-

iestinstrument

Li-S Energy’s GEN3 Lithium-Sulfur Battery Nears 500 Wh/kg in Commercial-Scale Cells

1. Introduction: A Practical Leap in Lithium-sulfur Battery Energy Density

Australian battery innovator Li-S Energy has announced significant progress in lithium-sulfur batteries technology. The company reports that its latest full-sized pouch cells are approaching a critical benchmark of 500 Wh/kg, showcasing a commercially viable path to ultra-high lithium-sulfur battery energy density. This achievement is notable for being demonstrated on larger-format, semi-automatically produced cells rather than small-scale laboratory prototypes.

2. A Commercial-Scale Benchmark: 10 Ah Cell Performance

Headquartered in Queensland, Li-S Energy‘s latest milestone centers on a 10 Ah semi-solid-state cell. Utilizing the company’s third-generation (GEN3) chemistry, this cell achieved an initial discharge energy density of 498 Wh/kg. Perhaps more importantly, it maintained 456 Wh/kg after conversion cycling, with ongoing tests showing consistent performance. This data comes from cells produced on the company’s automated pilot line, providing a realistic performance preview for potential partners.

Dr. Steve Rowlands, Li-S Energy’s CTO, emphasized the significance of this approach. He noted that while many researchers report high energy densities from first discharges of small button or coin cells, these figures often don’t translate to practical, larger formats. Li-S Energy’s focus on testing 10 Ah and 20 Ah pouch cells offers a more credible and commercially relevant performance dataset.

3. GEN3 Chemistry: Doubling the Gravimetric Energy Density

This breakthrough is powered by Li-S Energy’s third-generation semisolid lithium-sulfur chemistry, first introduced in April 2023. The company states that its GEN3 technology more than doubles the gravimetric energy density compared to conventional lithium-sulfur batteries and also offers a higher volumetric energy density than standard lithium-ion batteries. This combination of high specific energy and improved pack-level density is crucial for weight-sensitive applications.

4. Target Markets and Partner Integration

The near-500 Wh/kg threshold directly aligns with demands from advanced mobility sectors. Li-S Energy is actively targeting the drone, electric aviation, and defense markets, where reducing weight is paramount for extending range and payload. The company is already collaborating with Queensland-based drone developer V-TOL Aerospace and NSW-based solar cell manufacturer Halocell Energy to integrate its batteries into specialized drone platforms.

CEO Dr. Lee Finniear highlighted the direct impact of this energy density leap. “Lighter batteries immediately translate to improved range, payload capacity, and runtime for our partners’ products,” he stated. He described this as a major advance in the emerging lithium-sulfur batteries field, driven by explicit partner requirements for the highest possible energy densities, reliable production, and a scalable supply chain.

5. The Path Forward: Scaling Reliability and Forming New Partnerships

Looking ahead, Li-S Energy will concentrate on enhancing cell reliability, production precision, and throughput at its 2 MWh production facility in Victoria. Concurrently, the team will work closely with launch partners to co-develop bespoke battery management systems (BMS) and pack architectures. Dr. Finniear anticipates that these latest performance results will attract significant global interest, with new partnerships likely to be announced in the coming months.

6. Conclusion: where Li-S Energy fits in the battery landscape

Li-S Energy’s GEN3 semisolid cells, if independently validated at scale, represent an important milestone for lithium-sulfur batteries and their promised advantage in gravimetric energy density. By testing full-size 10 Ah and 20 Ah pouch cells on an automated line and reporting both initial and post-conversion figures, the company has taken steps to demonstrate commercial realism rather than lab-scale optimism. The near-500 Wh/kg range would be transformative for aerial platforms and other weight-sensitive systems, but broader qualification—especially around cycle life, safety and manufacturability—remains essential before broad deployment.

