-

iestinstrument

IEST Characterization Solutions Facilitate Top Journal Research: Integrated Polyanion-layered Oxide Cathodes Enabling 100,000 Cycle Life For Sodium-ion Batteries

1. Introduction

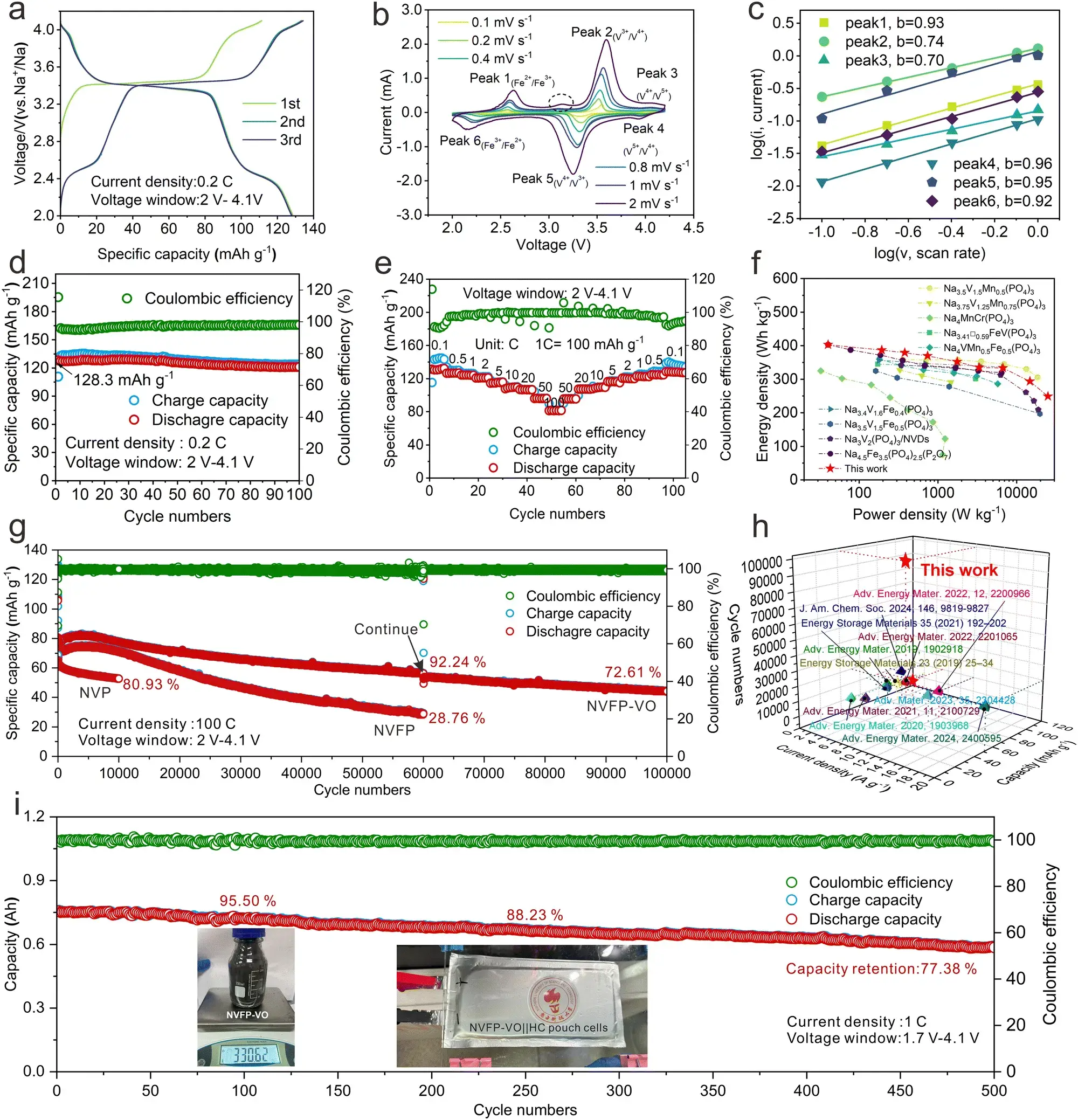

Recently, the team of Academician Zhao Tianshou, Han Meisheng, and Zeng Lin from Southern University of Science and Technology (SUSTech) published a breakthrough study on sodium-ion battery cathode materials in the top-tier international journal Energy & Environmental Science (EES), titled “Integrated polyanion-layered oxide cathodes enabling 100,000 cycle life for sodium-ion batteries“. The first authors are Zou Zhiyu and Mu Yongbiao from SUSTech. This research designed and constructed for the first time an integrated polyanion-layered oxide cathode material (NVFP-VO), achieving over 100,000 cycles at a high rate of 100C with a high capacity retention of 72.6%, setting a new cycle life record for polyanion-type cathode materials.

