-

iestinstrument

Application Issues Analysis of Si Anode in High Energy Density Lithium-ion Batteries

1. Abstract

The pursuit of higher energy density in lithium-ion batteries has positioned silicon as a promising next-generation anode material due to its high theoretical capacity. However, its practical implementation faces significant hurdles. In 2017, a team led by Jaephil Cho comprehensively summarized the key challenges of integrating Si anodes into full-cells, emphasizing that achieving high volumetric energy density requires careful cell design. Also place special emphasis on electrode swelling and capacity fade in full cells, and on methods for anode thickness measurement and tracking expansion during cycling. Their work provides a critical analysis of electrode expansion and capacity loss, underscoring the importance of manufacturing processes on final performance.

Figure 1. Electrochemical Cell Design

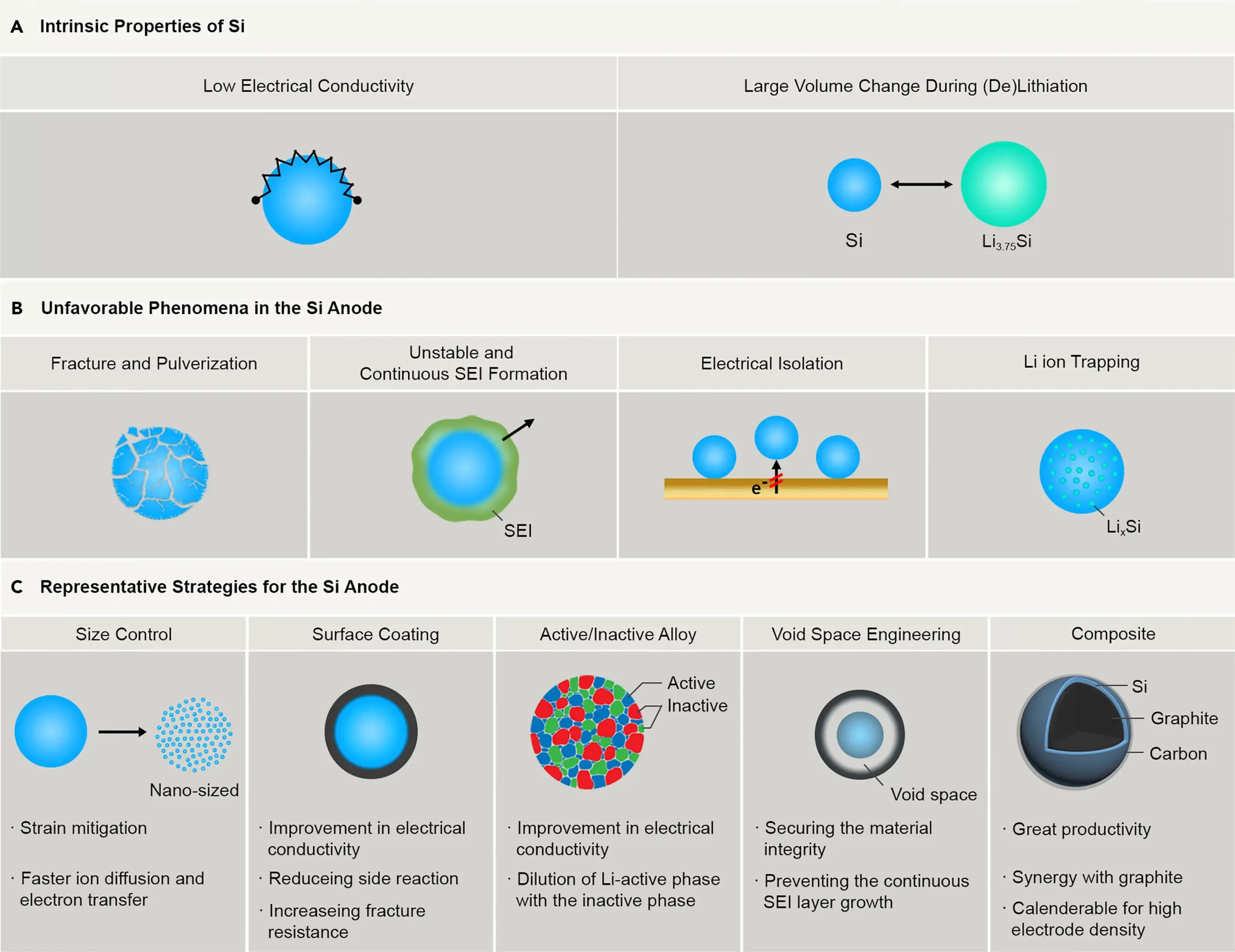

2. Why Si Anode Promises and Problems Coexist

Silicon’s theoretical capacity far exceeds graphite, but its widely reported drawbacks stem from two tightly coupled facts: intrinsic low electronic conductivity (on the order of 10⁻³ S·cm⁻¹) and very large alloying-induced volume change (~400% on full lithiation). As Si alloys to form LixSi during lithiation, the dramatic volume change repeatedly stresses particles, the electrode matrix, and the solid electrolyte interphase (SEI). These mechanical and interfacial stresses are the root causes of the most common failure modes seen in Si-containing electrodes.

3. Primary Failure Modes Observed With Si Anode

Practically, Si anodes exhibit several interrelated degradation phenomena:

-

Particle pulverization and cracking

-

Unstable Solid Electrolyte Interphase (SEI) growth

-

Loss of electrical contact within the electrode

-

Trapping of lithium ions in isolated regions

To address these issues, several improvement strategies are commonly employed, as summarized in Figure 2:

-

Silicon nanostructuring

-

Surface coating of silicon particles

-

Alloying and doping

-

Core-shell structures

-

Compositing with graphite or carbon

Figure 1. A summary of the key challenges and improvement strategies for Si anodes.

