-

iestinstrument

Quantifying and Analyzing 4680 Cylindrical Cell Expansion: An In-situ Study

1. The 4680 Format: Promise and the Expansion Challenge

The 4680 cylindrical cell, championed by Tesla, represents a next-generation lithium battery technology. Its larger format (46mm diameter, 80mm height) aims to optimize energy density, power, and cost, reshaping the landscape for electric vehicle power systems. With Tesla achieving volume production and installation, and major automakers like BMW and GM announcing adoption plans, global production capacity is rapidly expanding. Leading battery manufacturers such as CATL, Panasonic, and LG Energy Solution are accelerating their expansion, maturing the supply chain.

However, this larger format introduces distinct engineering challenges. The increased distance from the core (jellyroll) center to the casing wall impedes heat dissipation. During fast charging or high-rate discharge, the high heat generated from internal electrochemical reactions, if not effectively managed, can exacerbate material deformation and uneven side reactions. This leads to increased internal pressure and physical swelling. Furthermore, to achieve higher energy density, 4680 cells often employ highly active materials like high-nickel NCM cathodes and silicon-based anode materials. Silicon can undergo volume changes of up to 300% during cycling, directly driving significant anode and overall cell expansion. A critical question for engineers is: how much does the cell actually expand?

2. In-situ Optical Monitoring of Cylindrical Cell Swelling

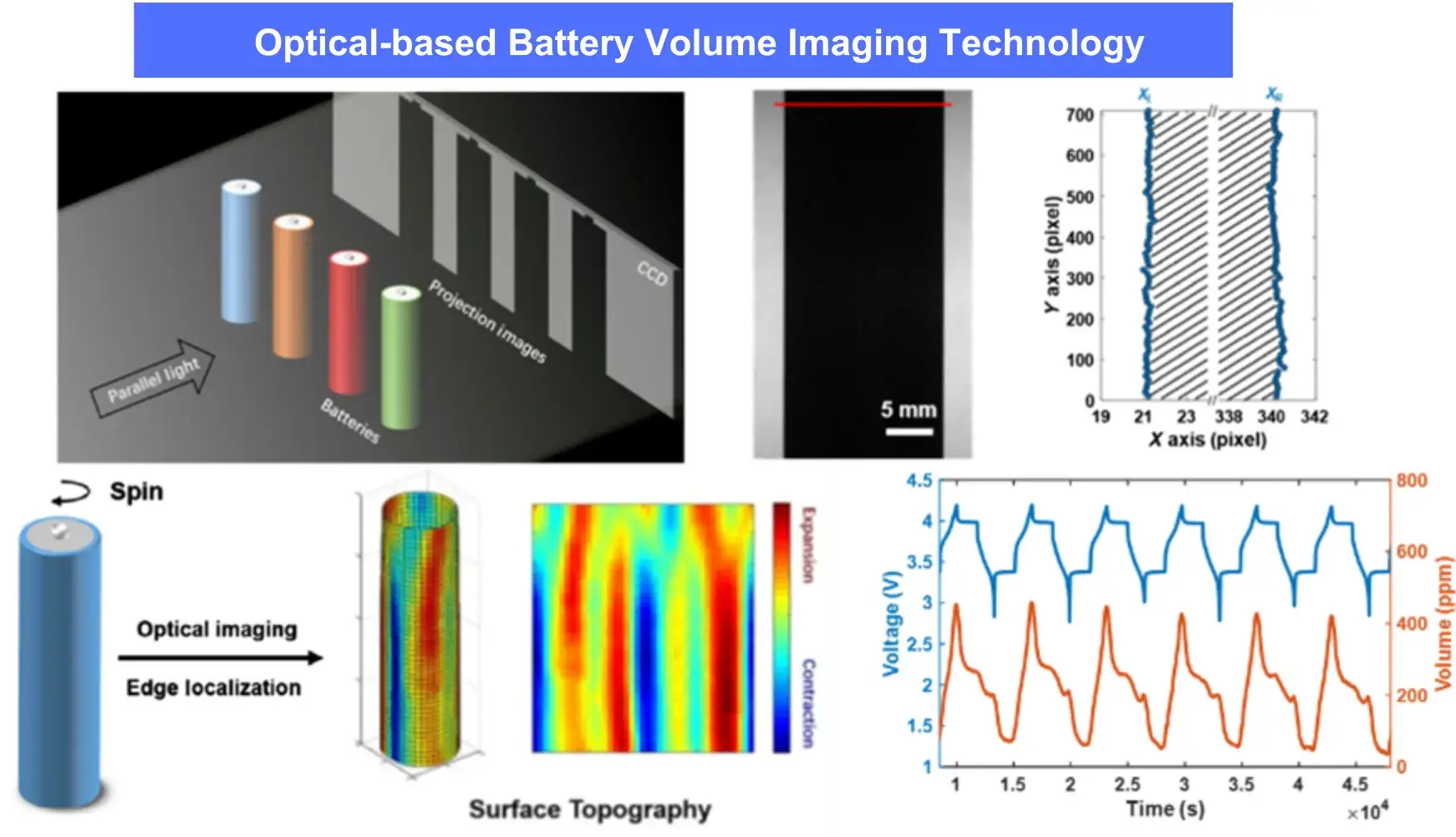

To address this need for precise measurement, IEST Instrument has developed a Cylindrical Cell Swelling Analysis System(CCS 1100). This system utilizes an optical methodology combined with proprietary algorithms to achieve accurate, real-time monitoring of cell expansion. The technique enables in-situ measurement of diameter (and thus volume) changes during charge and discharge cycles, while also characterizing the swelling distribution across different regions of the cylindrical cell.

Figure 1. CCS1100 and Principle: Optical Battery Volume Imaging Technology

3. Experimental Case Study: Monitoring an NCM811/SiC 4680 Cell

In this application study, a commercial 4680 cylindrical cell with an NCM811/SiC chemistry was subjected to a standard charge-discharge step (1C constant current-constant voltage charge / 1C constant current discharge) while its swelling was monitored in-situ.

