Description

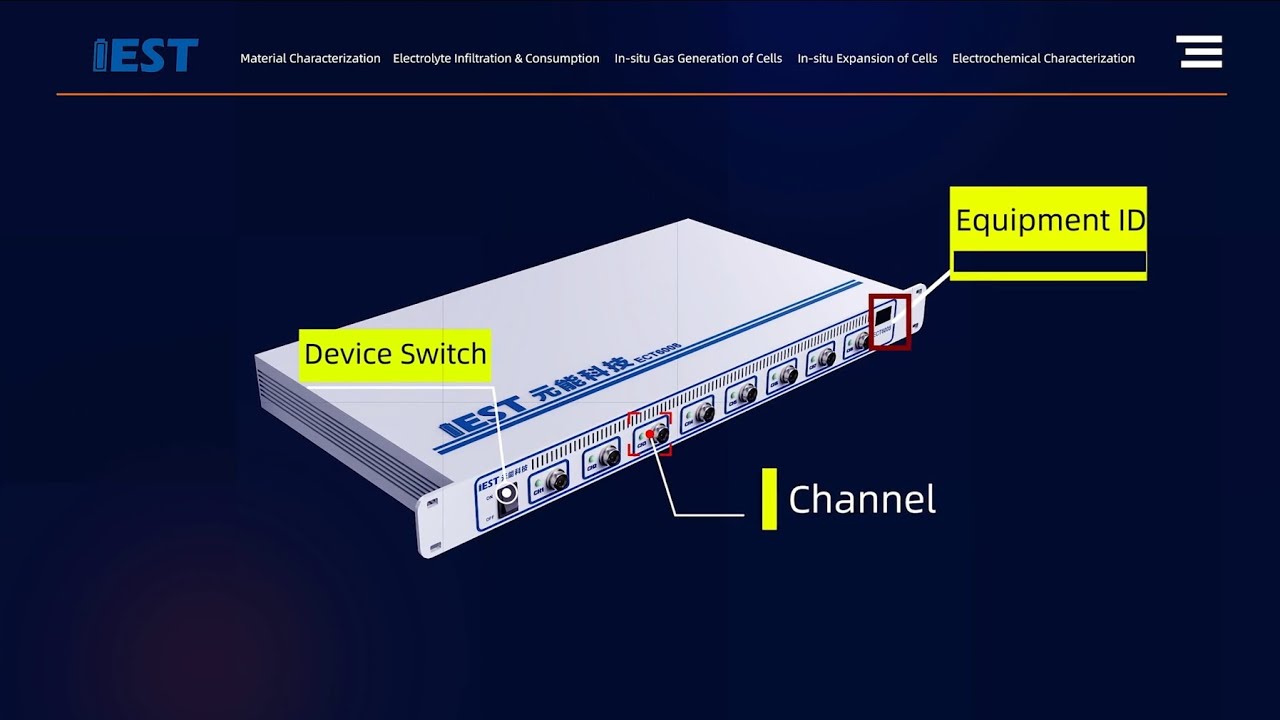

1. Battery Cyclers System ERT Series: Comparison

2. Innovative Solutions of IEST Battery Cycle Tester

- Provides accurate benchmark data for lifespan prediction, inventory efficiency, self-discharge, and micro-reaction testing, with voltage and current precision of 0.01%.

- Supports a wide range of cell types, capacitor materials, half-cell, three-electrode, coin cell, and small-capacity testing.

- Triple protection (software, hardware, firmware) ensures safe operation for both equipment and samples.

- Supports EIS testing from 0.01 Hz to 100 kHz.current control.(ERT7008 available)

- Supports electrochemical testing methods such as multi-scan rate cyclic voltammetry, linear sweep voltammetry, GITT, PITT, CA, and CP.

- Flexible auxiliary channel integration for temperature control, surface temperature monitoring, three-electrode setups, and pressure detection.

- Online calibration and independent operation of channels without interference.

- Private cloud platform and cloud server backup ensure data security and confidentiality.

