-

iestinstrument

Rapidly Assessing Pouch Cell Flatness With Pressure Mapping System

1. Abstract

This article demonstrates a practical, quantitative alternative: using a IEST Battery Pressure Mapping System(BPD1000) to instantly visualize and quantify surface pressure distribution, to characterize initial flatness across several pouch cell designs. . This method offers a fast, full-field assessment critical for process debugging and batch consistency monitoring.

2. Background

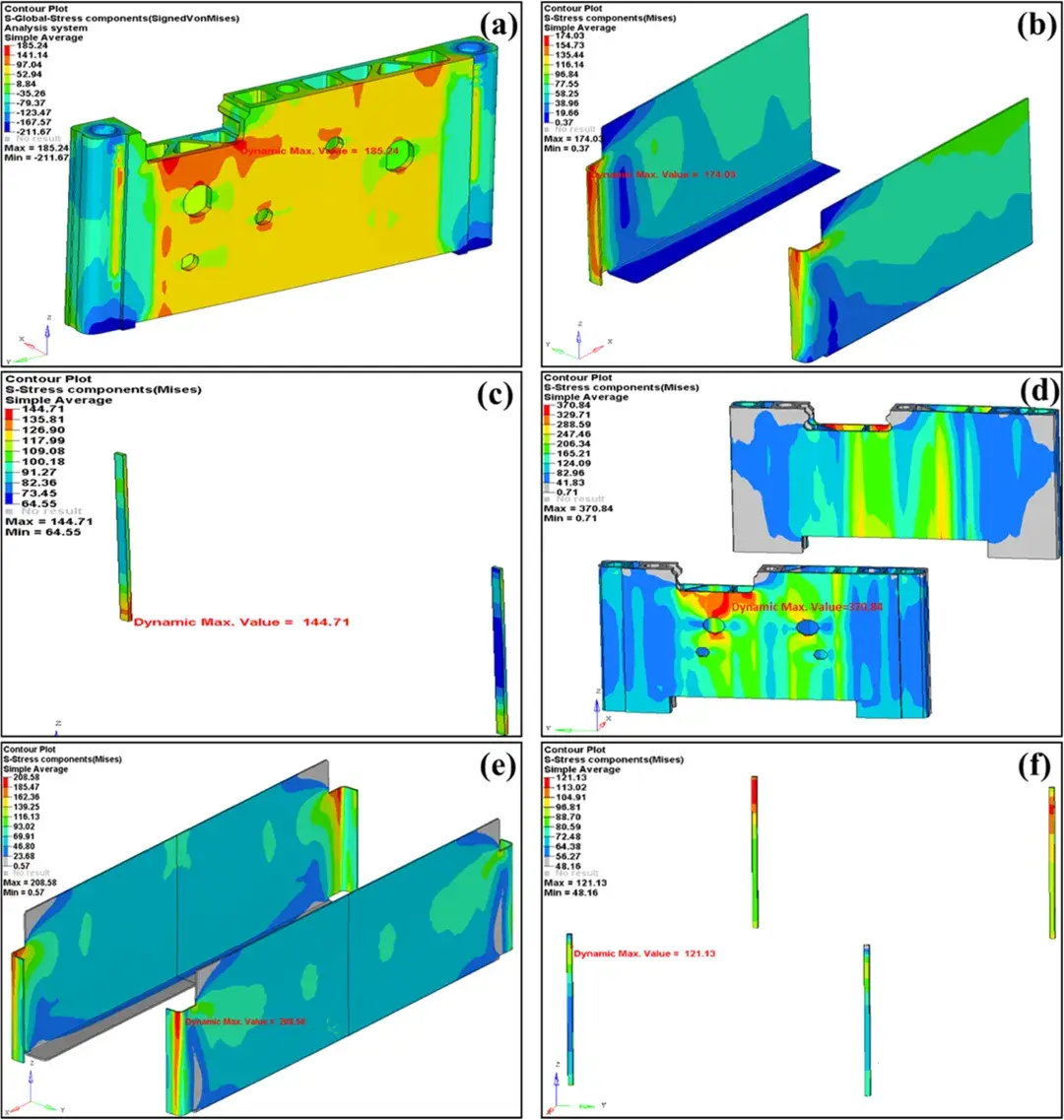

In the existing process, the method of measuring the flatness of the pouch cell is mainly the visual observation method, the micrometer thickness measurement or the laser scanning method. Visual observation method is to use the visible light to observe the surface state of the cell, is a roughly but not quantitative observation method, although the visible light observation is fast, it can not quantitatively give the difference of the flatness of the cell. Laser scanning method is to use optical equipment to scan the whole contour of the cell into a 3D model, and then calculate the difference between the overall thickness value and the thickness value of the section, which can be measured quantitatively, but the equipment is expensive, with limited application 1. Some researchers also simulated the surface force distribution mapping of the module cell through simulation(Figure 1), which can also see the obvious phenomenon of the uneven pressure distribution, which on the one hand is related to the initial flatness of the cell, on the other hand is also related to the stress distribution difference caused by the uneven current density distribution in the subsequent charge and discharge process 2.

