-

iestinstrument

A Universal Strategy for Precise Control of Initial Coulombic Efficiency in Li-Rich Mn-Based Cathode Materials

Authors: Dong-Liang Peng (Prof.), Qingshui Xie (Senior Researcher), Weibin Guo (first author), et al.

Source: A Universal Strategy toward the Precise Regulation of Initial Coulombic Efficiency of Li-Rich Mn-Based Cathode Materials, Adv.Mater., 2021, DOI:10.1002/adma.202103173.

1. Abstract

We report an oleic-acid (OA)-assisted interface engineering strategy that reproducibly introduces cation and anion dual defects together with an in-situ surface reconstruction layer in Li-rich Mn-based cathode materials (PLRM). By simply varying OA treatment time, the strategy enables precise tuning of the initial coulombic efficiency (ICE) and delivers improved reversible capacity and rate capability. The method is demonstrated as a generally applicable approach across Li-rich Mn-based systems.

2. Introduction

Improving the initial coulombic efficiency (ICE) of Li-rich cathodes is essential for practical high-energy lithium-ion batteries. In this work, an OA-assisted interface treatment is applied to a prototype Li-rich Mn-based material (PLRM). The treatment yields controllable lithium vacancies and transition-metal (TM) defects, while forming an organic coating that converts during subsequent annealing into a reconstruction layer featuring spinel/layered heterostructures and carbonaceous coverage. These structural modifications produce measurable improvements in electronic conductivity, charge-transfer resistance, reversible capacity and rate performance.

3. Sample Preparation and Testing

-

Synthesis of the pristine Li-rich manganese-based material (PLRM).

-

Preparation of OA-treated samples with different processing times: OAT-1, OAT-3, OAT-5.

-

Analysis included composition, crystal structure, morphology, powder conductivity, compaction density, and electrochemical performance.

