-

iestinstrument

Rapid Evaluation Of Silicon Anode Materials Swelling Performance

1. Preface

Silicon anode materials, with its unique advantages of high theoretical capacity (4200mAh/g) and abundant resources, is expected to replace widely used graphite negative electrodes and become the main negative electrode material for the next generation of lithium-ion batteries. The most promising silicon-based anodes for large-scale commercialization are silicon-carbon anodes and silicon-oxygen anodes, both of which have high specific capacities. However, due to the alloying and de-alloying mechanism of silicon, the significant structural swelling caused by it can damage the pre-existing solid electrolyte interface (SEI) on the surface of the silicon material. This leads to the continuous destruction and regeneration of the SEI film during cycling, consuming a large amount of electrolyte, and ultimately resulting in rapid decay of battery capacity. ² Therefore, evaluating the performance of a silicon material, aparts from the specific capacity, initial efficiency, and cycle efficiency, the evaluation of its swelling performance is also crucial.

The existing methods for evaluating swelling performance require the silicon anode materials to be prepared into a pouch cell or stacked cell, and then monitored for in-situ swelling using force structures and high-precision sensors (such as IEST’s SWE swelling series). However, the preparation process from powder material to finished cell not only requires a mature cell production line but also has a long evaluation cycle. Therefore, how to quickly evaluate the swelling performance of a silicon anode materials has become a difficult problem for many material researchers.

IEST has recently developed a four-channel Silicon-Based Anode Swelling In-Situ Screening System(as shown in Figure 1). Learned from the assembly mode of the coin cell, it has successfully achieved direct measurement of the swelling performance of silicon anode electrodes at the electrode end. This system eliminates the manpower, material, and time costs required for preparing finished battery cells and accurately evaluates the most important performance indicators of silicon negative electrode materials with minimal consumption and maximum efficiency, allowing you to stay ahead in research and development. In addition, this device is also compatible with conventional swelling testing of small-sized pouch cell and stacked battery cells (100*100mm), truly achieving multi-purpose use.

Figure 1. Silicon-based anode swelling in-situ fast screening system (four channels)

2. Swelling Test of Different Silicon-carbon Materials

2.1 Test Sample Information

Cathode Electrode: NCM811, is cut into diameter 14mm disc shape.

Anode Electrode: B, C, and D have similar capacities (~5.9mAh), but different modification methods,are cut into 16mm diameter discs shape (the B material is specially modified by a battery material company in Ningbo low-expansion silicon-carbon material, while C and D are two common silicon-carbon materials on the market).

Electrolyte: commercial electrolyte.

Separator: PP separator, is cut into 18mm diameter discs shape.

2.2 Test Information and Process

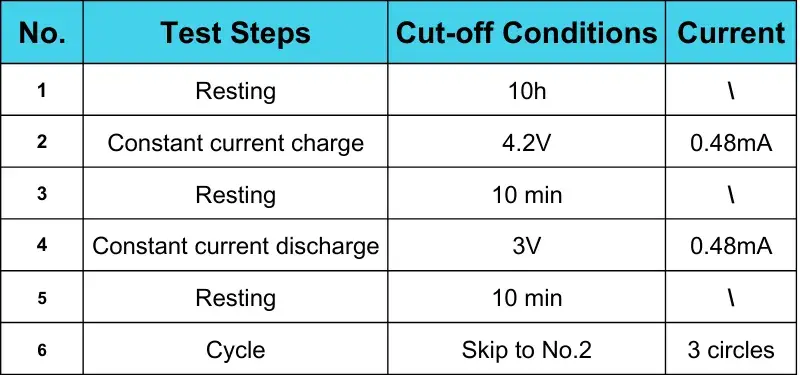

Table 1. Charge and Discharge Process

2.3 Analysis of Swelling Results

In the glove box, three silicon-carbon materials were assembled into a coin-cell full battery (the positive electrode uses the same NCM material to ensure the principle of single variable), and the rapid swelling test was performed using the silicon-based negative electrode expansion in-situ fast screening system of IEST Technology, and the result is shown in Figure 2. First of all, the three silicon-carbon materials all expand with charging and shrink with discharge, which is consistent with the swelling of lithium ion intercalation when the negative electrode is charged, and the shrinkage of lithium ion deintercalation during discharge. Therefore, although we assembled a full battery, the overall swelling behavior of the battery is still dominated by the negative electrode, while the swelling and contraction of the positive electrode is much smaller than that of the negative electrode³. Secondly, the inflection points of the swelling curves of the three are also highly consistent with the inflection points of the charge and discharge curves, indicating that the swelling curves can reflect the expansion and contraction behavior during the lithium-ion battery deintercalation process.

