Description

1. Introduction

Designing batteries that deliver optimal performance, extended cycle life and uncompromised safety requires a clear view of how pressure and temperature behave throughout development and manufacturing.

The IEST Battery Design Pressure Measurement System(BPD Series) integrates pressure and temperature sensors to supply engineers with high-accuracy, real-time interface maps and analytics — enabling faster process optimization and more reliable battery designs.

2. Why measure pressure & temperature in batteries?

During charging and discharging, electrodes, separators and cell housings undergo dimensional and thermal changes. If left unchecked, these effects can trigger problems such as:

-

Mechanical delamination and separator damage

-

Gas generation and swelling

-

Surface deformation and poor interfacial contact

-

Accelerated capacity fade and reliability loss

-

Elevated risk of thermal runaway

3. What real-time battery pressure mapping sensor delivers?

The IEST system provides dynamic, high-resolution visualization of surface pressure and temperature across cells, modules, and mechanical assemblies. Continuous pressure and temperature mapping produces reproducible, time-synchronized datasets.

With this visibility engineers can:

-

Ensure even stack compression across cells and modules

-

Minimize process variation during formation and assembly

-

Pinpoint high-stress or low-contact zones for corrective action

-

Monitor temporal trends and pressure drift over cycling

-

Capture pressure response during thermal excursions for safer fixture and pack design

