-

iestinstrument

In-situ Monitoring of Gas Evolution in NCM Material Pouch Cells During Storage and Overcharge

1. Abstract

Nickel-rich Lithium Nickel Cobalt Manganese Oxide (NCM Material) is a leading cathode choice for power batteries due to its high energy density. The Ni/Co/Mn ratio critically influences performance1-2, but high-Ni compositions raise the risk of gas generation (NCM gas) during high-temperature storage and overcharge. This study uses a dual-channel, temperature-controllable in-situ gas-volume monitor(GVM Series) to quantify gas evolution in pouch full cells made with two surface-coated 8-series high-Ni NCM materials. Continuous, real-time monitoring yields precise gas-onset points, inflection points, and gas-generation rates under different temperatures and SOC/overcharge conditions. These metrics enable rapid, accurate screening of NCM Material modifications (e.g., single- vs. double-coating) for improved storage and overcharge stability.

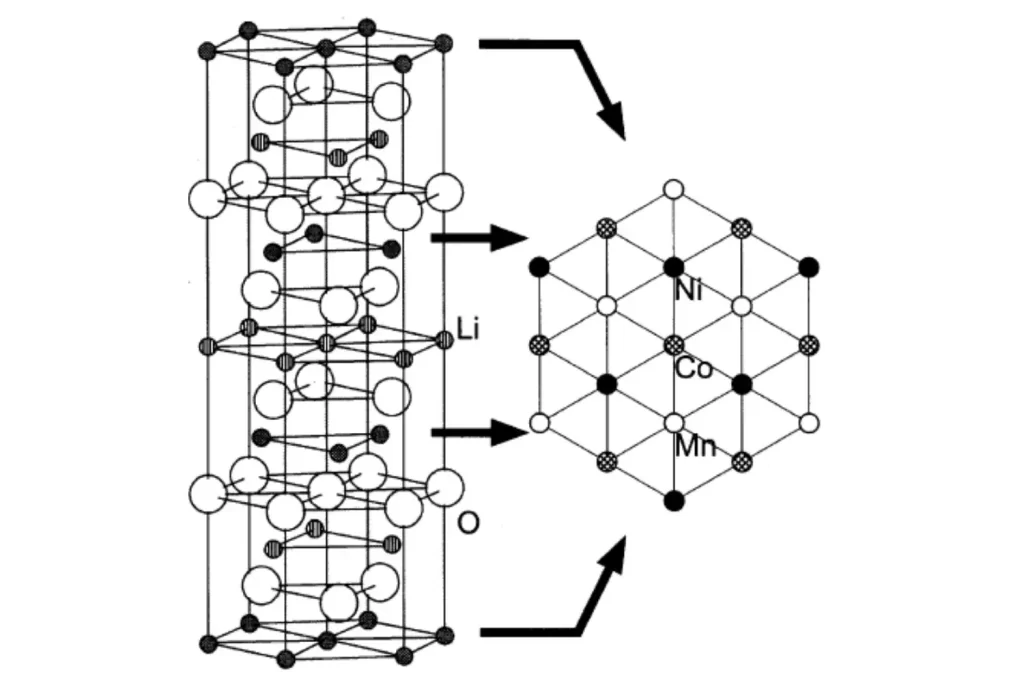

2. Background: why NCM Material composition affects gas generation

NCM (Ni/Co/Mn) layered oxides are favored for power batteries because higher Ni content increases specific capacity. However, composition shifts carry trade-offs:

-

Increasing Ni raises gravimetric capacity but can promote cation mixing (Ni/Li disorder), which hinders Li extraction/insertion and degrades electrochemical performance and thermal stability.

-

Co helps suppress cation mixing and improves electronic conductivity, but higher Co content increases material cost.

-

Mn improves structural stability and lowers cost, yet excessive Mn may destabilize the layered phase and form spinel domains, harming cycle life 3-5.

Current market demand for higher energy drives NCM toward high-Ni (and even low-/no-Co) formulations. During synthesis, high-Ni cathodes tend to retain more basic lithium oxides on particle surfaces. Upon exposure to moisture these residues convert to LiOH and Li₂CO₃. These surface lithium salts are thermally and electrochemically unstable and can generate gas (NCM gas) during high-temperature storage, initial formation, or overcharge, causing pouch swelling and safety risks. Therefore, surface modification (e.g., doping, coating) is commonly applied to reduce NCM gas generation and improve cell safety.

Figure 1. Schematic diagram of the nickel-cobalt-manganese NCM material structure 6

3. Limitations of Traditional Gas Measurement Methods

Conventional methods often use a single-point Archimedes principle measurement, weighing a cell intermittently to calculate volume change (Figure 2a). This ex-situ approach disrupts the cell’s real-time environment, leading to several issues:

-

Inability to accurately identify the onset, inflection points, and rate of NCM gas evolution.

-

Time-lagged measurements causing volume underestimation due to gas dissolution or diffusion during rest periods (Figures 2b & 2c).

-

Incompatibility with high-temperature environments.

