-

iestinstrument

In-Situ Expansion Analysis of Pouch Cells Under Constant Pressure and Constant Gap Conditions

Abstract

Accurate Expansion Analysis of lithium-ion pouch cells — tracking both thickness change and expansion force — is essential for cell design optimization and safety assurance 1-3. This study uses an in-situ swelling analyzer (IEST SWE2110) to compare traditional fixture limitations with automated constant-pressure and constant-gap test modes. We report synchronized voltage, current, differential-capacity (dQ/dV), thickness and force traces during charge/discharge and show how phase transitions map directly to mechanical response. Practical guidance is provided for researchers who need to measure pressure in pouch cell tests with high repeatability and fidelity.

1. Introduction

The traditional test method of the constant gap mode is to use a steel plate fixture to fix the battery cell in the middle of the pressure plate, fix the position of the upper and lower pressure plates with bolts, and install a force sensor on the upper pressure plate to monitor the pressure change, but this method is difficult to guarantee the test time The gap between the upper and lower platens is constant, and sometimes the gap will produce fluctuations of tens or even hundreds of microns. As shown in Figure 1, the red curve indicates that during the charging and discharging process of the cell, the gap change of the traditional fixture produces a fluctuation of about 65µm. The traditional test method is to place a constant weight on the surface of the cell, but it is difficult to freely adjust different pressures 4-7. Based on the above problems, we use an automatic pressure and displacement control system to accurately control the test pressure and gap to achieve true constant pressure and constant gap test modes. The green curve in Figure 1 represents the gap of the SWE test system in the constant gap mode. There is almost no change. The structure diagram of the in-situ swelling test system(SWE) is shown in Figure 2.

Figure 1. Thickness control comparison between traditional test method and SWE test system in constant gap mode

Figure 2. Schematic diagram of in-situ swelling test system SWE structure

2. Experimental Equipment and Test Methods

2.1 Experimental Equipment

All tests were conducted on the IEST SWE2110 In-Situ Swelling Analyzer(Figure 3). The SWE2110 integrates a high-precision displacement actuator, load cell, environmental control and synchronized electrochemical cycler. It supports both Constant Pressure and Constant Gap modes and logs cell thickness, thickness change, force/pressure, temperature, current, voltage and capacity simultaneously, enabling more reliable measure pressure in pouch cell applications.

Figure 3. Appearance of SWE2110 equipment

2.2 Cell Information

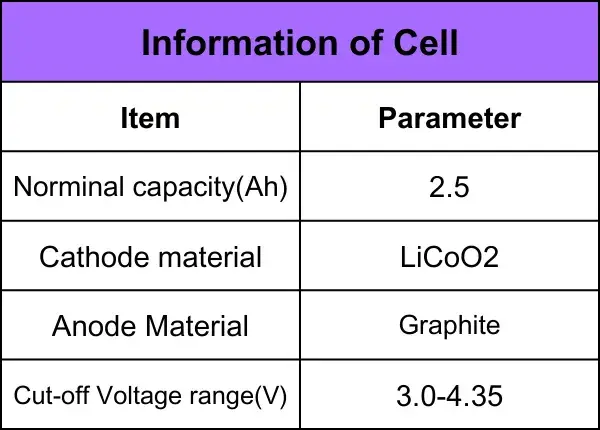

Pouch cells were used in this study. Specific cell details are summarized in Table 1.

Table 1. The Information of Battery

2.3 Charging and discharging process

Formation / test cycle (example): 25 °C rest 5 min → 0.5C CC to 4.35 V, CV to 0.025C → rest 5 min → 0.5C discharge to 3.0 V. All tests were repeated to confirm reproducibility.

2.4 Test modes — how they differ

-

Traditional constant-gap (manual): steel plate + bolts or fixed weight; prone to µm-to-100s µm gap fluctuations during cycling.

-

SWE Constant Pressure mode: user sets applied preload (e.g., 10 kg). The system actively adjusts gap to maintain the target pressure while recording thickness and force.

-

SWE Constant Gap mode: user fixes gap; SWE actively controls displacement to hold the gap while measuring the force required to do so — enabling precise measurement of expansion pressure under fixed dimensional constraints.

