-

iestinstrument

New Ideas For Process Testing Of Dry Electrodes

1. Preface

In recent years, with the continuous development of the new energy industry, new technologies have been continuously introduced, including the 46-series large cylindrical all-tab battery and semi-solid/solid-state batteries. Among these, the dry electrode process has unparalleled advantages over the wet process in reducing battery costs and enhancing battery performance. It is considered the ideal process for semi-solid, solid-state, and 46-series large cylindrical batteries.

In the current lithium battery manufacturing process, the preparation of electrode mainly uses the wet process. This involves mixing active materials, conductive agents, and binders in a solvent in a specific ratio, then applying this mixture onto the surface of a current collector using a coating machine, followed by drying and roll-pressing. In traditional wet processes, particularly when producing positive electrode, NMP (N-Methyl-2-pyrrolidone) solvent is required. This solvent is toxic and environmentally unfriendly, necessitating its recovery, which consumes a significant amount of energy. The coating and drying process, as well as solvent recovery, account for 22.76% and 53.99% of the costs related to equipment, labor, facilities, and energy consumption, respectively. Additionally, electrode sheets prepared using the wet process tend to suffer from binder and conductive agent agglomeration near the electrode surface due to capillary action, while the active material tends to settle, leading to electrode delamination. This impairs the construction of the conductive network within the electrode and reduces the bonding strength between the active material and the current collector[1]. Electrodes manufactured using wet coating technology also exhibit issues such as cracks, delamination, and poor flexibility[2], which are particularly exacerbated when producing thick electrodes. As a result, the thickness of the electrodes is significantly limited by the wet coating technology.

Compared to the traditional wet process, the dry process does not require solvents and directly compresses electrode material powders onto metal current collectors to form electrodes. Unlike the wet process, the dry electrode manufacturing technology does not need large factory spaces for solvent drying, significantly reducing the capital and labor expenditures required for the factory. It is also more environmentally friendly and better suited for large-scale production. Since no solvent is used in the mixing of the electrode components in the dry process, the different components of the electrode material can be evenly distributed due to the shear and friction between the mixer and particles. Furthermore, there is no slurry in the dry mixing process, thus eliminating electrode delamination caused by solvent evaporation. The dry film technology can also easily control electrode thickness and the uniformity of thick electrodes, without generating cracks, making it uniquely advantageous for the preparation of thick electrodes[3].

Currently, there are two relatively mature dry film formation processes: the binder fibrillation method[2] and the electrostatic spraying method[4]. In the binder fibrillation method, the active material powder is mixed with a conductive agent and then PTFE binder is added. An external high shear force is applied to the dry mixture, causing the PTFE to fibrillate and bind the electrode film powder, ultimately extruding the mixture to form a self-supporting film. The electrostatic spraying method uses high-pressure gas to spray pre-mixed active material, conductive agent, and binder particles. Under the action of an electrostatic spray gun, the powder becomes negatively charged and is sprayed onto a positively charged metal foil current collector. The binder-coated current collector is then hot-pressed, causing the binder to melt and adhere to the other powders, which are then compressed into a self-supporting film. However, the electrostatic spraying method does not perform as well as the binder fibrillation method in terms of subsequent processability, adhesion stability, electrode flexibility, and durability. Therefore, the binder fibrillation method is currently the mainstream production process for dry electrodes.

Fibrillation film formation is the preliminary stage of electrode sheet roll pressing. The mainstream machines for fibrillation film formation include: 1) airflow pulverizers, 2) screw extruders, and 3) open mill machines. Among these, airflow pulverizers are the most efficient, while screw extruders have the highest yield. Binder fibrillation involves mixing the uniformly blended powder with a special binder, then subjecting it to mixing and shearing, forming agglomerates. The shear force transforms the binder into fibrils, which interconnect during the mixing process to form a network that secures the electrode powder together. This process is influenced by machine and production parameters, and different production processes can significantly impact battery performance. If the binder is not adequately fibrillated, it may result in the inability to form a film or increased impedance in the electrode film due to binder agglomeration. For airflow mills, feed rate, grinding pressure, and gas pressure all affect the tensile strength and impedance of the electrode film. Experimental data indicates that the impedance of fibrillated dry films increases with decreasing feed rate and gas injection pressure, while it decreases with increasing grinding pressure. Additionally, the impedance of the electrode film decreases with increased roll pressing force. Therefore, the degree of fibrillation and roll pressing pressure both influence the impedance of the electrode sheet, ultimately affecting the battery’s electrical performance.

