-

iestinstrument

Charging Method of BYD Blade Battery

1. Background

The BYD Blade Battery is an improved lithium iron phosphate battery, and there are three basic structures inside each battery, the battery cell and the battery pack. BYD Blade battery have been widely used in fields such as electric vehicles and energy storage due to their high energy density, high safety, and long life.

The following are the BYD blade battery charging recommendations and precautions to help you better maintain the performance and life of the BYD blade battery:

2. The Correct way to the BYD Blade Battery Charging Recommendations

2.1 Use the charging equipment recommended by the original manufacturer

Use chargers, home charging posts or public charging posts officially provided or recommended by BYD, and avoid using charging equipment from informal channels to prevent unstable voltage or incompatibility.

2.2 Avoid overcharging and deep discharging

- It is most suitable to charge when the remaining power of the vehicle is 20%-30%, and it is the best power to charge to 80%, which can effectively improve the service life of the battery.

- Once fully charged (near or at 100%), disconnect the charger promptly to avoid the detrimental effects of prolonged “float charge.”

2.3 Follow the principle of slow charging priority

When using a charger to charge, use slow charging as much as possible for charging, with slow charging as the main and fast charging as supplementary, so as to slow down the battery decay speed.

2.4 Environmental temperature control

Optimum charging temperature: 0°C to 35°C. Too low or too high a temperature may result in reduced charging efficiency or accelerated battery aging.

2.5 Periodic Full Charge for Calibration

Schedule a complete charge cycle (typically via slow charging) at regular intervals. This helps calibrate the battery management system (BMS) and ensures accurate state-of-charge (SOC) display.

3. Recommendations For Special Charging Scenarios

3.1 Long-term parking

- If the vehicle is not used for a long period of time, it is recommended to keep the battery level in the 40%-60% range.

- If the battery sits unused for longer than 14 days, perform a full charge(100%) followed by discharge to between 40–60%.

3.2 Fast charging when going out

- When fast charging, it is recommended not to charge to 100%. The final stage of fast charging (80%-100%) is more stressful for the battery.

- During fast charging, avoid charging in direct sunlight or closed, stuffy environments.

3.3 Charging at low temperatures in winter

At low temperatures (e.g., below 0°C), some batteries may enter the warm-up mode, resulting in slower charging. You can allow the vehicle to warm up before charging, or warm it up by driving it while in use, and then charge it.

4. Summary Table: Best Practices for BYD Blade Battery Charging

| Practice | Recommendation |

|---|---|

| Daily Charging | Charging to 100% is fine with LFP chemistry; do so regularly (e.g. weekly). |

| Deep Discharge | Avoid discharge below 20%, but allow it occasionally (<10%) every few months for SOC calibration. |

| Float Charging | Disconnect immediately after reach full charge to avoid prolonged float. |

| Charger Type | Use OEM or certified chargers for safe and efficient charging. |

| Charge Rate | Prefer slow/AC charging; use fast/DC charging only when necessary. |

| Temperature | Charge within optimal ambient temperature ranges; avoid extremes. |

| Long-Term Storage | Maintain at 40–60% SOC if parked for extended periods. |

| Initial Charge | Fully charge before first use; limit long charging sessions to 8–10 hours. |

5. BYD Official Statement:

“Blade Battery’s cycle life exceeds 3,000 cycles at 25°C while retaining 80% capacity when operated within 20%–80% SOC. Avoid sustained high temperatures (>45°C) during charging.”

6. Advantages of Blade Battery

Compared with ternary lithium batteries, BYD blade battery have higher safety (high temperature resistance), lower cost, and longer service life, and blade batteries have inherited this very well, and on this basis one floor.

