-

iestinstrument

In-Situ Swelling Analysis of LiFePO4 Prismatic Cells: The Impact of Preload Force and C-Rate

1. Abstract

This prismatic case study uses an in-situ swelling analyzer (SWE2110) to quantify swelling force and surface temperature of LiFePO4/graphite prismatic cells (40 Ah) under different initial preload conditions (60 kg / 90 kg / 120 kg) and charge/discharge rates (1C, 1.5C, 2.5C). Results reveal how mechanical confinement and high C-rates influence reversible and irreversible swelling, accelerate stress evolution, and create risks for particle fracture, lithium plating and pack leakage. Based on the findings we discuss practical EV battery cell swelling compensation strategies — including the use of prismatic cell swelling pads, preload tuning, and leak testing protocols — to improve cycle life and pack safety.

2. Introduction

During the charging and discharging of lithium-ion prismatic battery cells, the intercalation and deintercalation of lithium ions cause significant mechanical stress, leading to volume changes known as swelling. This phenomenon is a critical factor affecting the battery’s life cycle and safety. Within the constrained environment of an electric vehicle (EV) battery pack, cells are subjected to external clamping pressure. While an optimal preload force ensures good electrical contact, excessive or poorly managed swelling force can result in internal structural damage, lithium plating, and in extreme cases, contribute to seam fatigue and electrolyte leakage.

Quantifying this swelling behavior is therefore paramount for designing effective swelling pads, predicting long-term performance, and ensuring safety. This article presents a comprehensive case study using in-situ swelling analysis to guide the engineering of prismatic cell systems.

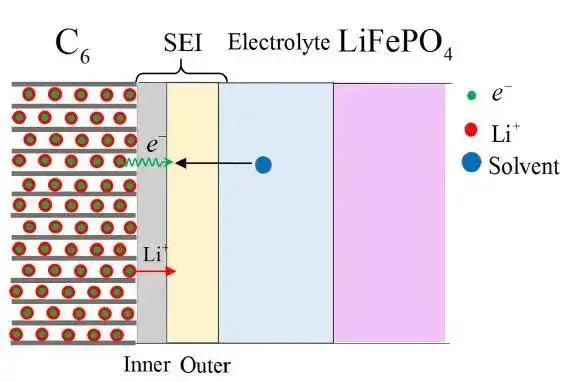

Figure 1. Schematic diagram of the LiFePO4 system battery cell

3. Experimental setup

3.1 Test equipment

-

In-situ swelling analyzer: SWE2110 (IEST) capable of applying 5–1000 kg of controlled compressive load while logging force, thickness and temperature.

-

Data acquisition synchronized to charge/discharge instrumentation to record voltage, current, capacity and differential capacity (dQ/dV).

Figure 2: Appearance of SWE2110 Equipment

3.2 Cell specification

-

Cell type: LiFePO4 (LFP) cathode / graphite anode prismatic cell

-

Capacity: 40 Ah (prismatic form factor)

3.3 Test matrix

- Preload comparison: 1C cycling under initial preloads of 60 kg, 90 kg, 120 kg.

- Rate comparison: constant preload at 60 kg; cycling at 1C, 1.5C and 2.5C.

- Measurements recorded: swelling force curve, cell surface temperature, voltage/current profile, and differential capacity (dQ/dV).