3. Application Scenario

Applications

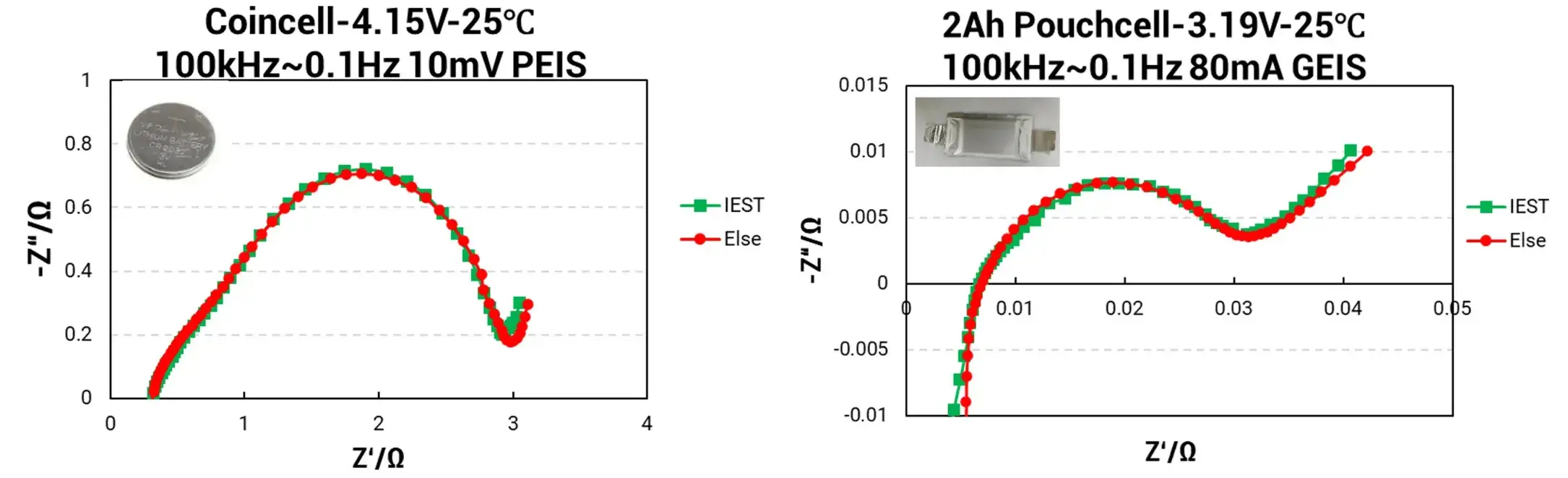

Case 1: EIS Analysis–Different Cell Impedance Analysis

High-frequency EIS impedance range: 0.01Hz~100kHz, meeting the high-frequency impedance test requirements of 10mΩ~1kΩ level batteries.

- Compared with the EIS test results of well-known foreign electrochemical workstations, the error is within 5%

