-

iestinstrument

Analysis of LiCoO₂ Powder Compaction and 3D Discrete Element Modeling of Its Electromechanical Behavior

1. Preface

The performance of lithium-ion batteries depends fundamentally on the quality of their electrodes. LiCoO2 (LCO) remains the dominant cathode material for 3C (Computer, Communication, and Consumer) electronic applications, prized for its high energy density, stable voltage plateau, and relatively simple production. The electrode manufacturing process—where a slurry of active material, binder, and conductive agent is coated, dried, and calendared—is critical. Optimizing this process, particularly the compaction step, is essential for enhancing battery stability, safety, and performance. A key to this optimization lies in understanding the intrinsic properties of the electrode powders themselves. This study establishes a comprehensive evaluation model by investigating the mechanical and electrical behavior of LiCoO2 powders under compaction.

We focus on four LiCoO2 powders with distinct particle size distributions. Using experimental compression testing and advanced Discrete Element Modeling (DEM), we analyze how pressure affects their resistivity and compaction density. This combined approach provides both empirical data and a theoretical framework to explain the underlying mechanisms.

2. Test Methods

2.1 Experimental Procedure:

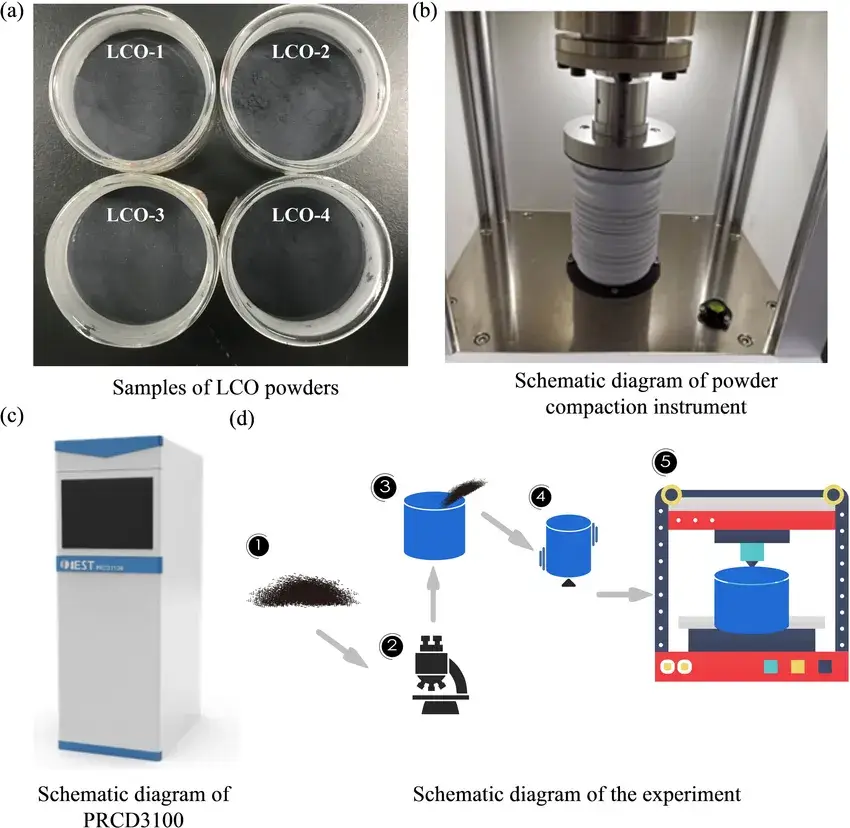

The conductivity, compaction density and compression performance of four types of LiCoO2 powders were tested using a Powder Resistivity & Compaction Density Measurement System(PRCD3100) developed by IEST. The test samples and equipment are shown in Figure 1.

2.2 Test Parameters:

The upper pressure head applies a pressure of 10-200MPa to the LiCoO2 powder in sequence, with an interval of 20MPa, and the pressure is maintained for 10s.

Figure 1. Schematic diagram of experimental materials and instruments: (a) Four LiCoO2 Powders with a mass of 2 g; (b) Internal diagram of powder compaction detector; (c) External diagram of a PRCD3100; (d) procedure of powder compaction experiment.