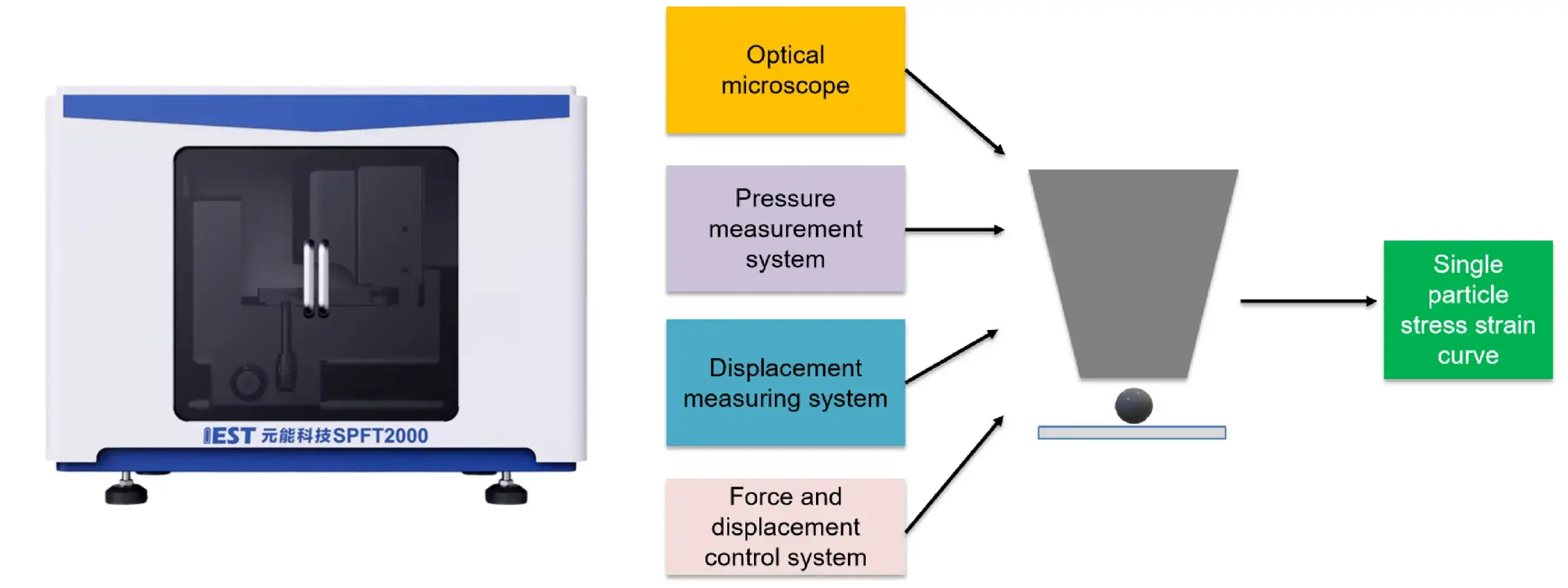

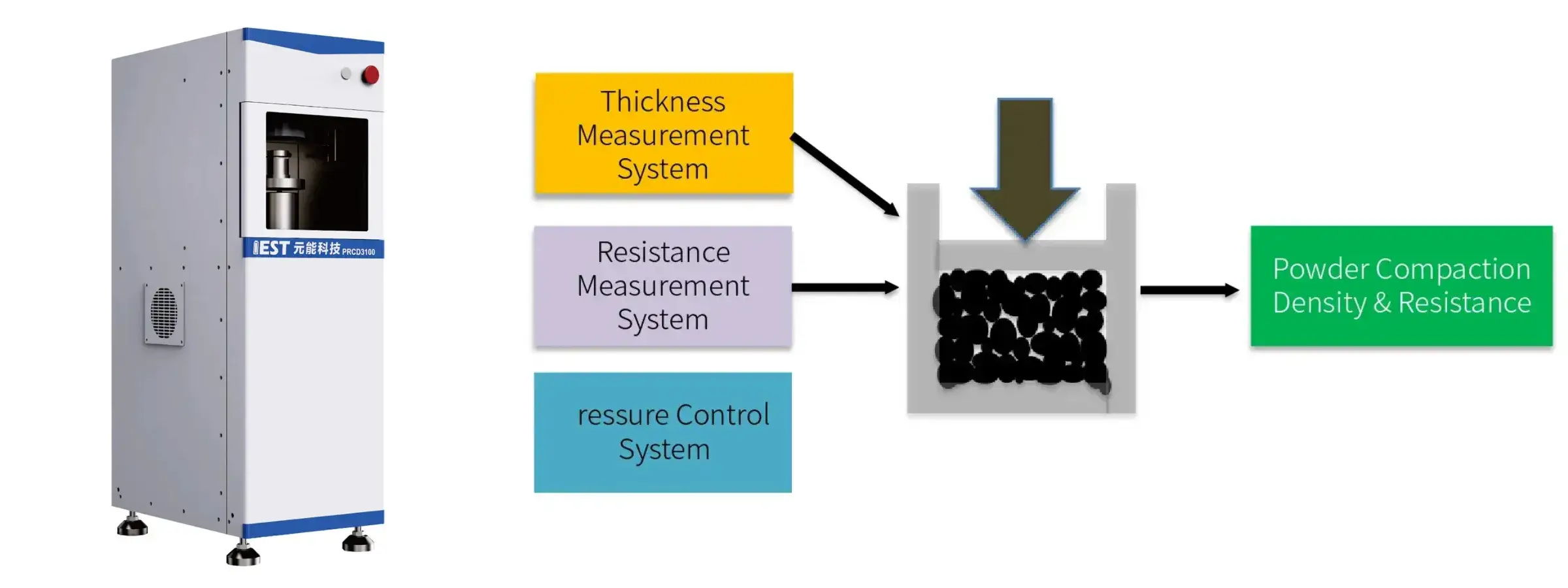

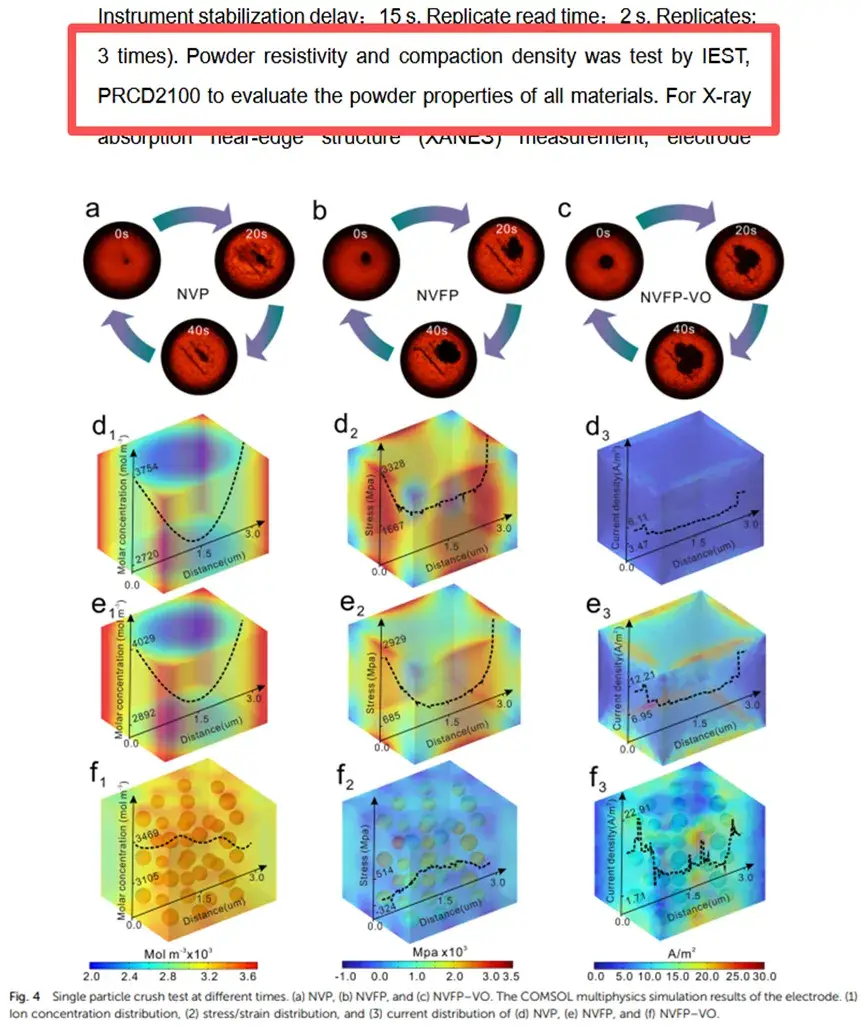

Notably, to elucidate the mechanisms behind the enhanced electrode kinetics, electrical conductivity, and mechanical stability in the composite cathode, the authors employed multi-physics simulations to analyze the ion concentration distribution, stress/strain accumulation induced by sodium ion intercalation, and electrode current density distribution. Prior to simulation, IEST Single Particle Force Properties Test System(SPFT series) and IEST Powder Resistivity & Compaction Density Measurement System (PRCD series) were used to measure intrinsic material property parameters such as Young’s modulus and electrical conductivity. The inherent mechanical behavior and physical properties of the active materials played a crucial supporting role in the material research, key characterization, and simulation data. The publication of this journal article also once again provides a typical example of the in-depth application of IEST’s SPFT series Single-Particle Mechanical Performance Evaluation System and PRCD series Resistivity and Compaction Density Evaluation System in high-level scientific research, further enhancing the international influence of domestic equipment.

Figure 1. IEST Single Particle Force Properties Test System and Test schematic

Figure 2. IEST Powder Resistivity & Compaction Density Measurement System and Test schematic

2. Research Background: Bottlenecks and Opportunities for Sodium-Ion Batteries

Sodium-ion batteries show broad prospects in energy storage and low-speed electric vehicles due to the abundance of sodium resources and low cost. However, mainstream polyanion-type cathode materials (e.g., Na₃V₂(PO₄)₃) face challenges such as poor electronic conductivity, low specific capacity, and sluggish reaction kinetics, severely limiting their practical application. How to achieve ultra-long cycle life while improving energy density has become a core research challenge.