4. Results and Analysis

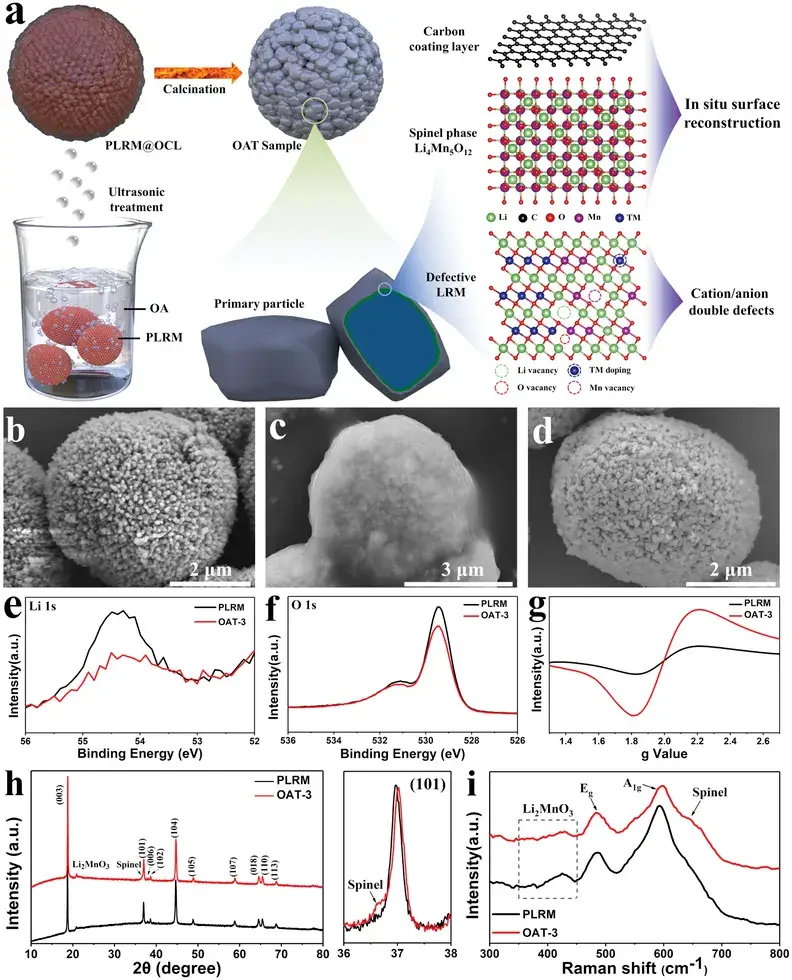

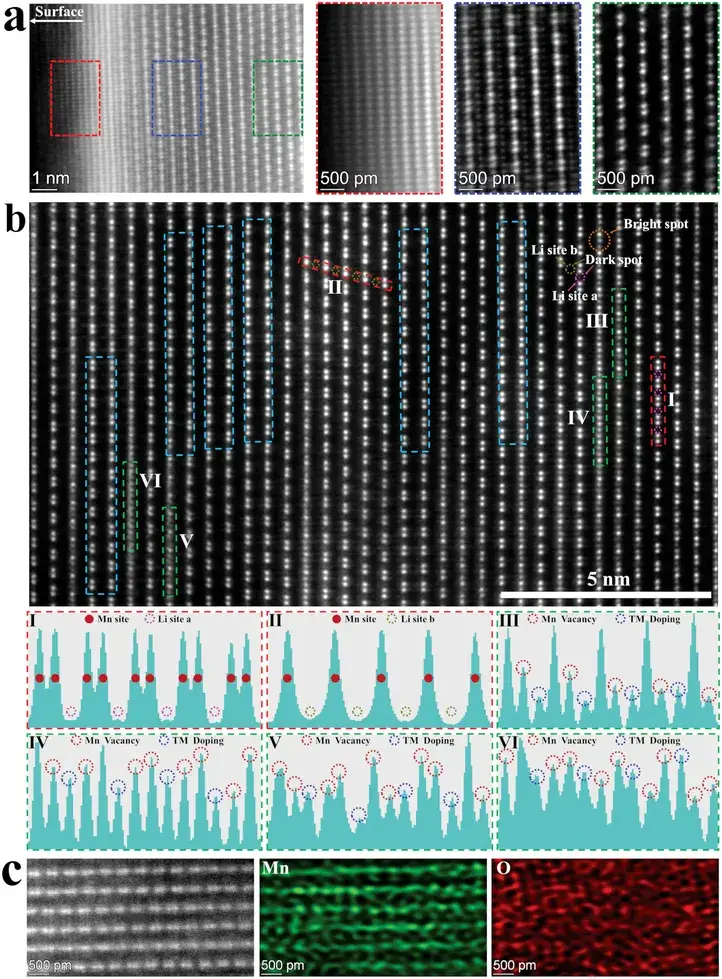

Comprehensive analysis of PLRM and OAT-3 revealed that OA provides abundant H⁺ ions to exchange with Li⁺ ions in PLRM, creating Li defects. Simultaneously, a self-polymerization reaction forms a uniform organic coating layer (OCL) on the PLRM surface. During subsequent calcination, transition metal (TM) ions occupy Li sites, leading to TM defects (Mn vacancies and TM doping). The OCL gradually carbonizes in air, introducing oxygen vacancies and triggering the in-situ formation of a surface reconstruction layer (comprising a spinel/layered heterostructure and a carbon coating).

Figure 1. Schematic of the OA-assisted engineering strategy and corresponding morphology, composition, and structure characterization data.