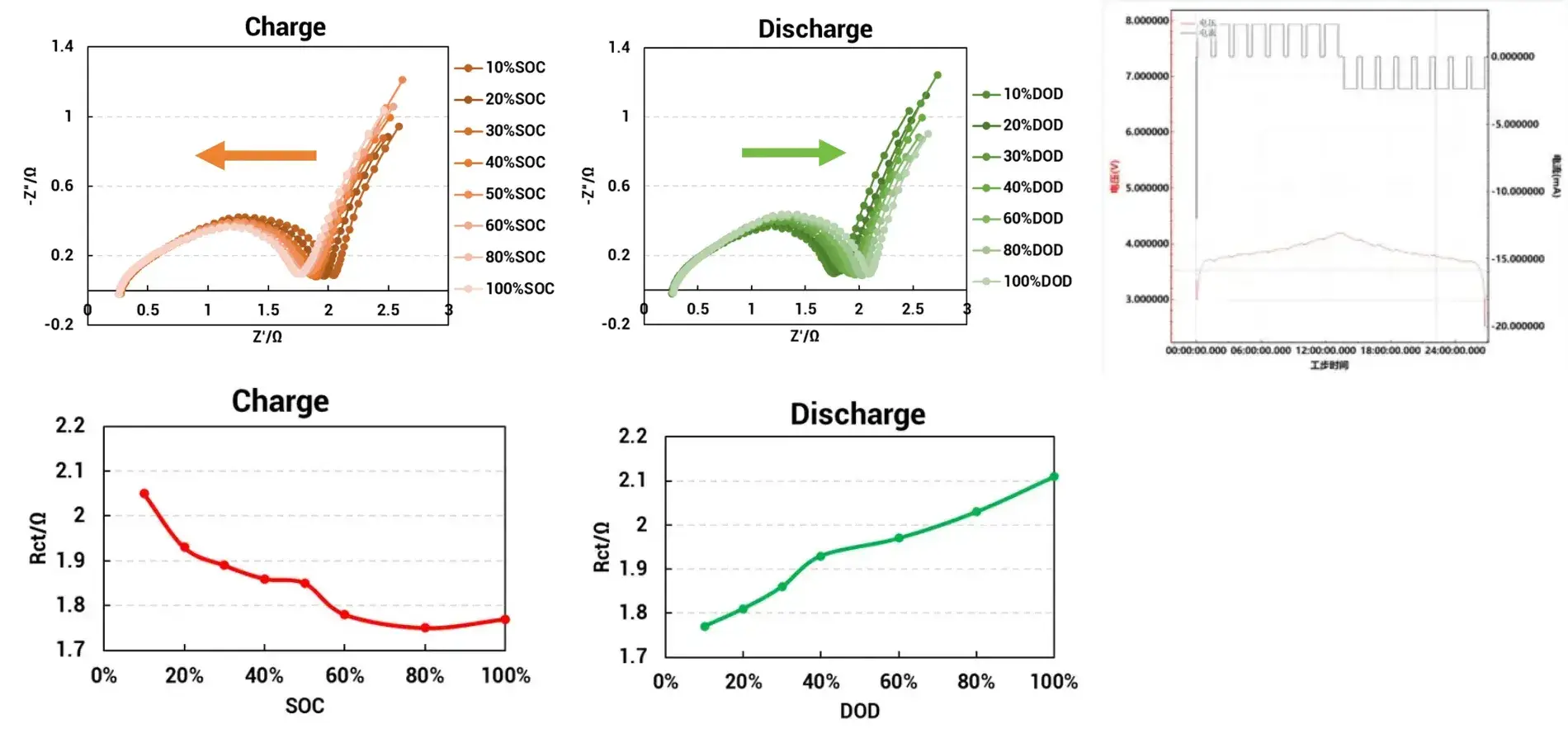

Case 2: Cell Cycle Impedance Test

- Rct decreases as SOC increases;

