-

iestinstrument

Analysis of Powder Compaction Density and Powder Conductivity — Comparison of Pressed and Unloaded Measurement Modes

1. Introduction

Accurate measurement of powder compaction density and resistivity is critical in lithium-ion battery material characterization. Relevant Chinese standards, such as GB/T 24533-2019 (“Graphite anode materials for lithium-ion batteries”) and GBT 30835-2014 (“Carbon composite lithium iron phosphate cathode materials for lithium-ion batteries”), outline specific testing protocols. Notably, the methods differ in whether properties are measured under applied pressure or after its release, leading to potential variations in reported values.

For graphite anode materials, the standard specifies measuring compaction density after pressure release. The powder is compressed, held under pressure for 30 seconds, and the thickness is measured after unloading using a vernier caliper. This “unloading” method accounts for the thickness rebound or spring-back that occurs post-compression. Conversely, for lithium iron phosphate (LFP) cathode materials, conductivity can be measured via two primary methods: Electrochemical Impedance Spectroscopy (EIS) and the Four-Point Probe Method. The EIS method typically involves measuring the impedance of a pellet after it has been pressed and removed from the die (an unloading-mode measurement). In contrast, the Four-Point Probe Method often measures resistance while the powder is under a specified applied pressure (a loading-mode measurement). Consequently, comparing material properties necessitates careful attention to the testing conditions and parameters used.

This article presents a comparative analysis of compaction density and powder conductivity for both graphite and LFP materials, examining the differences between measurements taken during the loading and unloading cycles.

Figure 1. Chinese National standards for graphite class and lithium iron phosphate materials

2. Methodology for Testing Powder Compaction Density & Conductivity

2.1 Test Equipment

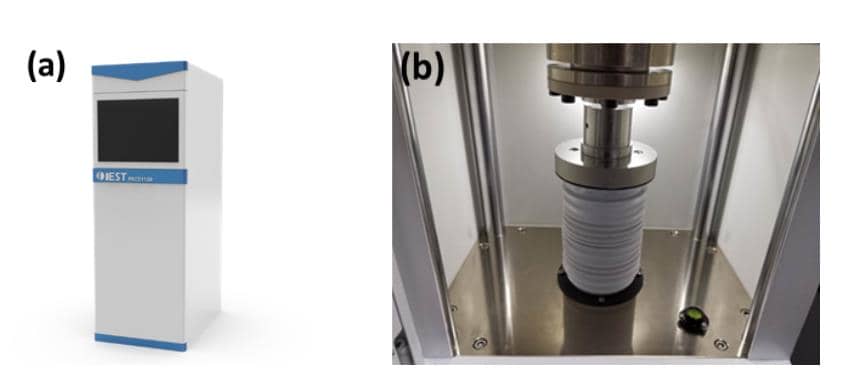

The tests were performed using the PRCD1100 powder resistivity and compaction density tester (IEST), as shown in Figure 2. This instrument is designed for synchronized measurement of density and resistance during pressurization and depressurization.

Figure 2. (a) Appearance diagram of PRCD1100; (b) Structure diagram of PRCD1100

2.2 Test Parameters

The experiments employed a four-point probe method. The applied pressure range was 10-200 MPa, with increments of 10 MPa. The pressure was held for 10 seconds at each step during loading. Subsequently, the pressure was reduced to 3 MPa and held for 10 seconds during the unloading phase.

2.3 Sample Mass

A precise mass of 1.0000 ± 0.0010 g was used for both graphite and LFP powders.