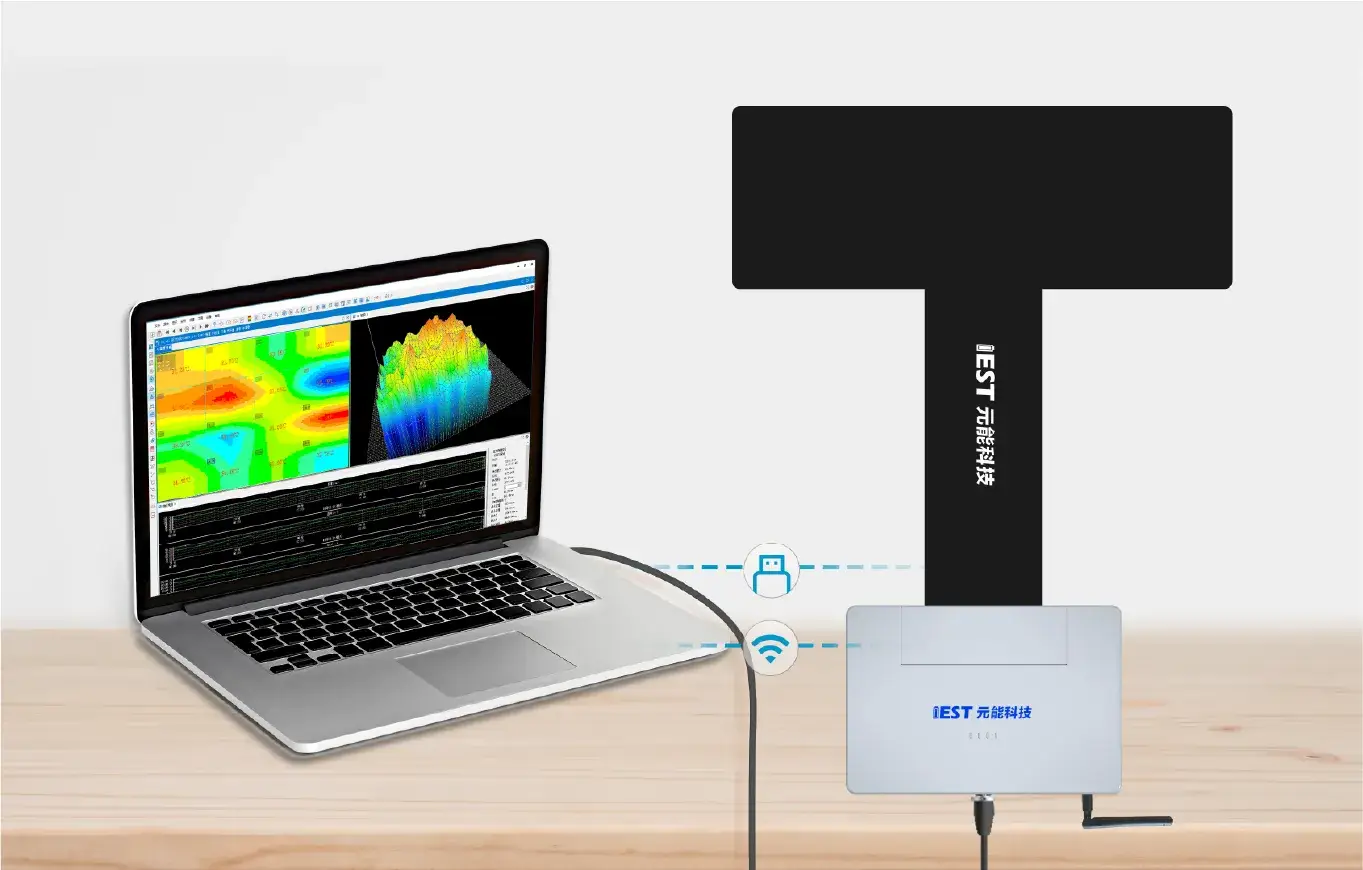

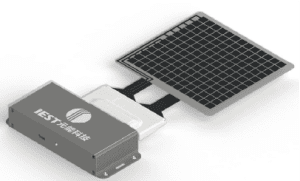

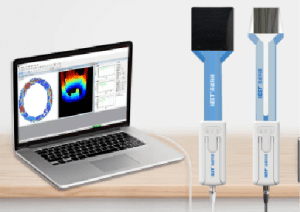

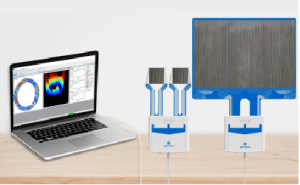

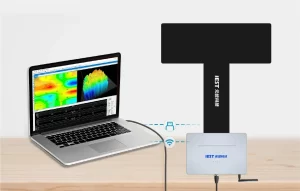

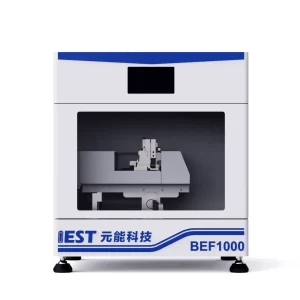

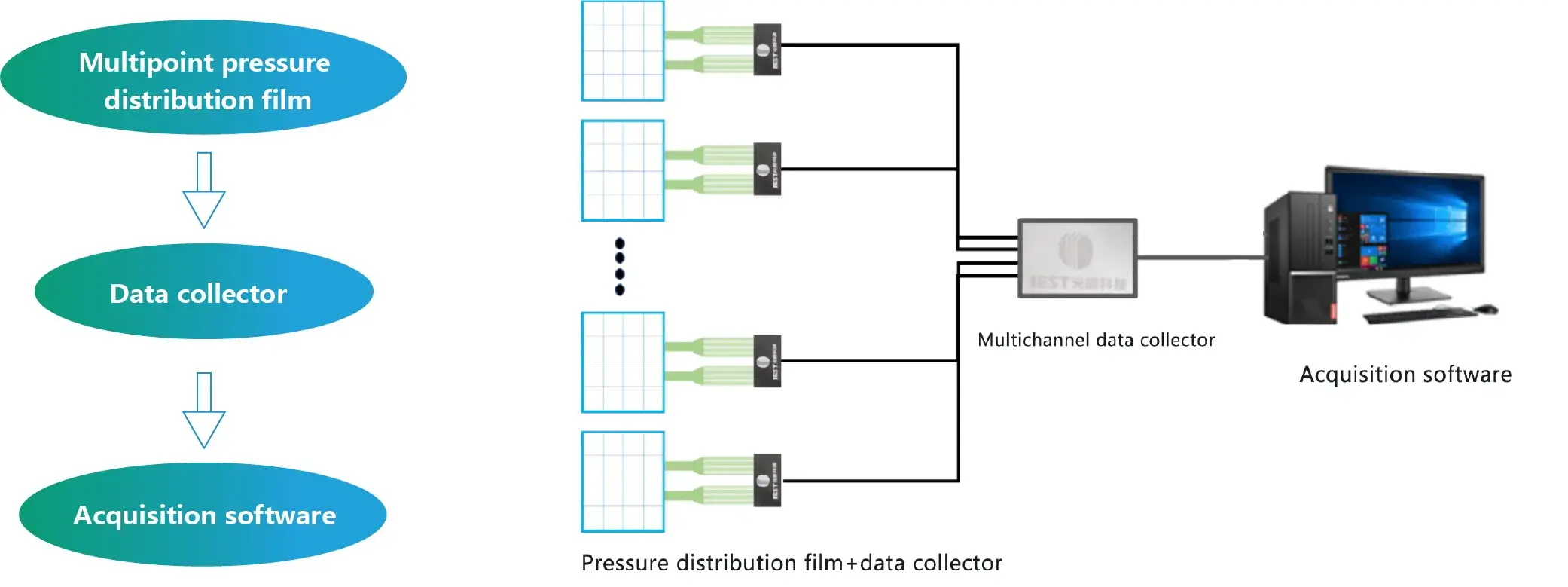

4. Structural Composition of Pressure Mapping Sensor Measurement System

5. Features

- Capable of displaying real-time total force curves from all sensors versus time.

- Flexible pressure-map selection and customizable sensing area to match coin cell, pouch cell, prismatic cell and module layouts.