Figure 1. Simulation of the stress distribution of the simulated module cells 2

3. Methodology: Integrating Pressure Mapping System with a Test Fixture

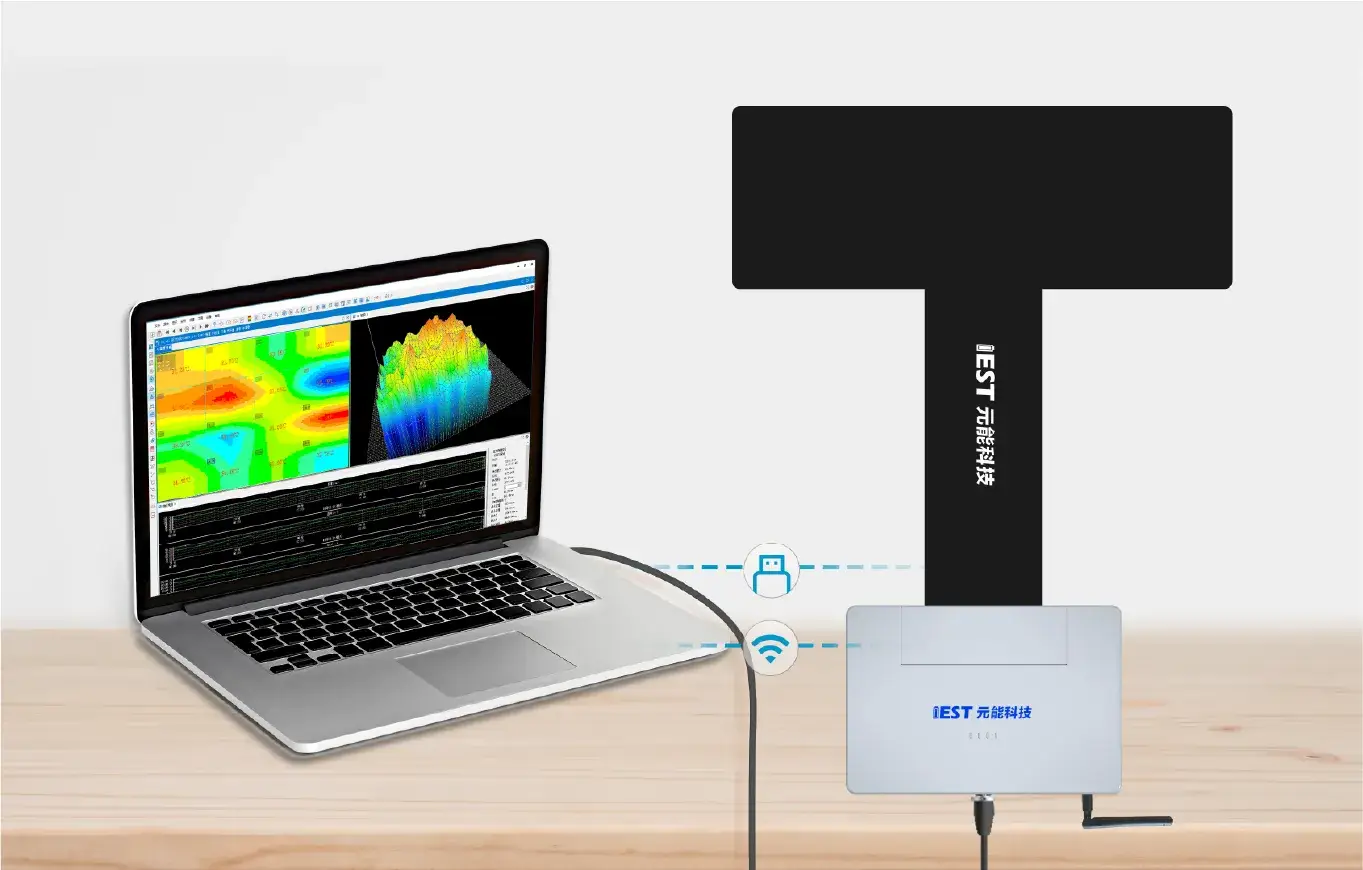

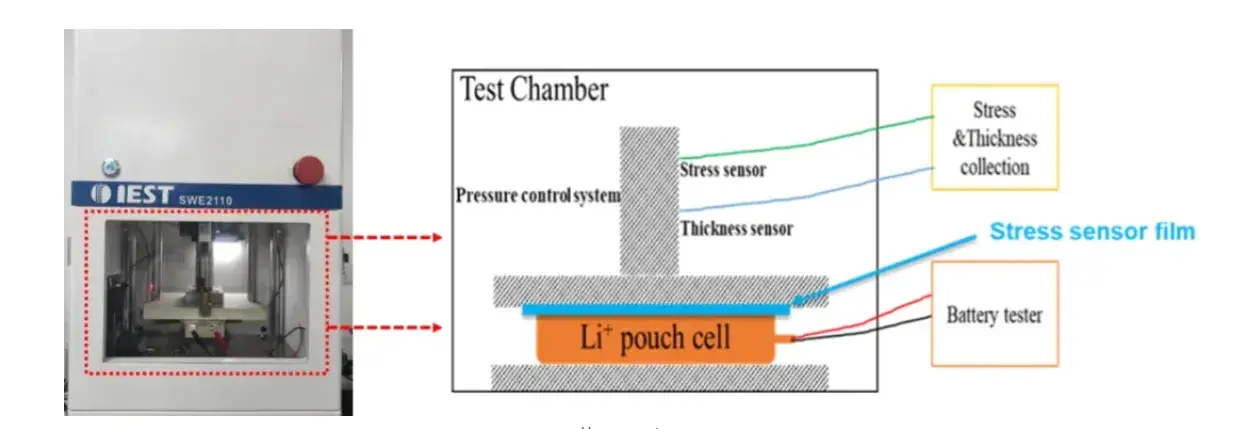

The core of this methodology is the IEST Battery Pressure Mapping System (BPD1000). The system utilizes thin, flexible pressure distribution films embedded with a high-density array of sensors, the pressure mapping setup supports an applied load up to approximately 8.8 MPa. For this study, the films were placed on the surface of pouch cells, which were then mounted inside the compression chamber of an IEST In-situ Swelling Analyzer(SWE2110).

Figure 2. IEST Battery Pressure Mapping System (BPD1000)

Figure 3. SWE2110 and schematic diagram of the cell pressure distribution test.

4. Test Parameter

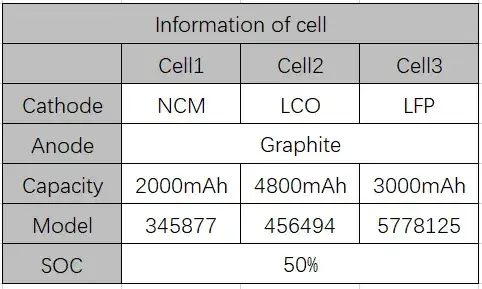

4.1 The Cell Information is Shown in Table 1

Table 1. Cell Information

4.2 Testing Process

Put the cell in the test chamber of in-situ swelling analyzer (SWE2110), place the pressure distribution film on the surface of the cell, set the constant gap mode, adjust the constant gap pressure of 300kg (i. e. apply 300kg external force to the cell), activate the pressure distribution system (BPD1000) and records local pressure distribution via pressure distribution films laid directly on the cell surface in real-time.