This article primarily uses the IEST Powder Resistivity & Compaction Density Tester (PRCD3100) to evaluate the positive and negative electrode powders with different degrees of fibrillation. The electrode resistance tester (BER2500) is used to compare the consistency of electrode resistance in dry electrode sheets prepared with different roll pressing pressures for the negative electrode and to assess the changes in resistivity of both positive and negative electrode sheets under different pressures. This method can help researchers compare the dry powders and electrode sheets prepared using different materials and processes, thereby improving and enhancing the dry electrodes process.

2. Test Conditions

2.1 Testing Equipment:

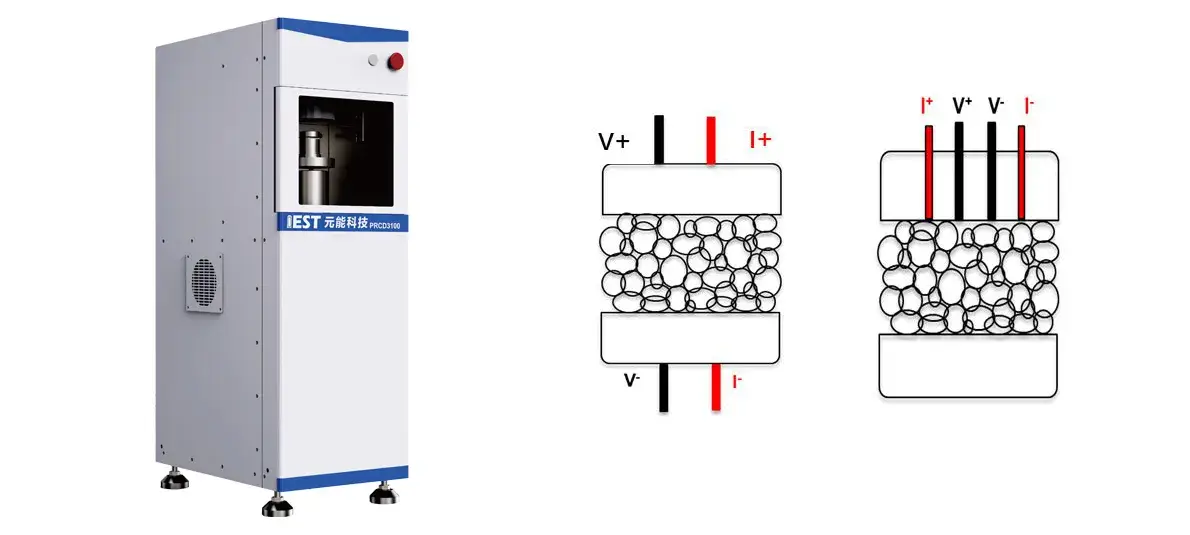

Figure 1 shows the PRCD3100, an independently developed powder resistivity and compaction density tester by IEST. This equipment allows simultaneous collection of parameters such as resistivity, conductivity, and compacted density of powder samples under different pressures (up to 5T). It assists researchers in studying the effects of varying pressures on the electrical and mechanical properties of powder samples.

Figure 1. Schematic diagram of the powder resistivity & compaction density meter (PRCD3100, IEST) and two test principles of powder resistivity

Figure 2 depicts the BER2500, a powder resistivity and compaction density tester developed independently by IEST. This equipment allows researchers to simultaneously collect parameters such as resistivity, conductivity, and compacted density of powder samples under different pressures (up to 5T), assisting in the study of the effects of pressure on the electrical and mechanical properties of powder samples.