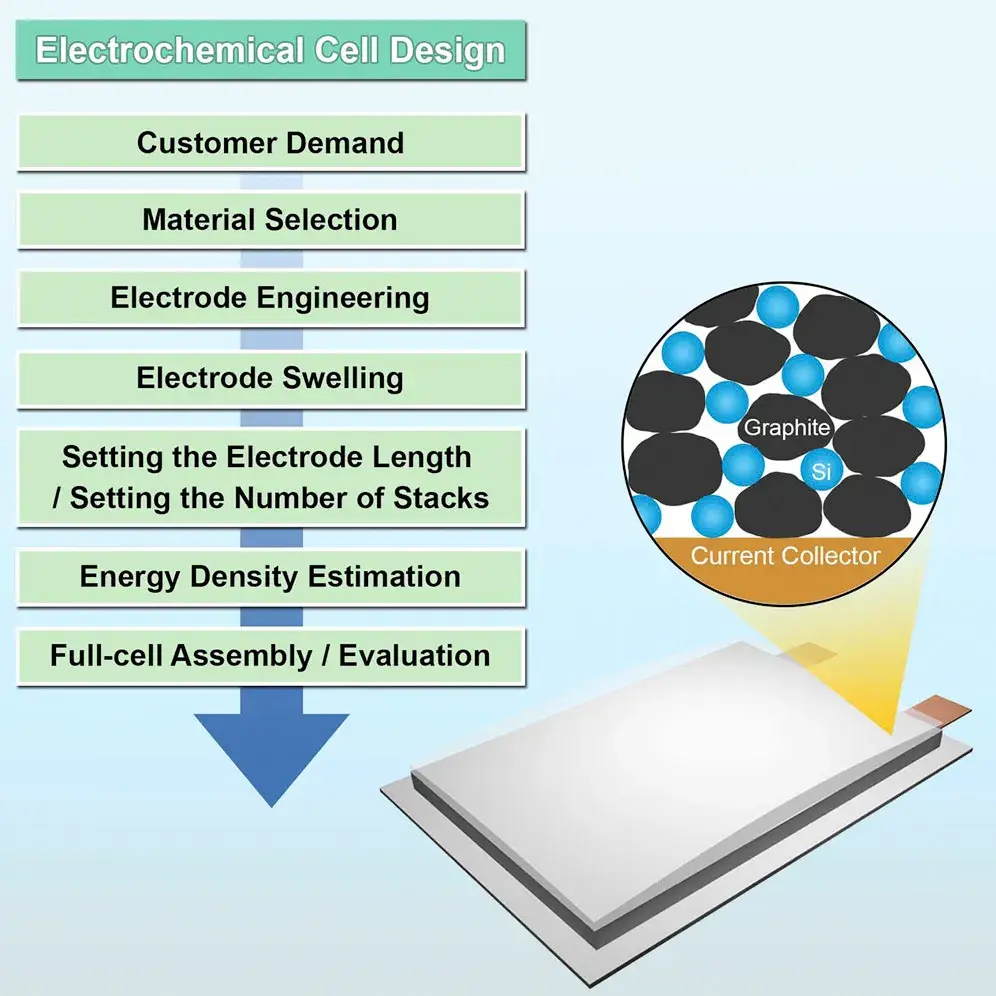

4. Full-cell Design Process

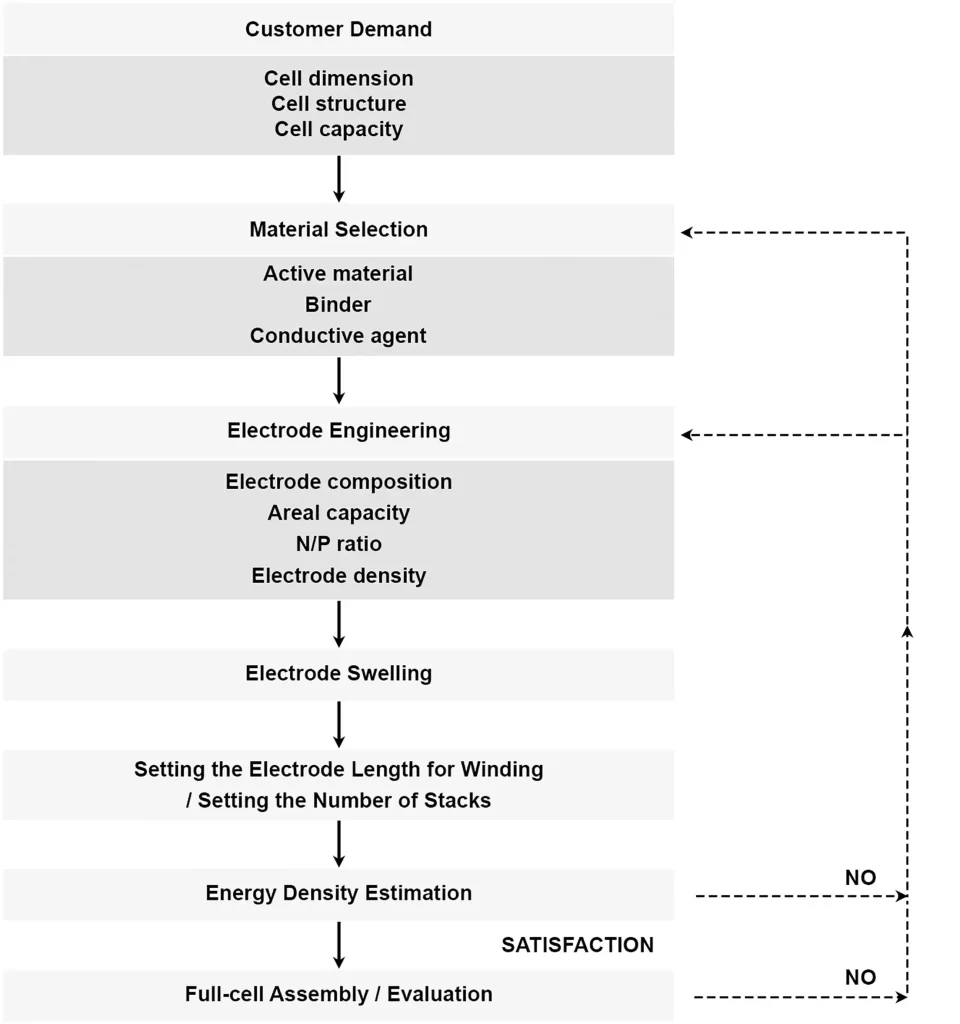

Incorporating a silicon-based anode into a commercial full-cell requires a systematic design approach. The process, outlined in Figure 3, involves selecting materials and tuning anode thickness measurement and other process parameters based on specific cell performance requirements before final assembly and electrochemical validation.