At the same time, the model coin cell swelling evaluation method can also effectively evaluate the swelling difference between different silicon-carbon materials. It can be clearly seen from Figure 2 that in the same operating voltage range, the overall swelling of the B-type silicon-carbon material is much smaller than that of the other two types of silicon-carbon materials, indicating that the special modification treatment can greatly inhibit the growth of the silicon-carbon negative electrode. Swelling, thereby reducing a series of side reactions caused by swelling, and ultimately improving the cycle performance of the material. In addition, Table 2 and Table 3 respectively count the swelling thickness and swelling rate data of the three silicon-carbon materials, from which it can be seen that: (1) The expansion of the three silicon-carbon materials for the first charge will be higher than that of the first discharge and the last two cycles The swelling of charge and discharge is much larger, and there is a certain irreversible swelling in the first cycle of charge and discharge. This is because the negative electrode will generate SEI film and produce certain irreversible swelling on the surface of active particles in addition to lithium intercalation swelling during the first charge. (2) Comparing the swelling data of the last two cycles of charging and discharging, it can be seen that the average swelling thickness of the B-type silicon-carbon material after modification is only ~4.2μm, and the swelling rate is ~8.9%, while the C-type material and D The average swelling of the type B material is 3.7 times and 5 times that of the B type material, respectively that the swelling modification effect of the B type material is very obvious.

![]()

Figure 2. Using the model battery to quickly evaluate the expansion thickness change of three different silicon-carbon materials during 3 cycles of charge and discharge, where the dotted line is the voltage versus time curve, and the solid line is the swelling thickness change curve with time.

Table 2. The swelling thickness of three silicon-carbon materials per charge and discharge cycle

![]()

Table 3. Expansion rate per turn of charge and discharge for three silicon-carbon materials

![]()

3. Electron Microscope Observation of Different Sic Materials

In addition, in order to compare the swelling of the electrode measured by the model button with the result of manual thickness measurement, we disassembled the fully filled silicon carbon electrode, and observed and compared the cross-section of the electrode under the scanning electron microscope. The thickness was measured and the results are shown in Figure 3. After deducting the thickness of the copper foil, the coating thickness of the Type B silicon carbon electrode expands from ~50.81 μm to ~55.45 μm after being fully charged, and the total swelling is ~4.64 μm, which is the same as the average swelling thickness measured by using the model buckle. very close. In addition, for the C and D silicon-carbon materials, the coating thickness expanded by ~11.98 μm and ~14.65 μm respectively after full filling, which is like the swelling data of the last two cycles in Table 2. To sum up, no matter whether the model is used for in-situ monitoring, or the electrode is disassembled for electron microscope observation, the swelling trends of the three silicon-carbon materials are consistent, that is, D>C>B.

![]()

Figure 3. Scanning electron microscope images of the cross-sections of three silicon carbon electrodes before being fully charged (Fresh) and after being fully charged (Full Charged). Among them, (a-b) is the electron microscope image of type B silicon-carbon material; (c-d) is the electron microscope image of type C silicon-carbon material; (e-f) is the electron microscope image of type D silicon-carbon material.

4. Summary

In this paper, three silicon-carbon materials with different modification conditions were rapidly tested for expansion using the IEST Silicon-Based Anode Swelling In-Situ Screening System(RSS 1400). The three silicon-carbon negative electrodes do not need to be prepared into pouch cell or stacked cell, but only need to be assembled into a model buckled cell to directly conduct in-situ testing of the expansion thickness of the silicon-carbon negative electrode sheet, which not only eliminates the cumbersome steps of preparing the finished cell, but also greatly improves the efficiency of the expansion evaluation of silicon-based materials. As can be seen from the results of the model buckling in-situ test, the expansion of the specially modified silicon-carbon material of model B is much smaller than that of the common silicon-carbon materials of models C and D on the market. At the same time, we also disassembled and observed the pole piece after full charging with electron microscope, and the observation results showed the same trend as the model buckling in-situ test, i.e., the expansion amount of model B silicon-carbon material is the smallest among the three, which indicates that IEST Silicon-Based Anode Swelling In-Situ Screening System can realize the direct evaluation of the expansion performance of the material on the end of the electrode, and accurately evaluate the most important performance indexes of the silicon anode electrode with the smallest consumption and the fastest efficiency, which makes your research and development faster! Let your R&D be one step faster!

5. References

[1] M. Ashuri, Q.R. He and L.L. Shaw, Silicon as a potential anode material for Li-ion batteries: where size, geometry, and structure matter. Nanoscale 8 (2016) 74–103.

[2] X.H. Shen, R.J. Rui, Z.Y. Tian, D.P. Zhang, G.L. Cao and L. Shao, Development on silicon/carbon composite anode materials for lithium-ion battery. J. Chin. Cream. Soc. 45 (2017) 1530-1538.

[3] R. Koerver, W.B. Zhang, L. Biasi, S. Schweidler, A. Kondrakov, S. Kolling, T. Brezesinski, P. Hartmann, W. Zeier and J. Janek, Chemo-mechanical expansion of lithium electrode materials – on the route to mechanically optimized all-solid-state batteries. Energ. Environ. Sci. 11 (2018) 2142-2158.

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.