-

iestinstrument

A Multi-Scale Analysis of Thermal–Overdischarge Coupling Aging in LFP Batteries

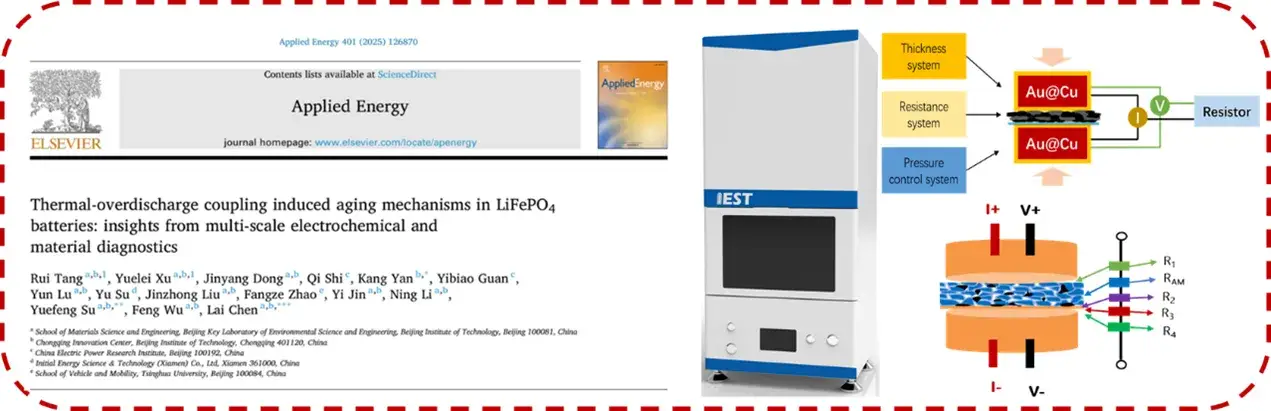

1. Article Info

First Authors: Tang Rui, Xu Yuelei

Corresponding Authors: Yan Kang, Su Yuefeng, Chen Lai*

Affiliations: Beijing Institute of Technology, Chongqing Innovation Center of Beijing Institute of Technology, China Electric Power Research Institute, IEST Co., Ltd. (Xiamen), Tsinghua University

Equipment Used: IEST Battery Electrode Resistance Tester(BER2100)

2. Abstract

This paper present a concise, technical translation of a multi-institutional study that maps how combined thermal stress and deep overdischarge accelerate aging mechanism in LFP batteries. Using an orthogonal experimental design, the authors measured capacity fade, DC internal resistance (DCIR), impedance (EIS), ultrasonic imaging, SEM/TEM, XRD and ToF-SIMS to reveal a three-stage aging evolution (“activation → linear decay → accelerated decay”) and to identify a DCIR inflection point that marks the onset of cooperative failure mechanisms (SEI runaway, dead-Li accumulation, metal dissolution/deposition). Under extreme coupling (65 °C / 0.5 V) they observed non-typical failure modes such as FePO₄ phase separation and copper migration. The results offer actionable metrics for lifetime prediction and field management of LFP batteries.

3. Understanding the Real-World Stress on LFP Batteries

LFP batteries are a cornerstone technology for electric vehicles and energy storage systems, prized for their safety and cost-effectiveness. In real-world applications, however, these batteries are frequently subjected to coupled thermal and electrochemical stresses. The combined effect of elevated temperature and deep over-discharge can significantly accelerate battery aging, leading to rapid capacity fade and impedance growth. While the individual impacts of heat or over-discharge have been studied, the synergistic aging mechanism under their combined stress remains insufficiently understood. A clear analysis of this coupled failure behavior is crucial for enhancing battery longevity and safety.

4. A Systematic Approach to Uncover Synergistic Failure

A research team employed a comprehensive, multi-scale diagnostic strategy to systematically reveal the aging mechanism of LFP batteries under thermal-overdischarge coupling. The study utilized an orthogonal experimental design to evaluate the effects of temperature (25°C, 45°C, 65°C) and discharge cutoff voltage (2.5V, 1.0V, 0.5V). Researchers combined electrochemical techniques like DCIR and EIS with advanced material diagnostics including ultrasonic imaging, SEM/TEM, XRD, and ToF-SIMS.