2.3 Post-Compaction Morphology via SEM

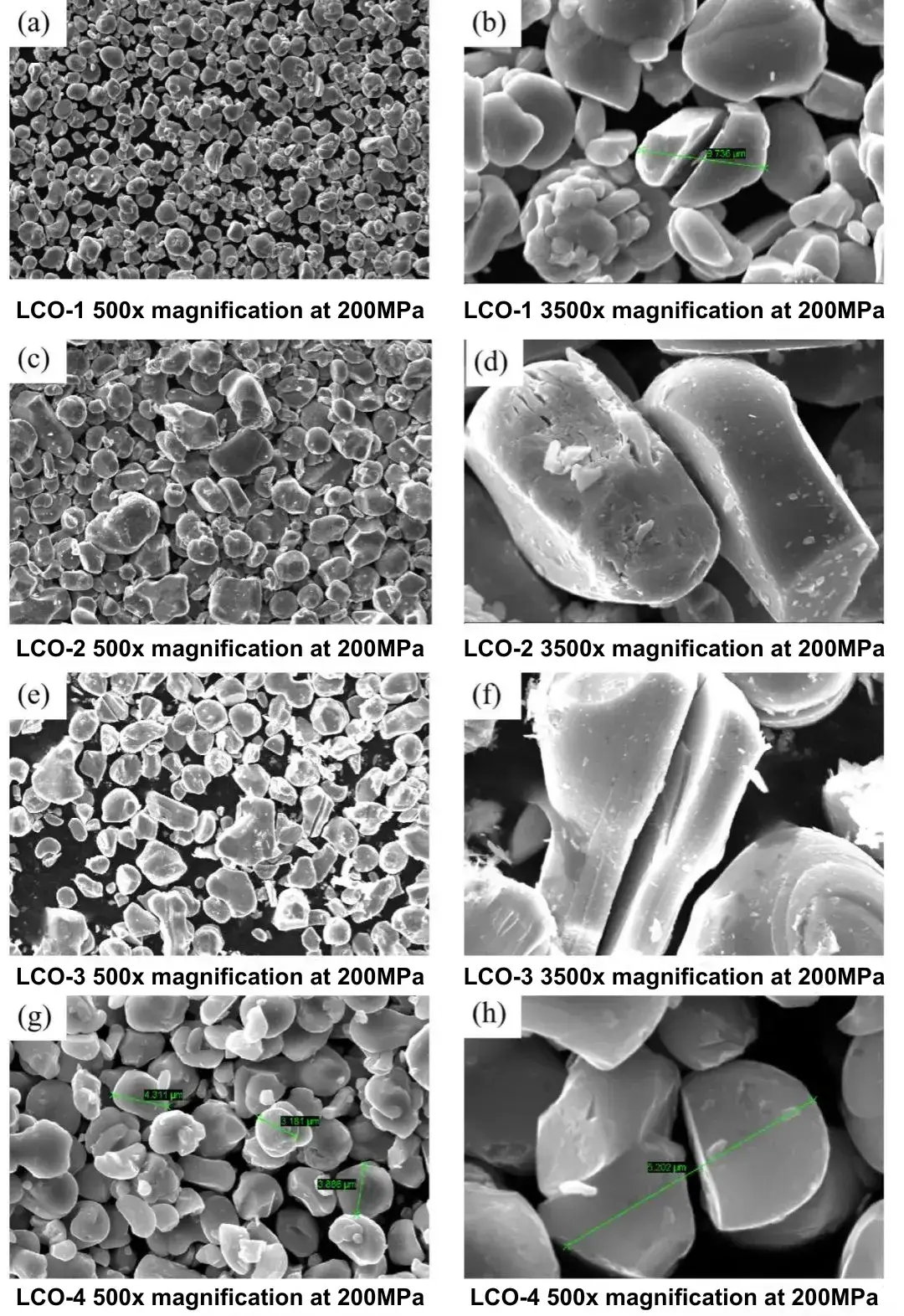

Following compression at 200 MPa, the morphology of each powder was examined using Scanning Electron Microscopy (SEM). Figure 2 reveals clear differences in the particle size distribution of the four samples:

-

LCO-1: Broad distribution (~5-30 μm)

-

LCO-2: Mid-range distribution (~5-15 μm)

-

LCO-3: Coarser distribution (~10-45 μm)

-

LCO-4: Primarily fine particles (~5 μm)

The SEM images also show evidence of secondary particle fracture under high pressure, a critical observation for understanding compaction limits. The particle size distribution directly influences the packing efficiency during compression, which in turn governs the final compaction density and electronic conductivity of the electrode.

