Description

1. Product Introduction

1.1 Background

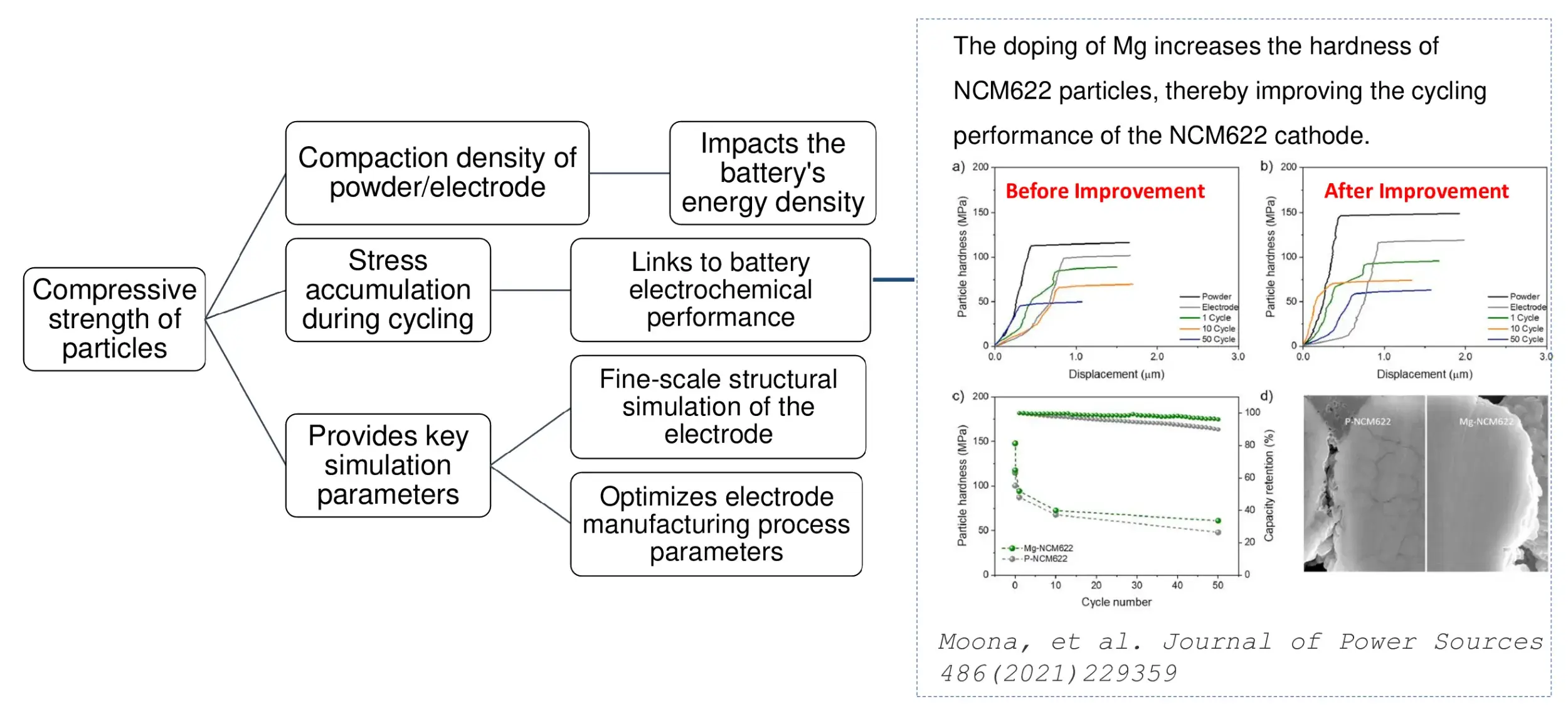

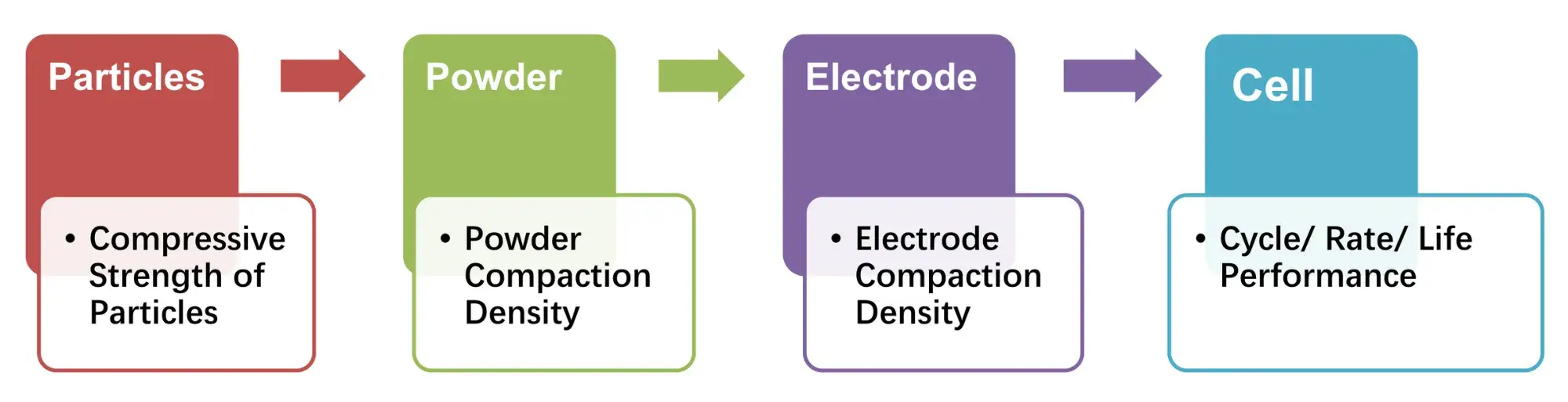

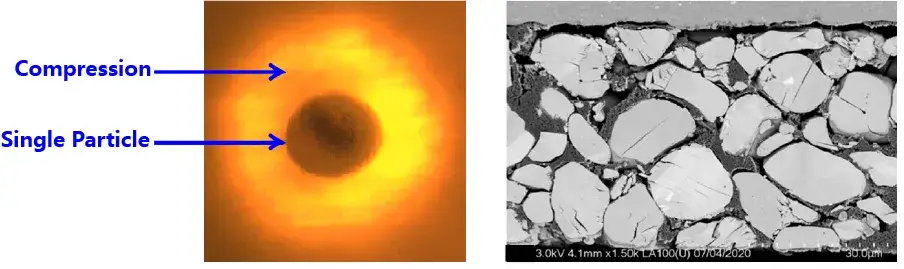

Testing the crushing strength of battery material particles can be used to evaluate the pressure resistance of the material and guide the rolling process. Materials with high mechanical strength will have better subsequent cycle stability.

1.2 Testing Object

Lithium battery cathode and anode electrode materials(Cathode: polycrystalline ternary; lithium-rich material; Anode: silicon-based, hard carbon, etc.; solid electrolyte)