3. Test Results

3.1 LFP Powder Analysis

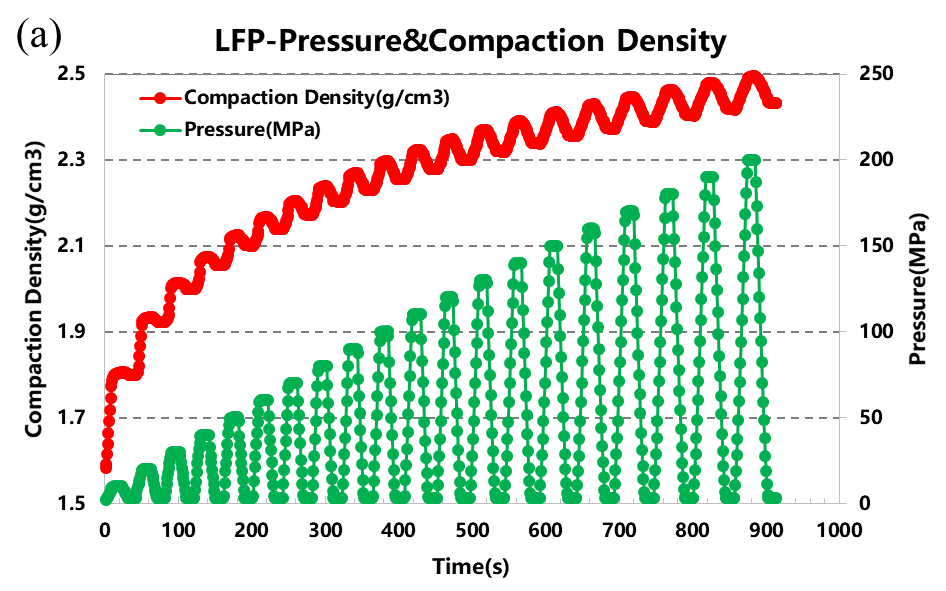

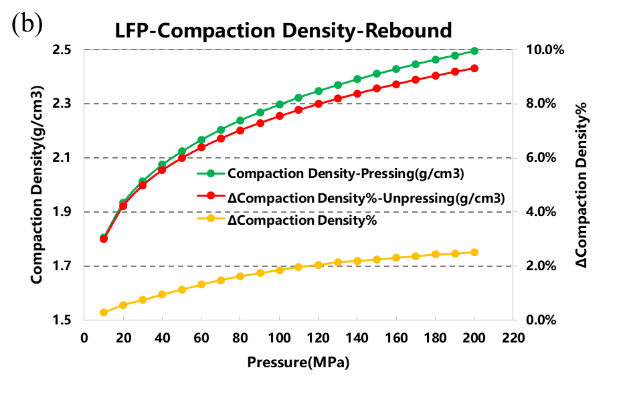

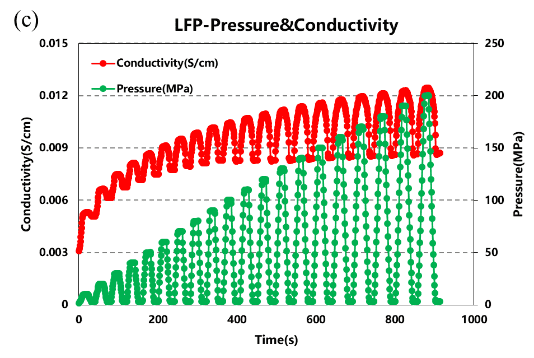

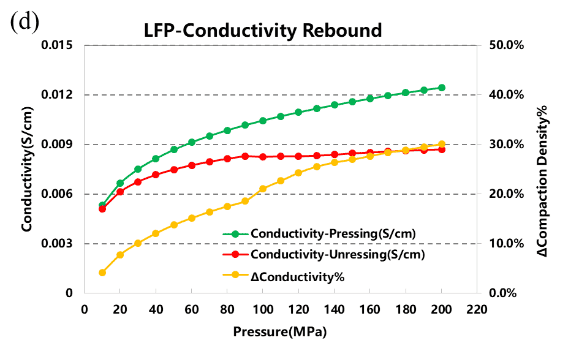

As shown in Figure 3, the compaction density and conductivity of LFP powder change with applied pressure during both loading and unloading cycles. Notably, at approximately 200 MPa, the difference in compaction density between the loading and unloading states is about 3%. However, the difference in powder conductivity is much more significant, reaching approximately 30%.

|  |

|  |

Figure 3. Curves showing the variation in LFP powder compaction density and conductivity during loading and unloading.