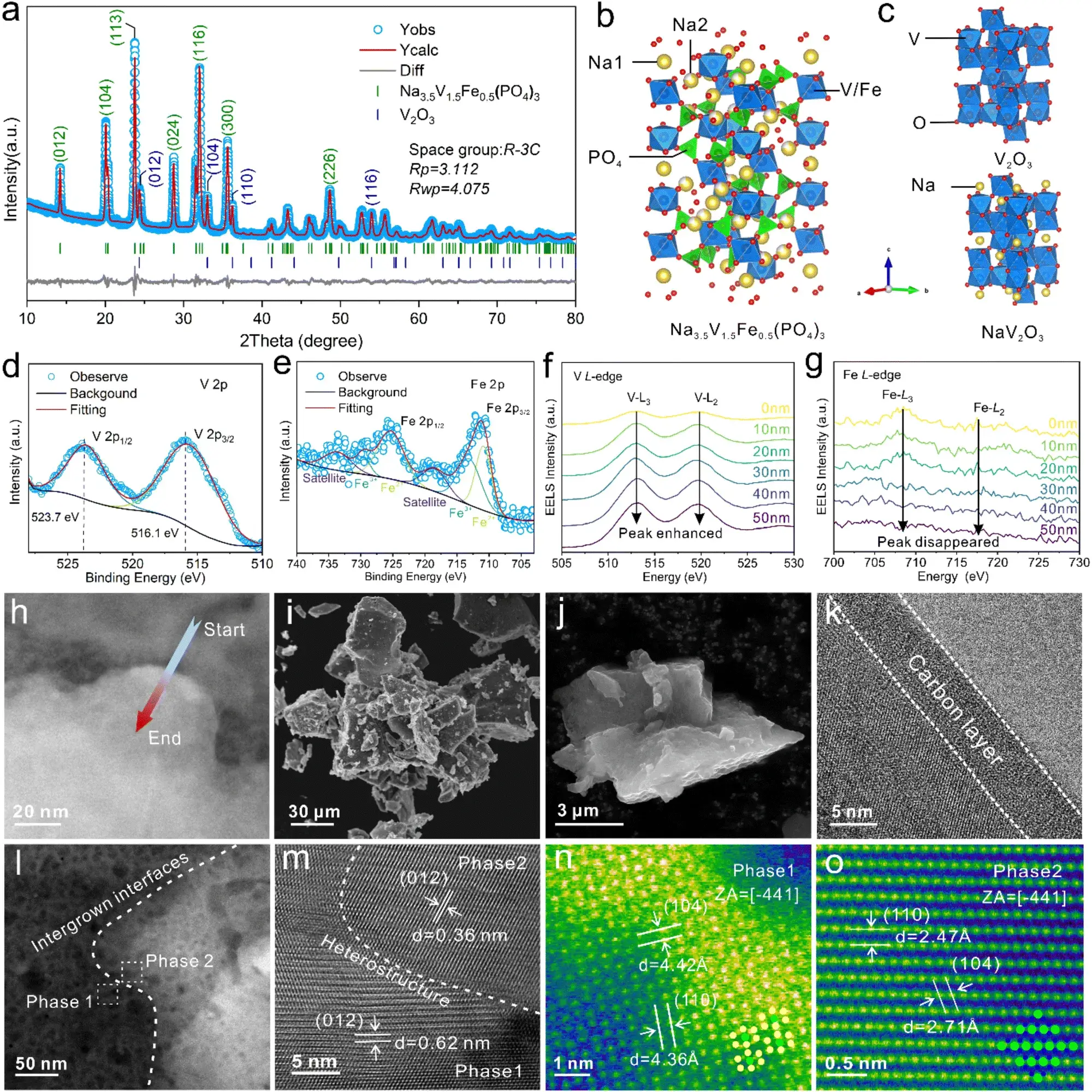

3. Material Design Breakthrough: Heterostructure + Multi-phase Integration

The research team innovatively proposed an integrated polyanion-layered oxide cathode, constructing a symbiotic biphasic heterostructure of Na~3.5~V~1.5~Fe~0.5~(PO₄)₃ (NVFP) and V₂O₃ (VO) embedded within a porous carbon framework via in-situ synthesis. The core advantages of this design include:

-

Fe Doping: Reduces the material bandgap, activates the V⁴⁺/V⁵⁺ redox couple, enhancing conductivity and capacity.

-

V₂O₃ Phase: Acts as a low-strain stabilizer, buffering volume changes and enhancing structural stability.

-

Porous Carbon Framework: Improves electron conduction capability and accommodates volume fluctuations during cycling.

-

Heterointerface Effect: Promotes charge redistribution, builds an internal electric field, and accelerates ion/electron transport.

4. Electrochemical Performance: Record-breaking Cycle Life and High-Rate Capability

Figure 3. Structural Characterization of the Symbiotic Heterojunction Cathode

The NVFP-VO cathode demonstrates outstanding overall performance in half-cells:

✅ High Reversible Capacity: Exceeds 130 mAh g⁻¹ at 0.1C.

✅ Ultra-high Rate Performance: Retains approximately 60% capacity at 100C.

✅ Ultra-long Cycle Life: Maintains 72.6% capacity retention after 100,000 cycles at 100C.

✅ High Energy Density: Estimated energy density reaches 403.2 Wh kg⁻¹ at 0.1C.

Furthermore, assembled Ah-level pouch full cells also exhibited an energy density of 153.4 Wh kg⁻¹ and stable performance for over 500 cycles.

Figure 4. Electrochemical Evaluation of the Composite Cathode

