-

iestinstrument

IEST SEMS Characterization Solutions Enable Groundbreaking Research: Pressure-Free Silicon-based Anode Achieves 1000 Stable Cycles in All-Solid-State Batteries

1. Abstract

A research team led by Chen Songyan and Wang Mingsheng from Xiamen University has recently published a groundbreaking study on silicon-based anode materials for all-solid-state batteries in the prestigious journal Nature Communications, titled “Silicon-based all-solid-state batteries operating free from external pressure.” The first author, Dr. Zhang Zhiyong, designed and constructed a Li₂₁Si₅/Si–Li₂₁Si₅ bilayer composite anode, successfully enabling an all-solid-state battery to operate stably without external pressure. The battery achieved 1000 cycles at a current density of 2.5 mA cm⁻² with a capacity retention rate of 54.9% and a minimal volume expansion of only 14.5%, setting a new record for the cycle life of silicon-based all-solid-state batteries under pressure-free conditions.

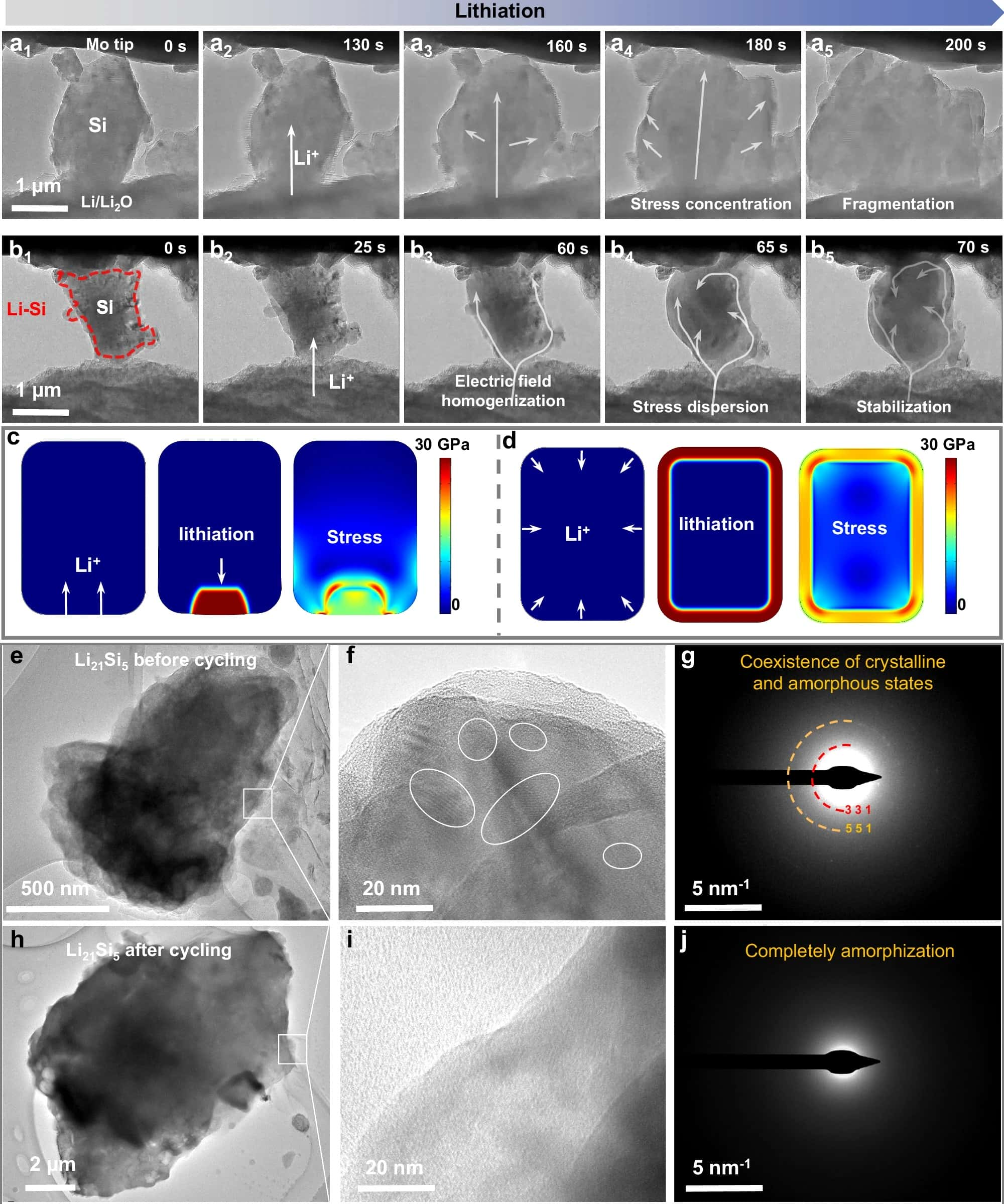

Notably, to clarify the interfacial stability and ion transport mechanism of this bilayer anode under pressure-free conditions, the authors employed COMSOL multiphysics simulations to model current density and stress distribution. Prior to simulation, the research team conducted a systematic analysis of the material’s microstructure, interfacial chemistry, surface potential, and lithium-ion states using various characterization techniques such as SEM, XRD, XPS, AFM, and SSNMR. This provided critical physical parameter support for the simulation modeling. The publication of this article once again highlights the essential role of multi-scale, multi-modal material characterization in mechanistic studies of all-solid-state batteries, offering a exemplary case of deep integration between domestic instrumentation and scientific research.

Figure 1. Structural characterization and surface potential of the Li21Si5/Si-Li21Si5 anode.

2. The Challenge: The “Pressure Dilemma” in All-Solid-State Batteries