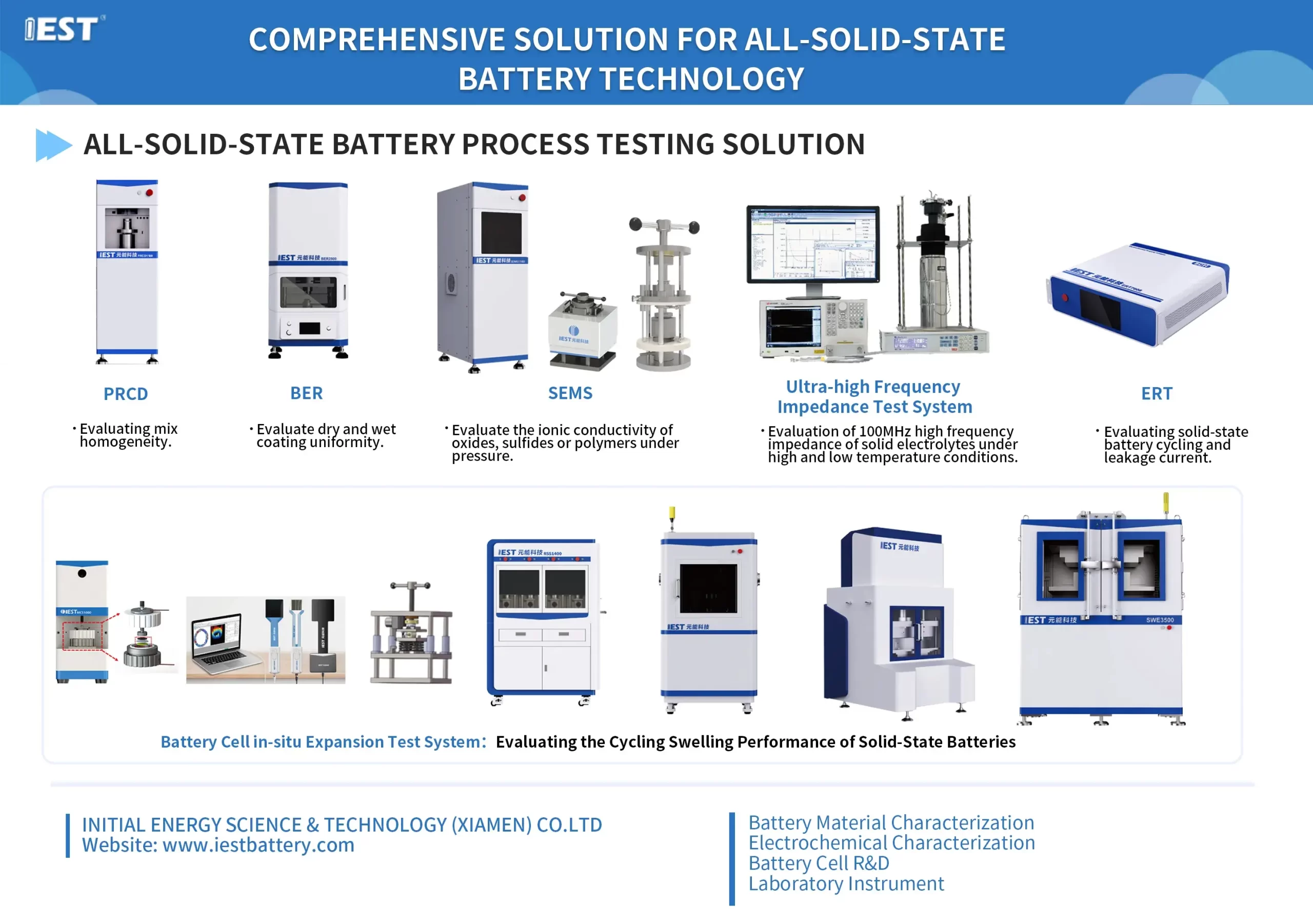

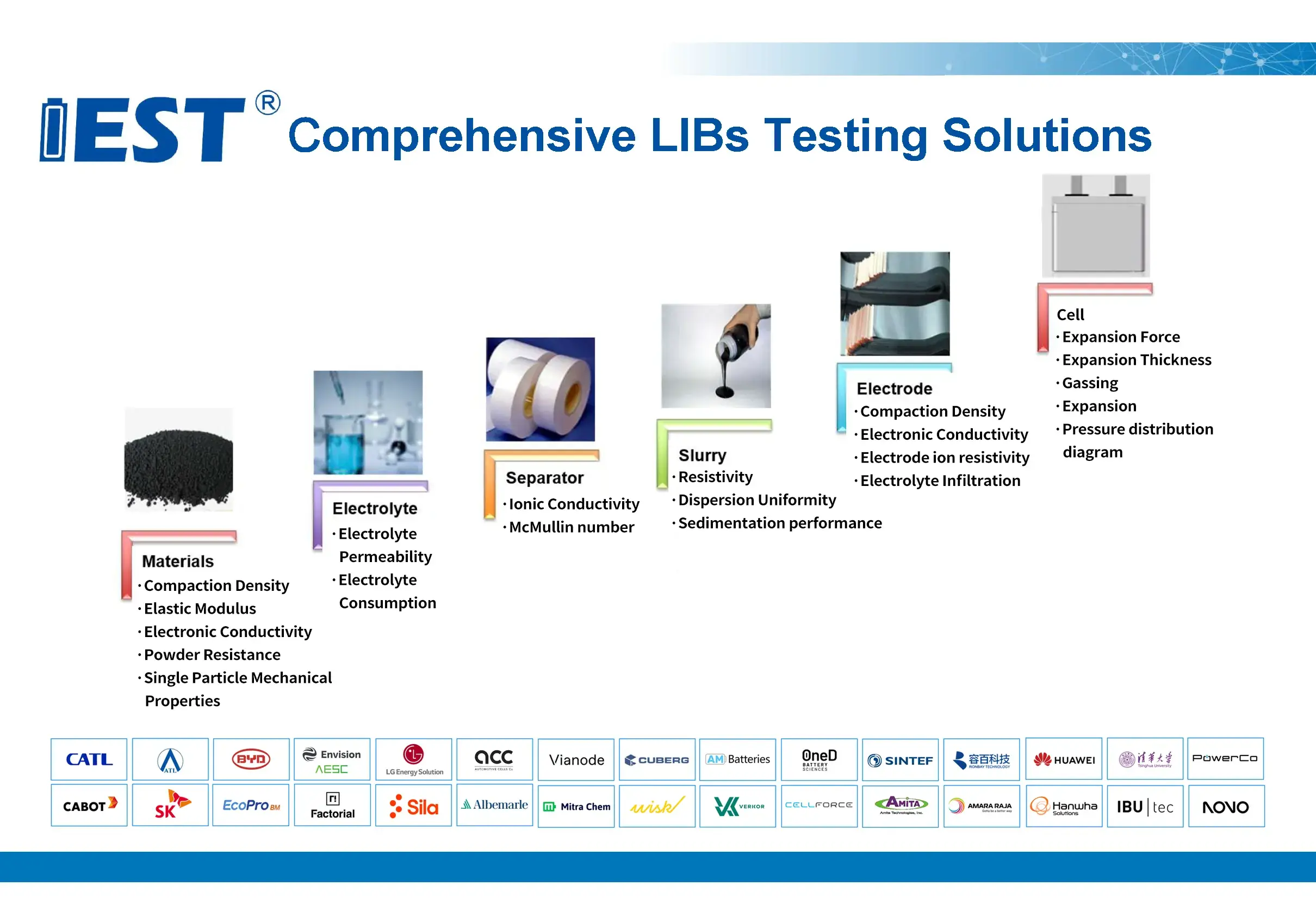

7. Lithium Battery Testing Solutions Recommend:IEST Instruments

IEST is a high-tech enterprise focusing on R&D and production of lithium ion battery tester. IEST is a professional manufacturer that integrating laboratory instrument R&D and production, method development, instrument sales and technical services. Committed to providing leading testing solutions and services for the global new energy field, IEST company serves key clients like CATL, BYD, Huawei, Svolt, GM, Leyden, Sintef, Factorial, Cabot, Cuberg.

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.