-

iestinstrument

IEST GVM2200 Facilitates CATL’s Breakthrough Study in Nature Nanotechnology: Unraveling Novel Interfacial Reactions In Lithium Metal Batteries

1. Introduction

A research team from CATL’s 21C Innovation Lab has achieved a significant breakthrough in lithium metal battery technology, with their independent study “Application-driven design of non-aqueous electrolyte solutions through quantification of interfacial reactions in lithium metal batteries. published in the prestigious journal Nature Nanotechnology. Led by researchers Ouyang Chuying and Wang Hansen, the study employs multi-scale characterization techniques to quantitatively analyze decomposition pathways of lithium salts and solvents in ether-based electrolytes for the first time, proposing a novel electrolyte design strategy that significantly enhances cycle life of lithium metal batteries.

Notably, critical gas solubility data supporting these findings were obtained using IEST’s GVM2200 In-situ Gas Volume Monitor, which provided essential experimental validation for understanding battery failure mechanisms.

2. Technical Challenges in Lithium Metal Batteries Development

Lithium metal batteries represent a promising next-generation energy storage technology due to their extremely high energy density, — lithium’s theoretical capacity is 3860 mAh g⁻¹ — but practical deployment still hinges on controlling interfacial chemistry, and commercialization faces two major challenges:

2.1 Parasitic reactions between Li metal and electrolyte:

Parasitic reactions between lithium metal and electrolyte continuously form a solid electrolyte interphase (SEI), consuming active lithium and electrolyte and ultimately leading to battery failure.

2.2 Ambiguous decomposition mechanisms

Insufficient understanding of electrolyte decomposition mechanisms, with traditional research lacking quantitative analysis of interfacial reactions to guide electrolyte optimization.

So, quantitative interfacial analysis battery techniques are therefore essential to identify dominant decomposition pathways and to translate mechanistic insight into better electrolyte formulations.

To address these challenges, the research team employed an integrated approach combining titration-differential electrochemical mass spectrometry (T-DEMS), extraction-chromatography analysis (E-G&IC), and IEST’s GVM2200 in-situ testing technology, enabling unprecedented quantitative tracking of electrolyte decomposition pathways.

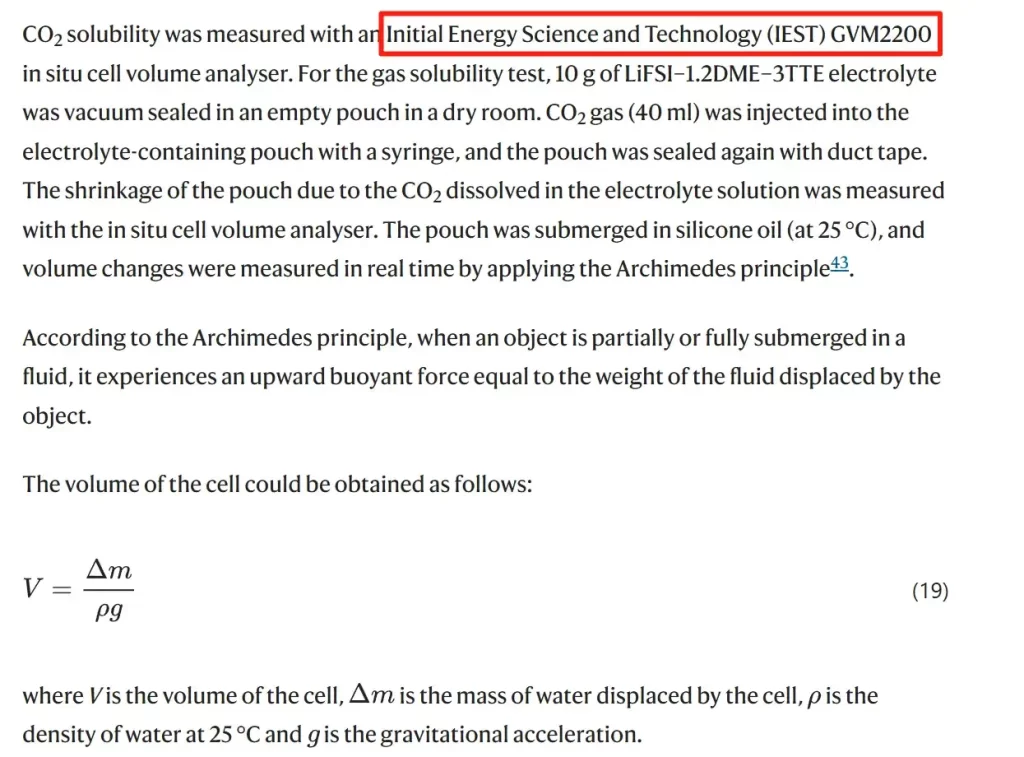

3. Key Measurement — GVM2200 for CO₂ Solubility (a tool for lithium-metal testing)

A critical element of the work was in-situ gas solubility quantification performed with the GVM2200 gas-volume monitor from IEST Instrument. The instrument tracks gas uptake in electrolyte via an Archimedes-type volume measurement and thereby yields accurate dissolved-gas concentrations in real time. By measuring CO₂ solubility under operating conditions, the team quantified how oxidation products formed at the cathode migrate through the cell and react at the lithium anode — a phenomenon we refer to here as electrode “cross-talk.” The GVM2200 data provided an independent, quantitative constraint for reaction-pathway analysis in lithium-metal testing.