During the roller pressing process, with the increasing roller pressure, the main morphological changes of the electrode include: ① the thickness of the electrode becomes thinner, the surface roughness decreases, and the surface of the electrode is smoother; ② the contact of each component of the electrode is closer, and the gap compression is reduced; ③ the combination of the collector and the coating is enhanced, and the particles are pressed into the surface of the foil to form a pit; ④ in the case of over-pressurization, the active particles are broken, and the secondary particles are formed into the visible cracks between the particles. The roller pressing process must use appropriate pressure conditions to achieve a reasonable compaction density of the electrode sheet. Overpressure may cause the broken particles to lose the excellent properties of the active particles and become less stable, and may cause the conductive network to break down and reduce the conductivity of the electrode sheet.

Figure 2. Overall and local SEM images of LiCoO2 powder

3. Results & Analysis: Linking Pressure to Density and Conductivity

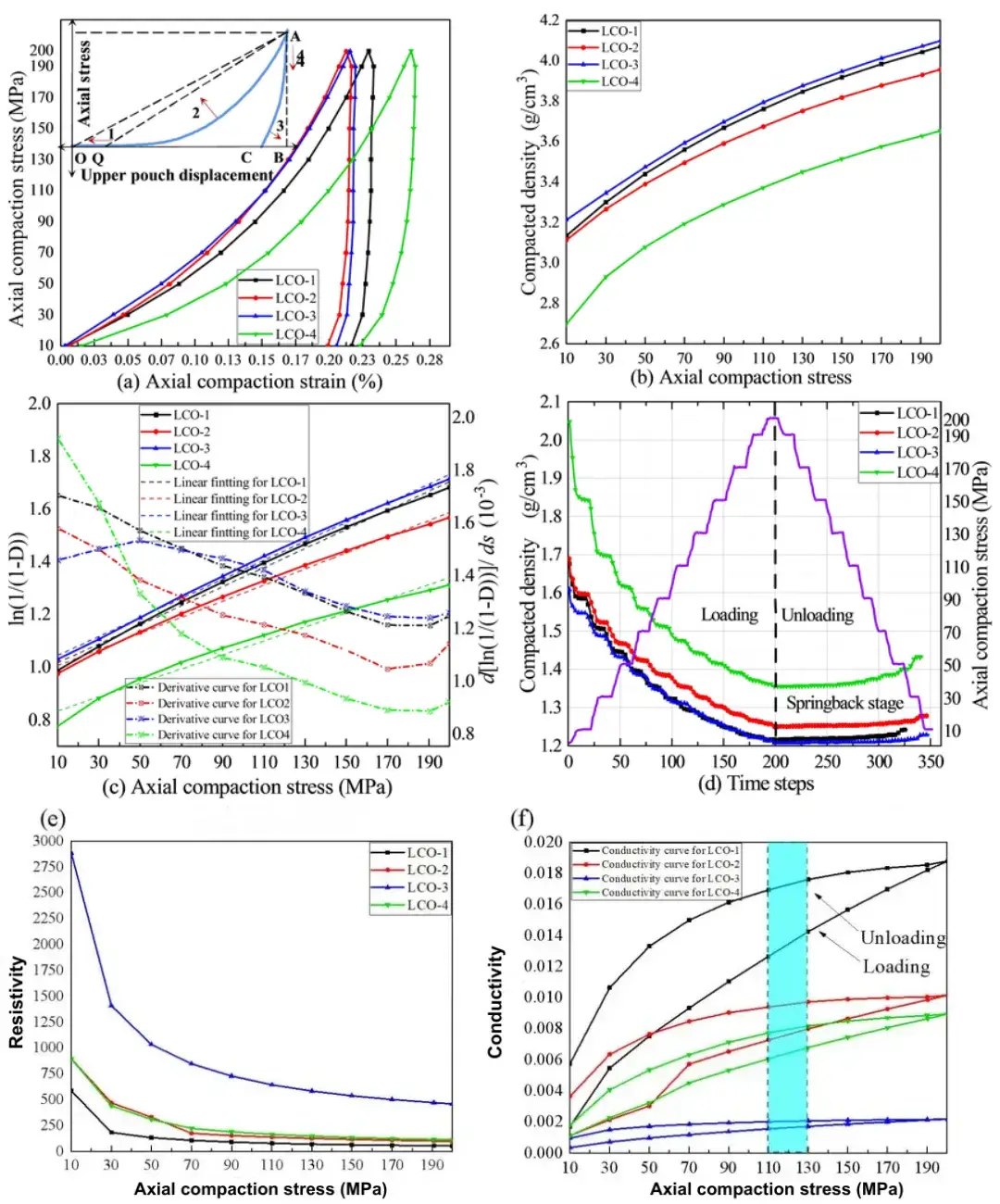

Figure 3 shows the stress-strain curves, compaction density curves, powder plasticity curves, powder thickness and applied force curves, resistivity curves and conductivity curves in the powder compaction process given by the PRCD3100. The compression performance of powder material is related to many factors such as particle shape, particle