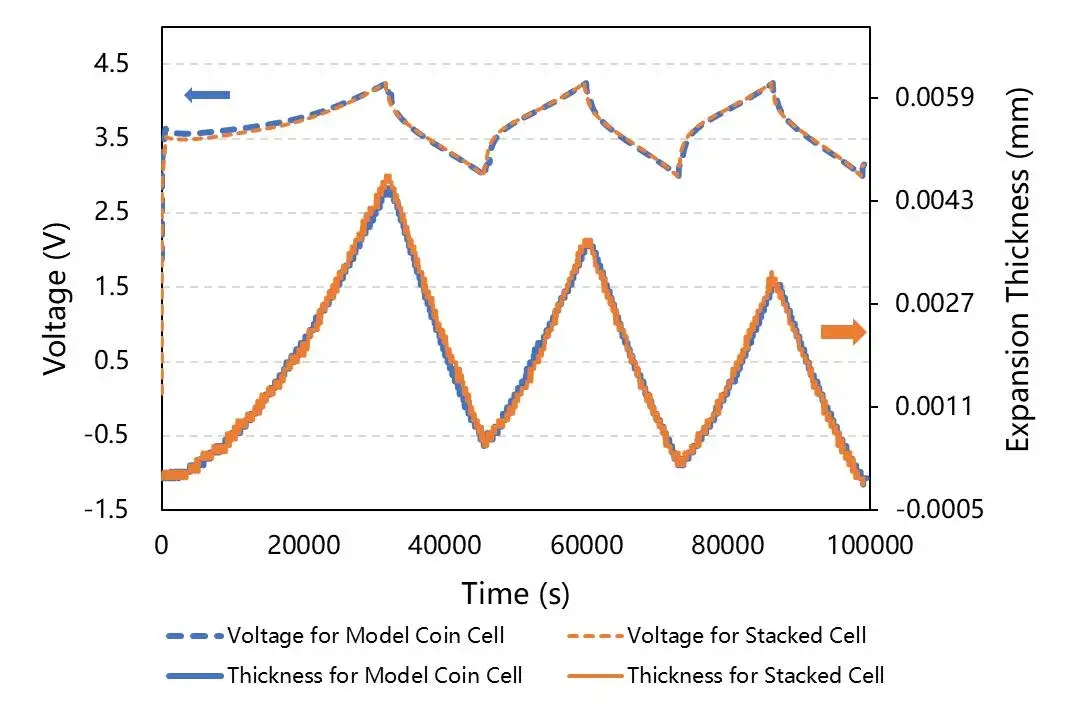

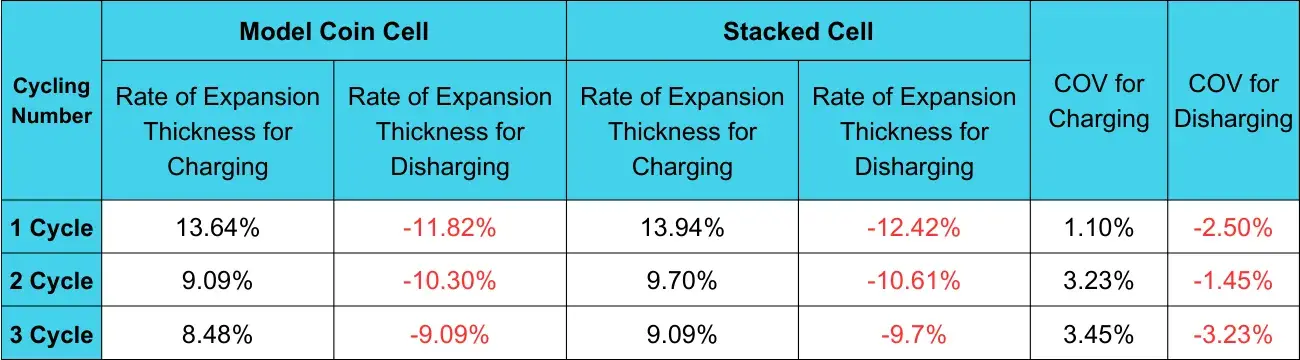

Figure 3 displays IEST’s model coin cell (left) and the single-layer pouch cell (right). Both configurations employed NCM cathodes and SiC anodes of identical composition, assembled into full cells. We monitored real-time thickness expansion during 0.1C charge-discharge cycles. The coin cell voltage profiles and thickness expansion curves for both configurations appear in Figure 4, with detailed full-cell cycling efficiency and thickness expansion comparisons presented in Tables 2 and 3, respectively.