Figure 3. Flow Chart of the Electrochemical Cell Design

5. Critical Performance Analysis: Expansion and Capacity Fade

5.1 Electrode Expansion: Why Anode Thickness Measurement Matters

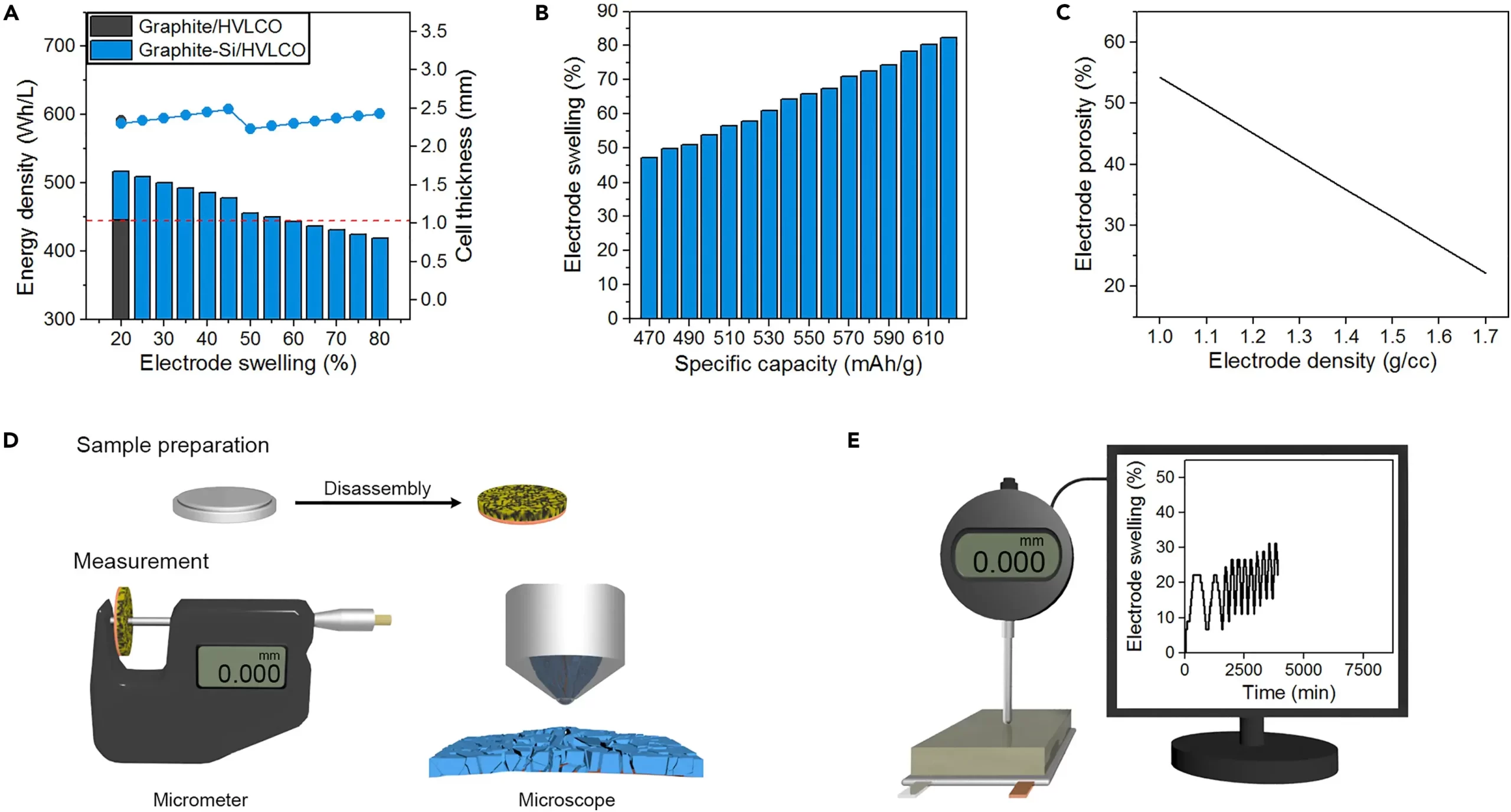

Electrode thickness increase during cycling reduces volumetric energy density and can cause mechanical interference with cell packaging. When the electrode expansion ratio exceeds 60%, the cell’s volumetric energy density is severely compromised. Furthermore, as the specific capacity of silicon-carbon composite anodes increases, so does the electrode’s expansion, as shown in Figure 4. Quantifying this swelling, either ex-situ or in-situ, is essential for cell design.