All-solid-state batteries (ASSBs) are a pivotal next-generation energy storage technology, promising superior safety and high energy density. However, integrating high-capacity silicon-based anodes presents a major roadblock. Silicon undergoes dramatic volume expansion (up to ~300%) during cycling, which disrupts the critical solid-solid contact at the electrode-electrolyte interface. Conventional solutions require applying substantial external pressure (tens to hundreds of MPa) to maintain this contact, a requirement that severely hinders practical device integration and scalability.

3. The Solution: An Innovative Bilayer Anode Architecture

To overcome this fundamental challenge, a research team from Xiamen University designed a novel Li₂₁Si₅/Si–Li₂₁Si₅ bilayer composite anode, fabricated via an integrated cold-pressing and sintering process. This architecture features two distinct functional layers:

-

Top Li₂₁Si₅ Layer: Acts as a mixed ionic-electronic conductor (MIEC), homogenizing the interfacial electric field and guiding uniform lithium-ion flux.

-

Bottom Si–Li₂₁Si₅ Layer: Forms a continuous 3D conductive network. This facilitates ion transport while effectively dissipating the mechanical stress induced by volume expansion.

A key, intrinsic feature of this design is a spontaneous “self-pre-lithiation” effect, where lithium migrates from the Li₂₁Si₅ phase to the surrounding Si, enhancing initial conductivity and structural integrity.

4. Exceptional Electrochemical Performance Without External Pressure

This ingeniously structured silicon-based anode enables all-solid-state batteries to operate without applied stack pressure while delivering remarkable performance:

-

High Initial Efficiency: An initial Coulombic efficiency of 97 ± 0.7%.

-

High Current Tolerance: A critical current density of 10 mA cm⁻² (at 10 mAh cm⁻²).

-

Practical Capacity: An areal capacity of 2.8 mAh cm⁻².

-

Record Longevity: Stable operation for 1000 cycles at 2.5 mA cm⁻² with a capacity retention of 54.9% and a minimal volume expansion of only 14.5%—a record for pressure-free silicon-based ASSBs.

-

Excellent Rate Capability: Stable discharge even at a high current density of 9 mA cm⁻².