size and its distribution, the actual powder material under pressure, particle stacking from the initial loose state through the filling effect to further tightly stacked, the filling effect produced by the overall deformation of the powder is the main irreversible deformation; when all the particles for the closest stacking between the particles, the pressure under the action of the particles will be the first elastic deformation will occur, there will be a stress, this deformation is a reversible deformation, the stress is a kind of compaction, the deformation is a kind of reversible deformation. This deformation is a reversible deformation, when the pressure unloading this deformation will occur reversible rebound; when the pressure exceeds the yield strength of the powder material, the particles undergo plastic deformation, which is also irreversible deformation. The actual powder particles compression process is a multi-gravity joint action, the stress is also a comprehensive change in the process.

Figure 3. Powder compaction test data curve

4. Discrete Element Modeling

4.1 Model Construction

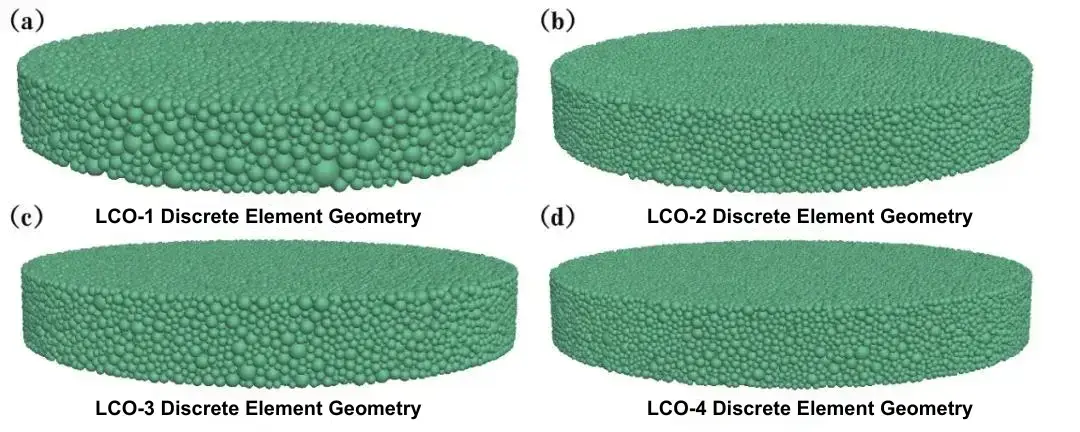

To gain deeper insight, we created high-fidelity Discrete Element Modeling (DEM) simulations replicating the experiment. Using the actual particle size distribution of each LCO powder, we generated systems containing between 13,418 and 61,149 spherical particles (Figure 4). A movable wall applied pressure from 10 to 200 MPa, mimicking the physical tester.