3. In-Situ Expansion Behavior Analysis

3.1 Thickness and Force Changes During Cycling

From the charging and discharging curves as well as the thickness and expansion force curves in Fig. 4, it can be seen that when charging, the expansion force and thickness of the cell increase, the expansion force of the cell reaches about 160 kg when fully charged and the thickness of the cell expands by about 2%, and when discharging, the expansion force and thickness of the cell decrease. The changes in the thickness and force curves during charging and discharging are not completely symmetrical, indicating the existence of irreversible thickness and stress residuals.

Figure 4. (a) Voltage and current changes during charge and discharge; (b) Expansion thickness and expansion force changes during charge and discharge

4.2 Correlation with Differential Capacity Curves

Figure 5 shows the expansion thickness and expansion force of the cell versus the differential capacity curve, and each peak of the differential capacity curve corresponds to the phase change of the de-embedded lithium. From the figure, it can be seen that during charging, when the first anode embedded lithium peak occurs, the thickness and the slope of the force curve also correspond to the increase, and each subsequent de-embedded lithium peak corresponds to the change of thickness and the slope of the force curve, which indicates that it is due to the phase change of the anode and negative structure that leads to the change of the expansion thickness and the expansion force of the cell. This indicates that it is the phase change of the positive and negative structure that leads to the change of the expansion thickness and expansion force.

Figure 5. (a) Expansion force and differential capacity curve; (b) Expansion thickness and differential capacity curve

5. Discussion — Best Practices to Measure Pressure in Pouch Cell Tests

-

Choose the appropriate mode for your question:

-

Use Constant Pressure when you want to know dimensional response under realistic pack preload.

-

Use Constant Gap to measure the mechanical stress generated under constrained stacking conditions (e.g., module clamping).

-

-

Control environmental variables: temperature affects swelling and pressure. Run tests in a controlled chamber or log temperature for post-analysis.

-

Sampling frequency & synchronization: sample force, thickness and electrochemical signals at sufficient rates to resolve phase transitions (e.g., 1 Hz–10 Hz or higher for fast transients). Ensure timestamps are synchronized.

-

Calibration and zeroing: calibrate load cells and displacement sensors before each experiment. Zero the system at the intended baseline pressure/gap to remove fixture preload offsets.

-

Repeatability & statistical robustness: test multiple cells and multiple points per cell to capture manufacturing scatter and irreversible effects.

-

Interpretation: map dQ/dV peaks to mechanical features to separate reversible elastic swelling from irreversible structural change (e.g., particle fracture, SEI growth).

6. Summary

Automated pressure-displacement control (as implemented in the SWE2110) significantly improves the fidelity of Expansion Analysis in pouch cells, enabling accurate, repeatable measurements of thickness and expansion force and enabling researchers to measure pressure in pouch cell setups with confidence. This method helps correlate mechanical changes with electrochemical phase transitions, offering valuable insights for battery developers aiming to improve cell durability and safety.

R&D personnel can apply this in-situ approach to evaluate different battery systems and optimize manufacturing processes for better performance.

7. Reference

[1] Amartya Mukhopadhyay,Brian W. Sheldon. Deformation and stress in electrode materials for Li-ion batteries. Progress in materials science, 2014, 63, 58-116.

[2] John Cannarella, Craig B. Arnold. State of health and charge measurements in lithium-ion batteries using mechanical stress. Journal of Power Sources, 2014, 269, 7-14.

[3] Ruihe Li, Minggao Ouyang et al. Volume Deformation of Large-Format Lithium Ion Batteries under Different Degradation Paths. Journal of The Electrochemical Society, 2019, 166 (16) A4106-A4114

[4] Shiyao Zheng, Yong Yang et al. Correlation between long range and local structural changes in Ni-rich layered materials during charge and discharge process. J. Power Sources. 2019,412,336–343;

[5] Y. Reynier, R. Yazami, B. Fultz. The entropy and enthalpy of lithium intercalation into graphite. Journal of Power Sources .2003, 119–121 850–855

[6] Jan N. Reimers and J. R. Dahn. Electrochemical and In Situ X-Ray Diffraction Studies of Lithium Intercalation in LixCoO2. Journal of Electrochemical Society, 1992, 139, 8.

[7] Haifeng Dai, Chenchen Yu, Xuezhe Wei, Zechang Sun. State of charge estimation for lithium-ion pouch batteries based on stress measurement. Energy, 2017,129, 16.

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.