- Real-time synchronization with charge/discharge data to correlate electrochemical events with mechanical stress.

- One-click to export the data report.

- Real-time pressure calibration and optional integration with in-situ swelling fixtures for combined thickness/force studies.

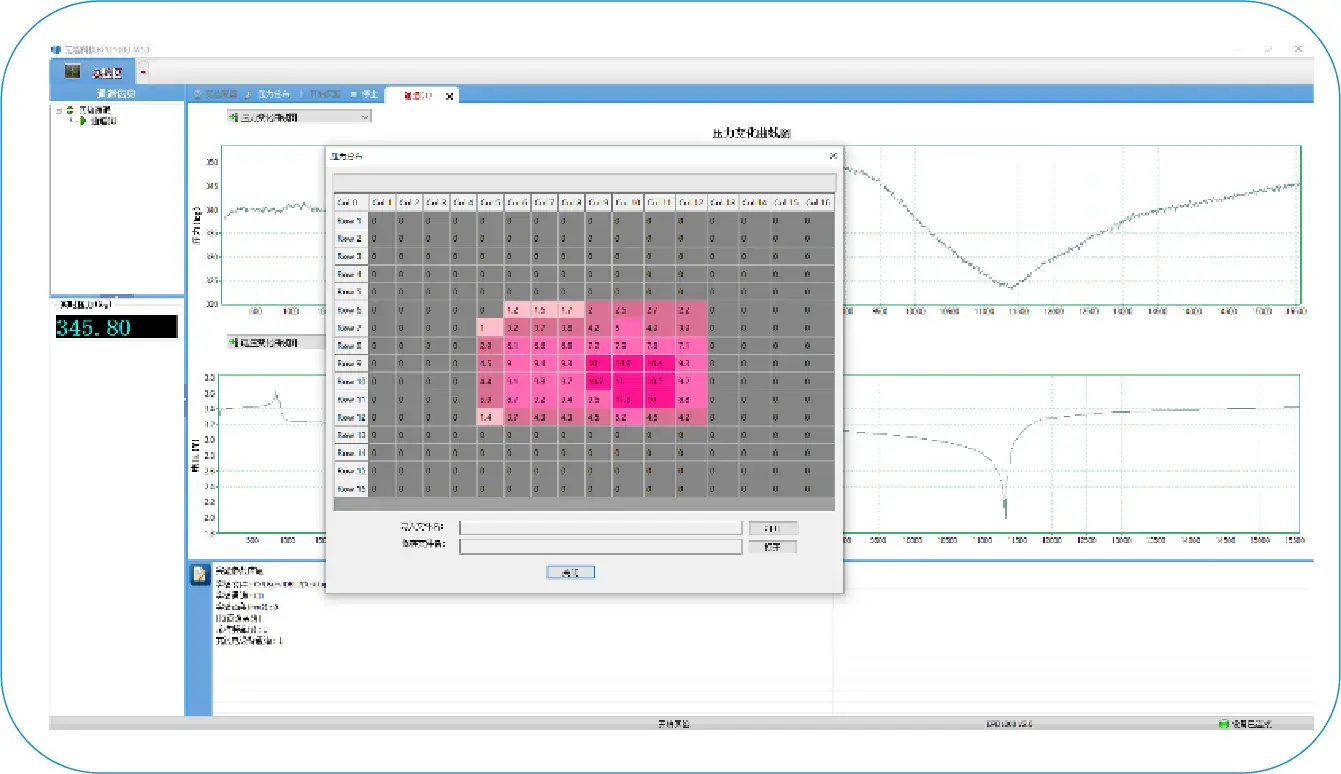

6. Software Interface

-

2D/3D topographic color mapping, contour visualization and per-region/time-domain analytics for fast interpretation.