5. Electrochemical Performance Enhancement

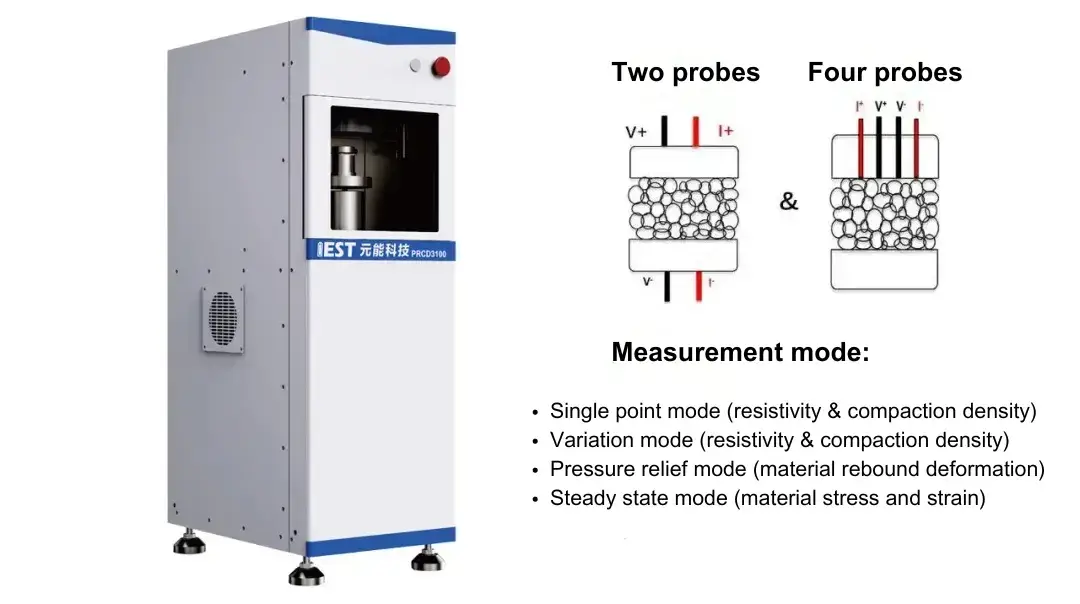

Comparing the powder compaction density and conductivity before and after treatment showed almost unchanged density. However, the OAT-3 sample exhibited significantly higher conductivity than PLRM. Electrochemical Impedance Spectroscopy (EIS) on coin cells confirmed this, showing substantially reduced electronic and charge transfer resistance for OAT-3. This indicates that introducing oxygen vacancies and the in-situ surface reconstruction layer enhances the material’s conductivity.

Figure 2. Comparison of powder compaction density & conductivity before/after treatment, and EIS results.

6. Precise Control of Initial Coulombic Efficiency

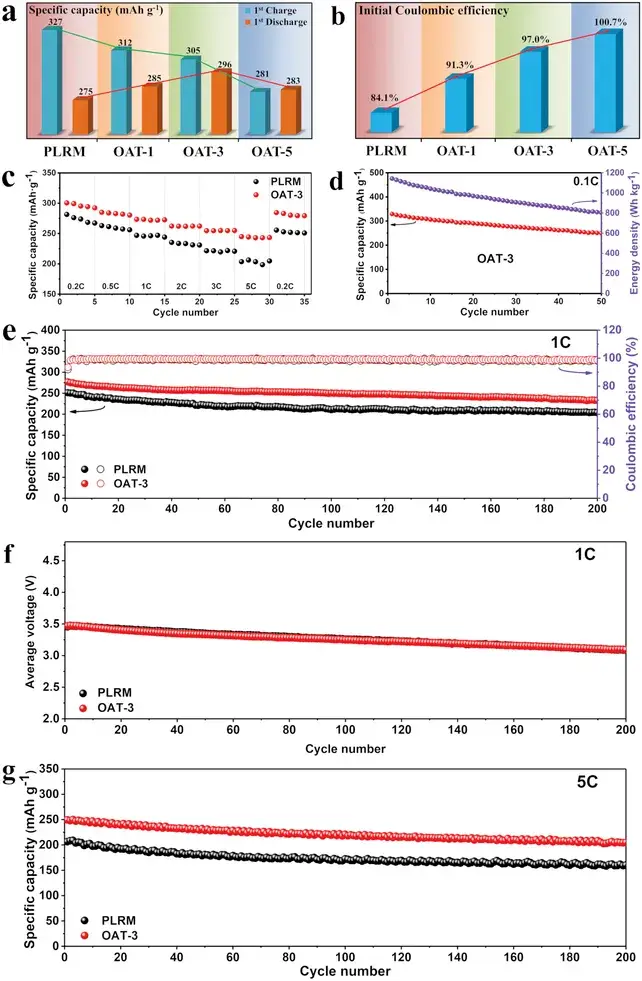

Electrochemical performance tests (Figure 3) revealed that as OA treatment time increased, the first charge capacity gradually decreased, while the first discharge capacity initially increased then decreased. Consequently, the Initial Coulombic Efficiency was precisely controlled, increasing from 84.1% to 100.7%. This demonstrates that simply adjusting the OA treatment time allows for fine-tuning of the initial coulombic efficiency.