We next compared thickness (height) expansion during cycling for NCM // SiC full cells assembled as model button cells and as single-layer pouch cell:

-

Coin cell voltage and thickness profiles during 0.1 C cycling showed strong overlap between the two formats (profiles illustrated in the source figures).

-

First-cycle full-cell Coulombic efficiencies were 41.82% for the model button cell and 42.42% for the single-layer pouch cell; the largest difference across the subsequent two cycles was only 0.12%.

-

Thickness expansion variability across three cycles yielded COV values under 3.5% for both formats, showing close agreement in measured expansion ratios.

Taken together, the model button cell provides thickness expansion trends that closely match those observed in single-layer stacked pouch cells, supporting its use for rapid screening of expansion behavior in silicon-based anodes.

Figure 3. Left: IEST’s model coin cell; Right: Single-layer stacked pouch cell

Figure 4. Blue dashed/solid lines: coin cell voltage curve and thickness expansion curve; Orange dashed/solid lines: Single-layer pouch cell voltage curve and thickness expansion curve

Table 3. Thickness expansion comparison between NCM//SiC model coin full-cells and single-layer pouch cells

Table 3. Thickness expansion comparison between NCM//SiC model coin full-cells and single-layer pouch cells

4. Discussion & practical benefits

Why the model coin cell works: the IEST model button cell preserves critical stack architecture and electrode-to-electrode pressure conditions that determine thickness changes during cycling. When tested under a controlled preload in RSS1400, the model format captures the same deformation trends observed in single-layer pouch assemblies.

Key advantages for R&D:

-

Faster screening: dramatically shortens evaluation cycles compared with full pouch builds.

-

Lower resource use: reduces electrode and cell component consumption for early material triage.

-

High sensitivity: RSS1400’s sub-micron resolution enables detection of minute reversible and irreversible expansions tied to phase changes or mechanical degradation.

-

Good predictive power: close correlation with single-layer pouch results supports confident down-selection for scale-up.

Recommended use case: use the IEST model button cell together with RSS1400 for early-stage evaluation of high-expansion anode materials (e.g., silicon composites) to rapidly compare formulations, coating thicknesses, and pre-treatment strategies before committing to larger pouch or cylindrical prototypes.

5. Summary

This study comprehensively evaluated the charge/discharge efficiency and thickness expansion measurement capabilities of IEST’s model button cells. Results demonstrate that the model coin cells provide cycling efficiency essentially equivalent to commercial 2032 stainless steel coin cells, while thickness expansion rates across three cycles show fundamental agreement with measurements from single-layer pouch cells.

For optimal results in silicon-based anode expansion tests, we recommend using the model button cell with the Silicon-Based Anode Swelling In-Situ Screening System (RSS1400). This system offers exceptional precision, with thickness measurement accuracy of 0.1 μm and resolution up to 0.01 μm, enabling detection of subtle phase-change-induced expansion—making it an essential tool for developing next-generation, low-expansion, high-capacity anode materials.

6. References

[1] J. Lin, L. Wang, Q.S. Xie, Q. Luo, D.L. Peng, C. B. Mullins and A. Heller, Stainless Steel-Like Passivation Inspires Persistent Silicon Anodes for Lithium-Ion Batteries. Angew. Chem. 135 (2023) e202216557.

[2] M. Ashuri, Q.R. He and L.L. Shaw, Silicon as a potential anode material for Li-ion batteries: where size, geometry and structure matter. Nanoscale 8 (2016) 74–103.

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.