5. Key Findings: From Accelerated Aging to Stage Transition

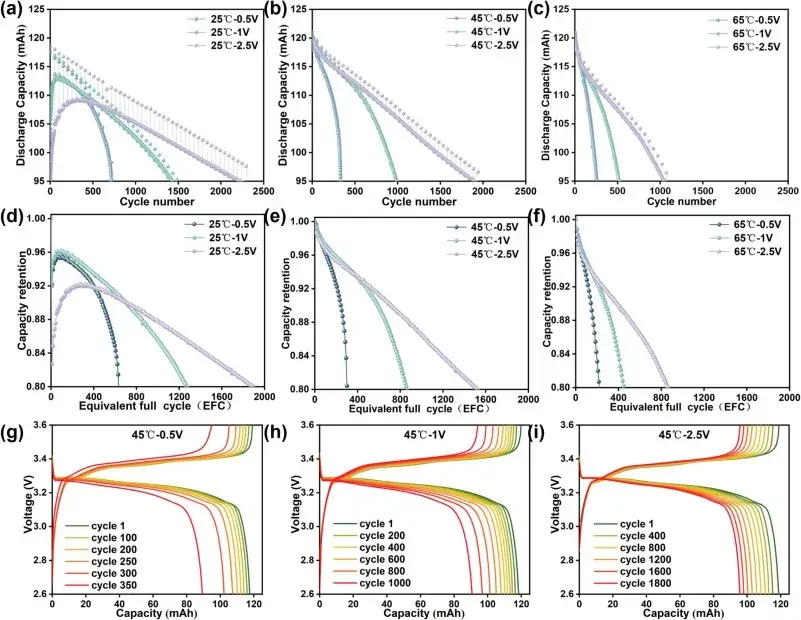

5.1 Accelerated Life Degradation

The orthogonal experimental design quantified a powerful synergistic effect. Battery life acceleration factors reached 7.33x under 45°C/0.5V conditions and 8.80x under 65°C/0.5V, far exceeding the impact of either stressor alone.

Figure 1. Validation of the accelerated aging effect under coupled stress of high temperature and deep over-discharge.

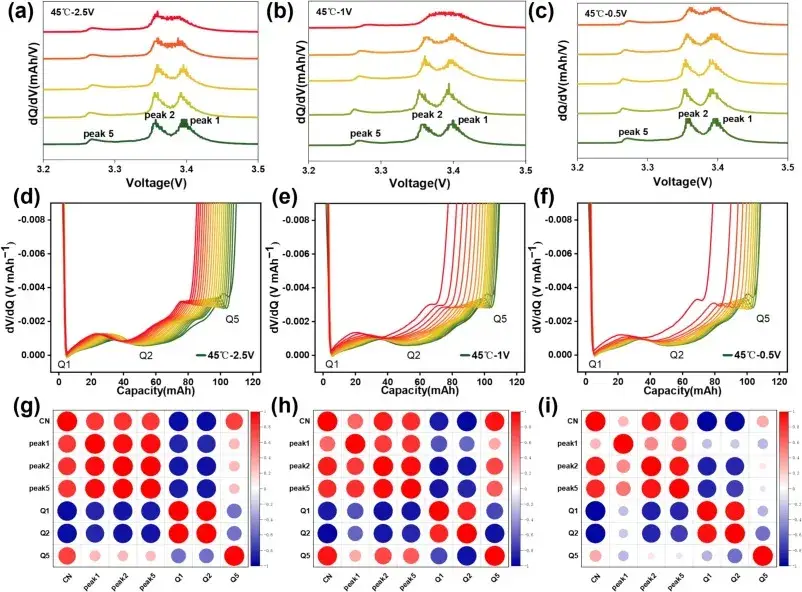

5.2 Three-Stage Aging Evolution

Aging consistently exhibited three distinct stages: activation, linear decay, and accelerated decay. Increasing temperature and discharge depth shortened the linear stage and brought forward the accelerated decay phase, accompanied by significantly increased polarization.

Figure 2. IC/DV curves under different coupled stress conditions and correlation analysis of stress factors.

