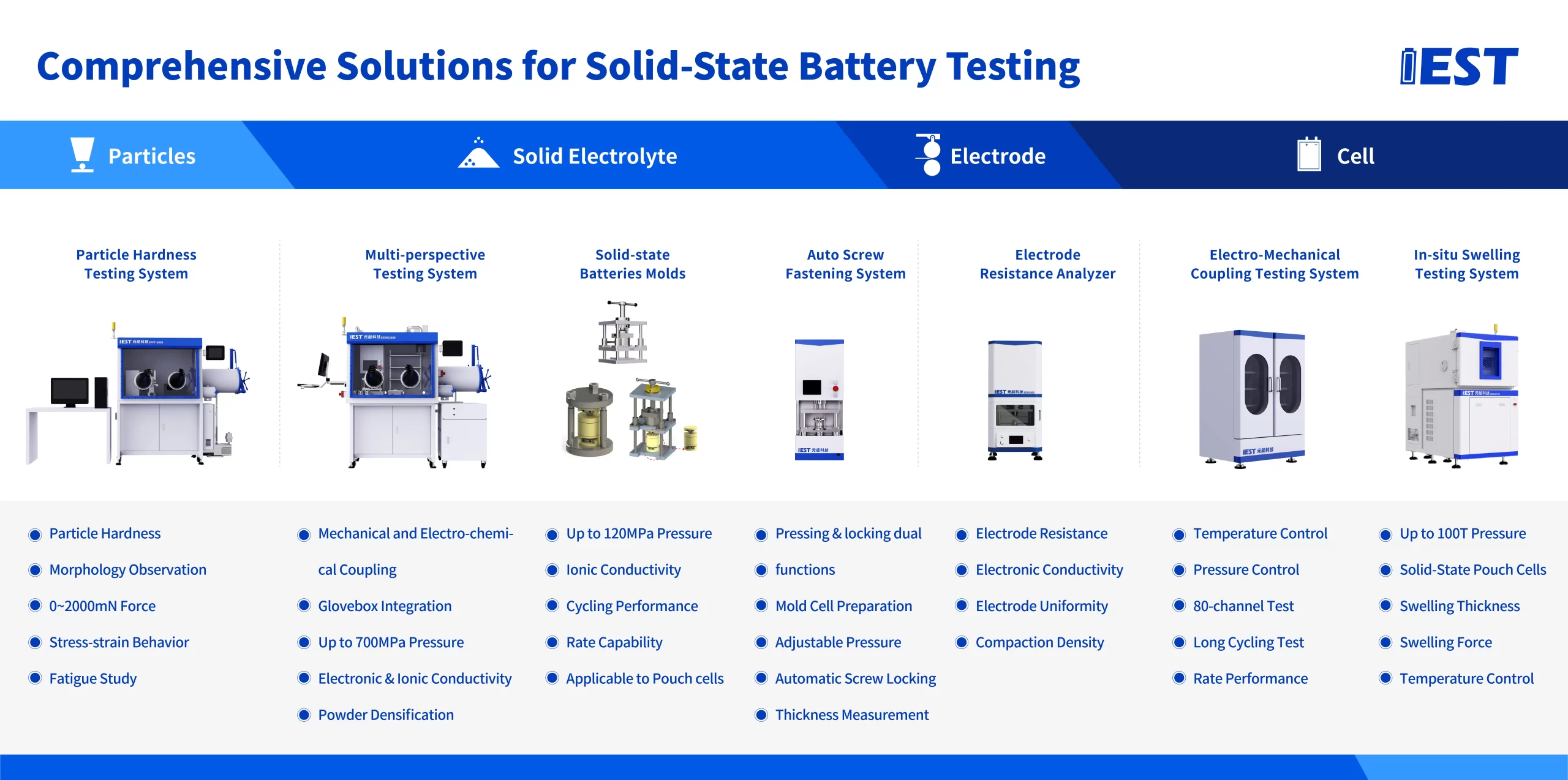

Solid-State Battery Testing Solutions

Comprehensive Solid-State Battery Testing Solutions

Accelerating the R&D of Solid-state Batteries

Solid-state batteries represent the next frontier in energy storage technology, offering enhanced safety, higher energy density, and longer cycle life. However, their complex structure and material properties demand advanced and precise testing methods to ensure performance, reliability, and scalability.