-

Requirement for multiple cells to obtain process data points.

-

High dependency on cell-to-cell consistency.

This study utilizes an in-situ gas volume monitor to track gas behavior in NCM pouch cells under various storage and overcharge conditions, providing accurate data on gas onset for rapid material evaluation.

Figure 2 . (a) Measurement structure diagram of a traditional balance. (b) After the overcharge test is completed, the cell is left for 0min. (c) After the overcharge test is completed, the cell is left for 5min.

4. In-Situ Monitoring Principle and Methodology

4.1 Measurement Principle

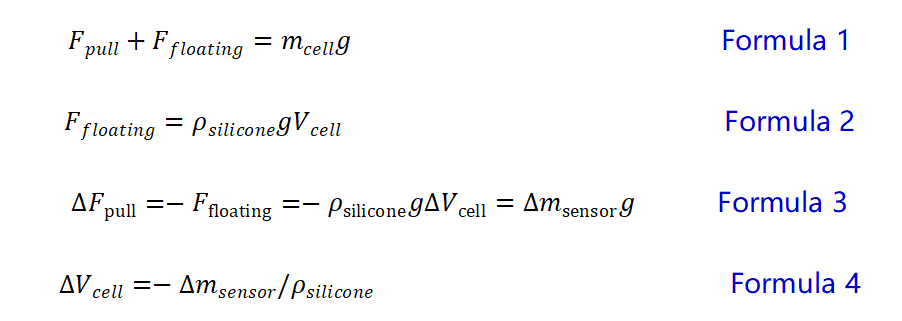

The technique is based on Newtonian mechanics and the Archimedes buoyancy principle. A specialized sensor continuously measures the apparent mass change of a submerged cell during testing, which is converted into a real-time volume change. The calculations use a gravitational acceleration (g) of 9.8 m/s² and a silicone oil density (ρ_silicone oil) of 0.971 g/ml at 25°C.

4.2 Experimental Setup

Model GVM2200 (IEST), the test temperature range is 20 ℃ ~ 85 ℃, support dual channel (2 cells) synchronous test, the appearance is shown in Figure 3.

Figure 3. Appearance of GVM2200 Device

4.3 Test Method

Initially weigh the cell m0, put the cell to be tested into the corresponding channel of the device, start the MISG software, set the corresponding cell number and sampling frequency parameter of each channel, the software automatically reads the volume change and test temperature , Current, voltage, capacity and other data.

5. Results: In-Situ Gas Evolution Monitoring of NCM Cells

5.1 High-Temperature Storage Gas Evolution

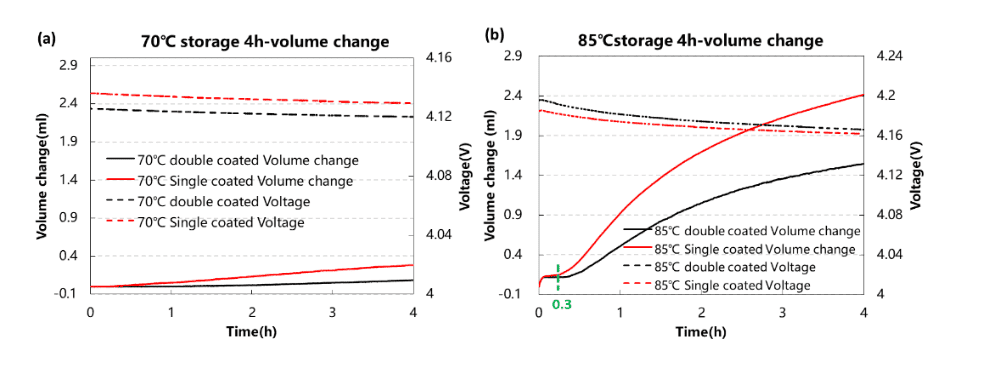

Modifying high-nickel NCM Material surfaces is crucial for enhancing electrochemical performance and storage stability. Figure 4 shows the in-situ gas evolution of two modified 8-series NCM materials (single-coating vs. double-coating) during fully-charged storage at 70°C and 85°C.

-

70°C storage (4 h, 100% SOC): Both materials produced less than 0.4 mL total gas and ~6% cell volume change. The single-coated sample showed slightly higher gas output than the double-coated sample (Figure 4a).

-

85°C storage (4 h, 100% SOC): Both samples remained near baseline for the first ~20 min, then entered a rapid gas-generation regime. After 4 h the single-coated cell produced ~2.4 mL gas (~46% volume change), while the double-coated cell produced ~1.5 mL (~27% volume change) (Figure 4b).

These results demonstrate that a double-coating strategy can significantly suppress high-temperature storage gas generation in high-Ni NCM Materials. Continuous in-situ monitoring clearly identifies the gas-onset time and the subsequent growth rate, providing actionable metrics for materials optimization.

Figure 4. (a) Gas production monitoring at 70℃ full charge storage for 4h. (b) Gas production monitoring at 85℃ full charge storage for 4h.