1.3 Test Particle Size

Single particle size: 5~50 μm

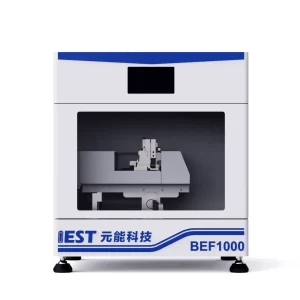

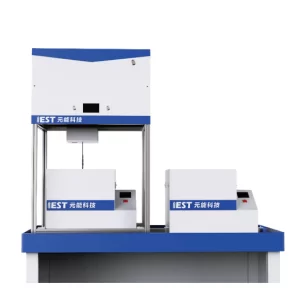

1.4 Equipment Composition

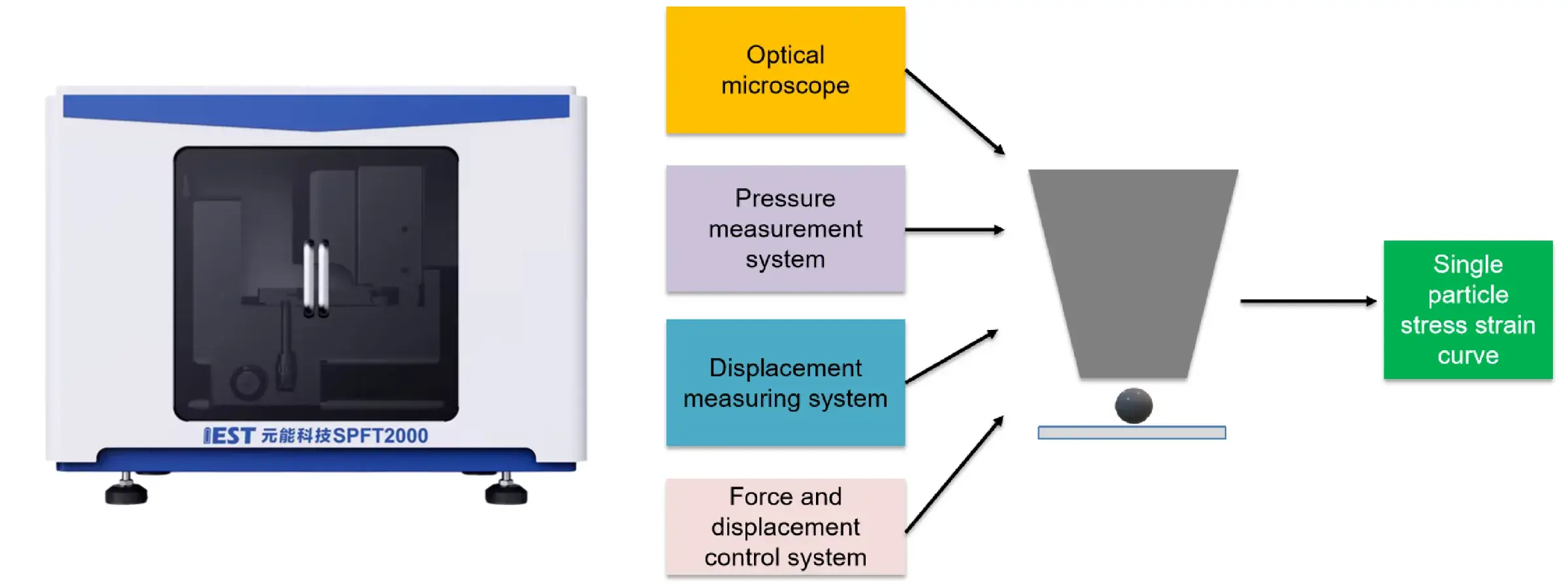

-

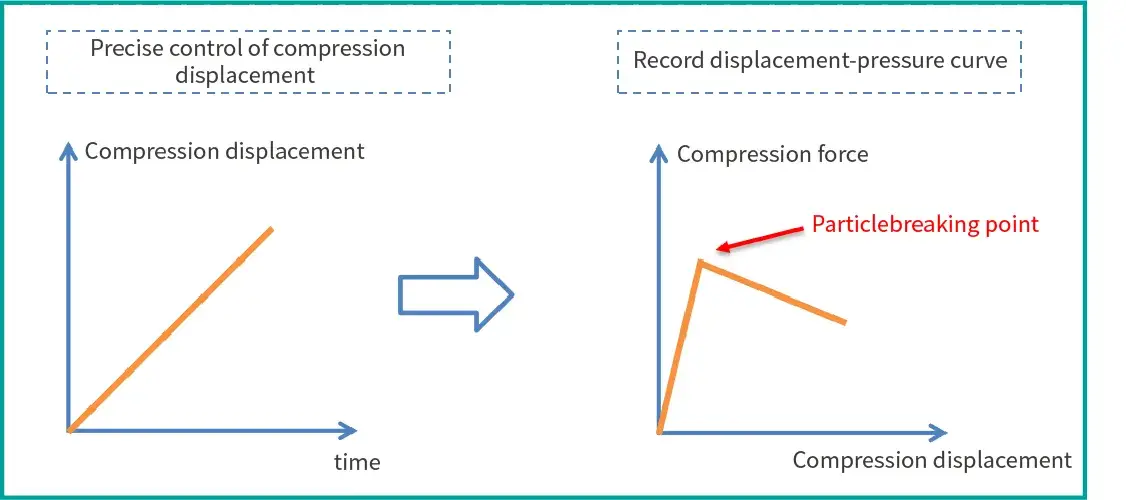

Core Function: Particle compression with force-displacement curve recording — identifying the failure point: the force at which the particle is crushed (fails).

-

Functional Modules: Integrated control of displacement and pressure via software; real-time particle imaging and video recording.

1.5 Equipment Features

1.5.1 Diverse Structural Functions

-

High-resolution optical imaging

-

Precise displacement control

-

Inverted optical system design

-

Automated XY displacement stage

1.5.2 Multiple Testing Modes

-

Displacement control mode

-

Pressure loading-unloading mode

-

Fatigue testing mode