Figure 2. (a) External view of BER2500; (b) Structural diagram of BER2500.

2.2 Experimental Procedure:

Dry electrode process experimental steps: Active particles, conductive agents, and PTFE binder are mixed in a V-type mixer in a ratio of 95:3:2 by mass. The mixture is thoroughly blended, and then the uniformly mixed powder is fibrillated in an airflow pulverizer. Different feed rates are used to achieve varying degrees of fibrillation in the mixed powder. After fibrillation, the negative electrode mixed powder is roll-pressed under different pressures to form a self-supporting film.

2.2.1 Dry powder resistance testing:

- Prepare two sets each of uniformly mixed positive and negative electrode powders, named Positive-1, Positive-2, Negative-1, and Negative-2. These two sets of powders are fed into the airflow pulverizer at different feed rates to fibrillate them and prepare dry electrode powders. Specifically, the feed rates are Positive-1 > Positive-2 and Negative-1 > Negative-2.

- Within the pressure range of 6 to 350 MPa, with 20 MPa increments, apply pressure in a stepwise manner while maintaining pressure for 10 seconds. Utilize the PRCD3100’s built-in four-probe resistance testing module and thickness testing module to continuously record the changes in resistivity and thickness under different pressures. This allows for the characterization of how resistivity and compacted density of the positive and negative dry electrode powders vary with pressure.

2.2.2 Dry electrode resistance testing:

- Prepare negative dry electrode sheets prepared under different roll pressing pressures for single-point testing, named Negative-1 and Negative-2. Prepare a set of stable production process positive and negative electrode sheets for variable pressure testing.

- Single-point testing: Set up testing parameters in the MRMS software, select single-point testing mode with a pressure of 5 MPa and a holding time of 15 seconds. Sample 6 data points per electrode sheet, with the software automatically recording thickness, resistance, resistivity, conductivity, and other data.

- Variable pressure testing: Set up testing parameters in the MRMS software, select variable pressure testing mode with a lower pressure limit of 5 MPa and an upper pressure limit of 60 MPa, with 5 MPa increments and a holding time of 15 seconds. Select 1 point per electrode sheet for testing, with the software automatically recording thickness, resistance, resistivity, conductivity, and other data.