5.3 DCIR as a Critical Failure Indicator

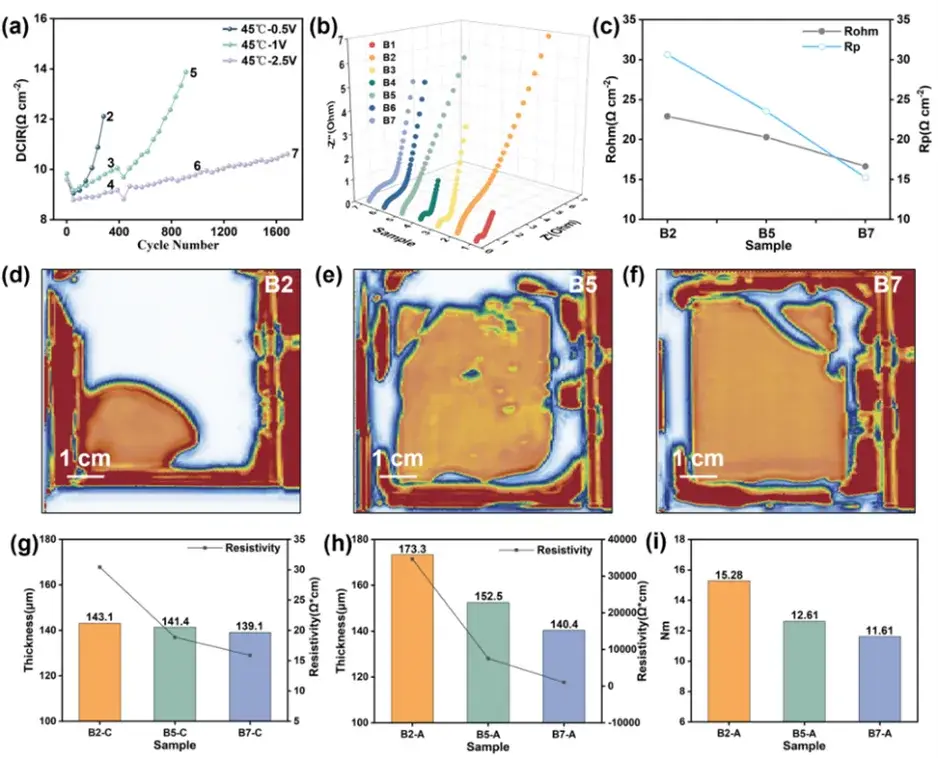

The evolution of DCIR provided a clear, non-destructive marker for failure stage transition. Under moderate 2.5V discharge, DCIR increased linearly. At a deep discharge of 1.0V, its growth shifted from linear to exponential. At the extreme 0.5V cutoff, DCIR exhibited exponential growth from the beginning. This inflection point reliably indicates the onset of synergistic failure mechanisms like SEI breakdown, dead lithium accumulation, and metal deposition.

Figure 3. DCIR curves under different coupled stress conditions, alongside impedance, electrolyte wetting, electrode thickness, and resistance data.

6. Multi-scale Materials Diagnostics: Root Causes of Coupled Failure

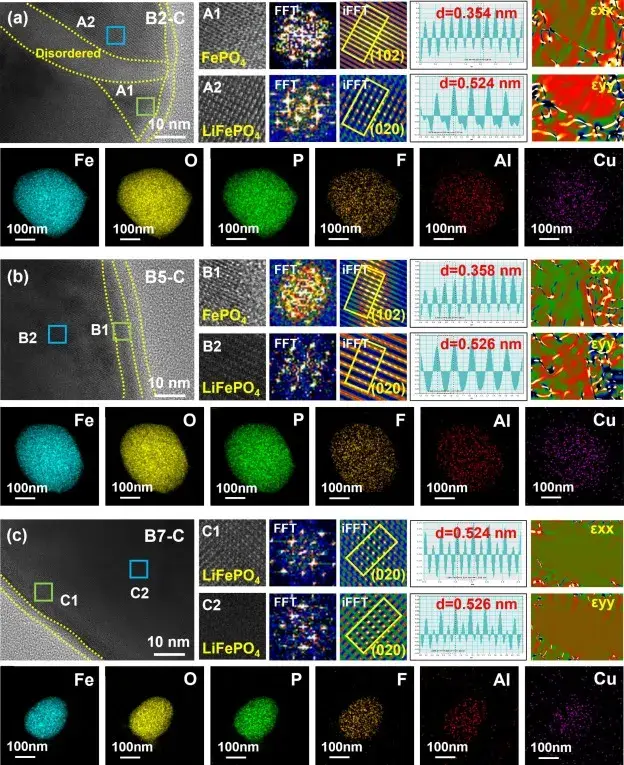

Combining microscopy and spectroscopy uncovers mechanistic details:

-

Graphite anode: deep overdischarge causes graphite structural collapse and pronounced SEI thickening. ToF-SIMS and TEM show concentrated Li- and SEI-rich layers; μXRF and μ-probe mapping reveal copper enrichment consistent with current collector dissolution and migration.

