-

iestinstrument

Analysis of Electrical Conductivity and Compaction Density of LMFP Material

1. Preface

With the rapid advancement of the new energy sector, lithium-ion batteries have emerged as essential energy storage solutions. Among these, lithium iron phosphate (LiFePO₄) batteries are highly regarded for their superior safety, long cycle life, cost-effectiveness, abundant raw materials, and relatively low environmental impact. However, their relatively low discharge voltage plateau (~3.4 V) and limited energy density have restricted broader application.

Lithium manganese phosphate (LiMnₓFe₁₋ₓPO₄, or LMFP) presents a promising alternative. With the same olivine-type structure as LiFePO4, LMFP offers a higher Li⁺/Li electrode potential of 4.1 V, resulting in a higher voltage platform. Through iron doping into LiMnPO4, LMFP achieves a stable structure and enhanced voltage characteristics, making it a highly attractive next-generation cathode material. Figure 1 illustrates the crystal structure of lithium manganese phosphate (Li MnxFe1-xPO4)[1].

![Analysis of Electrical Conductivity and Compaction Density of LMFP Material 1 Figure 1. Lithium-manganese iron phosphate (Li MnxFe1-xPO4) Schematic diagram of the crystal structure of the[1]](https://iestbattery.com/wp-content/uploads/2024/08/Figure-1.-Lithium-manganese-iron-phosphate-Li-MnxFe1-xPO4-Schematic-diagram-of-the-crystal-structure-of-the1.webp)

Figure 1. LMFP Structure: Crystal Diagram of Lithium Manganese Iron Phosphate (LiMnₓFe₁₋ₓPO₄)[1]

First-principles calculations indicate that the electronic band gap of LiFePO₄ is 0.3 eV, characteristic of a semiconductor, whereas LMFP has a band gap of 2 eV, behaving more like an insulator. To overcome the inherently poor electronic conductivity of LMFP, carbon coating is widely adopted during material synthesis. Carbon not only inhibits particle growth and shortens lithium-ion diffusion paths but also significantly enhances electronic conductivity.

This study evaluates the conductivity and compaction density of five LMFP samples under varying pressure conditions using the PRCD3100 powder testing system. Additionally, the compression and rebound behaviors of two selected high-conductivity LMFP materials are examined to assess their performance differences.

2. Test Method

The PRCD3100 Powder Resistivity & Compaction Density System was employed to measure the conductivity and compaction density of the five LMFP materials. The system, shown in Figure 2, operates in a two-probe configuration. Testing parameters included applied pressures from 10 to 200 MPa at 20 MPa intervals, with a 10-second holding time at each step.