- Rct increases as DOD increases

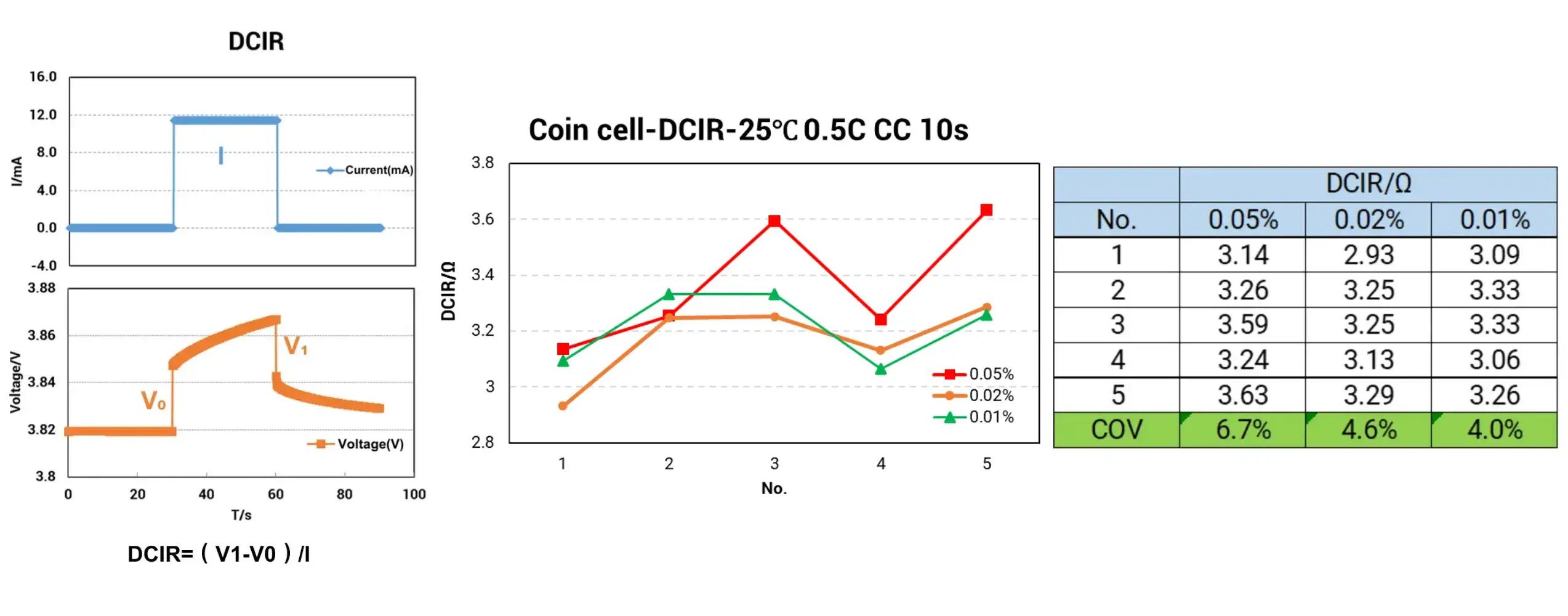

Case 3: Accurate DCIR Performance

- Three devices with different voltage accuracies were used to perform DCIR (Direct Current Internal Resistance) testing on five groups of coin cells, with data points collected every 0.1 seconds.

- The results demonstrated that higher voltage accuracy yields better consistency in the DCIR of coin cells.

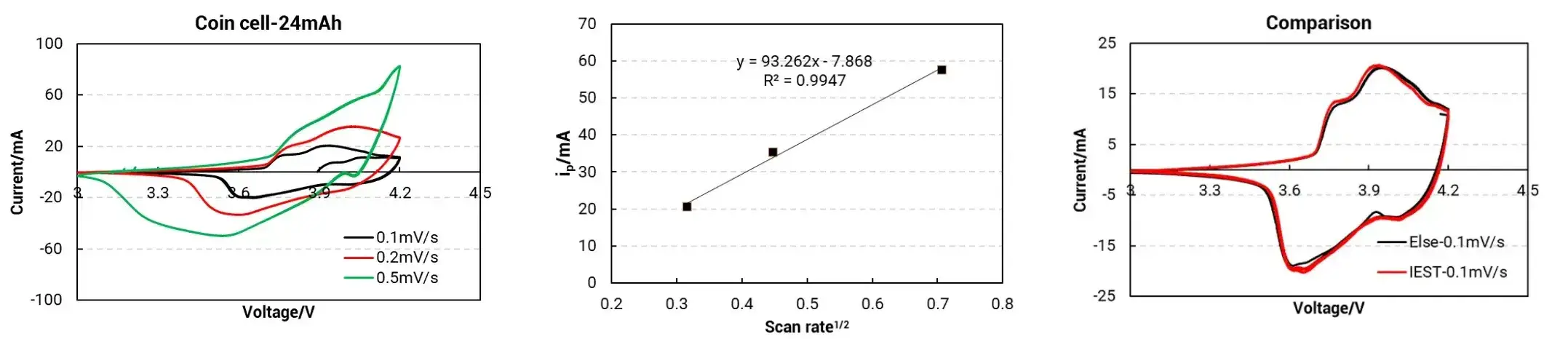

Case 4: Cyclic Voltammetry(CV) to Evaluate Materials Properties

- The peak current of the reversible reduction is proportional to the square root of the scan rate.