-

Copper current collector: under severe deep-discharge and high temperature, Cu dissolves and migrates across the cell, eventually depositing on the cathode surface—further disrupting electrode function.

-

LFP cathode: at extreme coupling (65 °C / 0.5 V) evidence of FePO₄ phase separation and lattice damage appears, indicating cathode structural degradation beyond typical cycling effects.

-

Macroscopic: ultrasonic imaging verified gas generation and electrode delamination in heavily stressed cells.

These observations show that thermal and overdischarge stresses synergistically destabilize both electrodes and the cell’s internal chemistry, generating unique failure pathways that accelerate DCIR and capacity loss.

Figure 4. TEM results showing material degradation under different coupled stress conditions.

7. Practical Implications For Monitoring, Testing and System Management

From an engineering viewpoint the study suggests several actionable points:

-

Use DCIR inflection detection as a field-deployable, nondestructive early-warning metric to trigger protective actions or further inspection.

-

Design accelerated aging tests that combine thermal and electrical stressors realistically, rather than treating them independently, to obtain valid lifetime projections. The orthogonal design framework provides an efficient blueprint.

-

Mitigate deep overdischarge risk through BMS policies, especially in systems that may experience elevated ambient temperatures.

-

Consider materials and manufacturing countermeasures (improved SEI stabilizers, copper corrosion inhibitors/coatings, and cathode microstructure optimization) to resist coupled stress.

8. Conclusion

This comprehensive multi-scale study demonstrates that thermal and overdischarge stresses act synergistically to accelerate aging in LFP batteries and can trigger atypical failure modes (copper dissolution, FePO₄ phase separation) under extreme coupling. The identification of a DCIR inflection point as a nondestructive marker of failure-mode transition is a particularly practical outcome. These insights should inform more realistic accelerated test protocols, BMS safeguards and materials design choices for safer, longer-lived LFP batteries systems.

9. Original Article

Rui Tang, Yuelei Xu, Jinyang Dong, Qi Shi, Kang Yan, Yibiao Guan, Yun Lu, Yu Su, Jinzhong Liu, Fangze Zhao, Yi Jin, Ning Li, Yuefeng Su, Feng Wu, Lai Chen. Thermal-overdischarge coupling induced aging mechanisms in LiFePO4 batteries: insights from multi-scale electrochemical and material diagnostics. Applied Energy, 2025, 401: 126870.

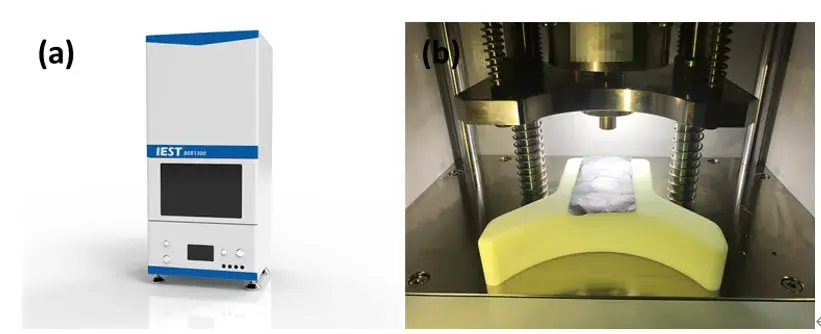

10. Testing Instrument Recommended

IEST Battery Electrode Sheet Resistance Tester(BER2500)

The BER Series Multifunctional Electrode Resistance Analyzer combines a high-precision pressure control system with integrated capabilities for electrode thickness measurement and resistance analysis. Using the double-sided controllable pressure disc electrode method, this electrode resistance analyzer directly measures the total through–thickness resistance of practical electrode samples, including coating resistance, coating–current collector contact resistance, and current collector resistance. It is an ideal tool for electrode formulation development and process stability monitoring.

Subscribe Us

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.