At IEST, we provide a comprehensive suite of cutting-edge testing solutions designed specifically for solid-state batteries—from material-level characterization to full-cell performance evaluation, from multi-dimensional powder compression & EIS (SEMS series) to glovebox-integrated single-particle mechanics, automatic mold-pressing, SWE in-situ swelling analyzers and BPD pressure/temperature mapping. Our integrated systems enable researchers and manufacturers to accurately measure mechanical, electrochemical, and thermal behaviors under realistic operating conditions, accelerating the development and commercialization of next-generation batteries.

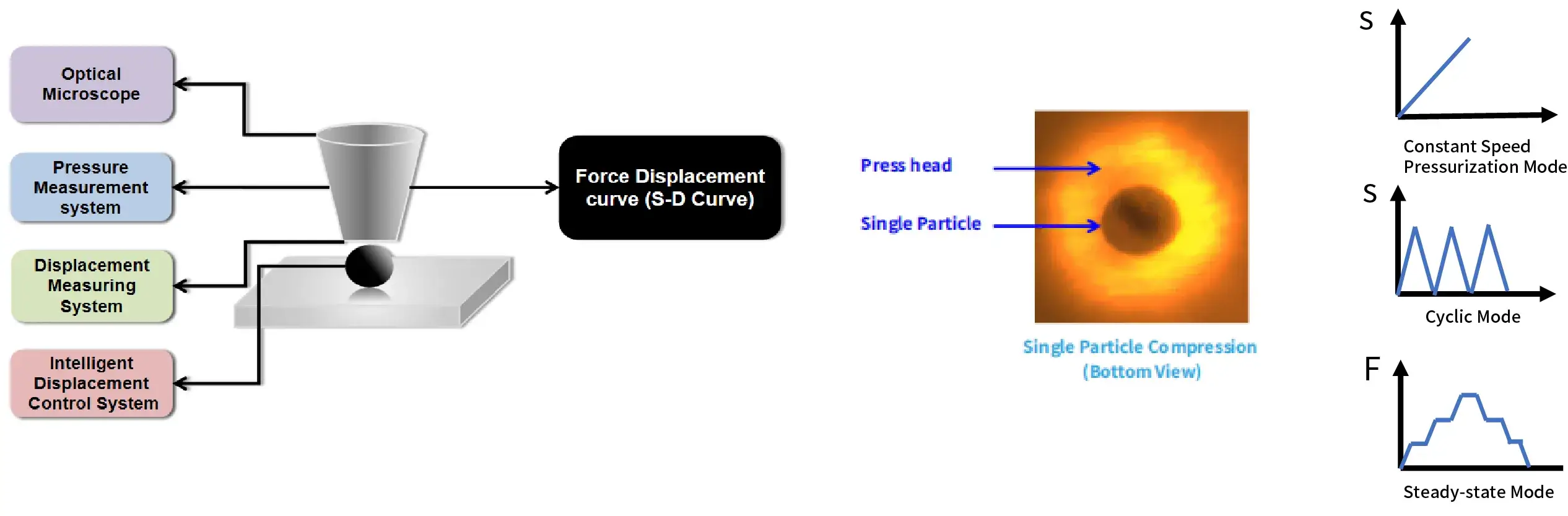

Single Particle Crushing Force Tester-SPFT3000

Introduction: IEST’s Single Particle Crushing Force Test System (SPFT) enables material-level mechanical characterization at the microparticle scale. lntegrating an optical subsystem, pressure measurement module, displacement monitoring unit,and automated control platform, it supports real-time detection of deformation, slip, collapse, and fatigue life of microparticles during compression.

For solid-state batteries, lEST has developed a glove-box integrated SPFT, enabling inert atmosphere protected mechanical testing of cathode, anode, and electrolvte materials. This configuration ensures precise characterizationof particle mechanical properties under simulated battery operating environments.

Functions:

- Atmosphere protection for solid-state sample

- High-precision displacement with a range of 0-75 µm

- Multiple test modes enable diverse sample analysis

- Sample particle dimensional range 5~50 µm

- Auto-cleaning function, easy to operate

- Rapid analysis, intelligent calculation ofcrushing force and data comparison

Multi-dimensional Solid-State Electrolyte Testing System-SEMS3200

Introduction: The Multi-dimensional solid-State Electrolyte Testing System(SEMS) facilitates comprehensive powder-level material evaluation. lt combines atmospheric protection system, pressurization system, pressure measurement system, thickness measurement system, pressing & lock system, electrochemical testing system, integrated with unified software to enable in-situ monitoring of compaction density and electrochemical performance under adjustable pressure and atmospheric conditions.