5. In-depth Mechanism Analysis: Synergistic Effects Revealed by Multiple Techniques

To clarify the intrinsic mechanisms for the performance enhancement, the research team utilized a combination of techniques:

-

In-situ XRD: Revealed the reversible structural evolution during charge/discharge and the pseudocapacitive behavior of VO.

-

Spherical Aberration-corrected TEM: Directly visualized the symbiotic interface between NVFP and VO.

-

PRCD Resistivity & Compaction Density: Characterized material conductivity properties.

-

SPFT Single-Particle Crushing: Evaluated intrinsic mechanical properties of the material.

-

XANES/EXAFS: Tracked valence changes and local structural evolution of V and Fe.

-

DFT Calculations: Confirmed that Fe doping and the heterointerface effectively reduce the Na⁺ migration energy barrier.

-

COMSOL Simulation: Modeled ion concentration, stress distribution, and current density, validating structural stability.

Figure 5. Single-Particle Crushing Test and COMSOL Multi-physics Simulation

6. Summary and Outlook

This study, through ingenious multi-phase integrated cathode design, successfully combines the advantages of the two mainstream cathode material types – polyanion and layered oxide cathode – achieving the unification of high energy density, fast-charging capability, and ultra-long cycle life. It points a new direction for the development of next-generation sodium-ion battery cathode materials.

7. Original Article

Integrated polyanion-layered oxide cathodes enabling 100 000 cycle life for sodium-ion batteries. Electronic supplementary information (ESI) available.

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.