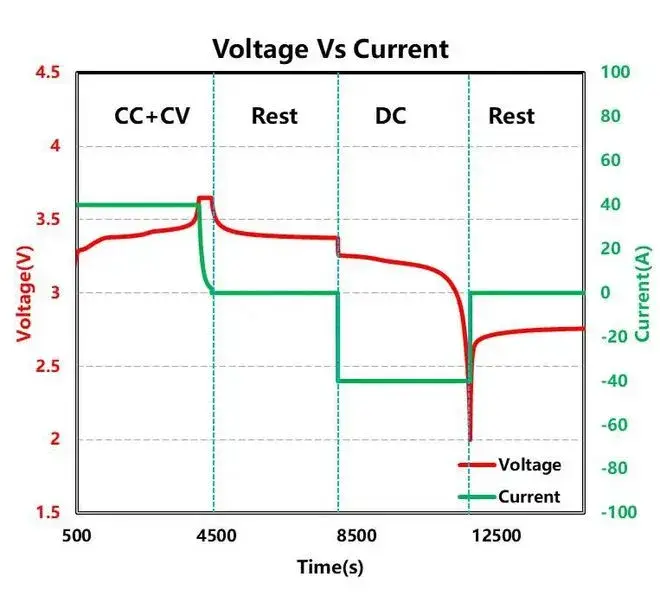

The voltage and current changes of the battery charge and discharge cycle are shown in Figure 3.

Figure 3. Schematic diagram of battery charging and discharging

4. Result Analysis

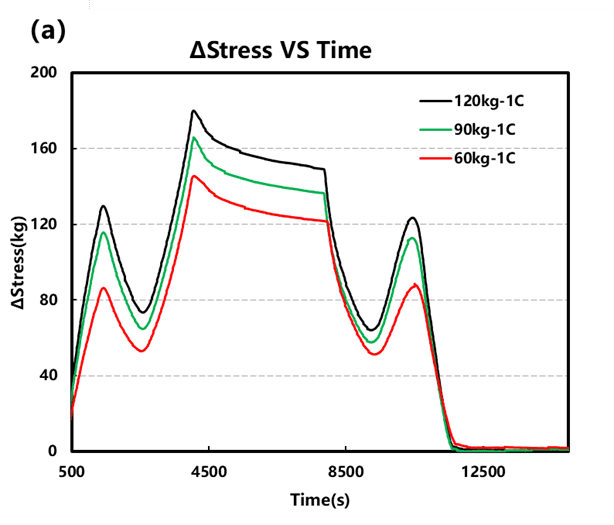

4.1 Effect of initial preload on swelling force and temperature

-

Under 1C cycling, higher initial preload raised the maximum measured swelling force during charge/discharge. This is attributed to smaller initial gaps and greater mechanical constraint that converts lattice expansion into contact force.

-

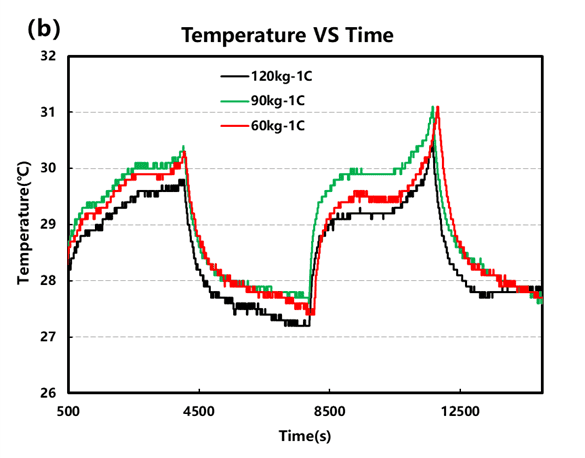

In Figure 4(b), surface temperature increased by roughly ~3°C during cycling across preload conditions; temperature relaxed during rest periods.

-

in Figure 4(c), differential capacity analysis showed a leftward shift of certain peaks when preload increased from 60 kg to 90 kg, then little further change at 120 kg — indicating moderate preload reduced polarization but excessive preload offers diminishing returns and may harm ion transport.

Practical interpretation: moderate preload improves particle contact and reduces electrode delamination, but excessive preload can close separator pores and obstruct ion pathways — increasing local current density and the risk of lithium plating.

|

|

|

Figure 4. Cell under 3 kinds of preload conditions (a) swelling force curve; (b) temperature change curve; (c) differential capacity curve.