Furthermore, OAT-3 exhibited superior rate capability compared to PLRM. Discharge capacities at 0.2, 0.5, 1, 2, 3, and 5 C were 301, 285, 274, 262, 255, and 245 mAh g⁻¹, respectively. When returning to 0.2 C after cycling at 5 C, the capacity recovered to 285 mAh g⁻¹, indicating excellent electrochemical reaction kinetics and structural stability. At 0.1 C, OAT-3 delivered a high specific capacity of 330 mAh g⁻¹ and a high energy density of 1143 Wh kg⁻¹. Additionally, OAT-3 showed higher discharge capacity and capacity retention after 200 cycles at both 1 C and 5 C, confirming better cycling stability. The minimal difference in average voltage between PLRM and OAT-3 during 1 C cycling indicates that this mild OA-assisted strategy does not sacrifice voltage stability.

Figure 3. Electrochemical performance test results for PLRM and OAT samples with different treatment times.

7. Discussion — Why Initial Coulombic Efficiency is tunable and improved

The observed improvements can be attributed to two key factors:

-

Dual defect engineering (cation + anion): Lithium vacancies lower Li-diffusion barriers and thus enhance Li-ion diffusivity.

-

In-situ surface reconstruction: The reconstructed spinel/layered heterostructure and carbonized surface increase electronic conductivity and stabilize lattice oxygen, which together reduce parasitic reactions that consume lithium during first cycles and therefore raise initial coulombic efficiency.

These mechanisms act in concert to enable precise adjustment of ICE simply by varying OA exposure time.

8. Practical considerations and equipment note

The OA-assisted approach is facile and appears broadly applicable to other Li-rich Mn-based cathodes. For materials development and QA, synchronized measurements of tap density and powder electrical resistance are useful diagnostics: the IEST Powder Resistivity & Compaction Density Measurement System(PRCD Series) is recommended for simultaneous two-probe/four-probe testing across compression states and for multi-point evaluation, including single-point, multi-point and compression-release rebound modes.

9. Summary

In summary, a simple and universal OA-assisted interfacial engineering strategy successfully introduced dual cation-anion defects and an in-situ surface reconstruction layer into the LRM material. This approach enabled precise control of the initial coulombic efficiency from 84.1% to 100.7%, while simultaneously enhancing reversible capacity and rate performance. The introduced dual defects lower the diffusion barrier for Li⁺ ions, improving their diffusion rate. The induced surface reconstruction layer enhances conductivity and stabilizes surface lattice oxygen. Consequently, the OAT-3 sample achieves a high specific capacity of 330 mAh g⁻¹ and a high energy density of 1143 Wh kg⁻¹ at 0.1 C.

10. References

Weibin Guo, Chenying Zhang, Yinggan Zhang, Liang Lin, Wei He, Qingshui Xie,* Baisheng Sa, Laisen Wang, Dong-Liang Peng,* A Universal Strategy toward the Precise Regulation of Initial Coulombic Efficiency of Li-Rich Mn-Based Cathode Materials, Adv.Mater., 2021, DOI:10.1002/adma.202103173.

11. Recommended Testing Equipment from IEST Instrument

Powder Resistivity & Compaction Density Measurement System(PRCD Series)

-

Simultaneously measures compaction density and resistance of all lithium battery powders under pressure application and release.

-

Supports both two-probe and four-probe test methods.

-

Offers three primary test modes:

a. Single-point pressure application with synchronous testing.

b. Multi-point pressure application with synchronous testing.

c. Rebound testing under both pressure application and release conditions.

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.