Figure 4. The relationship between electrode energy density and thickness expansion.

5.2 Capacity fade in half-cells vs full-cells

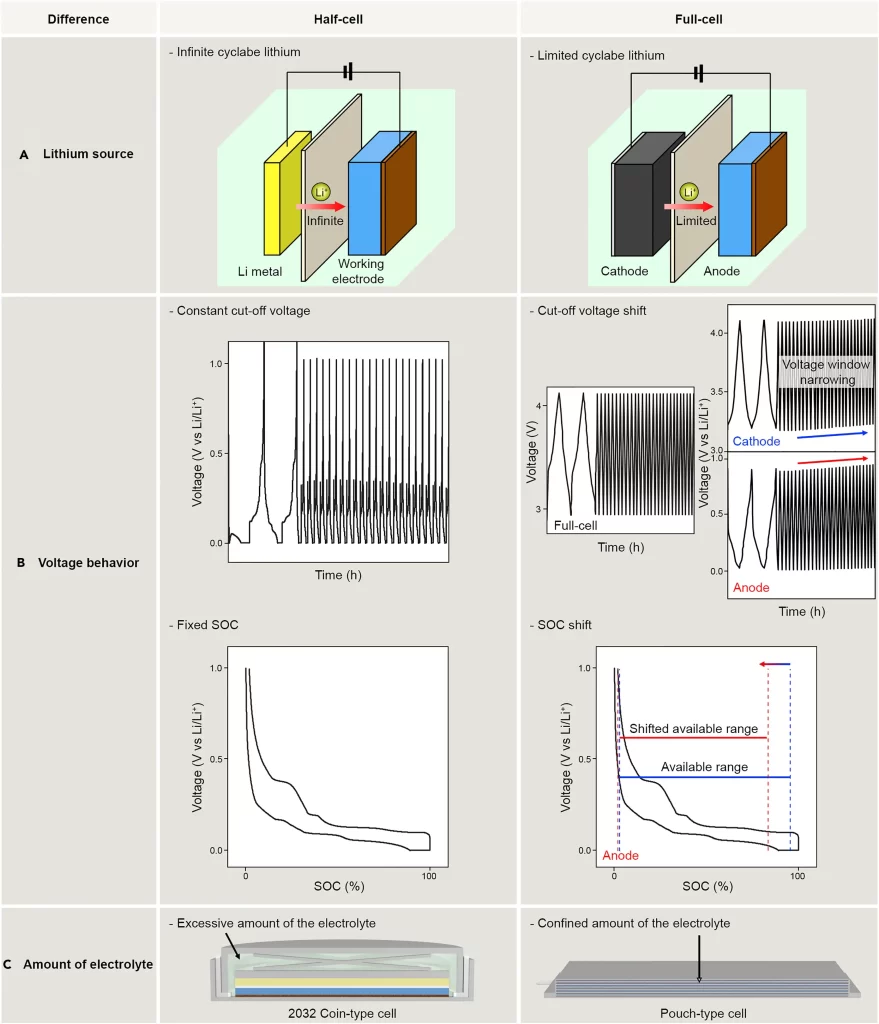

Capacity fade mechanisms manifest differently in half-cells (Li metal counter electrode) versus full-cells:

-

Half-cells typically have abundant Li (from the lithium metal) and excess electrolyte, so initial SEI formation and Li consumption may appear less critical to long-term capacity loss. The half-cell environment can therefore overpredict stability relative to a full-cell.