3. Data Analysis

3.1 Analysis of Dry Powder Resistivity

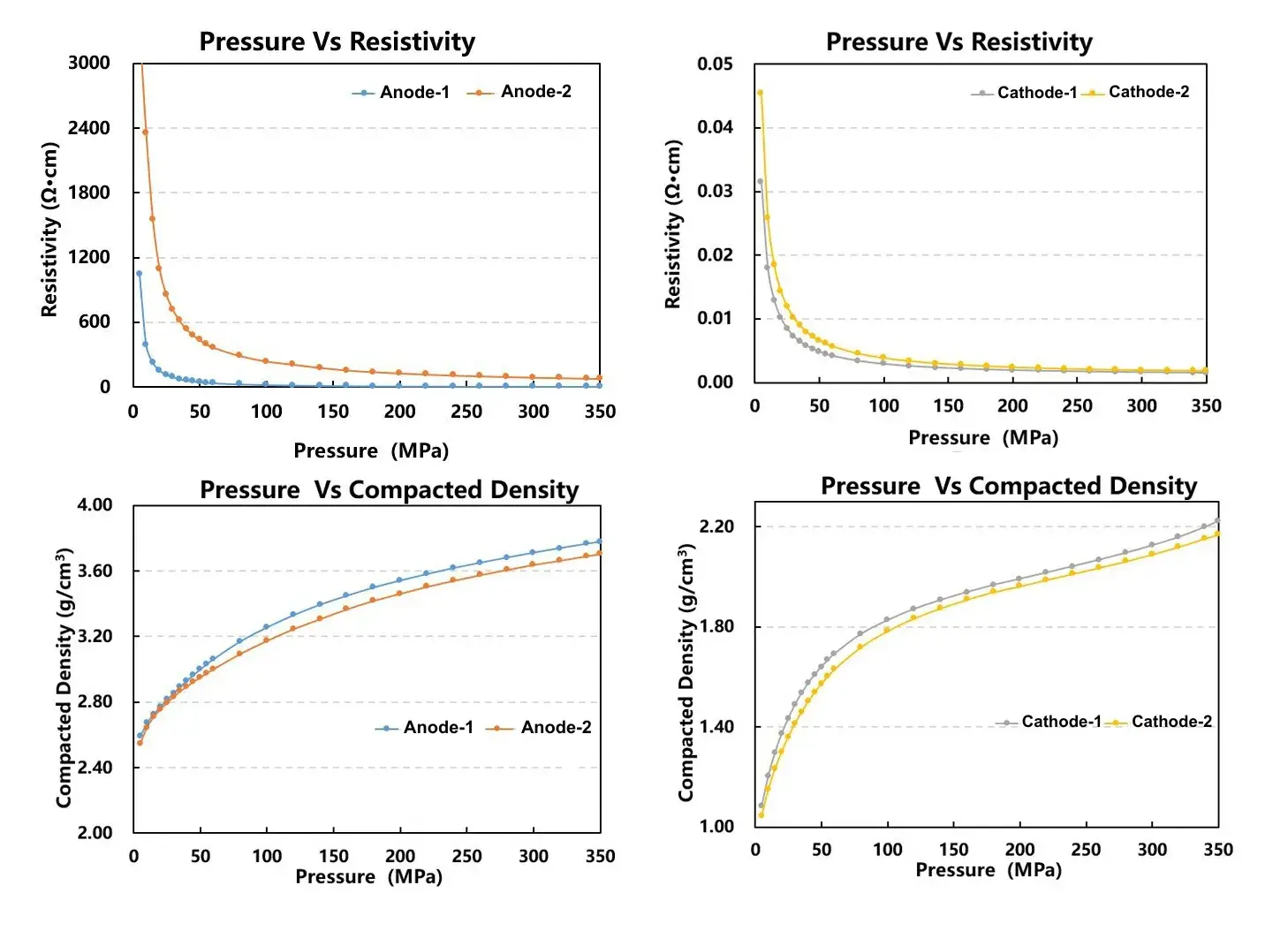

Figure 3. Comparison of resistivity and compacted density test results for positive and negative dry electrode powders.

Figure 3 displays the test results of resistivity and compacted density for cathode and anode dry electrode powders prepared at different feed rates, where Positive-1 > Positive-2 and Negative-1 > Negative-2. The results indicate that higher feed rates lead to lower electronic resistivity and slightly higher compacted density of the prepared powders. This is primarily due to the increased degree of PTFE binder fibrillation with higher feed rates. During the fibrillation process, at the initial stage, micron-sized active particles embed into original PTFE particles ranging from 100-200 microns. As the mixture undergoes further mixing and shearing, the active particles move and separate from each other. This process pulls out larger primary PTFE fibrils, with diameters reaching several microns. These primary fibrils can extend to long lengths under the continued shear mixing process. Newly formed primary fibrils interact with moving NMC particles, effectively adhering to them. These primary fibrils further stretch or unfold, forming finer secondary fibrils. Greater fibrillation of the binder results in nanofibers wrapping around active particles more extensively. This ensures more thorough contact between active materials, conductive agents, and binders, facilitating the formation of a conductive network and resulting in lower electronic resistivity. Moreover, thorough fibrillation enables closer contact of active materials, exhibiting slightly higher compacted density.