Functions:

- Atmosphere protection for solid-state electrolyte

- Enhanced pressure control through motor servo

- Thickness test accuracy: ±10µm

- Integrated pressing and lock for easier operation

- Equipped with internationally certified electrochemical workstations

- Unified software for comprehensive test control

- Rapid analysis, smart ion conductivity calculation, and one-click export

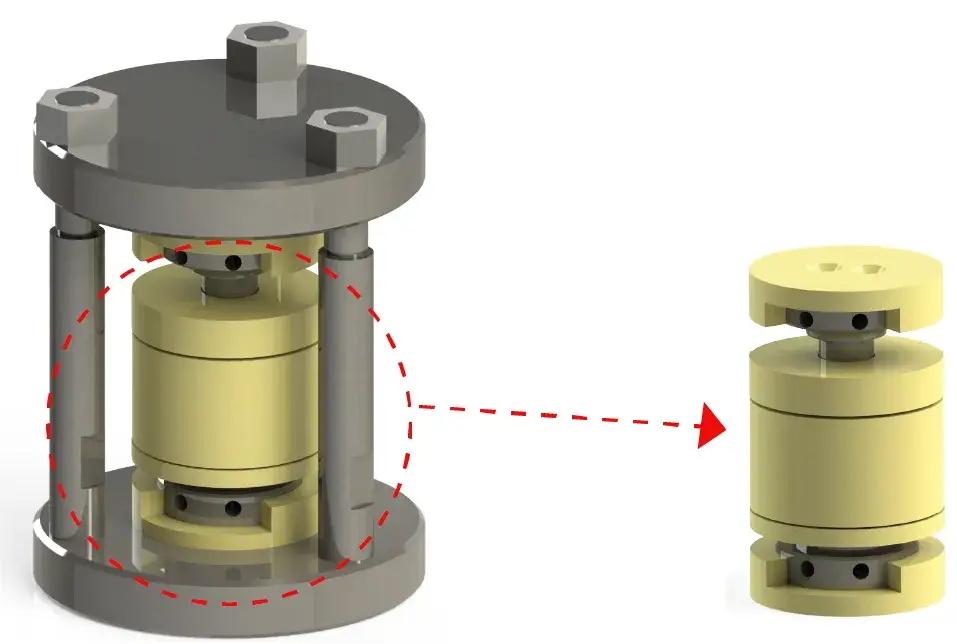

Solid-State Battery Mold & Fixture

1. Mold & Fixture

Introduction: The Gas-tight mold’s inner liner is made of ceramic, which can withstand pressure up to 600MPa. Unique insulating cover design ensures structuralstability and zero deformation under 60℃ high-temperature testing.