1.5.3 Fully Automated Software

-

Real-time force-displacement curve display

-

One-click data analysis

-

Real-time observation and recording of particle crushing process

1.5.4 Customized for Lithium Battery Materials

-

Cathode materials

-

Anode materials

-

Precursor materials

-

Solid electrolyte materials

1.5.5 High Cost-Effectiveness

-

Offers comparable functionality to similar foreign instruments at a significantly lower price.

2. Testing Program

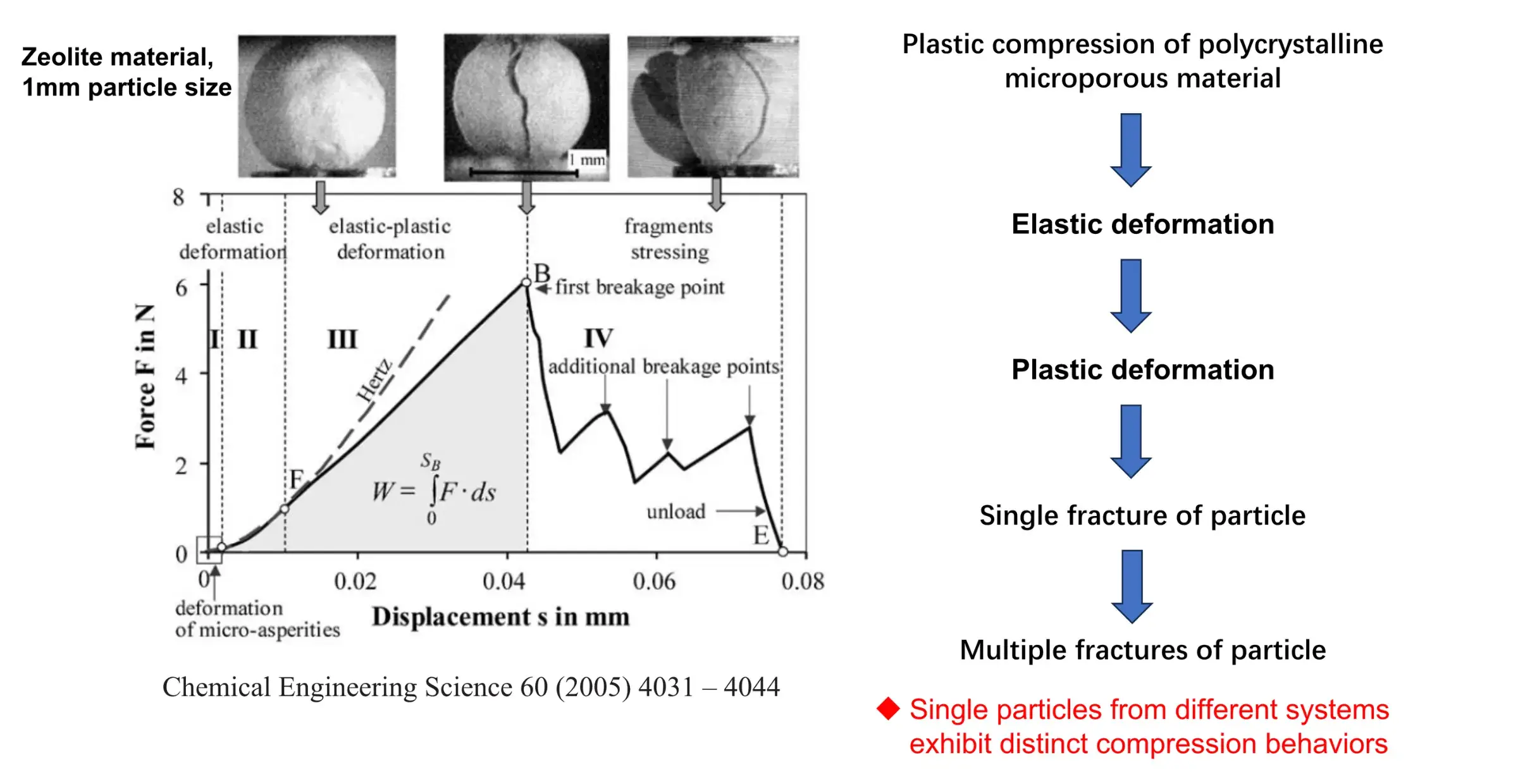

2.1 Testing Method

Disperse the powder into the liguid, add it dropwise to the glass slide. Locate the single particle under an optical microscope. Control the pressure head to press down at a constant speed. Collect the force and displacement curves during the particle compression process and calculate the mechanical properties of the single particle.