- It is consistent with the CV (Cyclic Voltammetry) curves obtained from the electrochemical workstation.

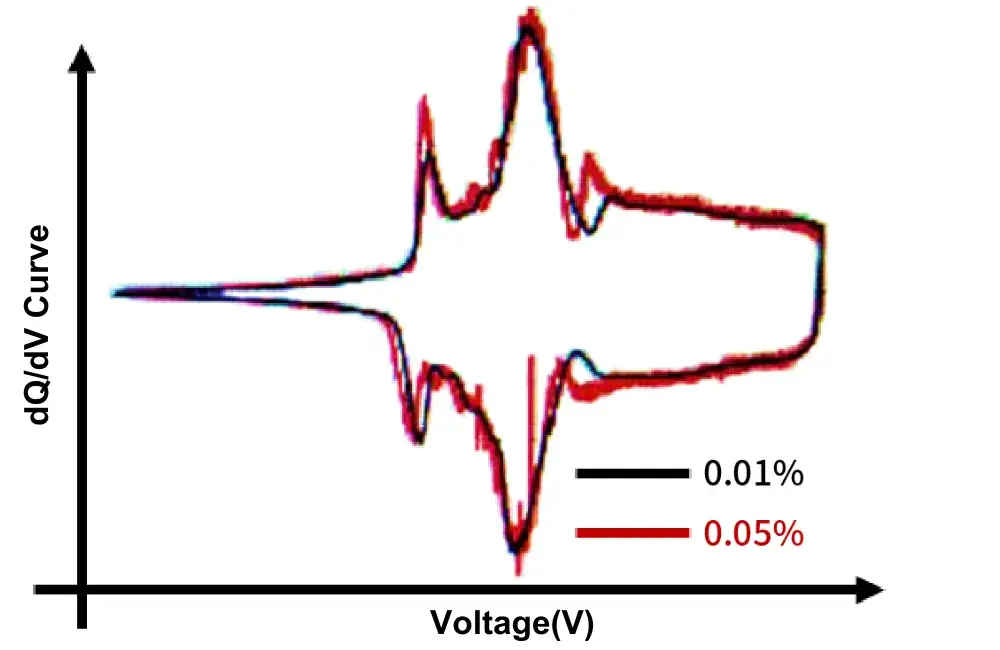

Case 5: dQ/dV Curves to Evaluate Material Phase Changes

dQ/dV Curve Analysis:

Curve Smoothness:

- High-precision equipment: dQ/dV curves are smooth and continuous, capable of capturing subtle electrochemical changes.

- Low-precision equipment: Curves exhibit noise or discontinuities, with difficulty in accurately identifying detailed features.

Electrochemical reaction characteristics:

- High-precision equipment: Clearly reveals characteristic peaks of multi-stage reactions in the battery, uncovering material phase transitions or side reactions.

- Low-precision equipment: Characteristic peaks are obscured by measurement noise, prone to missing critical information.

In dQ/dV curve analysis, high-precision equipment is crucial for studying electrochemical details, improving data reliability, and identifying material characteristics. Low-precision equipment can perform basic testing but may miss critical details, especially in high-demand research scenarios.