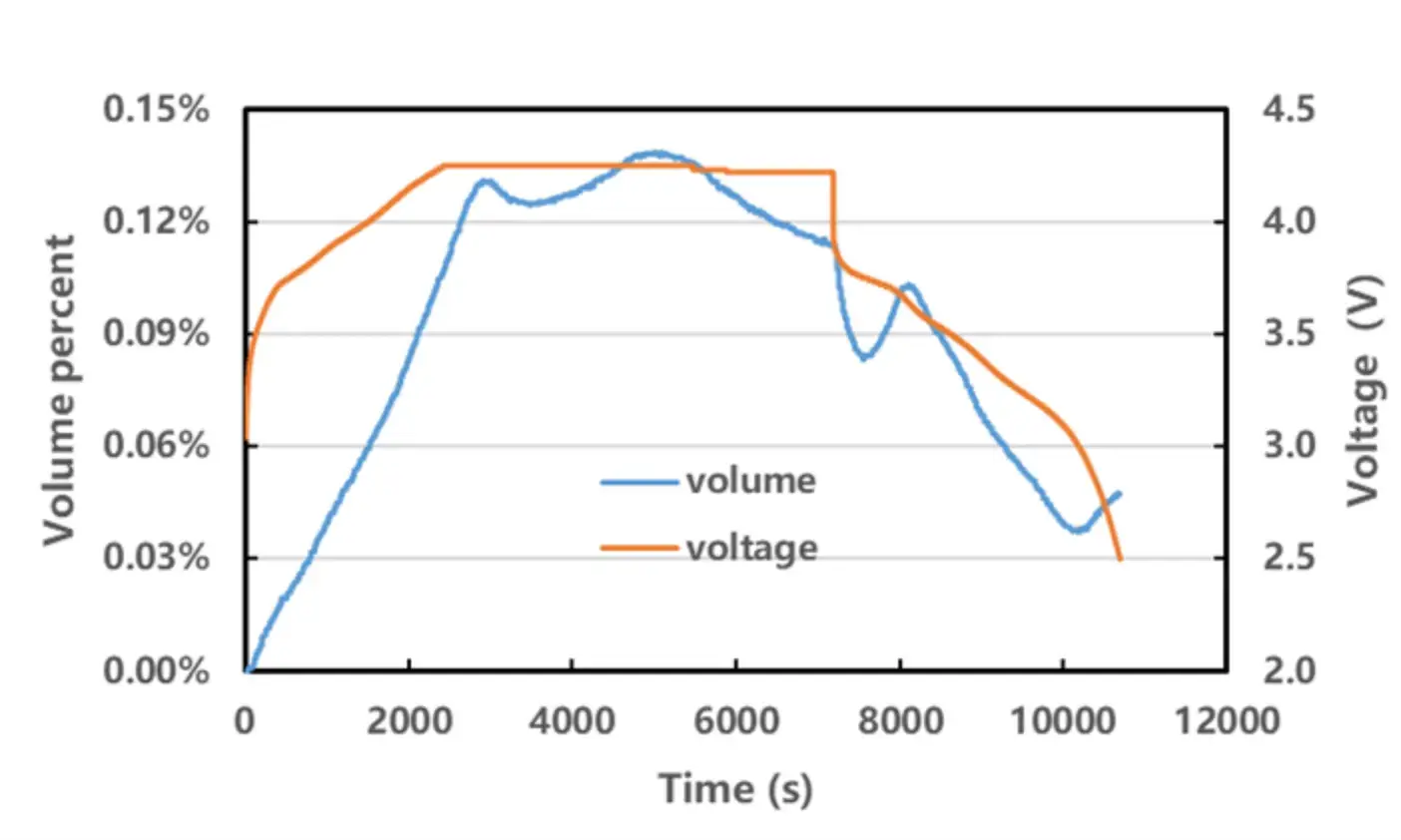

The system precisely captured the cell’s diameter and volumetric changes, as shown in Figure 2. The overall trend shows volume expansion during charging, with a maximum expansion of approximately 0.14% at full charge, followed by contraction during discharge. This behavior correlates with phase transformations in the electrode materials. Notably, characteristic “M-shaped” expansion peaks are observed during the late charging and early discharge phases, a known signature associated with high-nickel ternary cathode materials. The volume increase in the later stages of discharge is potentially linked to cumulative thermal effects within the large-format cell during this phase.

Figure 2. Volume change of a 4680 cylindrical cell during charge and discharge cycles.