- Solid-state Electrolyte lonic Conductivity Test

- Mold Cell Electrochemical Performance Test

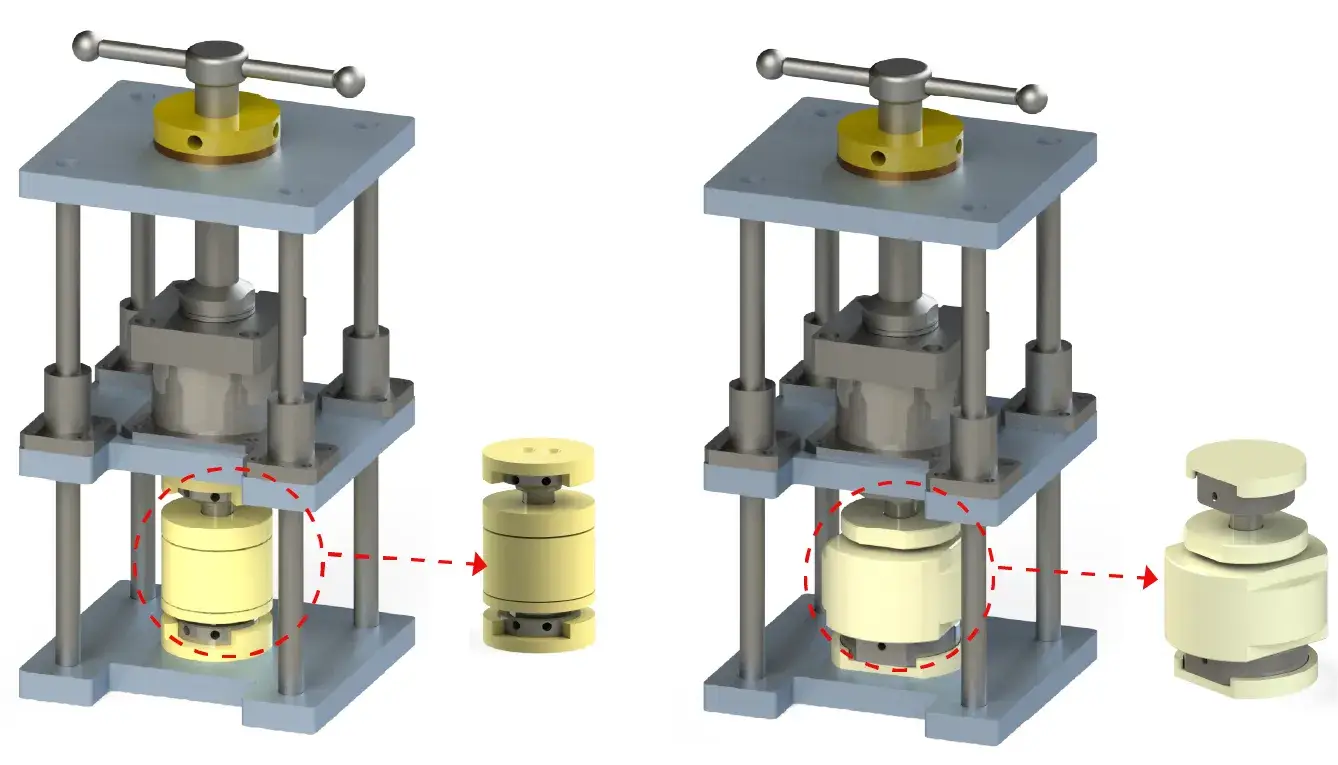

2. Mold Cell Pressure Control Testing System

Introduction: The three-plate steel structure is designed to maximize stability by mitigating pressure changes caused by bolt deformation during testing, thereby enhancing testing stability.

- Solid-State Electrolyte lonic Conductivity Test

- Mold Cell Swelling Force Monitoring(requiring swelling force > accuracy)

- Mold Cell Electrochemical Performance Test

- Adaptable to Swelling Force Testing Requirements for Certain Pouch Cells

Mold Cell Automatic Pressing & Locking Machine-APLM

Introduction: With a maximum pressing force of 10,000 kg, the system allows for freely adjustable pressurization force and pressure holding time. Triaxial simultaneous screw tightening post-pressure application, eliminating uneven pressure distribution caused by manual handling.

Functions:

- Pressure range: 0-10 tons, customizable based on mold dimensions.

- Simultaneously lock/unlock screws during pressure holding to enhance operational efficiency.

- Precisely control screw torque to ensure balanced triaxial pressure and torque.

Battery Electrode Resistance Analyzer-BER Series

Introduction: The BER Series Multifunctional Electrode Resistance Tester integrates a high-precision pressure control system with thickness and resistance measurement capabilities. Utilizing the double-sided controllable pressure disc electrode method, it directly measures the overall through-thickness resistance of practical electrodes, which encompasses the coating resistance, coating-current collector contact resistance, and current collector resistance. It demonstrates strong discrimination capability for the uniformity of the electrodesheet’s electronic conductive network.

Functions:

- Direct measurement of the true through-thickness resistance of practical electrodes – including coating resistance, coating-current collector contact resistance, and current collector resistance.

- Separate voltage/current terminals to eliminate inductive interference on voltage sensing, enhancing measurement accuracy.

- Equipped with reference resistance blocks and thickness standards certified by third-party metrology institutes.