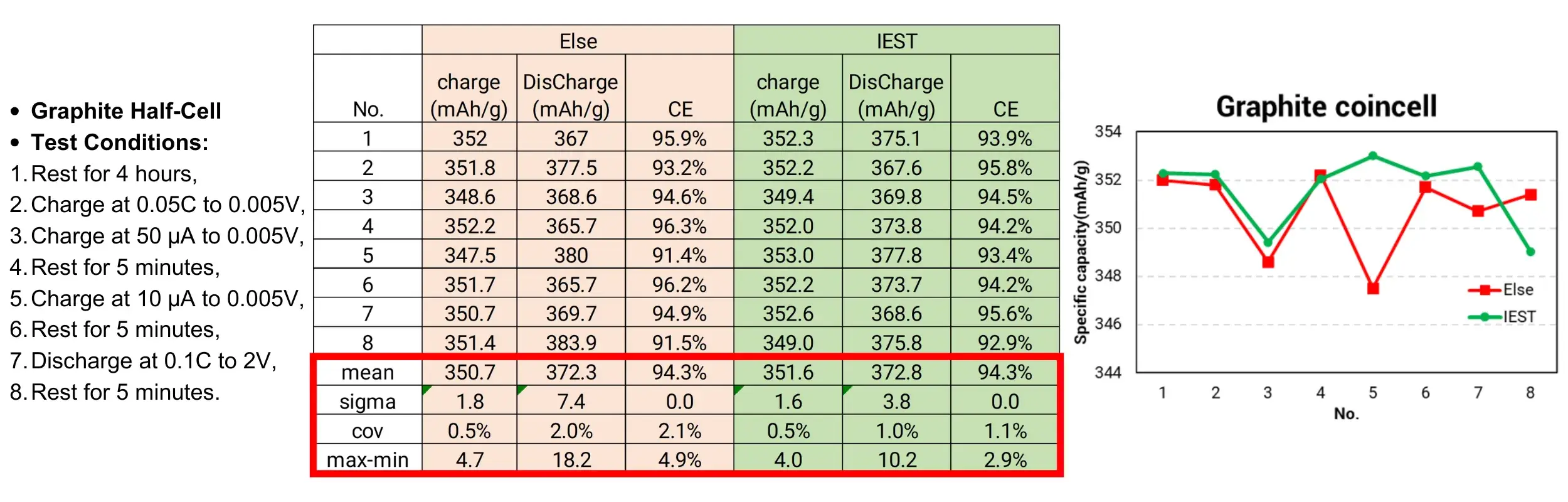

Case 6: Charge and discharge Evaluation of Materials Gravimetric Capacity

- Gravimetric capacity tests were conducted on eight graphite half-cells, demonstrating better consistency in specific capacity!