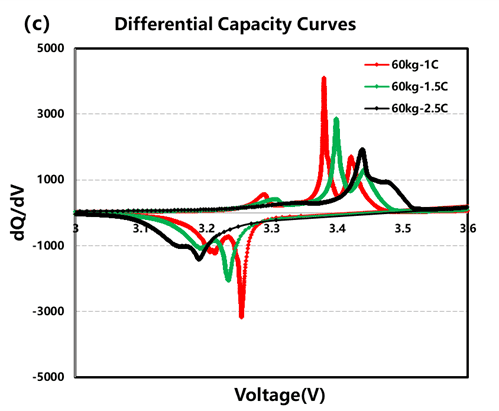

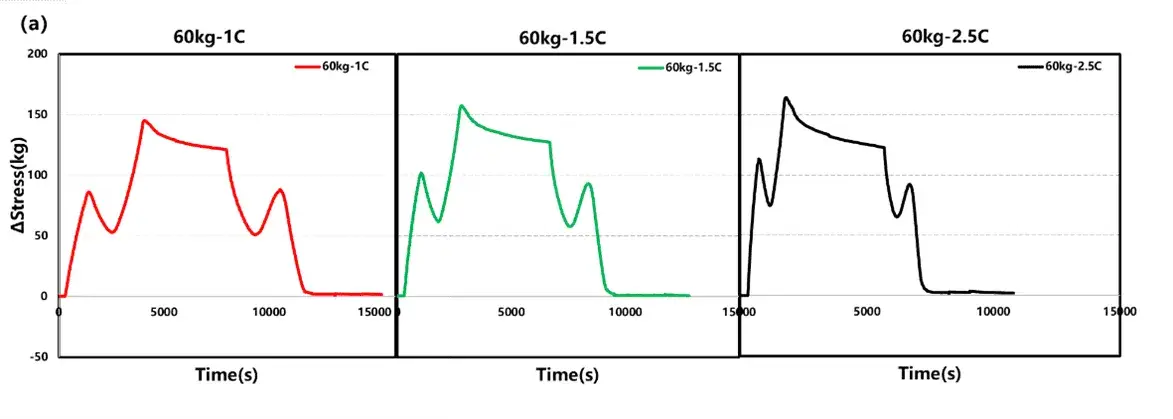

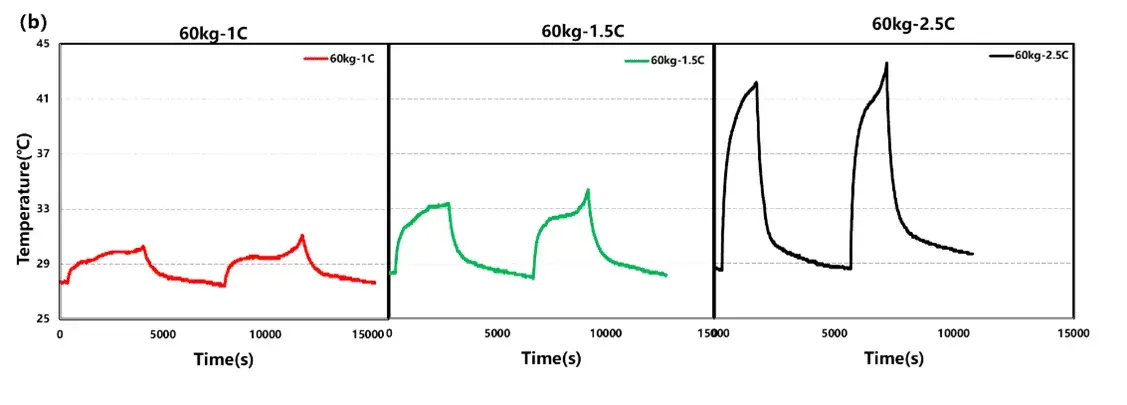

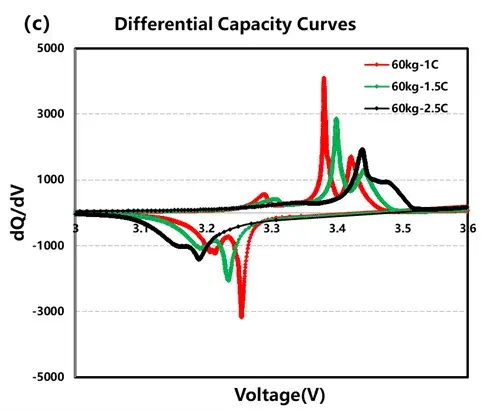

3.2 Effect of charge/discharge rate on swelling and thermal response

-

With preload fixed at 60 kg, increasing C-rate raised both maximum swelling force (≈ from 144 kg → 164 kg) and surface temperature.