3.2 Analysis of Dry Electrode Resistivity:

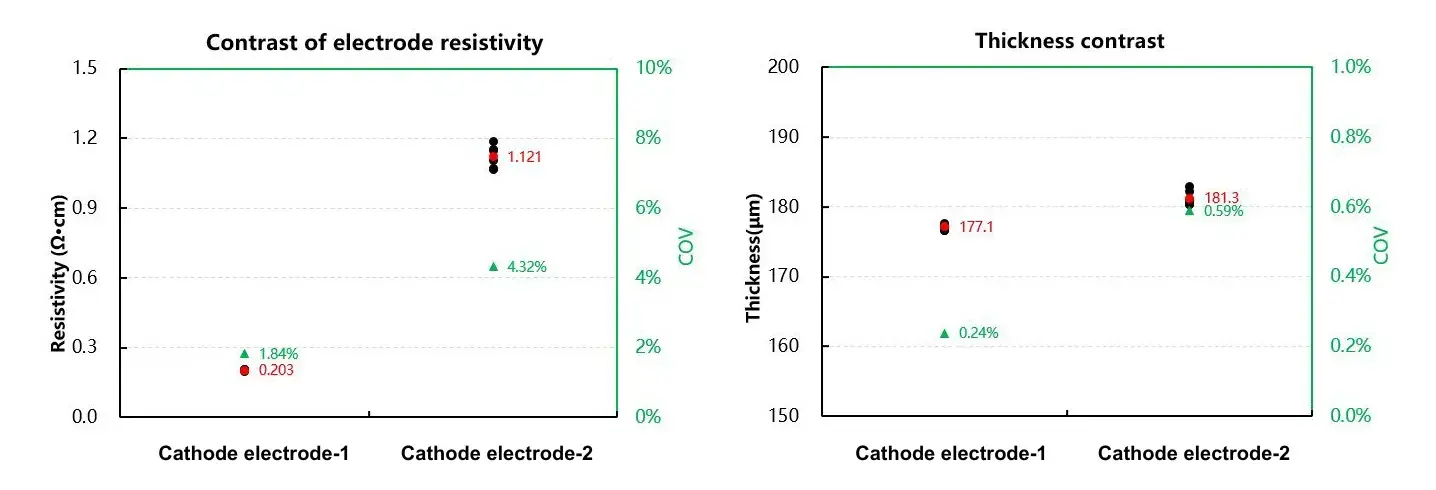

Figure 4. Comparison of resistivity and thickness test results for cathode dry electrode.

Figure 4 illustrates the resistivity and thickness test results of negative dry electrode sheets under different roll pressing pressures, where Roll Pressing Pressure Cathode-1 > Cathode-2. As the roll pressing pressure increases, the thickness of the electrode sheet decreases while the compacted density increases. There is a noticeable decrease in the overall resistivity of the electrode sheets, indicating that higher roll pressing pressures promote closer contact between active materials, facilitating the formation of a complete conductive network. This enhances the electrode’s conductivity performance. Additionally, Negative-1 COV < Negative-2 COV, indicating that higher roll pressing pressures can improve the consistency of resistivity in dry electrode.