2.2 Test Parameters

- Magnification: up to 1200 times;

- Pressure test range: 0-100 mN;

- Pressure test accuracy: ±0.1 mN;

- Minimum displacement unit: 10 nm;

- Data collection frequency: 1000HZ;

- Comply with national standard GB/T 43091-2023″Powder Compressive strength Test Method”

Applications

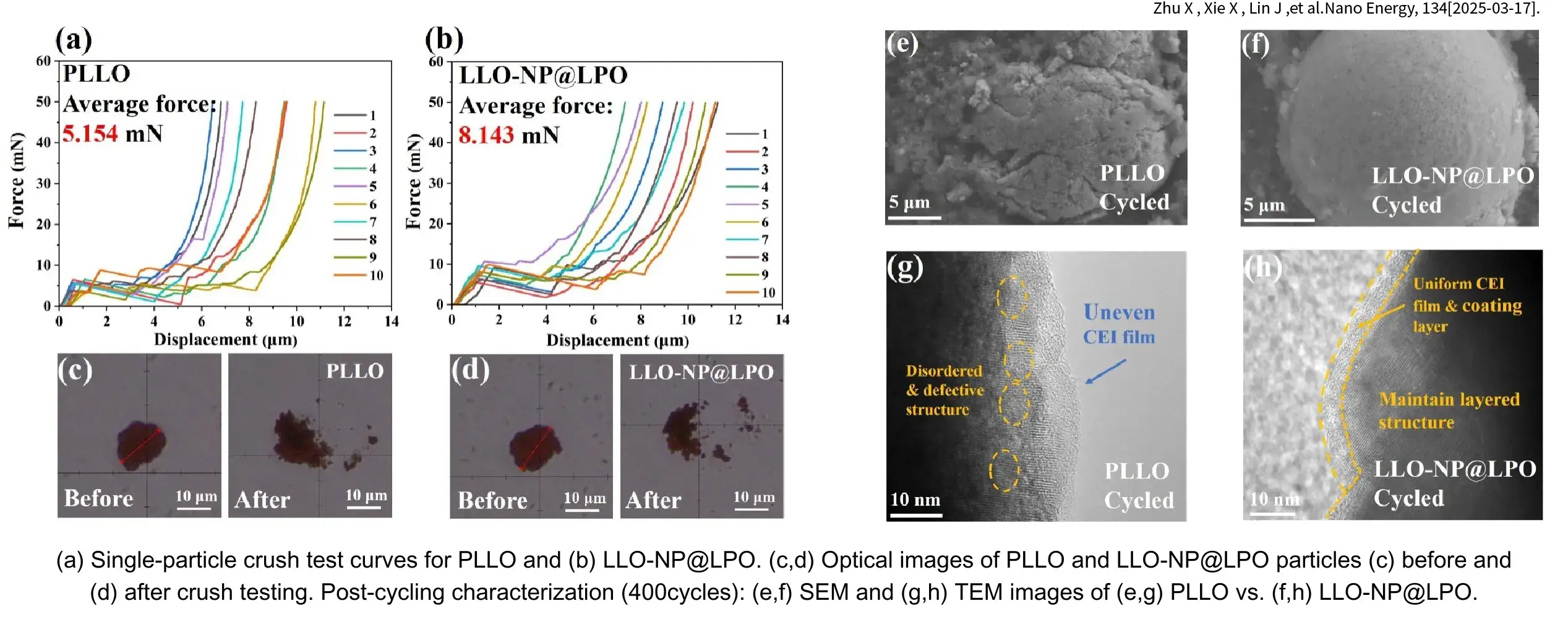

1. Cathode: Lithium-rich Manganese-based Layered Oxides (LLOs)

-

The coated LLOs exhibits superior pressure resistance, which corresponds to better structural stability and higher capacity retention after cell cycling.

-

Single-particle crush measurements reveal the intrinsic relationship between mechanical properties and electrochemical stability in cathode materials at the microscale. This approach not only provides direct assessment criteria for evaluating and screening high-performance materials, but also drives optimization of surface modification strategies and construction of battery lifetime prediction models through quantitative, high-precision testing methodologies. It serves as a critical bridge connecting material design with practical applications.