4. Revealing Spatial Heterogeneity in Expansion

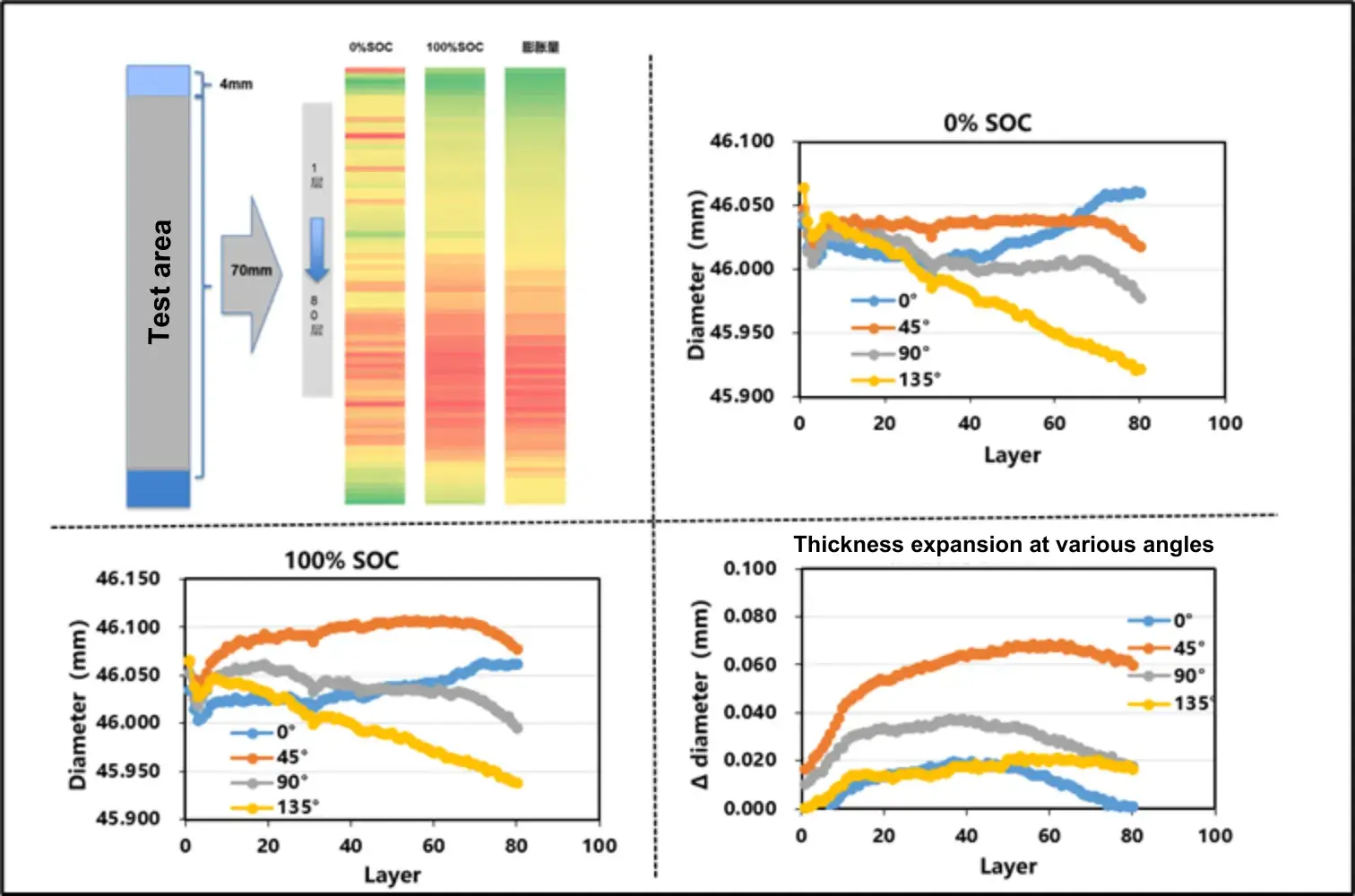

The monitoring scope covered a 70mm region starting 4mm from the cell top (positive terminal). This area was divided into 80 layers for analysis. Figure 2 presents data from a random observation angle of 45° (relative to the initial position). The results clearly reveal that the initial diameter is not uniform along the cell’s longitudinal axis. More importantly, the expansion during charging also demonstrates significant spatial heterogeneity.

Using the 0% State of Charge (SOC) condition as a baseline, the distribution at full charge (100% SOC) shows that the middle section of the cell expands more than the two ends. This non-uniformity is likely related to the greater mechanical constraint imposed by the steel casing at the cap and bottom compared to the central region. These empirical findings provide direct, actionable data for optimizing the structural design of cylindrical cell casings to better accommodate internal stresses.

Figure 3. Radial diameter change distribution along the longitudinal axis of a 4680 cylindrical cell during cycling.

5. Conclusion: Data-Driven Development for Next-Generation Cells

The in-situ and precise characterization of swelling behavior in 4680 cylindrical cells has become a critical enabler for technological iteration. This capability not only aids in the development of high-expansion systems like silicon-carbon anodes by informing material formulation optimization but also provides empirical data to guide improvements in steel can manufacturing processes and mechanical reinforcement design. By addressing expansion at its root, this approach contributes to enhancing cell cycle life and safety margins, ultimately accelerating the maturation and successful deployment of large-format cylindrical battery technology.

Subscribe Us

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.