4. What the Measurements Revealed — CO₂ Production, Dissolution, and Cross-talk

The study revealed that oxidation of DME solvent at the cathode generates CO₂, which migrates to the anode via inter-electrode crosstalk, reacting with lithium to form Li₂CO₃ (4Li + 3CO₂ → 2Li₂CO₃ + C). This process critically contributes to active lithium loss. IEST GVM2200 quantified CO₂ solubility in real-time by monitoring volume changes via Archimedes’ principle. Results corroborated with theoretical simulations clarified CO₂ crosstalk’s impact on performance, providing key parameters for electrolyte design.

5. Innovative Electrolyte Design: From Mechanism to Application

Guided by the quantified reaction pathways, the authors proposed an optimized electrolyte concept summarized as “high salt concentration + low-viscosity diluent.” The specific formulation tested in cells was: LiFSI-1.2DME-3BTFE (molar ratio notation preserved from the paper). The optimized solvent system balances ionic mobility with reduced solvent oxidation and, importantly, changes the solubility/transport behavior of oxidative decomposition products.

Key reported properties for the optimized electrolyte:

-

Ionic conductivity: 4.1 mS cm⁻¹ (measured at room temperature).

-

Viscosity: 3.3 mPa·s.

These values indicate maintained ionic transport while lowering viscosity relative to some high-salt approaches, which helps electrolyte wetting and rate capability.

6. Performance Demonstrated in Lithium-metal Testing

When assembled in 20 µm Li || NMC811 cells under lean-electrolyte conditions (2.1 g Ah⁻¹), the optimized formulation achieved 483 cycles with 77% capacity retention. The authors note that this performance represents an ≈80% improvement in cycle life over a reference formulation under the same lean-electrolyte constraints. These results verify that mechanistic, quantitative interfacial analysis battery data can be translated into practically meaningful electrolyte designs.

7. Why high-frequency, quantitative gas analysis matters for interfacial studies

Two important experimental takeaways emerge:

-

Dissolved gaseous products matter. Gas-phase species (e.g., CO₂) are not merely bystanders; they can dissolve, diffuse, and drive secondary reactions at the opposing electrode. Quantifying their dissolved fraction is therefore critical for closing reaction mass balances.

-

Instrumentation sensitivity and compatibility are essential. The GVM2200’s capability to detect small volume changes and to operate under lithium-battery conditions provided the missing experimental constraint that tied oxidation events at the cathode to deposition chemistry at the anode. Without reliable dissolved-gas data, electrolyte design would lack a key parameter that governs cross-talk.

8. Practical Implications for cell R&D

-

Design electrolytes with cross-talk in mind. When targeting lithium metal anodes, consider not only solvent oxidation propensity but also the solubility and transport of gaseous oxidation products.

-

Measure dissolved gas quantitatively. Integrate in-situ gas-volume or solubility monitoring into interfacial analysis battery workflows to detect pathways that may otherwise be missed by standard gas-collection or ex-situ chemical methods.

-

Balance salt loading and viscosity. The LiFSI-rich, low-viscosity diluent approach demonstrated here is a practical template: increased salt concentration suppresses some parasitic mechanisms while a low-viscosity diluent preserves ionic mobility.

9. Conclusions

This work illustrates a clear chain from mechanism → measurement → materials design. By quantifying CO₂ production and dissolved-gas behavior with a high-sensitivity instrument (GVM2200), the research team identified a dominant cross-talk pathway and then engineered an electrolyte that mitigates its impact. The result is a practical electrolyte recipe that substantially improves cycle life in lean-electrolyte Lithium Metal Batteries. More broadly, the study reinforces that rigorous, quantitative lithium-metal testing and interfacial analysis battery methods can accelerate rational electrolyte and interface engineering.

10. IEST: Enabling Cutting-Edge Research with Precision Tools

This study demonstrates the value of IEST GVM2200 in-situ gas volume monitor (shown below) in high-impact research:

- High sensitivity: Detects minute volume changes from gas dissolution/side reactions.

- Broad compatibility: Withstands harsh experimental conditions in lithium metal batteries.

- Data reproducibility: Provides reliable benchmarks for modeling and engineering.

IEST remains committed to advancing in-situ characterization solutions for energy materials research, accelerating breakthroughs in battery technology.

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.