5. Results & Analysis: Decoding Pressure Maps to Diagnose Flatness

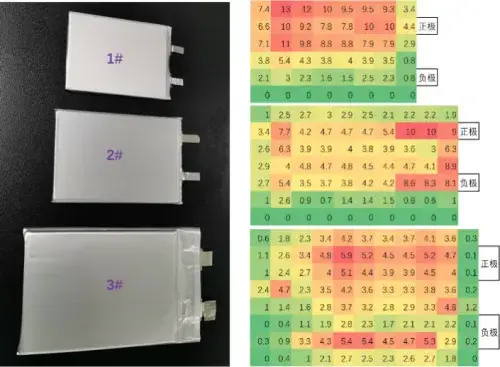

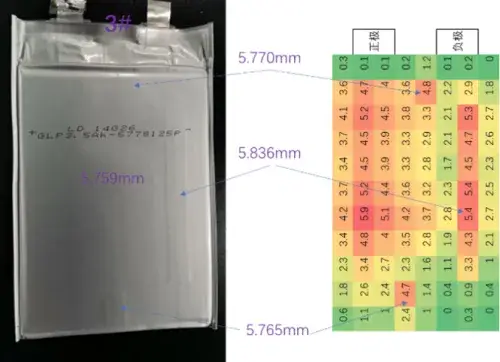

Using pressure mapping system (BPD1000) respectively test the pressure distribution of following three cells, according to 9.5*9.5mm divided into each small area, and the color scale display the cell force, as shown in Figure 4: the total measured force was less than the applied 300 kg, which is expected due to gaps between individual sensor pads and unmeasured edge effects.

Figure 4. Voltage and pressure change curve of the cell during charging and discharging

Further analysis of the surface of the different positions of the flatness reason, as shown in figure 4,5 because the aluminum foil crater size has larger margin, cell’s head tail shows no pressure pressure . The position of the finishing tape, show greater pressure, this is likely to be one of the important factors leading to its uneven.

Figure 5. Comparison between Cell pressure distribution and Physical Cell

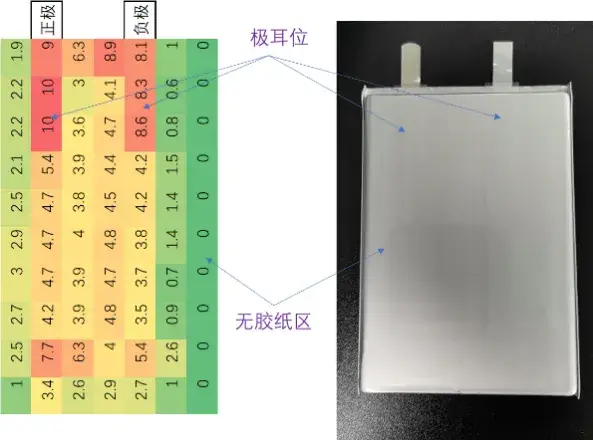

Analysis of the pressure distribution of 2 # cell is shown in Figure 6: it is obvious that the position of the positive and negative tab is obvious, and areas along the edges without tape showed negligible pressure. . This indicates that tab thickness and the strategic application of edge tapes are dominant factors influencing the flatness and pressure distribution for this cell design.