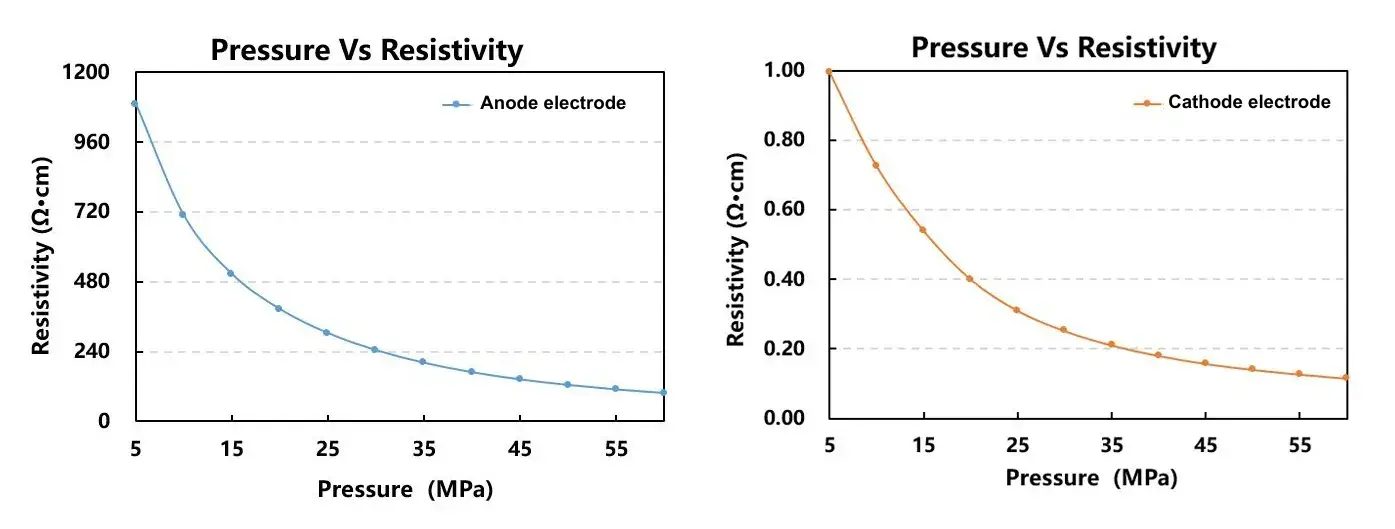

Figure 5. Comparison of variable pressure test results for cathode and anode dry electrode.

Figure 5 shows the variable pressure test results for positive and negative dry electrode sheets. The test results indicate that the resistivity of the electrode sheets decreases with increasing test pressure, indirectly simulating the changes in resistivity under different roll pressing pressures. This testing method can assist researchers in quickly identifying the optimal compacted density suitable for the material, thereby saving research and development testing time.

4. Summary

This study utilized IEST developed PRCD3100 Powder Resistivity & Compaction Density Tester and BER2500 Electrode Resistivity Tester to evaluate the resistivity of dry electrode powders prepared at different feed rates and dry electrode sheets prepared at various roll pressing pressures. It can be concluded that in the PTFE binder fibrillation process, increasing feed rates effectively reduce the resistivity of the prepared dry electrode powders. This reduction is likely attributed to the increased fibrillation degree of PTFE, facilitating better interlocking of powder particles to form an effective physical cross-linking network. Additionally, in the roll pressing stage, increasing roll pressing pressure results in decreased resistivity of the prepared electrode sheets, indicating that higher roll pressing pressure enhances adhesion and film-forming properties of the electrodes. This leads to closer contact between active material particles and between the active material and the current collector, thereby reducing the resistivity of the electrode sheets.

Dry electrode technology represents a comprehensive upgrade over traditional wet methods. In terms of manufacturing processes, dry electrodes involve fewer steps, resulting in lower production costs and energy consumption. The raw materials used are more environmentally friendly, making dry electrodes more suitable for large-scale production. Regarding battery performance, dry electrodes enable higher energy density, superior electrical and mechanical performance in batteries. In application, dry electrode technology is well-suited for the manufacturing needs of next-generation batteries like solid-state and 4680 cells. However, while dry electrode technology is not yet fully mature and faces various process challenges, its potential to significantly enhance battery performance makes it a promising direction for technological advancement.

5. References

[1] Li Qingying et al., Dry preparation technology of electrodes and related materials [J] CHINESE JOURNAL OF RARE METALS, 2023, Vol.47 No.12 1705~1715.

[2] DUONG H,SHIN J,YUDI Y. Dry electrode coating technology[A]. 48th Power Sources Conference[C]California: Maxwell Technologies,Inc.,2018: 34-37.

[3] Li Yongxing, et al. Progress in solvent-free dry-film echnology for batteries and supercapacitors[J]. Materials Today,2022.

[4] Al-Shroofy M, Zhang Q, Xu J, et al. Solvent-free dry powder coating process for low-cost manufacturing of LiNi 1/3 Mn 1/3 Co 1/3 O 2, cathodes in lithium-ion batteries[J]. Journal of Power Sources, 2017, 352:187-193.

Subscribe Us

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.