-

Playback and slow-motion review of recorded tests, center-of-pressure tracking, and per-sensor numeric outputs for downstream modeling.

-

Open data export (CSV, common formats) and API support for integration with lab data systems and custom analysis pipelines.

Applications

Applications

- With the swelling force test fixture or in-situ expansion test equipment, the pressure distribution at different positions on the surface of the cell during the cycling process is characterized.

- Quickly and quantitatively evaluate the surface flatnessof the cell.

- Pressure uniformity validation in hot press lamination processes

- Rapid evaluation of lamination uniformity and module-level swelling forces.

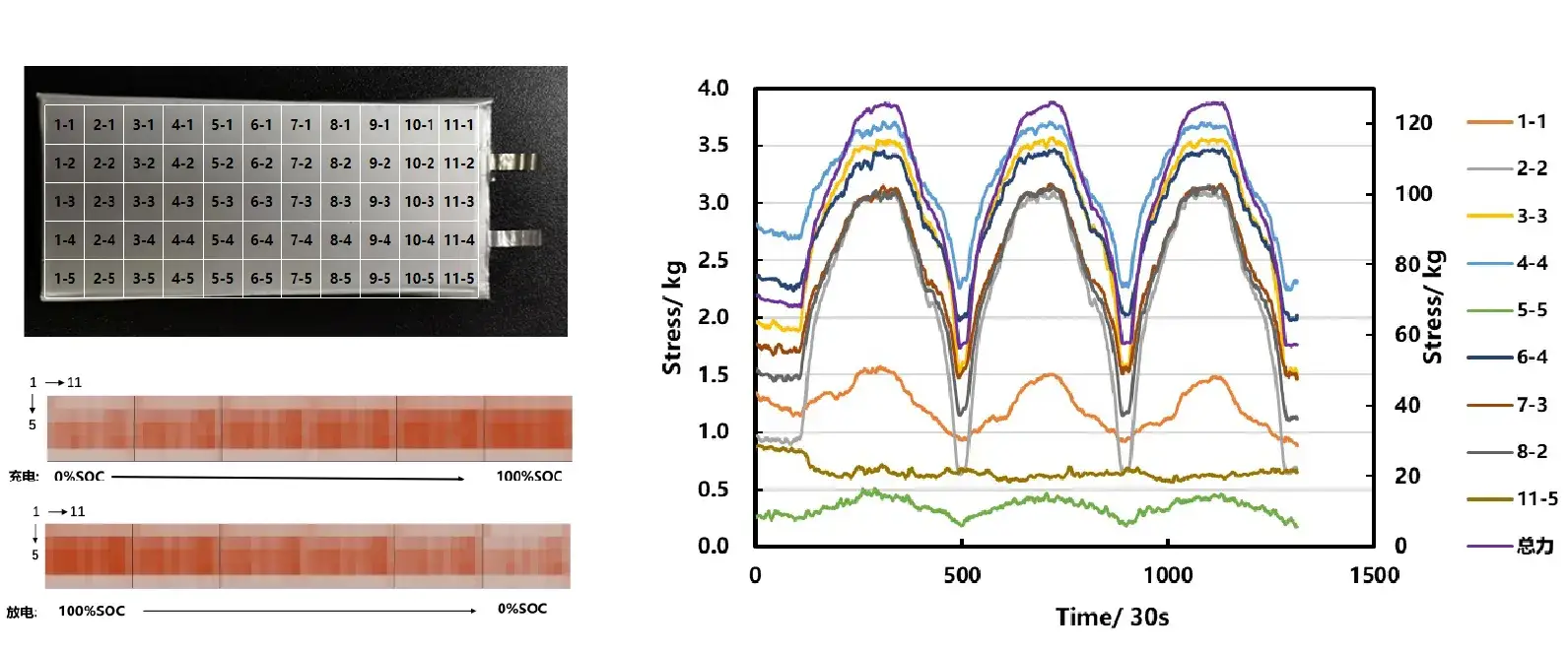

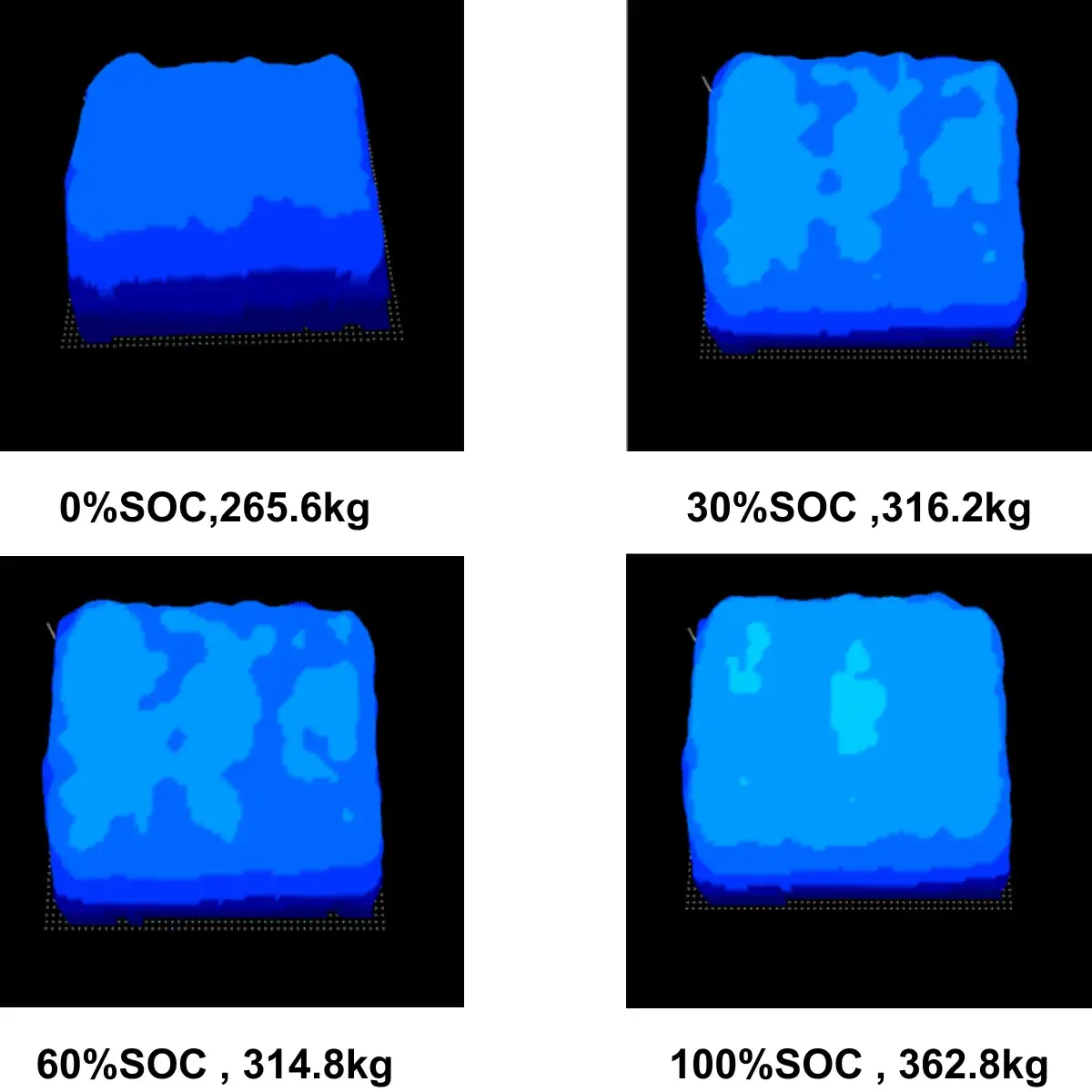

1. Test of pressure distribution on the surface of the cell during the cycle

- Test information: NCM-Graphite system,3~4.3V, 0.5C, 50kg preload;

- Result analysis: It can quantitatively characterize the difference of pressure distribution on the surface of the cell, provide a deeper perspective for the stress analysis of the cell, and help technicians analyze the pressure distribution in the battery cell, explore the causes of failure of the battery cell and develop a safer and more reliable cell.