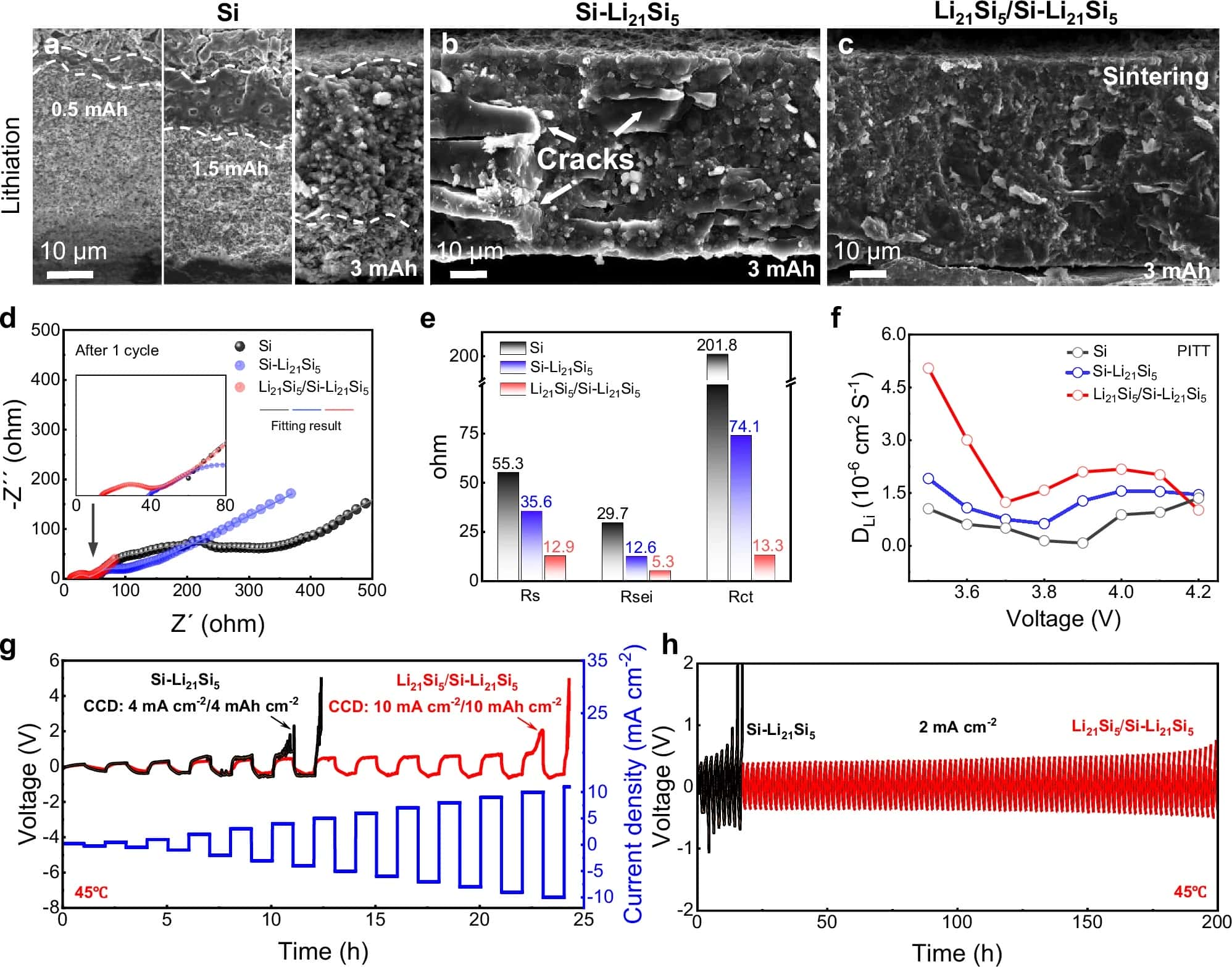

Figure 2. Characterization of ionic/electronic transport property of the Li21Si5/Si–Li21Si5 anode for ASSBs.

5. Mechanistic Insight: Multi-Modal Characterization Reveals the Stable Interface

To unravel the mechanism behind this pressure-free stability, the team employed a comprehensive suite of characterization techniques:

-

Microstructure & Chemistry: SEM, XPS, and XRD were used to analyze morphology, interfacial chemistry, and phase composition.

-

Lithium-Ion Environment: Solid-state NMR (SSNMR) probed the local chemical state of lithium ions.

-

In-Operando Observation: In-situ TEM provided real-time visualization of silicon particle lithiation and structural evolution without pressure.

-

Modeling & Simulation: Data from these techniques informed a COMSOL Multiphysics model. The simulation validated that the bilayer design successfully homogenizes current density and redistributes mechanical stress, preventing localized failure.

Figure 3. Structure evolution of the Li21Si5/Si–Li21Si5 anode during cycling.

6. Practical implications for All-Solid-State Batteries and volume expansion control

This work advances a pathway toward All-Solid-State Batteries that do not rely on impractically high external pressure. Key engineering implications:

-

Cell/pack simplification: removing external pressure relaxes mechanical design constraints, making ASSB integration into packs and modules more feasible.

-

Scalability signals: cold-press sintering and composite layering are compatible with manufacturing flows, but reproducibility (control of pre-lithiation, microstructure and porosity) will determine scale-up success.

-

Rate capability & safety trade-offs: achieving high critical currents (multi-mA·cm⁻²) with modest volume expansion suggests the design balances kinetics and mechanics—an important combination for fast-chargeable, high-energy ASSBs.

7. Conclusion and Future Outlook

This groundbreaking work demonstrates a viable pathway to overcome the “pressure dilemma” for silicon-based anodes in all-solid-state batteries. By moving beyond external mechanical constraints through intelligent material and interfacial design, the research paves the way for developing simpler, more robust, and commercially feasible high-energy-density ASSBs. This anode architecture opens new possibilities for applications in electric vehicles and flexible electronics where maintaining high stack pressure is impractical.

8. Original Paper

Zhang, Z., Zhang, X., Liu, Y. et al. Silicon-based all-solid-state batteries operating free from external pressure. Nat Commun 16, 1013 (2025).