-

At 2.5C, the cell surface temperature rise reached about 15°C, and dQ/dV peaks shifted right — consistent with increased polarization and concentration gradients.

-

High C-rates promote larger concentration differences between particle core and surface, increasing mechanical stress within particles and the likelihood of cracking or irreversible damage.

Key takeaway: rate acceleration intensifies reversible expansion per cycle and favors mechanisms of irreversible swelling (SEI growth, gas formation, particle fracture, and possible lithium dendrite formation).

These findings are critical for EV battery pack designers. High-power applications (e.g., rapid acceleration or fast charging) induce greater mechanical and thermal stress. Understanding this relationship is vital for developing robust swelling compensation systems and thermal management strategies to ensure safety and longevity, preventing issues that could necessitate rigorous leak testing.

Figure 5. (a) Swelling force change; (b) Temperature change; (c) Differential capacity curve under different charge and discharge rates of the cell.

4. Discussion — reversible vs irreversible swelling and lifecycle implications

-

Reversible swelling: lattice expansion/contraction during Li insertion/extraction; largely recoverable each cycle but contributes to cyclic mechanical fatigue over time.

-

Irreversible swelling: SEI thickening, gas evolution, particle fracture, delamination and lithium plating; these accumulate and reduce usable capacity and cycle life.

From the prismatic cell life cycle perspective, both excessive confinement and high C-rates shorten lifetime by accelerating irreversible damage modes. This prismatic case study shows that optimizing preload and C-rate is critical to balance good electrical contact (reducing ohmic losses) against long-term mechanical degradation.

5. Engineering implications & mitigation strategies

5.1 Preload tuning and mechanical design

-

Design rule: apply moderate preload sufficient to ensure uniform electrode contact without closing separator pores or creating stress concentrations. Based on our tests, 60–90 kg range produced beneficial effects; 120 kg offered limited additional benefit and increased risk.

-

Use even load distribution features in module frames to avoid local hotspots of compression.

5.2 Swelling pads and swelling compensation

-

Prismatic cell swelling pads (silicone foam, closed-cell elastomer, or engineered polymer pads) provide distributed compliance to absorb reversible thickness changes while maintaining assembly compressive load.

-

EV battery cell swelling compensation approaches include: elastic pads, controlled spacer gaps, spring-loaded compression systems, and pack laminates that allow controlled expansion without compromising sealing. Design pads with adequate thermal conductivity and aging resistance.

5.3 Thermal management

-

High C-rate tests showed significant temperature rise (up to ~15°C). Effective thermal paths and active cooling maintain temperature uniformity and reduce stress accumulation.

5.4 Leak testing and QC

-

Excessive swelling or bulging compromises enclosure seals. Implement prismatic battery leak testing in production: pressure decay, helium leak detection, or sniffer tests for gas escape.

-

Use swelling data to define leak test acceptance thresholds — e.g., allowable bulge before rework.

5.5 Monitoring & diagnostic controls

-

Integrate periodic diagnostic checks (dQ/dV analysis, impedance monitoring) to detect early signs of irreversible swelling or particle damage and update end-of-life predictions.

6. Tips For Pack Engineers (Practical Checklist)

-

Standardize and record initial assembly preload and distribution on each module.

-

Specify and qualify prismatic cell swelling pads for lifetime, compression set and thermal conductivity.

-

Limit charge/discharge rates in software or hardware during early life or high-stress conditions.

-

Add leak testing steps informed by swelling thresholds.

-

Use in-situ swelling or thickness testing (SWE2110 or equivalent) during R&D to validate pack tolerances and design margins.