Figure 2. (a) PRCD3100 appearance diagram; (b) PRCD3100 structure diagram

3. Test Results and Analysis

3.1 Powder Resistivity

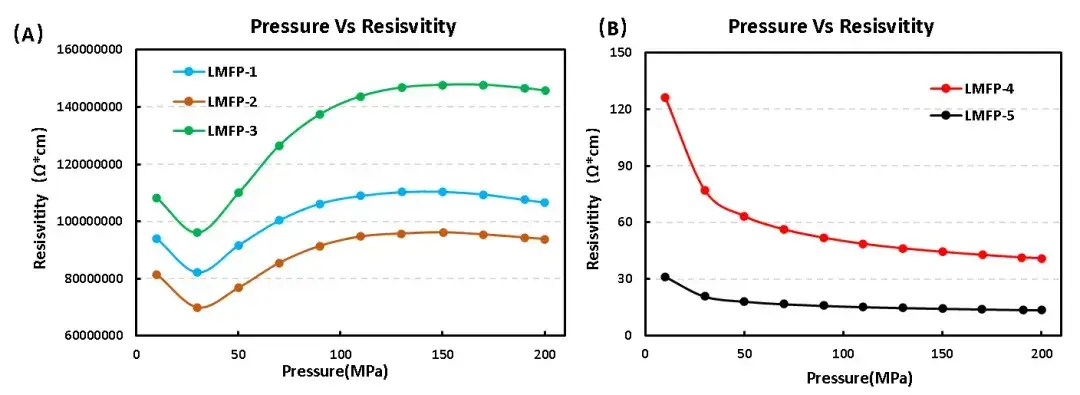

In the early development of lithium manganese iron phosphate, limited by its low conductivity and multiplier performance, the commercialization process is slow.With the progress of modification technologies such as carbon coating, nanotechnology and lithium filling technology, its conductivity has been improved to some extent, and the electrochemical properties of lithium manganese iron phosphate have been improved by controlling particle morphology, nano-chemistry and ion doping. Material conductivity evaluation can be used as an effective way to evaluate material physicochemical properties.Figure 3 shows the resistivity test results of five different lithium manganese iron phosphate materials. From the resistivity test results, LMFP-4/5 electron-conductivity samples are much better than L MFP-1, L MFP-2 and L MFP-3 samples. From the results of different materials, the material modification can effectively improve the poor conductivity of lithium manganese iron phosphate materials.In addition, the resistivity of the first three groups of L MFP increases with the increase of the test pressure, which may be due to the deterioration of the particles due to the deformation and crushing.

Figure 3. Resistivity test results of the five LMFP materials

3.2 Compaction Density

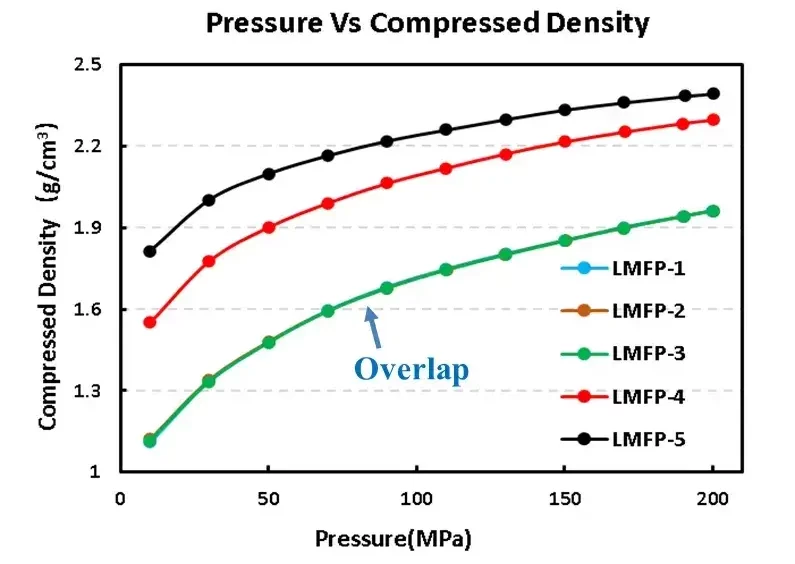

The material compaction density is closely related to the specific capacity, efficiency, internal resistance and battery cycle performance of lithium-ion battery. Figure 4 shows the compaction density test results of five lithium manganese iron phosphate materials. LMFP-1/2/3 compaction density, while LMFP-4 and LMFP-5 improve the compaction density, the overall performance is required to obtain better overall performance.