Figure 4. Discrete elemental model of LiCoO2 powder

4.2 Calibration with the Edinburgh Elasto-Plastic Adhesion (EEPA) Model

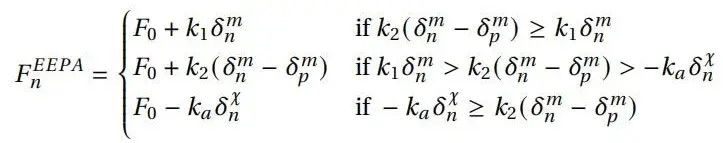

Combined with the powder stress-strain curves in the experiment in Figure 3, the Edinburgh elastic-plastic adhesion model (EEPA) is applied between the powder particles as a contact model, and the EEPA can be regarded as a deformation of Hooke’s law of the linear elasticity model. Equation (1) gives the stress-strain relationship defined by the EEPA model.

Figure 5. Edinburgh elastic-plastic adhesion model(Equation 1))

Figure 6 plots the mechanism of action of the powders in the EEPA model.

Figure 6. Introduction to the EEPA model

4.3 Simulation Results: Force Chains and Anisotropic Contact Fabric

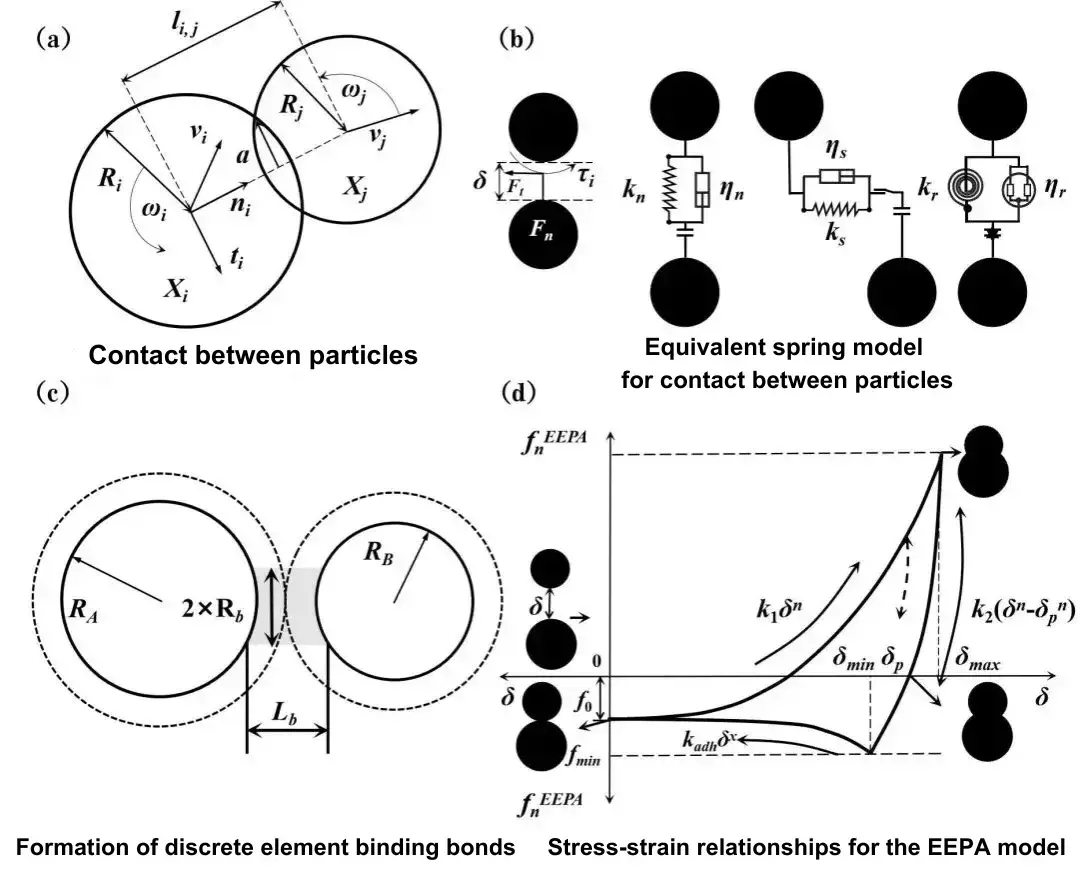

The DEM simulations showed excellent agreement with experimental stress-strain curves (Figure 6), validating the model’s accuracy. Further analysis provided unique visualizations:

-

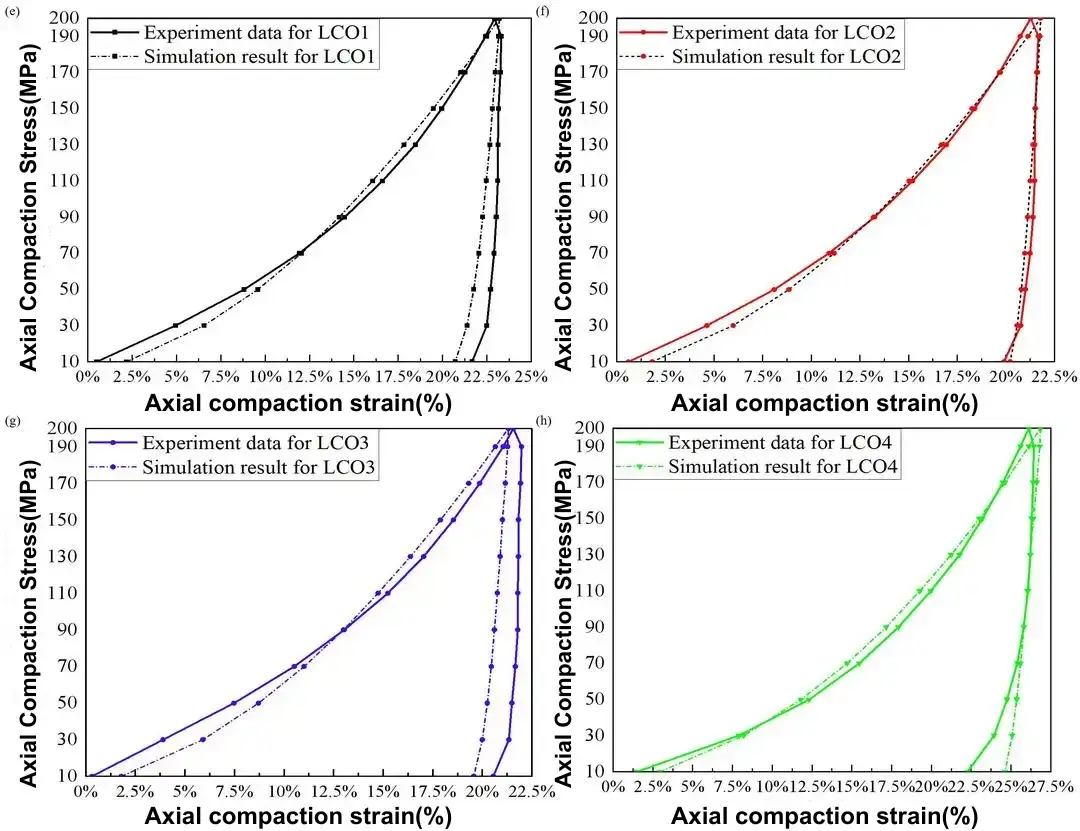

Force Chains: Figure 7 maps the strong, load-bearing networks of particles (force chains) within the compacted powder. These chains, visualized for LCO-4 at 50 MPa and 200 MPa, are hypothesized to also represent preferential pathways for electron conduction.