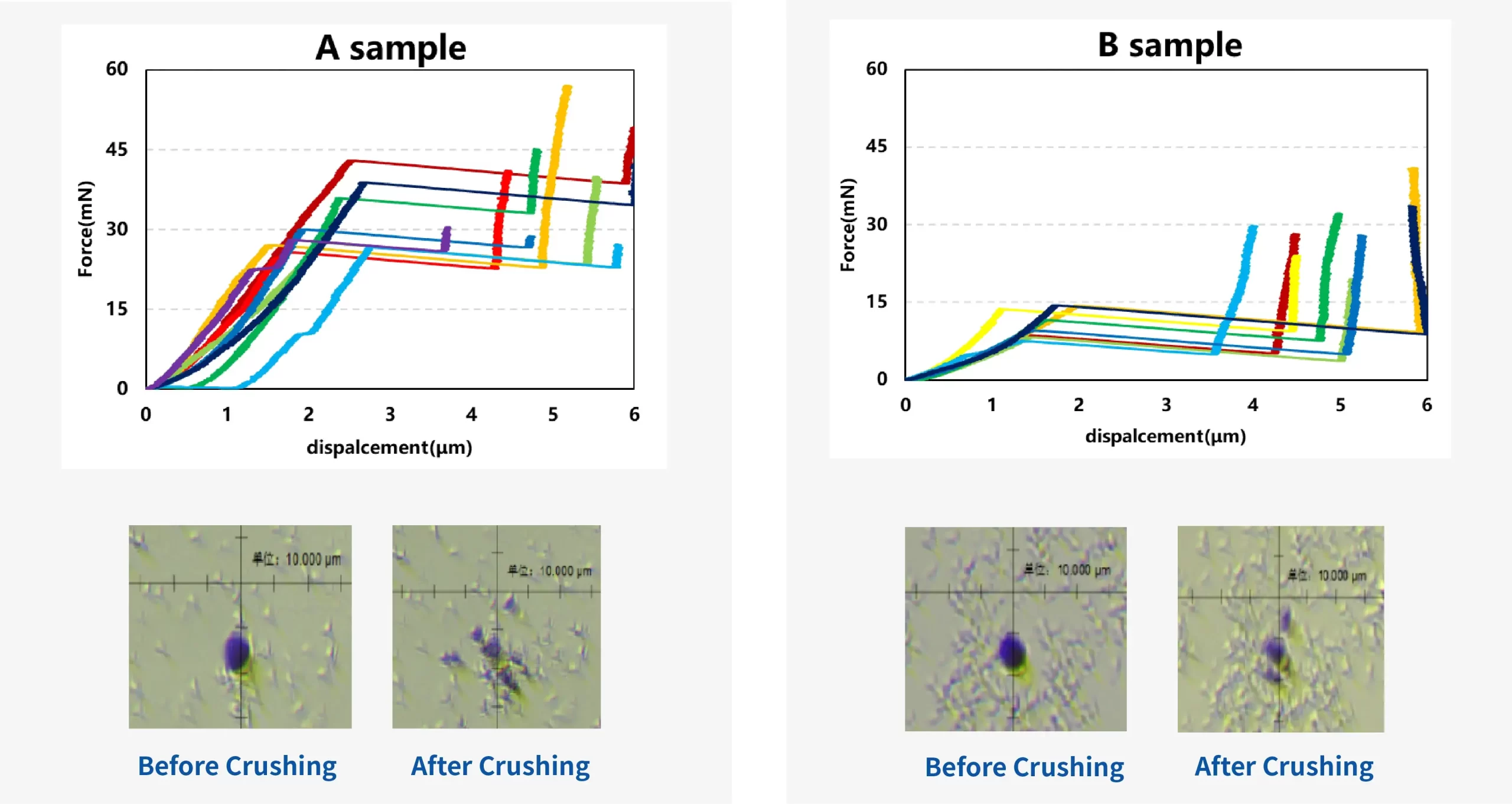

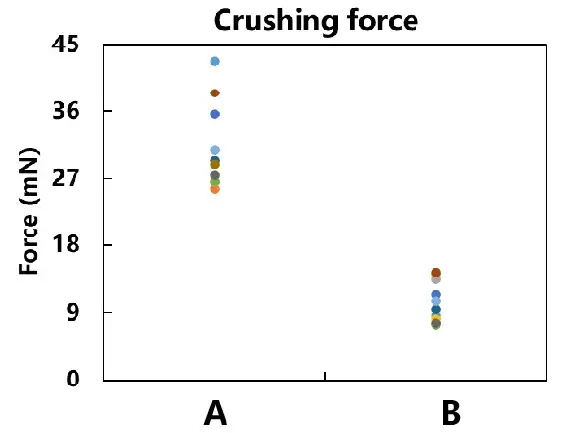

2. Anode Material-SiC

Two silicon-carbon materials with different electrode compaction.

Two silicon-carbon materials with different electrode compaction.- Comparison of crushing force distribution: A>B.

- Analysis of stress-displacement curves: Sample A exhibits initialmicro-crackingfollowed by complete collapse, while sample B expe-riences direct structural collapse and fragmentation.

- Comparison of Disintegration States: after fracturing, all three groups disintegrate into fine granular states.