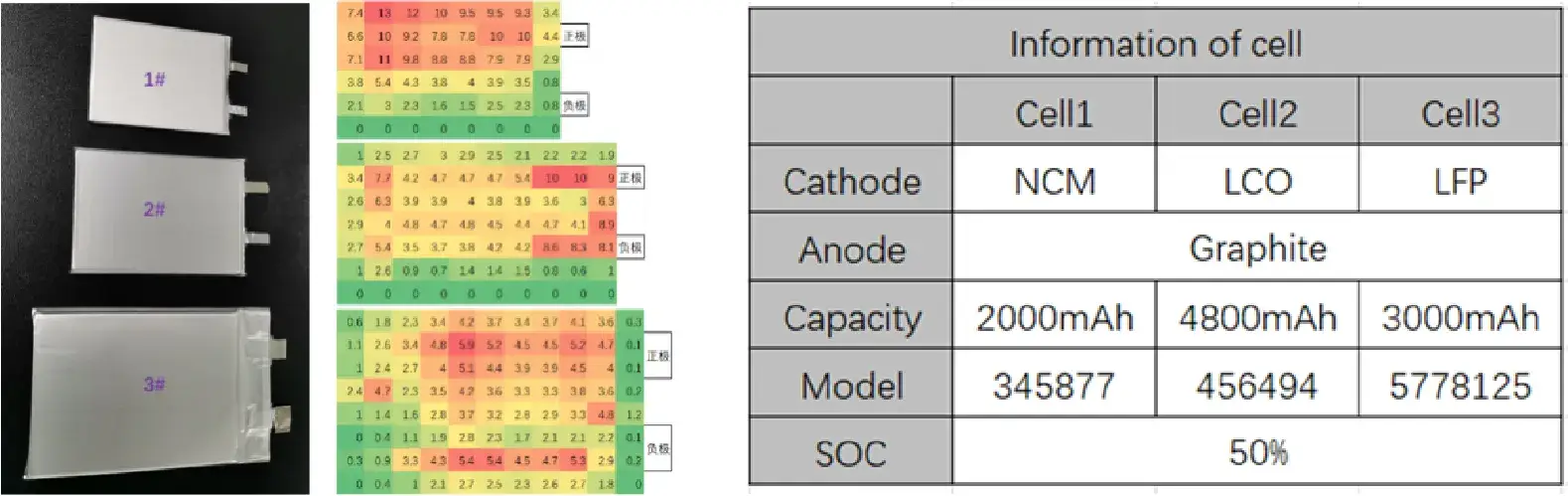

2. Surface flatness test of fresh cell

- Result analysis: there is a certain correlation between the cell process design and the cell pressure distribution(flatness). Technicians can develop appropriate distribution standards through the pressure distribution system to monitor the batch stability of the delivered cells.