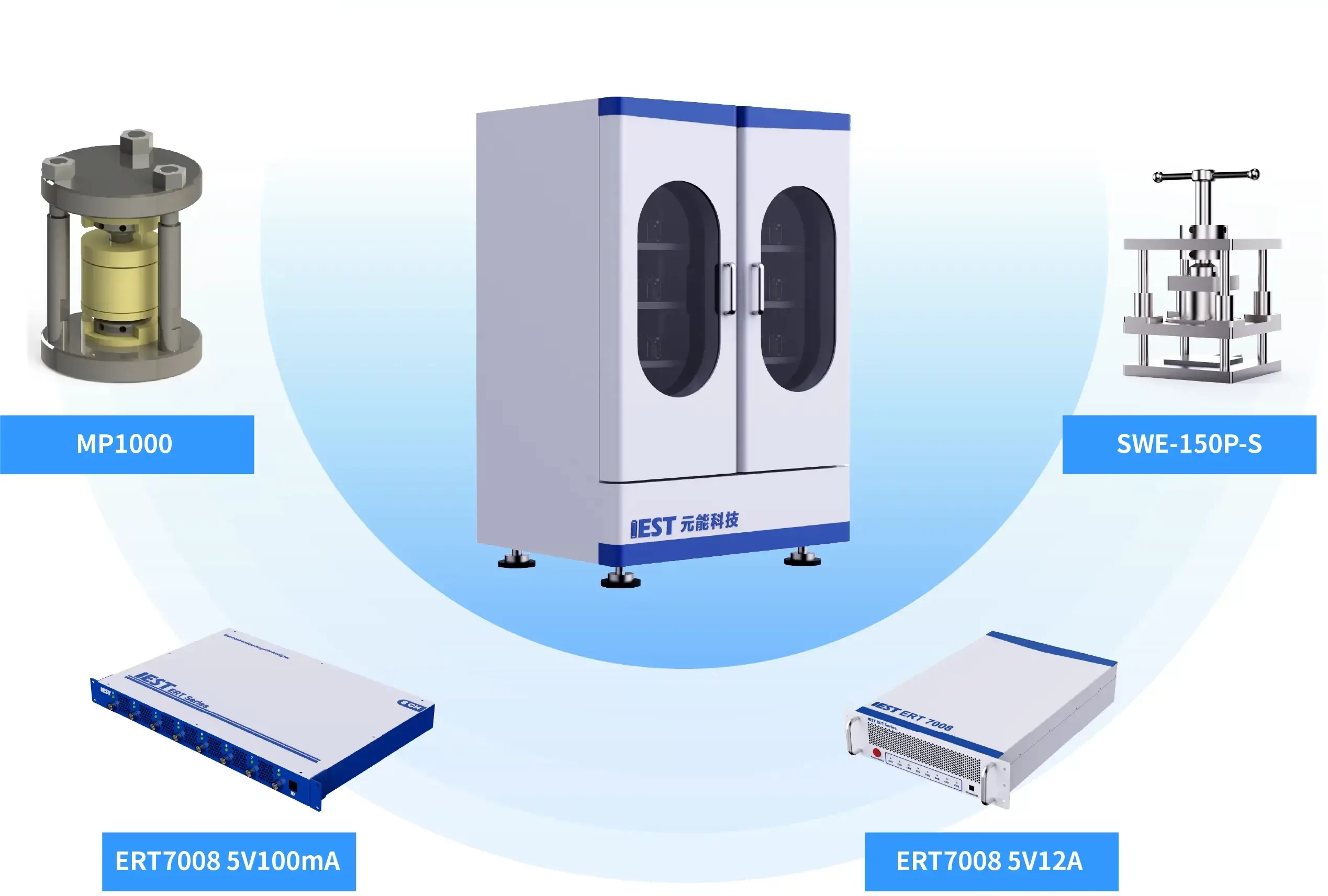

High-throughput Pressure & Electric Coupling Test System

Introduction: A comprehensive solution combining temperature control, electrochemical performance evaluation, and pressure testingmodules, designed to perform pressurized tests on pouch cells and mold battery samples under room temperature (RT) to 80℃ conditions. The system features 5-layer drawer type sample carrier for effortless operation, enabling seamless integration of pressure application and electrochemical measurements across varying temperatures.

Application Scenarios:

- High-throughput mold cell test

- High-throughput pressurized test of pouch cell

Features:

- RT~80°C, Meet multi-scenario testing.

- Unique circulation air duct design, excellent temperature uniformity.

- High-throughput design, supporting simultaneous testing of up to 80 mold batteries or 80 pouch batteries.

- 0.01%F.S. High precision voltage and current control for rapid life evaluation.

- EIS/LSV/CV/P|TT/GITT/ and Conventional electrochemical performance.

- Automated Pressuring & Lock System reducing operational workload.