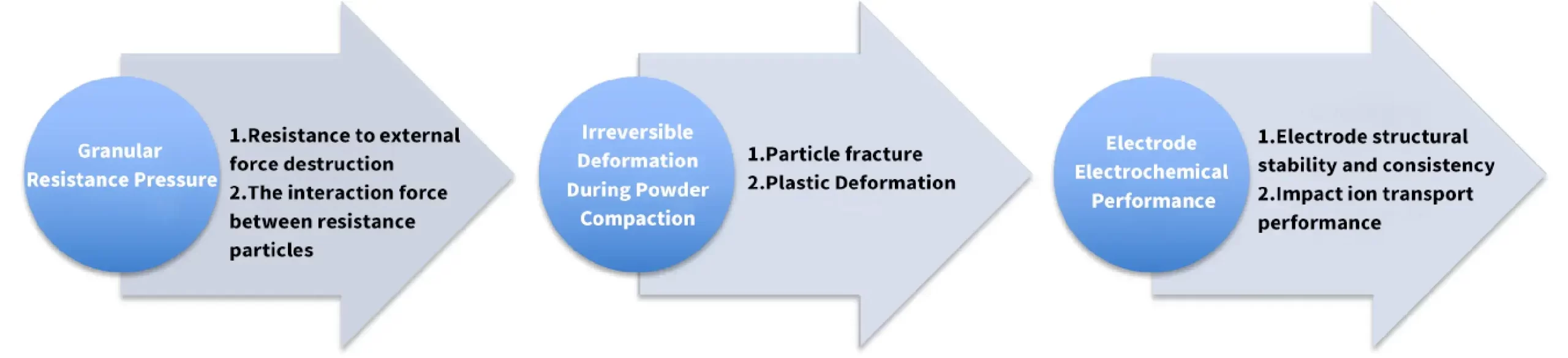

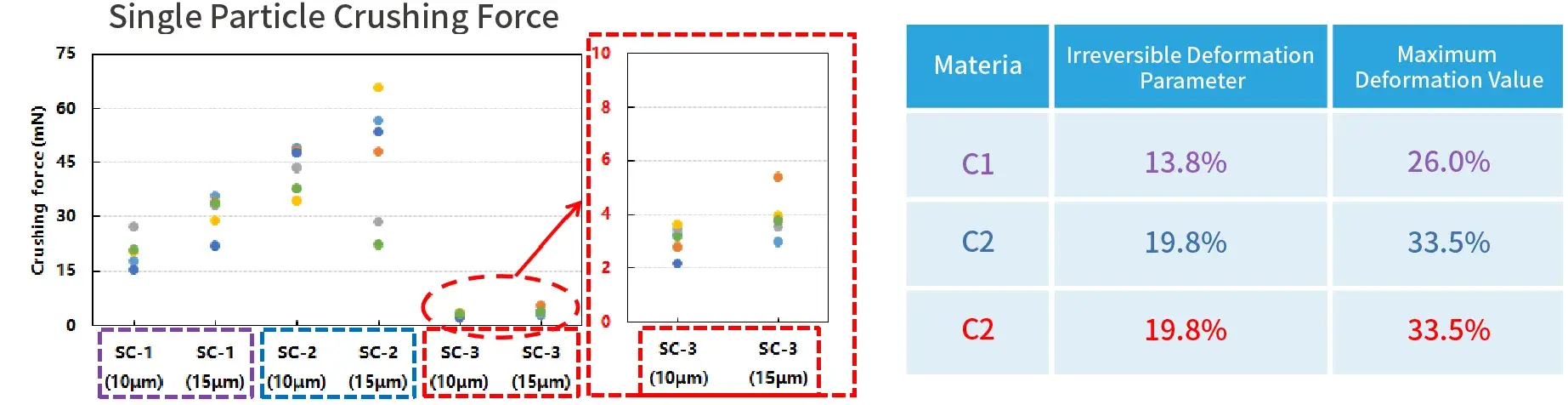

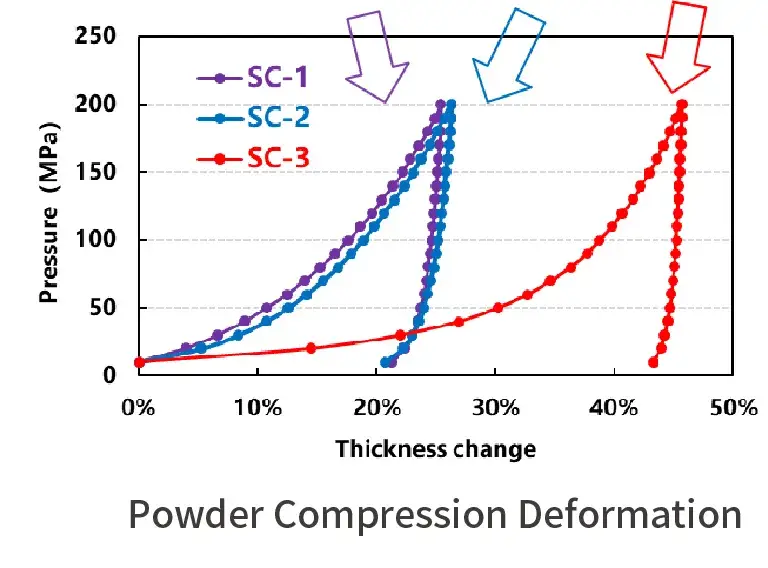

Particle Compression Resistance and Powder Compaction

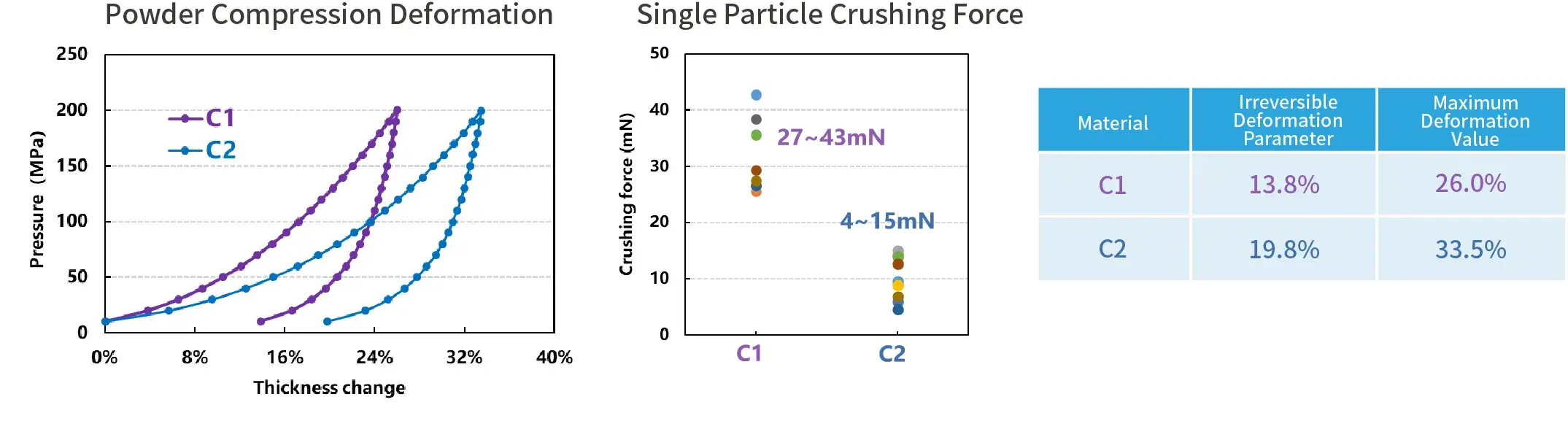

Case 1: Two Different Pure Carbons

- The compressive resistance of particle level C1 is stronger. Corresponding to the powder end, C1has a higher compression modulus than C2, with both maximum deformation and irreversible deformation smaller than C2.