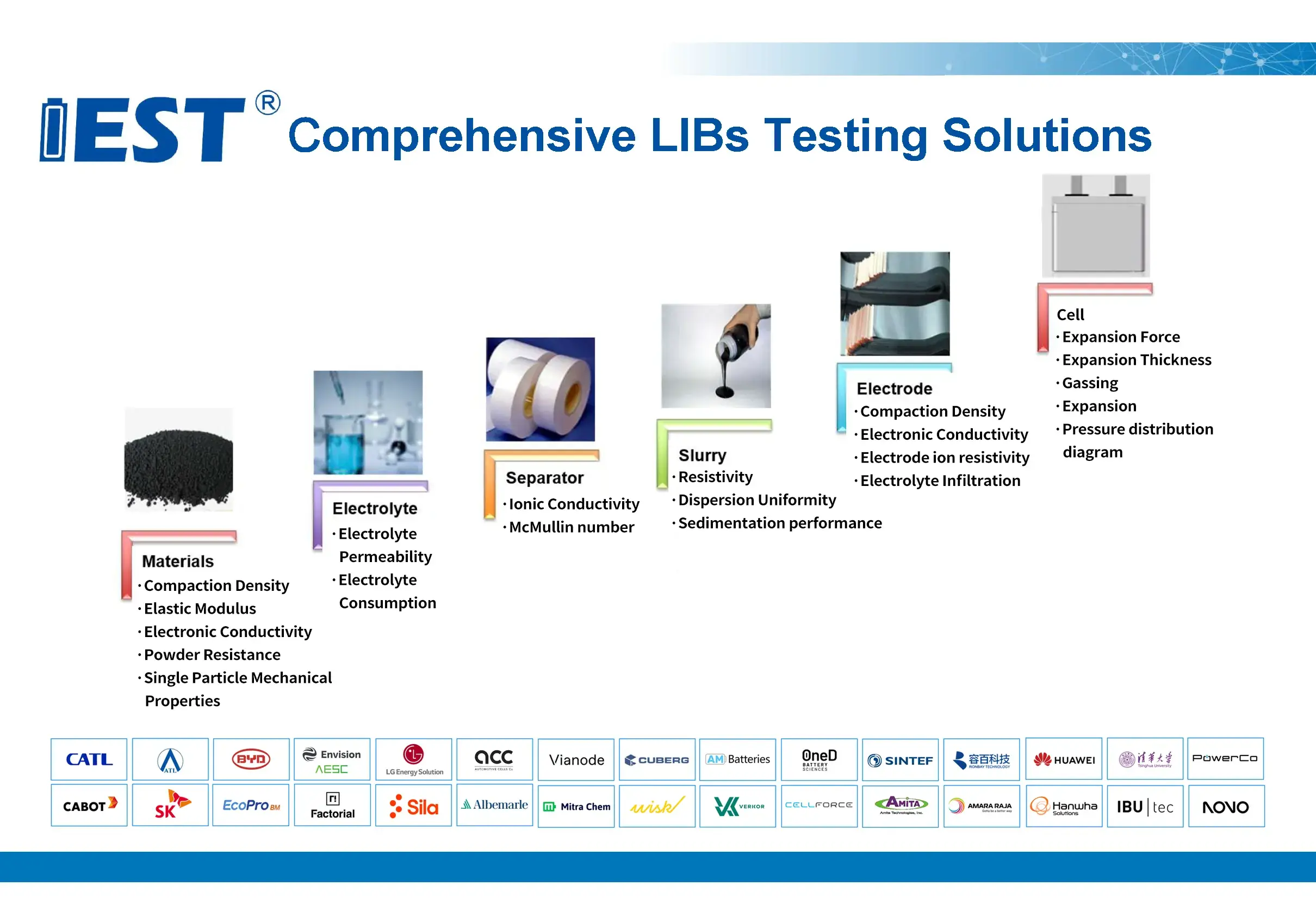

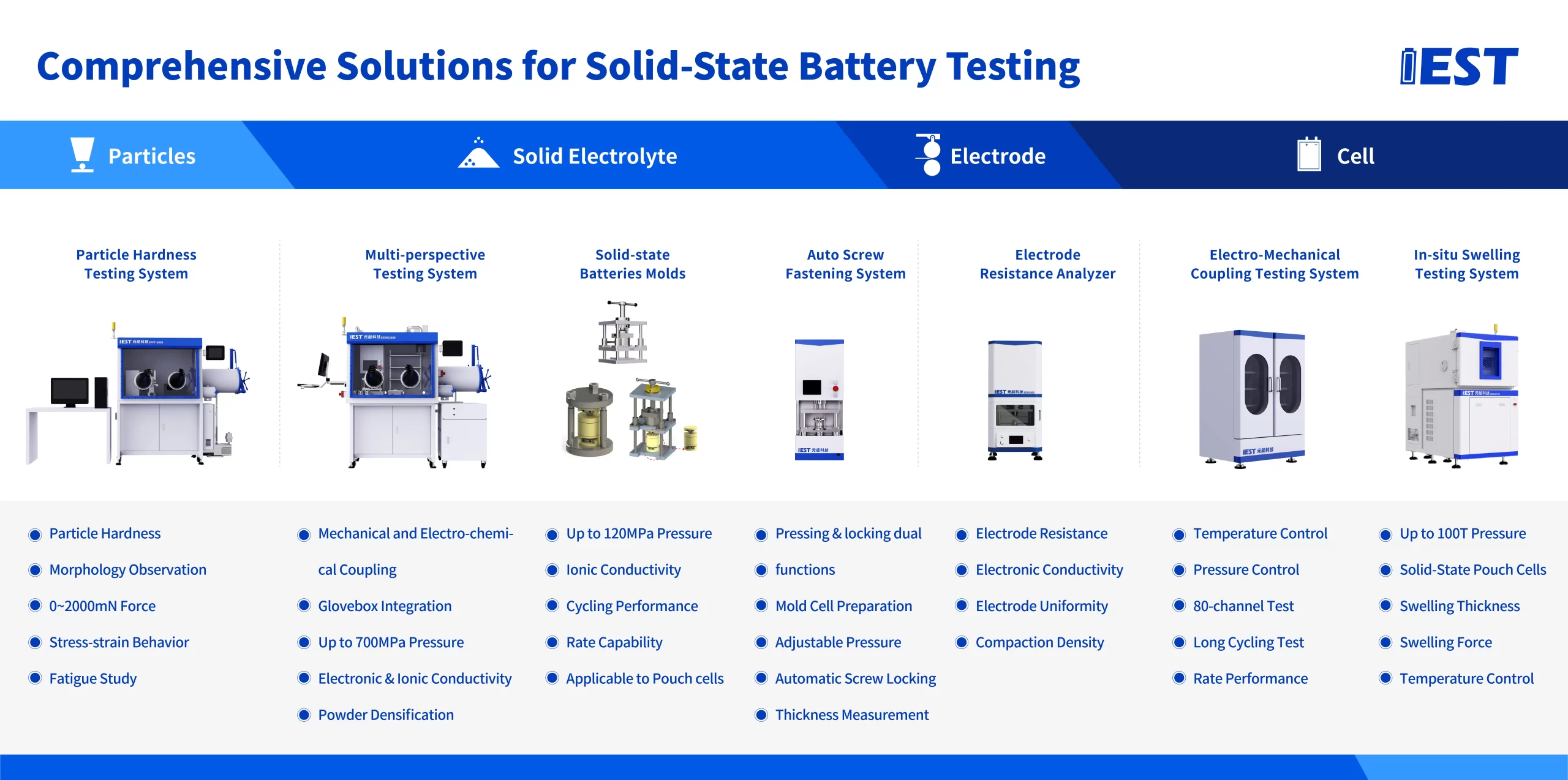

7. All-Solid-state Lithium Battery Testing Solutions Provider:IEST Instrument

IEST is a high-tech enterprise focusing on R&D and production of lithium ion battery tester. IEST is a professional manufacturer that integrating laboratory instrument R&D and production, method development, instrument sales and technical services. Committed to providing leading testing solutions and services for the global new energy field, IEST company serves key clients like CATL, BYD, Huawei, Svolt, GM, Leyden, Sintef, Factorial, Cabot, Cuberg.

At IEST, we provide a comprehensive suite of cutting-edge testing solutions designed specifically for all-solid-state batteries—from material-level characterization to full-cell performance evaluation, from multi-dimensional powder compression(PRCD Series) & EIS (SEMS series) to glovebox-integrated single-particle mechanics(SPFT Series), automatic mold-pressing, SWE in-situ swelling analyzers and BPD pressure/temperature mapping. Our integrated systems enable researchers and manufacturers to accurately measure mechanical, electrochemical, and thermal behaviors under realistic operating conditions, accelerating the development and commercialization of next-generation batteries.

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.