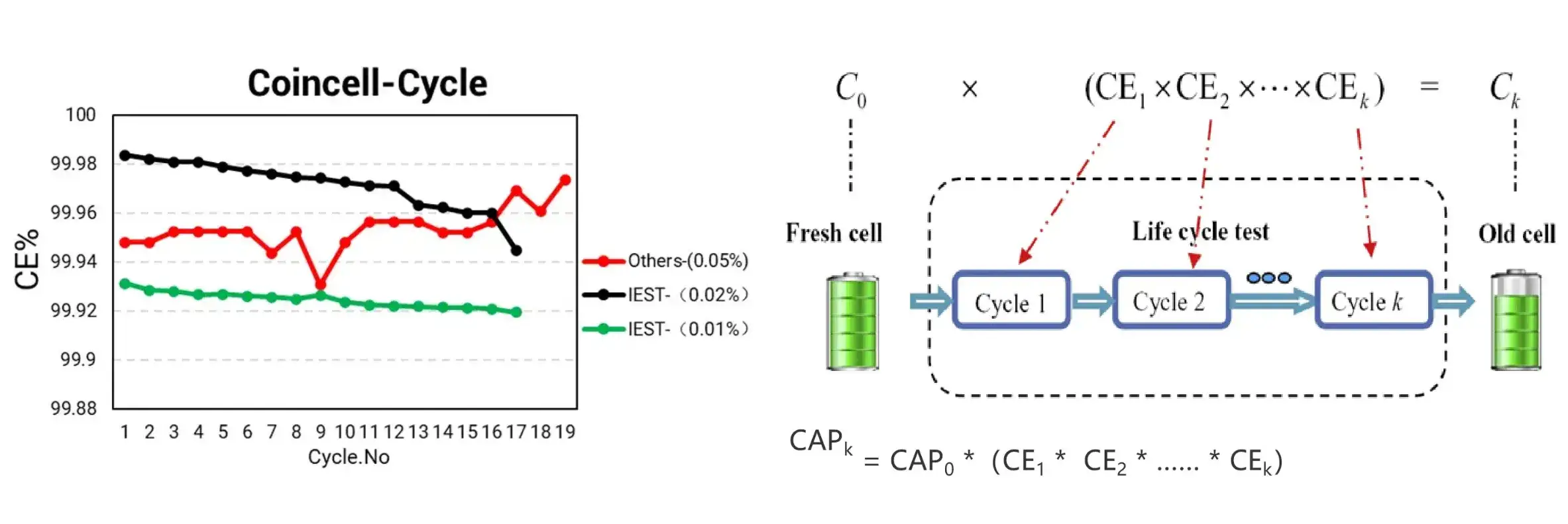

Case 7: Evaluation of Coulombic Efficiency in Cells via Charge and Discharge Testing

Coulombic Efficiency Testing:

- A lifetime prediction model based on coulombic efficiency can forecast battery capacity degradation. For effective lifetime prediction, the accuracy must be maintained at least at 1‱, with noise interference kept below 10 ppm.

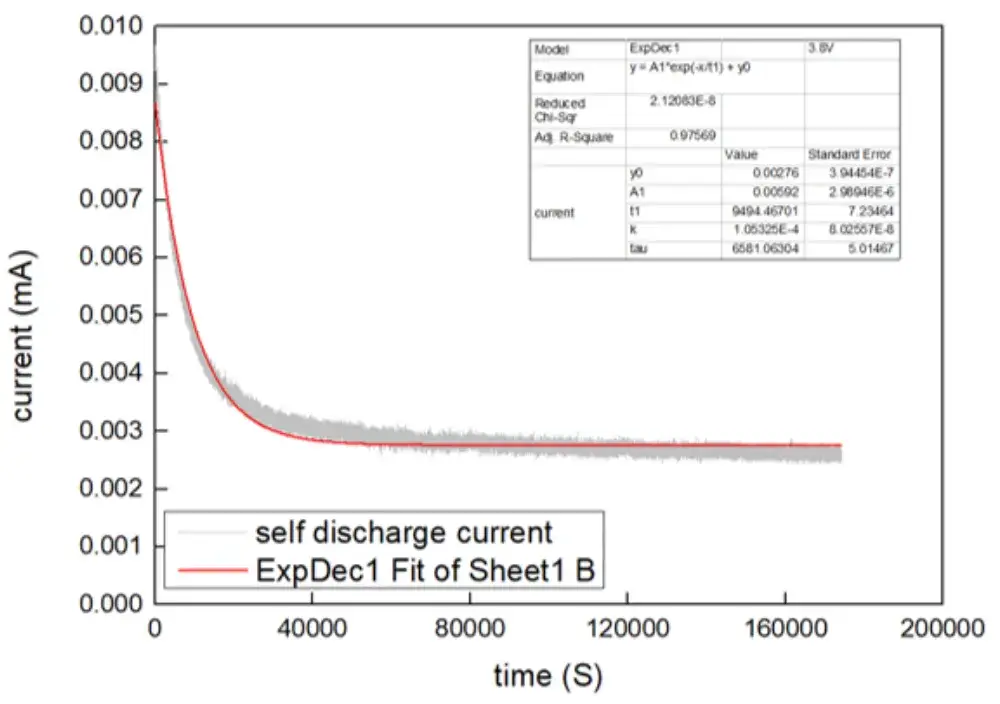

Case 8: Evaluation of Cells Self-Discharge Under Constant Voltage Charging

- High precision supports leakage current testing of large capacity and low internal resistance cells

- Replace the time-consuming and labor-intensive solution of measuring K value, enabling faster and more accurate monitoring of battery cell self-discharge characteristics.

Coin Cell Leakage Current Test:

- Electrodes: NCM (ф14 mm) vs. Lithium (ф20 mm)

- Capacity: 2 mAh

- Equipment: ECT6008 High-Precision Device

- Test Procedure: Constant Current/Constant Voltage (CC/CV) Charging: 0.8 mA, 3.8 V, for 72 hours

IEST High-Precision Battery Cycler System is capable of monitoring currents as low as the nanoampere (nA) level, supporting the measurement of minute leakage currents.

Video