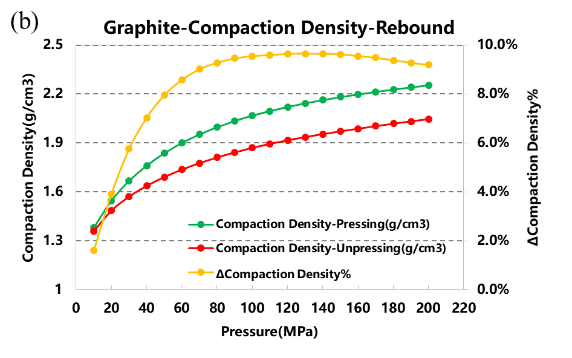

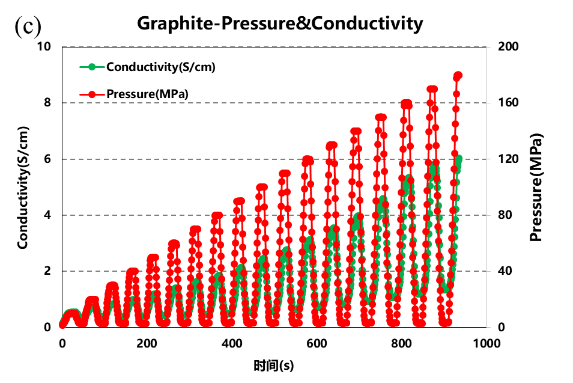

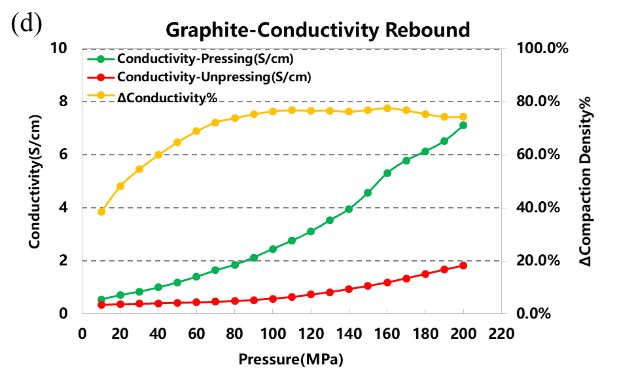

3.2 Graphite Powder Analysis

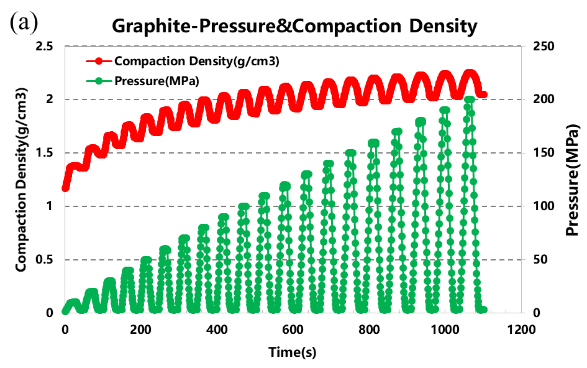

Figure 4 illustrates the behavior of graphite powder. The divergence between loading and unloading curves for both density and conductivity is more pronounced than for LFP. At nearly 200 MPa, the compaction density difference between cycles is about 10%, while the conductivity difference is substantially larger, at approximately 80%.

|  |

|  |

Figure 4. Curves showing the variation in graphite powder compaction density and conductivity during loading and unloading

4. Discussion — interpreting the loading/unloading gap

The experimental data demonstrate two central points:

Compaction density depends on measurement state. Unloaded density values incorporate elastic rebound and therefore understate instantaneous packing that a cell experiences during calendering or in a compressed electrode stack.

Powder conductivity is strongly pressure dependent. Conductivity measured under load (four-probe) reflects improved particle–particle and particle–probe contact and reduced pore resistance. The unloaded EIS / pellet measurement captures post-relaxation conductivity and will be lower in many cases — sometimes dramatically, as with graphite (≈80% lower near 200 MPa).

These effects arise because compression closes interparticle gaps, increases real contact area, and can cause deformation that creates metallic or graphitic contact bridges. Upon unloading, elastic recovery reintroduces gaps and reduces the number of percolation paths.

5. Summary

Our results demonstrate that testing conditions profoundly impact the measured values of lithium battery powder properties. The choice between loading and unloading modes significantly influences the outcome. At a pressure close to 200 MPa:

For LFP materials, the difference in compaction density is ~3%, while the difference in powder conductivity is ~30%.

For graphite materials, the difference is more substantial, with compaction density varying by ~10% and powder conductivity by ~80%.

Therefore, explicitly stating the measurement mode (loading vs. unloading) is essential for accurate material comparison and quality control.

6. Recommended IEST Equipment for Powder Testing

PRCD Series Powder Compaction Density & Resistance Tester (IEST): Compaction density and resistance synchronous tests for all lithium powder pressure / discharge state, supporting two probe and four probe test methods, mainly with the following three test modes.

a.Single-point pressure synchronization test.

b .Multi-point pressure synchronization test.

c .Backash test of pressure and discharge state.

6. References

[2] GB/T 24533-2019《 Lithium-Ion Battery Graphite Negative Pole Material”》

Subscribe Us

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.