Case 2: Three Different Carbon-Silicon Materials

- SC-3 has weaker compressive strength of its particles, resulting in significantly larger maximum deformation and irreversible deformation when the powder is compressed compared to theother two materials.

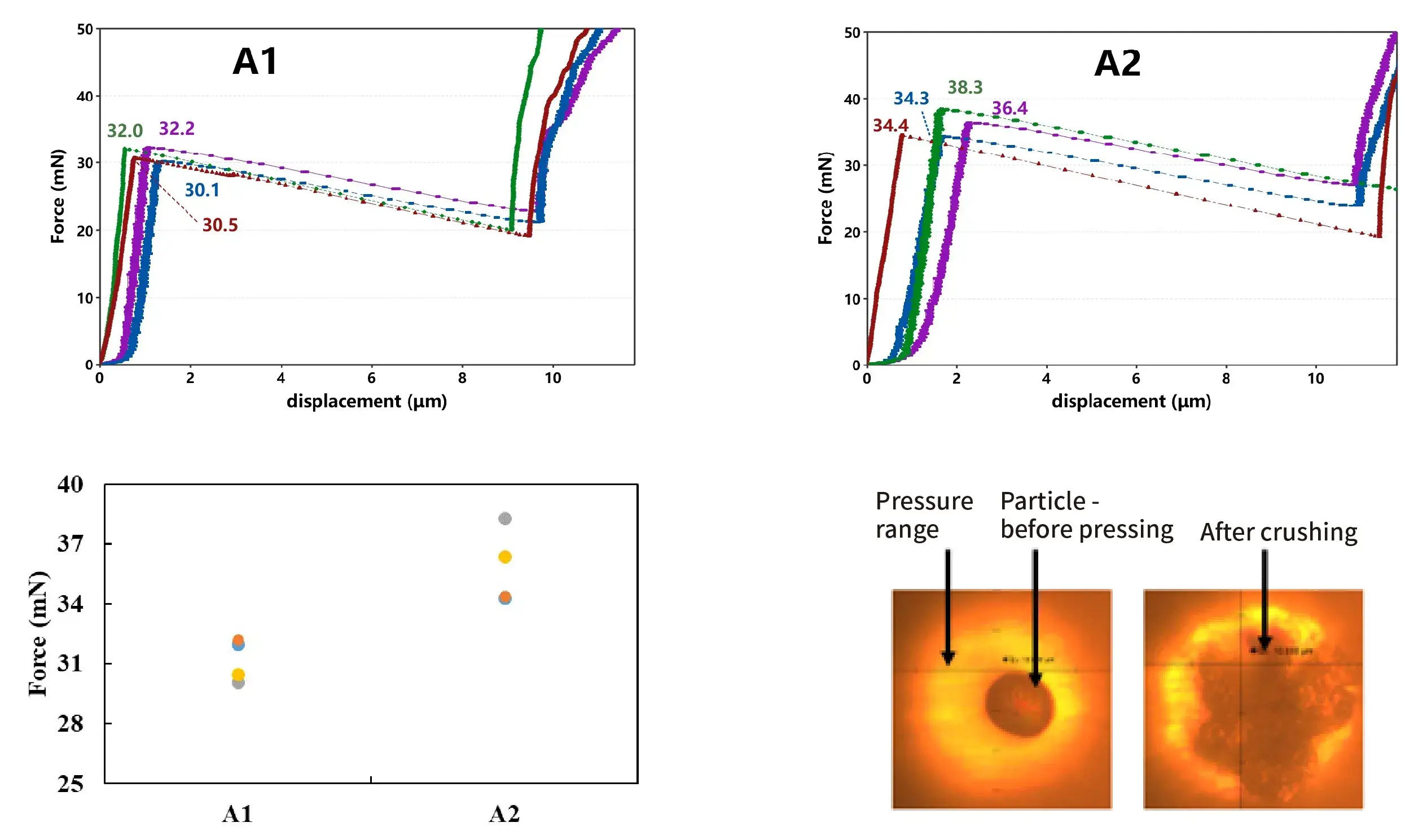

3. Ternary Cathode Material-NCM811

Case 1:

-

Ternary cathode materials A1 and A2 are sintered from the same precursor but undergo different sintering processes, with both exhibiting a particle size D50 of 18 μm.

-

A2 demonstrates superior compressive strength compared to A1, indicating that modifying the sintering process can enhance material hardness. The single-particle mechanical characterization method provides valuable guidance for optimizing sintering parameters.