Figure 4. Compaction density test results of the five LMFP materials

3.3 Compression / Rebound Behavior

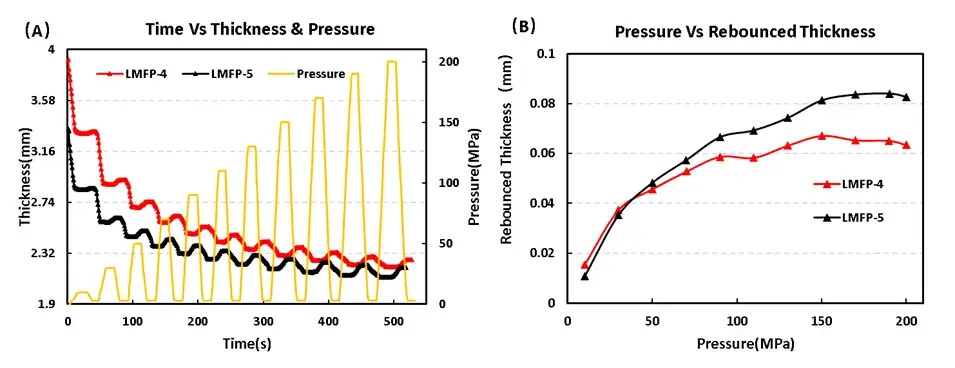

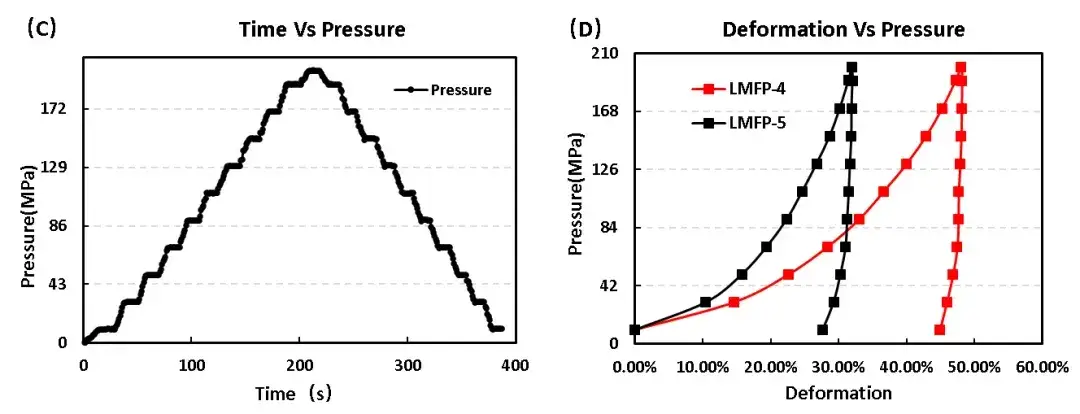

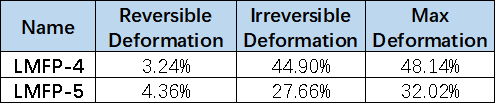

Pressure application and release tests were conducted on LMFP-4/5. Figure 5(a) shows the pressure profiles, while Figures 5(b) and 5(c) illustrate the changes in material thickness and rebound behavior. Under the same sampling mass, LMFP-5 exhibited greater thickness rebound than LMFP-4. Beyond 150 MPa, thickness rebound stabilized, indicating that interparticle voids were largely eliminated, and further rebound was mainly due to elastic deformation of the particles themselves.

The stress-strain curves derived from continuous compression tests (Figure 5(d)) reveal that LMFP-5 undergoes slightly more deformation than LMFP-4. The higher slope of the stress-strain curve for LMFP-5 indicates greater resistance to compression, consistent with the results in Figure 5(a). These findings suggest that LMFP-4 can achieve higher compaction density compared to LMFP-5.

Figure 5. Stress and strain curves during compression and unloading of two LMFP materials

Table 1. Summary of Shape Variable Data for the Two LMFP Materials

4. Conclusion

The powder resistance and compaction density tester (PRCD3100) equipment is used to detect the conductivity and compaction density. The test results show that the conductivity and compression density, with different compression properties, which is closely related to the material structure, can further realize deeper mechanism analysis with SEM and other test methods.The resistivity, compaction density and compression performance detection methods mentioned in this paper can be used as an effective material physical performance detection method to help researchers to quickly assess the difference in intermaterial conductivity and compaction density at the powder level.

5. References

[1] Tfyac E , Ying L, Zf D, et al. Improving the cycling stability and rate capability of LiMn0.5Fe0.5PO4/C nanorod as cathode materials by LiAlO2 modification. ScienceDirect[J].Journal of Materiomics, 2020, 6(1):33-44.

[2] Ma Guoxuan, Liu Rui, Liu Hongquan, et al. Study on cathode materials coated with lithium manganese iron phosphate [J].Journal of Shandong University of Science and Technology: Natural Science Edition, 2020,39 (6): 7.

[3]Dong D A, Ym A, Mk A, et al. Holey reduced graphene oxide/carbon nanotube/LiMn0.7Fe0.3PO4 composite cathode for high-performance lithium batteries .ScienceDirect [J].Journal of Power Sources, 449.

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.