7. Summary

The swelling force in LiFePO4 prismatic cells is influenced by both reversible (lattice volume change) and irreversible (SEI growth, gas production, particle cracking) processes. This case study demonstrates that both mechanical constraints (preload force) and electrical operating conditions (C-rate) are decisive factors governing these processes.

-

Optimal Preload: An initial preload must be carefully calibrated to reduce polarization without inducing excessive stress that shortens the life cycle.

-

C-rate Management: Higher currents intensify swelling and heating, increasing the risk of failure modes. This data is essential for defining safe operating envelopes.

The insights gained from in-situ swelling analysis(SWE Series) are directly applicable to improving prismatic cell module design, informing the selection of swelling pads, and establishing parameters for quality control measures like leak testing.

8. FAQs

Q1: Why is monitoring swelling force critical for prismatic battery cells?

A: Monitoring swelling force is essential for predicting the mechanical life cycle of a cell and ensuring the structural integrity of the battery module. Excessive force can damage cell internals, lead to leakage, or cause connections to loosen, all of which are critical failure modes in EV battery packs.

Q2: What is prismatic cell life cycle and how does swelling affect it?

A: The prismatic cell life cycle refers to capacity retention and performance over repeated charge/discharge cycles. Repeated reversible swelling causes mechanical fatigue, and irreversible swelling (SEI growth, particle fracture, gas) reduces active material — together these accelerate capacity fade and shorten life. Managing preload and C-rate reduces these aging drivers.

Q3: How does this research relate to leak testing for prismatic cells?

A: Our research into swelling force provides the root-cause data behind a key failure mode that leak testing aims to catch. Continuous, high swelling forces can fatigue cell seals and welds over time. Therefore, understanding swelling behavior helps in designing more effective leak test protocols and identifying cells prone to early-life leakage.

Q4: What are prismatic cell swelling pads and how does this study help design them?

A: Swelling pads or compensation pads are components placed between cells in a module to absorb and manage expansion. This study provides quantitative data on the magnitude of swelling force and how it changes with preload and C-rate. This data is crucial for engineers to select materials with the correct compressive strength and elasticity to effectively manage expansion throughout the battery’s life cycle.

Q5: How does EV battery cell swelling compensation work?

A: Compensation uses springs, compliant pads, pre-defined gaps, or hinged module structures to allow controlled expansion without over-stressing seals or components. Effective compensation balances thermal expansion, mechanical preload and electrical contact stability.

Q6: What is prismatic battery leak testing, and why is it needed?

A: Prismatic battery leak testing ensures pack and cell seals remain intact despite swelling. Methods include pressure decay, helium leak detection and gas sniffers. Leak tests should be tied to swelling thresholds observed during qualification tests.

Q7: How should manufacturers incorporate prismatic battery leak test data into QC?

A: Use in-situ swelling and bulge tolerance data to set pass/fail leak test criteria. Cells that exceed defined bulge or internal pressure levels should be flagged for rework or rejection before module assembly.

9. References

[1] Dongjiang Li, Dmitri Danilov, Jie Xie, Luc Raijmakers, Lu Gao, Yong Yang, Peter H.L.Notten, Degradation Mechanisms of C6/LiFePO4 Batteries: Experimental Analyses of Calendar Aging, Electrochimica Acta.

[2] Thomas M. M. Heenan, Paul R. Shearing*, Identifying the Origins of Microstructural Defects Such as Cracking within Ni-Rich NMC811 Cathode Particles for Lithium-Ion Batteries. Adv. Energy Mater. 2020, 2002655.

[3] Dai H, Yu C, Wei X, Sun Z, State of charge estimation for lithium-ion pouch batteries based on stress measurement, Energy (2017).

[4] M Lewerenz,A Marongiu,A Warnecke,DU Sauer. Differential voltage analysis as a tool for analyzing inhomogeneous aging: A case study for LiFePO4|Graphite cylindrical cells. Journal of Power Sources 368 (2017) 57~67

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.