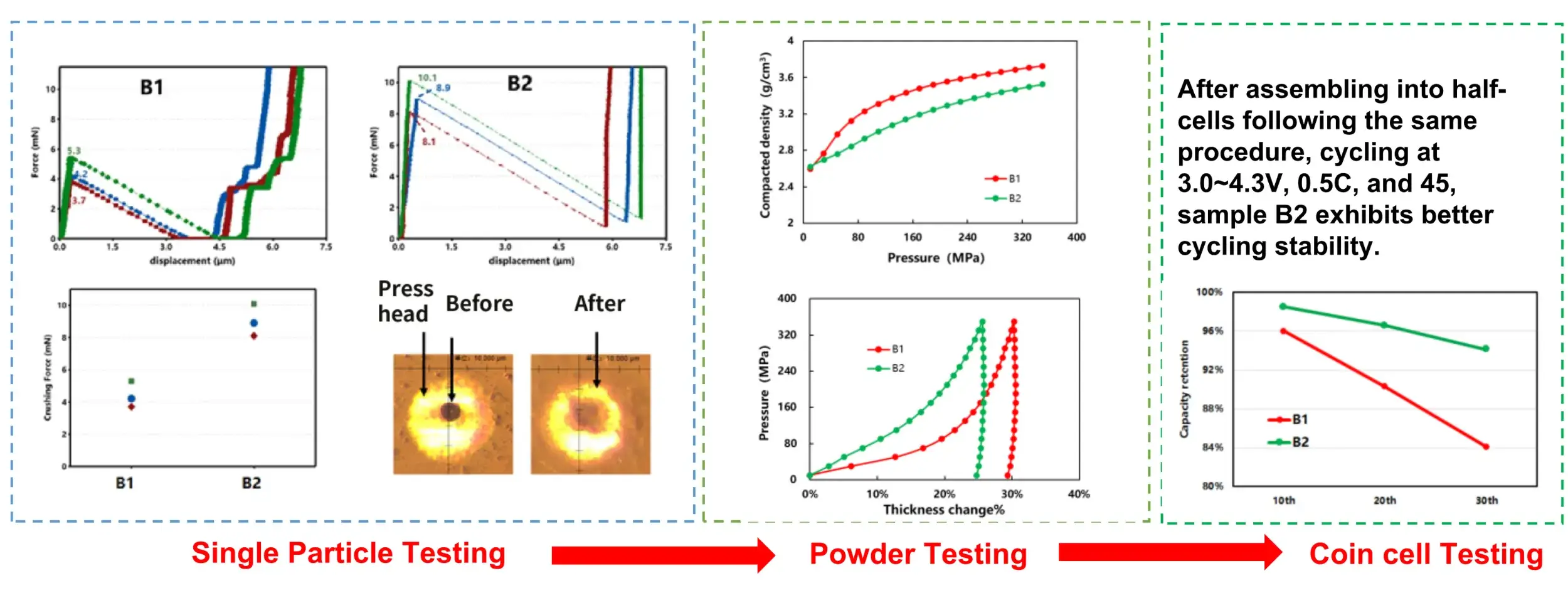

Case 2:

-

B1 and B2 are sintered from different precursors, both with a particle size D50 of 9.5 μm.

-

They exhibit differences in: particle fracture mechanisms; powder compaction behavior; and coin cell cycling performance.

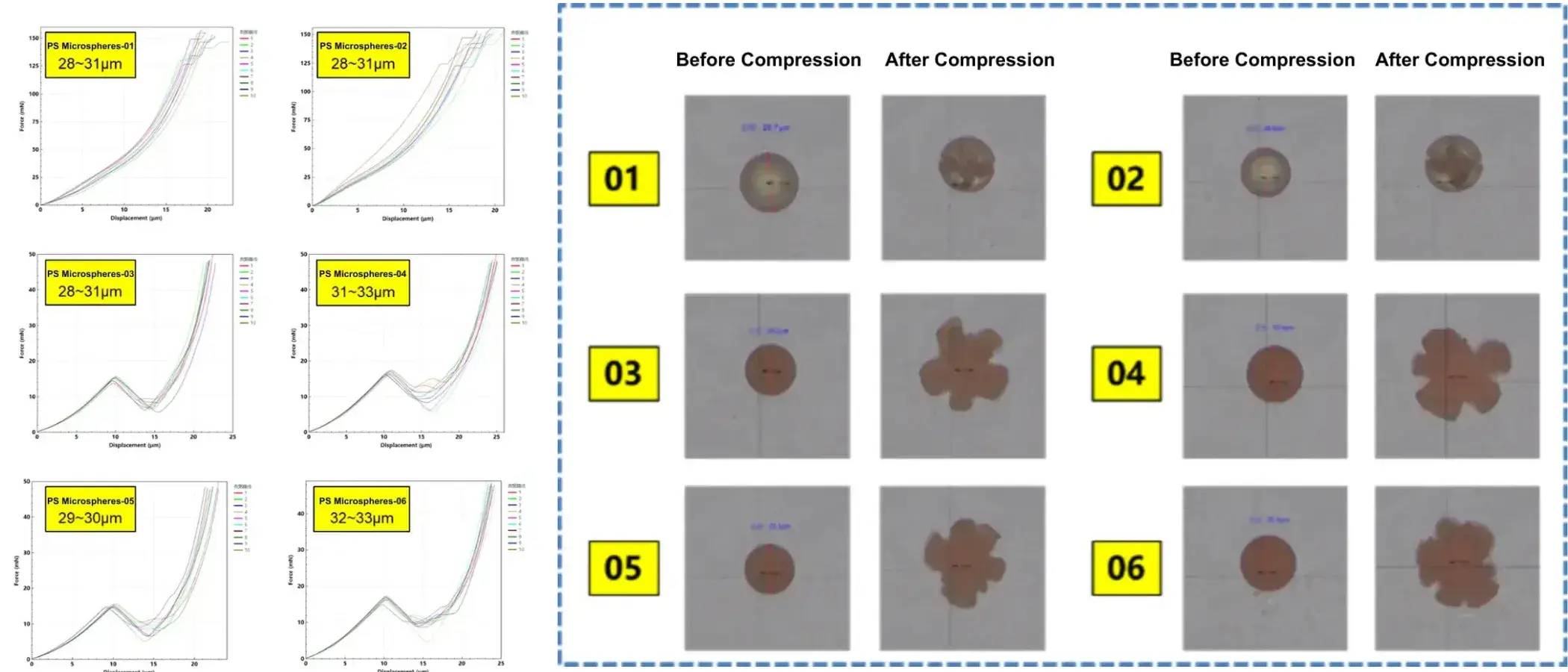

4. Non-battery Application: Polystyrene Microspheres

- Polystyrene microspheres of different types exhibit significant variations in compressive properties, deformation mechanisms, and fracture behaviors. These distinct characteristics determine their respective application scenarios.

Video