5.2 Overcharge Gas Evolution Monitoring

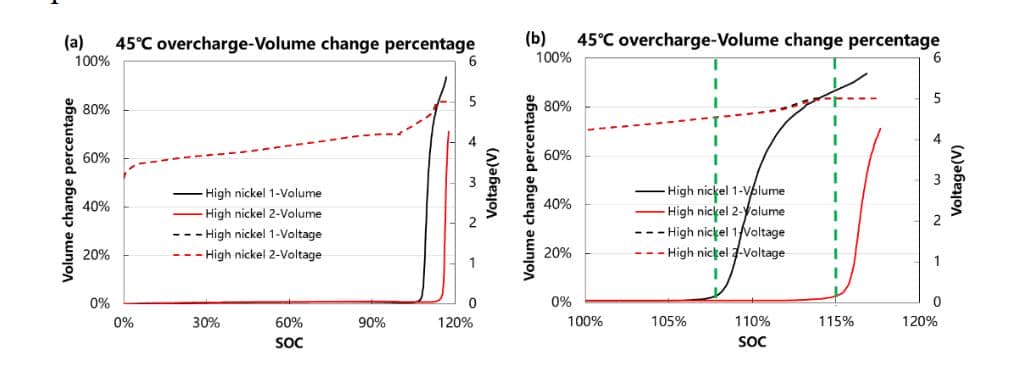

Applying high voltages to NCM materials is a pathway to higher energy density but challenges structural stability. Monitoring gas evolution during overcharge serves as a key characterization method. Figure 5 shows the gas evolution of two high-nickel NCM cells during a 45°C overcharge test.

-

Up to 100% SOC, both materials showed no measurable gas generation, indicating structural stability within the nominal SOC window (Figure 5a).

-

In the expanded view from 100% to 120% SOC (Figure 5b), the two materials diverged:

-

High-Ni 1 began to release gas at ~108% SOC (≈4.5 V).

-

High-Ni 2 began gas evolution at ~115% SOC (≈5.0 V+).

-

Hence, High-Ni 2 tolerates higher overcharge voltages before gas evolution initiates, implying better structural robustness at elevated states of charge and a potential for increased accessible capacity before safety limits are reached.

By mapping gas-onset SOC and the corresponding cell voltage, researchers can define safe voltage windows and quantify how surface modifications extend overcharge tolerance.

Figure 5. (a) 45℃ overcharge gas production monitoring. (b) 45℃ overcharge gas production enlarged view.

6. Practical Implications and Benefits of In-situ NCM Gas Monitoring

Continuous, temperature-controlled, dual-channel in-situ monitoring delivers several practical advantages:

-

Precise identification of gas-onset and inflection points, enabling quantitative ranking of material modifications.

-

High temporal resolution to compute gas-generation rates and correlate them with SOC and voltage.

-

Ability to perform elevated temperature tests (up to 85°C) that are difficult with simple balance methods.

-

Reduced sample consumption compared with discrete methods — one cell yields a full time series.

-

Improved reproducibility and reduced dependence on tight cell matching.

These benefits make the method well suited for rapid screening of NCM Material variants and for R&D work focused on minimizing NCM gas and improving cell safety.

7. Summary

We used a temperature-controlled in-situ gas-volume monitor(GVM2200) to track NCM gas generation from high-Ni pouch cells during storage and overcharge. The technique yields accurate gas-onset points, peak gas volumes, and the SOC/voltage coordinates of gas initiation. In the tested case, double coating of an 8-series high-Ni NCM reduced high-temperature storage gas and delayed overcharge gas onset compared with single coating. Continuous in-situ monitoring therefore provides a fast, reliable method to assess and rank NCM Material modifications for improved safety and higher usable energy density.

8. References

[1] Brian L. Ellis, Kyu Tae Lee, and Linda F. Nazar. Positive Electrode Materials for Li-Ion and Li-Batteries. Chem. Mater. 22(2010), 691–714 691.

[2] Jing Xie, Yi-Chun Lu. A retrospective on lithium-ion batteries. Nature Communications. (2020) 11:2499.

[3] C. P. Aiken, J. R. Dahn et al. An Apparatus for the Study of In Situ Gas Evolution in Li-Ion Pouch Cells. J. Electro Soc, 161(2014) A1548-A1554.

[4] Yongseon Kim. Mechanism of gas evolution from the cathode of lithium-ion batteries at the initial stage of high-temperature storage. J. Mater Sci, 48(2013), 8547–8551.

[5] Hyung-Joo Noh, Yang-Kook Sun et al. Comparison of the structural and electrochemical properties of layered Li[NixCoyMnz]O2 (x=1/3, 0.5, 0.6, 0.7, 0.8 and 0.85) cathode material for lithium-ion batteries. J. Power Sources, 233(2013)121-130.

[6] Yukinori Koyamaa, Tsutomu Ohzukub et al. Crystal and electronic structures of superstructural Li1-x[Co1/3Ni1/3Mn1/3]O2 (0 _ x _ 1). J. Power Sources, 119–121(2003) 644–648.

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.