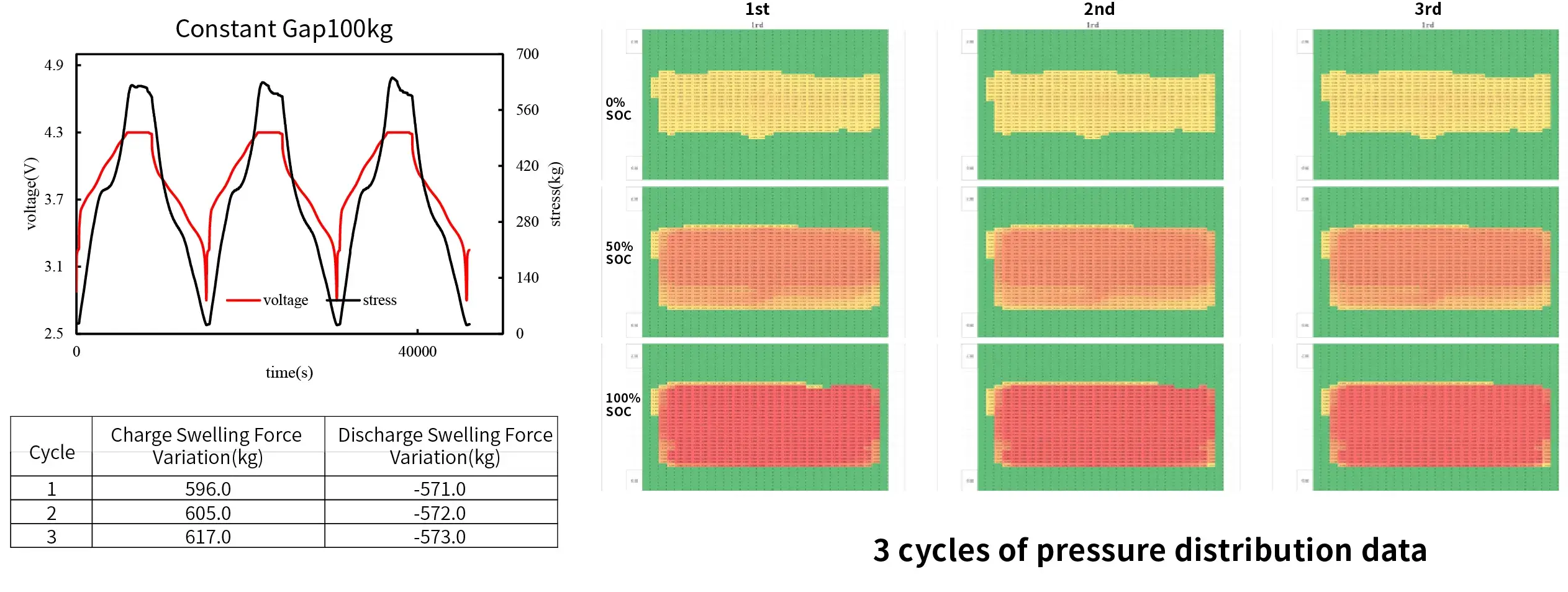

3. Swelling force distribution

3.1 Pouch cell test

➤ Cell: 2 Ah

➤ Mode: constant gap

- When used in conjunction with swelling equipment, it outputs the changes in expansion force while displaying the distribution at each stage.

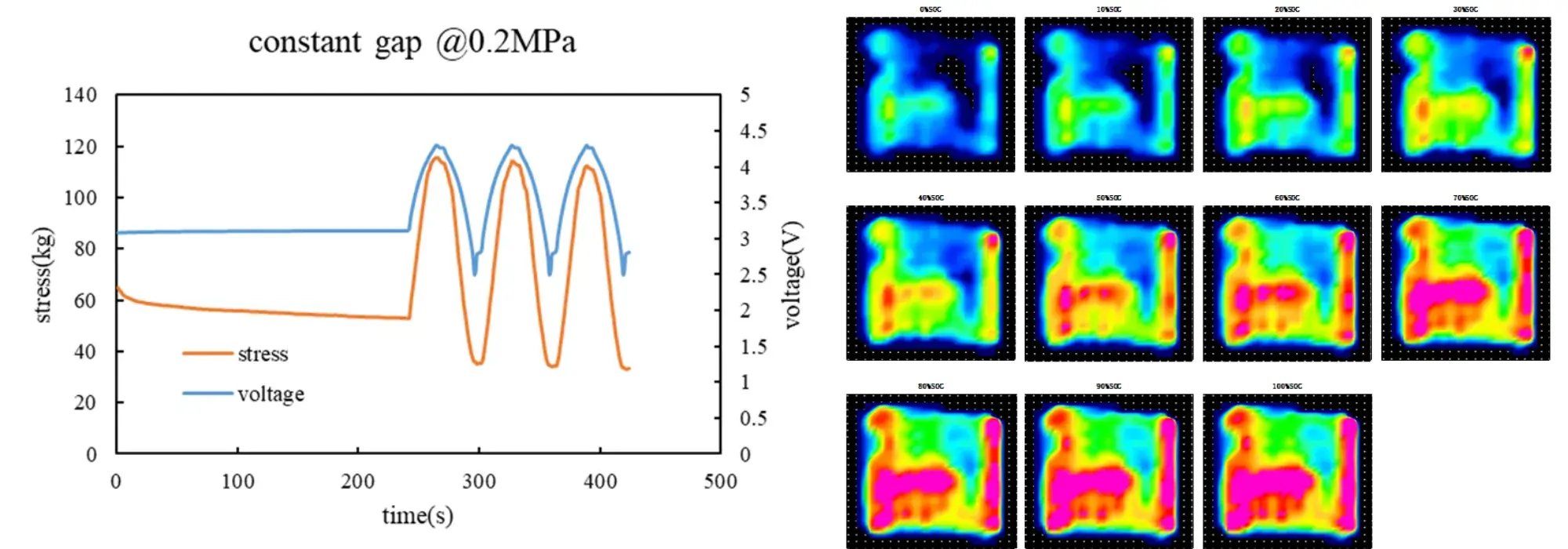

3.2 Prismatic cell test

➤ Cell: 334 Ah

➤ Mode: constant gap

➤ Test with silicone pad

-

After adding the silicone pad, the overall force distribution uniformity has been improved;

-

However, during the 30% to 60% stage, influenced by the silicone pad, the force actually decreases.