-

Full-cells have limited Li inventory (determined by the cathode), and initial SEI formation during the first charge consumes a fraction of that finite Li, shifting SOC windows of both electrodes. Over time this results in a reduced usable capacity window and often an accelerated apparent capacity loss. Additionally, restricted electrolyte volumes and constrained porosity in practical cells can accelerate SEI growth and dry-out effects in later cycles.

Figure 5. A comparison of capacity fade mechanisms in half-cells vs. full-cells.

6. Summary

Successfully integrating silicon anodes into high-energy-density lithium-ion batteries requires a holistic approach that addresses fundamental material challenges through strategic cell design. A deep understanding of electrode expansion and the distinct capacity fade mechanisms in full-cells is paramount. Focusing on manufacturing processes and precise characterization, including anode thickness measurement during cycling, is critical for optimizing performance and accelerating the adoption of silicon-based anodes.

7. Original Article

SujongChae, Minseong Ko,Kyungho Kim,Kihong Ahn and Jaephil Cho. Confronting Issues ofthe Practical Implementation of Si Anode in High-Energy Lithium-Ion Batteries.Joule 1, 47–60, September 6, 2017.

8. IEST Related Test Equipment Recommended:

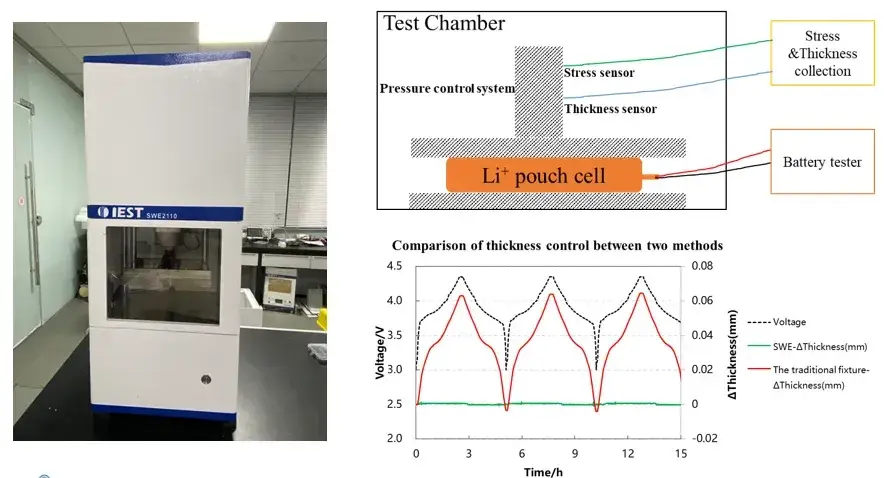

SWE Series In-situ Swelling Analysis System

- A Variety of Cell in-situ Characterization Methods (stress & swelling thickness): the swelling thickness and swelling force of the cell charging and discharge process are measured at the same time, so as to quantify the changes of cell swelling thickness and swelling force.

- More Refined and Stable Test System: Using a highly stable and reliable automatic adjustment platform, equipped with a high precision thickness measurement sensor and a pressure regulation system, the relative thickness measurement resolution is 0 m, to realize the long cycle monitoring of the long-term charging and discharge process of cells.

- Diversity of Environmental Control and Test Functions: SWE series equipment can adjust the temperature of the charge and discharge environment to help study the swelling behavior of cell cells under high and low temperature; In addition to conventional thickness and pressure test, cell swelling force, compression modulus and compression rate can be tested.

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.