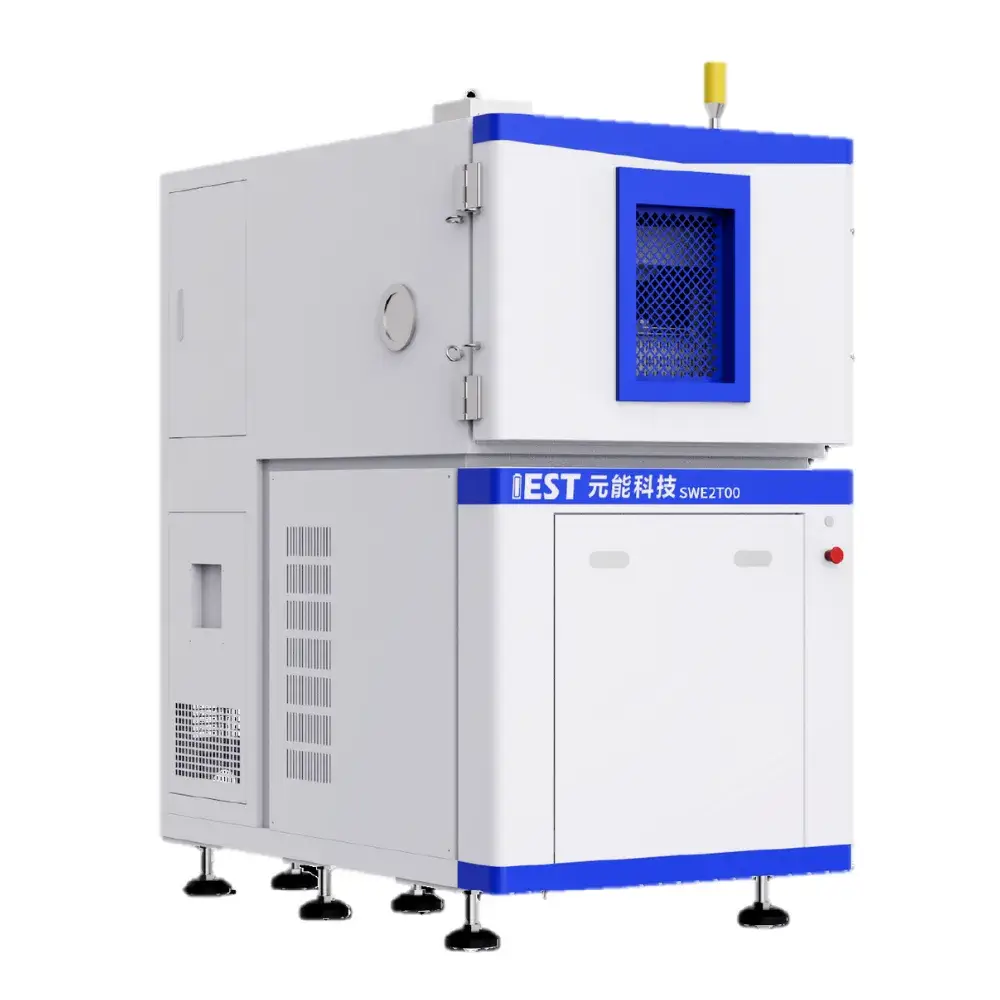

In-Situ Cell Swelling Analyzer 20T-SWE2T00

Introduction: This 20T high-precision thermal testing platform features a robust metal/insulating material frame for mechanica stability and electrical insulation. lt integrates servo-driven pressure control, high-precision thickness monitor ingand a charge/discharge system for in-situ cell force and thickness analysis.

Features:

- Auto-controlled lifting.

- Transparent window for real-time battery state observation.

- Integrated protective cover to isolate external interference.

- High-precision thickness sensor (measuring initial thickness and deformation).

- Cell temperature control (-20°c to 85°c), synchronized with charge/discharge equipment via host software.

- Automated data acquisition (time, thickness, pressure, temperature) with realtime display and export(Excel/CSV/TXT)

- Safety protection: Halt testing and trigger alerts if parameters exceed predefined thresholds.

In-Situ Cell Swelling Analyzer 60T-ASST60TT

Introduction: The 60T In-Situ Cell Swelling Analyzer features a temperature-controlled thermal platform (35-85℃) with a robustmetal/stainless-steel frame. lt integrates hydraulic pressure regulation, real-time thickness monitoring, and charge/discharge capabilities for in-situ analysis of cell expansion dynamics.

Features:

- Supports temperature control ranging from 35-85°c, for swelling test at high-temperature.

- Constant Pressure Mode & Constant Gap Mode.

- Automated data acquisition (time, thickness, pressure, temperature) with realtime display and export(Excel/CSV/TXT)

- Safety protection: Halt testing and trigger alerts if parameters exceed predefined thresholds.