-

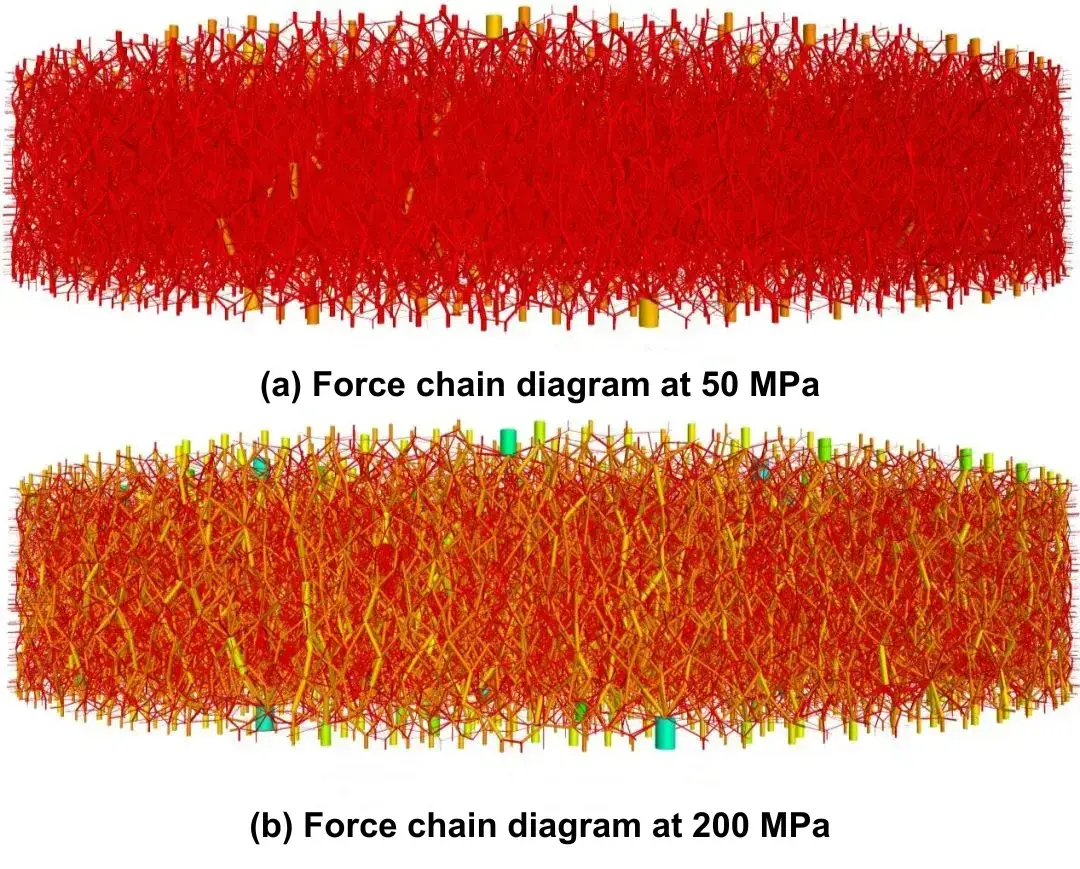

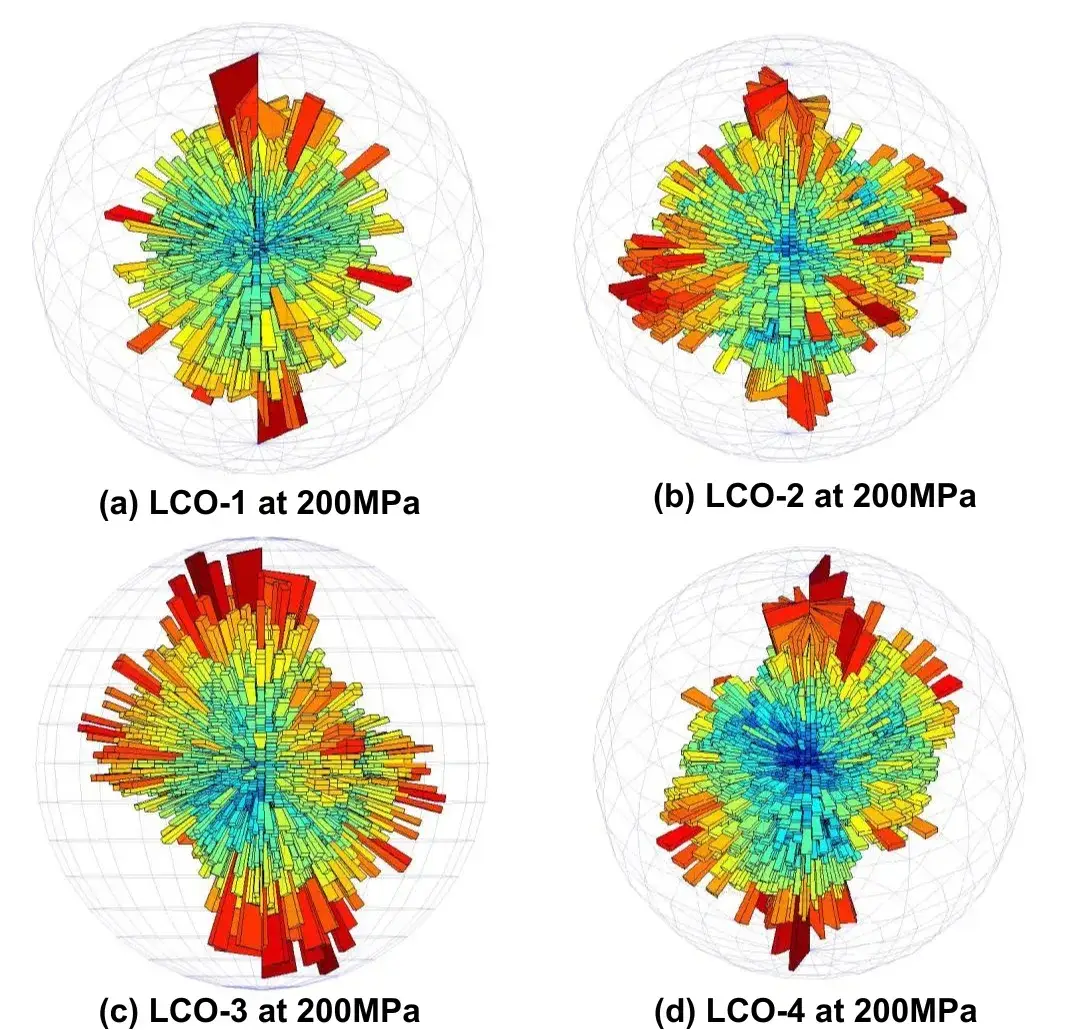

Anisotropic Contact Fabric: Figure 8 reveals the directional nature of contacts after uniaxial compression. The contact fabric becomes highly anisotropic, meaning contacts are stronger and more numerous in the direction perpendicular to the applied pressure. This structural anisotropy helps explain the well-documented directional differences in electrode electrical conductivity and pore tortuosity.

Figure 7. Discrete element simulation diagram

Figure 8. Force chain distribution of LiCoO2 powders

Figure 9 shows the anisotropic contact group configuration, the sphere is divided into 3600 equal surface area regions, the length of the column in each direction indicates the contact strength in that direction, the warmer the color the stronger the strength. As can be seen from the figure, there are obvious anisotropies in each of the powder axial direction after compaction. A large number of studies have shown that the anisotropic characteristics of the battery electrode sheet after roll compaction, such as graphite particles more form a balanced distribution of morphology with the collector; electrode conductivity in the thickness and lateral direction there are several orders of magnitude difference; and pore tortuosity there is also an obvious difference in direction, often thickness direction pore tortuosity is greater than the other direction, especially for the flake or ellipsoidal particles morphology. This contact group configuration is highly correlated with resistivity.

Figure 9. Anisotropic contact grouping

5. Summary

We combined IEST PRCD3100 compaction/conductivity experiments and Discrete Element Modeling (DEM) to build a predictive understanding of LiCoO2 powder compaction. By analyzing four powders with different particle size distributions, we quantified how pressure governs density and conductivity. The DEM simulations, validated against experimental data, offer a powerful tool for visualizing internal force chains and anisotropic structure development. This combined methodology provides researchers and engineers with a new framework to optimize calendaring processes, prevent over-compaction, and design better-performing electrodes through informed particle engineering.

6. References

[1] Q. Liu, J.G. Wang, B.W. Hu. Progressive Damage Analysis for Spherical Electrode Particles with Different Protective Structures for a Lithium-Ion Battery. Acs Omega.

[2] S.C. Thakur, H. Ahmadian, J. Sun, J.Y. Ooi, An experimental and numerical study of packing, compression, and caking behaviour of detergent powders. Particuology, 12 (2014) 2-12.

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.