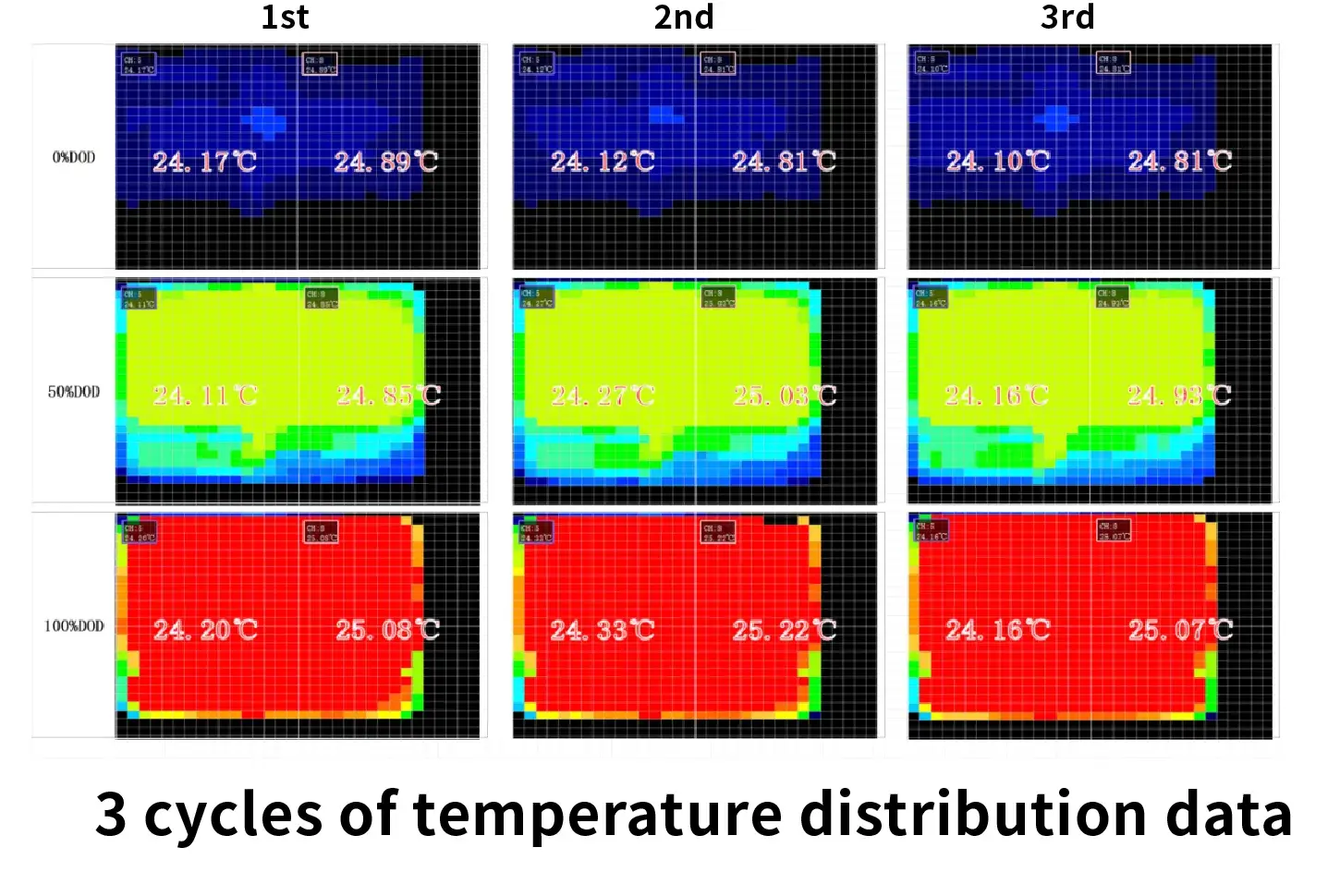

4. Pressure and temperature distribution

- The test results were consistent after three cycles test, and the pressure distribution underdifferent SOC could be seen as well.

- The test results were consistent after three cycles test,and the temperature distribution under different SOCcould be obtained.