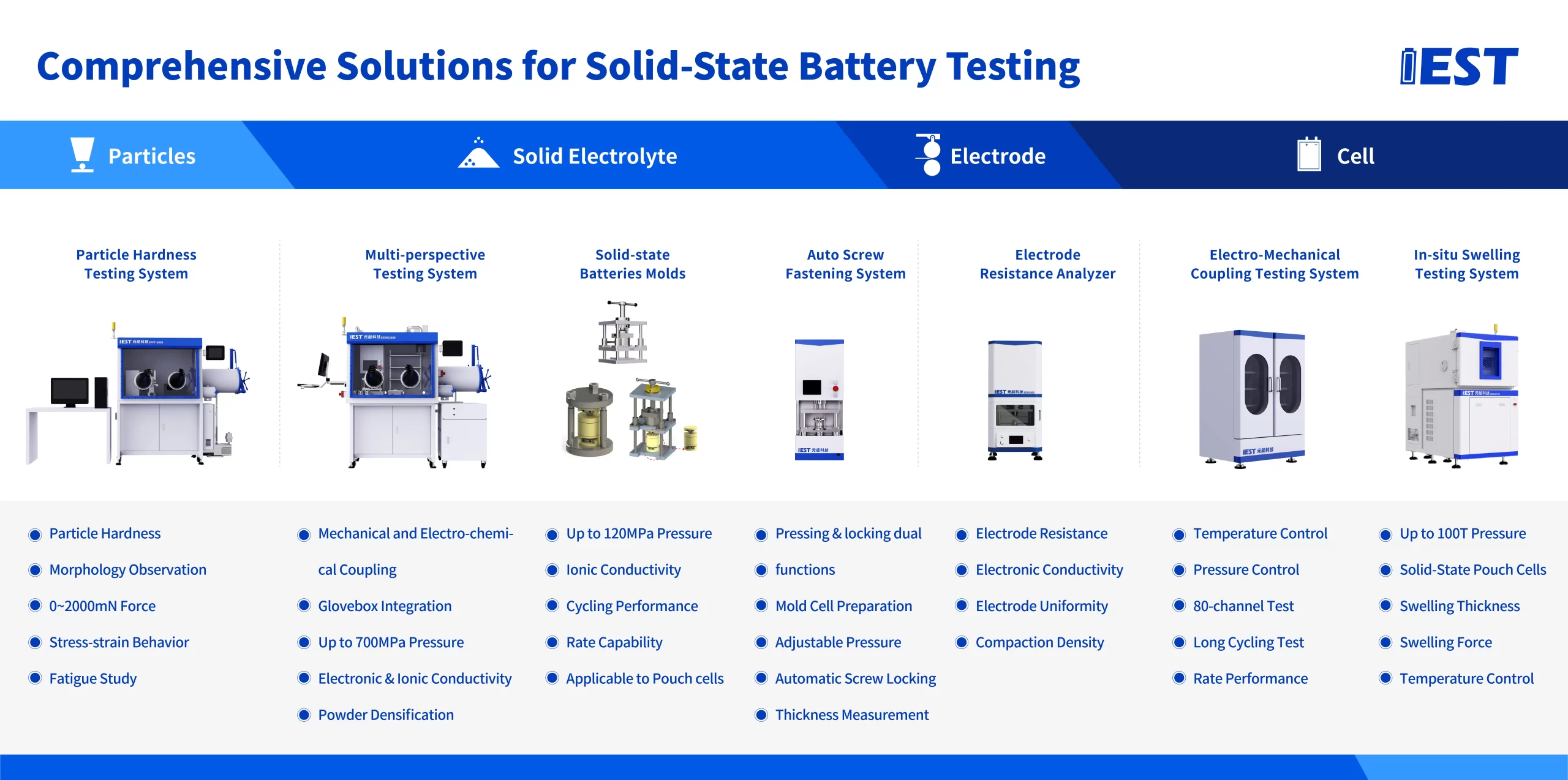

9. Comprehensive Solid-State Battery Testing Solutions

At IEST, we provide a comprehensive suite of cutting-edge testing solutions designed specifically for solid-state batteries—from material-level characterization to full-cell performance evaluation, from multi-dimensional powder compression & EIS (SEMS series) to glovebox-integrated single-particle mechanics, automatic mold-pressing, SWE in-situ swelling analyzers and BPD pressure/temperature mapping. Our integrated systems enable researchers and manufacturers to accurately measure mechanical, electrochemical, and thermal behaviors under realistic operating conditions, accelerating the development and commercialization of next-generation batteries.

Subscribe Us

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.