Figure 6. Comparison between Cell pressure distribution and physical cell

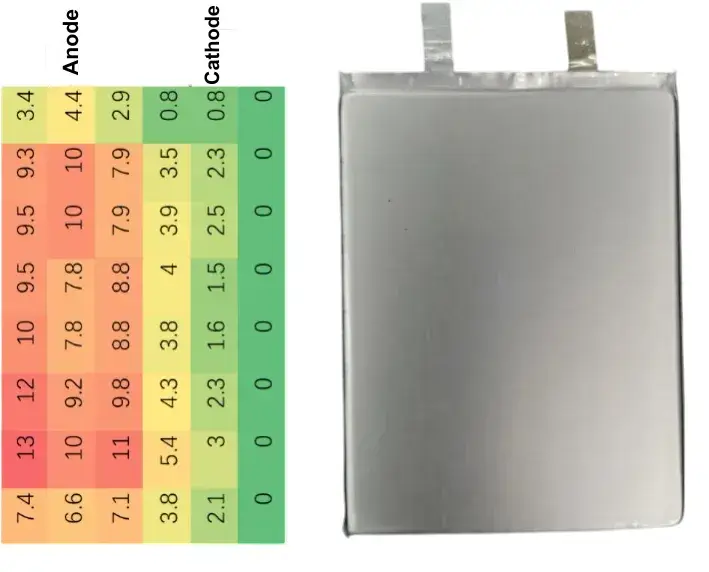

Cell #1 (Figure 7) did not show the same clear correlations with tabs or tapes as Cells #2 and #3. Its pressure distribution was more globally non-uniform, suggesting that other factors—such as intrinsic electrode coating uniformity, stack alignment, or laminate quality—play a more significant role in its overall flatness.

Figure 7. Comparison between Cell pressure distribution and physical cell

6. Root Causes and Implications of Non-Uniform Flatness

From the mapping and process review, we identified the main contributors to uneven cell thickness and pressure distribution:

-

Electrode foil thickness variation. Typical electrode sheet thickness lies between 100–200 μm. If a single-sheet thickness deviation exceeds 5 μm, and a stack contains 41 sheets, cumulative variation can reach ~0.2 mm — a non-negligible contribution to surface non-flatness.

-

Non-uniform separator or pouch film (aluminum-plastic laminate) thickness. These components can introduce localized bulges or depressions.

-

End-wrap (closure) tape. Tape thickness and its placement create local pressure peaks.

-

Stacking/lamination gaps. Poor sheet alignment or trapped voids during stacking lead to localized low-pressure regions.

-

Incomplete vacuum during electrolyte filling and sealing. Residual gas inside the pouch can produce local swelling after sealing.

-

Swelling from conductive additives/binders or electrolyte decomposition. Solvent uptake and gas generation during formation or aging also create uneven thickness profiles.

7. Implications for Performance and Manufacturing Control

When the thickness of the cell is not uniform, the electrode will be subjected to different aluminum-plastic film shell pressure in the process of charge and discharge, which may lead to the uniformity of charge and discharge state, and reduce the capacity and stability of the battery. Therefore, the flatness needs to be controlled to improve the consistency in the design and manufacturing. Special attention on processes include:

- Electrode coating and roll pressure thickness needs to be controlled to improve the thickness uniformity.

- Suitable thermal pressing process to improve the thickness uniformity.

- Aluminum-plastic film punching and assembly process to ensure the cell flatness.

- Good liquid injection fluid sealing process to ensure the removal of internal air and electrolyte uniformity.

8. Summary

This paper describes the surface flatness of the pouch cell by using the pouch cell pressure mapping system(BPD1000). From the result analysis, there is a certain correlation between cell process design and cell pressure distribution (flatness).

This application demonstrates that a pressure mapping system is a powerful tool for moving beyond subjective flatness checks. By providing immediate, quantitative, and visual data, it:

-

Accelerates Root-Cause Analysis: Quickly links pressure anomalies to specific design or assembly features (e.g., tabs, tapes, pocket dimensions).

-

Enables Standardization: Allows for the establishment of quantitative pass/fail criteria based on pressure distribution uniformity for batch release.

-

Guides Process Optimization: Offers direct feedback on the effectiveness of processes like hot pressing, vacuum sealing, and stack lamination in improving flatness.

Integrating pressure distribution films and analysis into cell development and quality control workflows provides a critical data layer for enhancing manufacturing consistency and building more reliable, high-performance battery packs.

9. References

[1].Bo Xu Ren Zhengxin Zheng Yanjun Ma Hua Liu Feng Wang Chiwei. Method for quantitatively determining the cell flatness [P]. China: CN112665548B, 2022.5.

[2].Yongkun Li, Chuang Wei, Yumao Sheng, Feipeng Jiao, and Kai Wu. Swelling Force in Lithium-Ion Power Batteries,Ind. Eng.Chem. Res,2020, 59, 27, 12313–12318.

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.