Description

1. The Significance of Powder Resistivity Test

The rate capability of lithium-ion batteries is closely related to their internal resistance, which consists of ionic resistance and electronic resistance. Ionic resistance primarily includes the resistance to lithium-ion transport through the electrolyte within electrode pores, the resistance due to ion migration through the SEI film, the charge transfer resistance at the active material/SEI interface where ions and electrons interact, and the solid-state diffusion resistance of lithium ions within the active material. Electronic resistance, on the other hand, mainly comprises the resistance of the active materials in the cathode and anode, the current collectors, the contact resistance between active material particles, the interfacial resistance between active materials and current collectors, as well as the resistance from tab welding.

In practical battery development and manufacturing processes, ionic resistance must be evaluated at the finished cell level, whereas electronic resistance can be rapidly assessed at the material and electrode sheet stages. Therefore, accurate evaluation of electronic resistance in materials and electrodes—for instance, via a powder resistivity measurement system—is highly significant for predicting the overall resistance of the final battery cell.

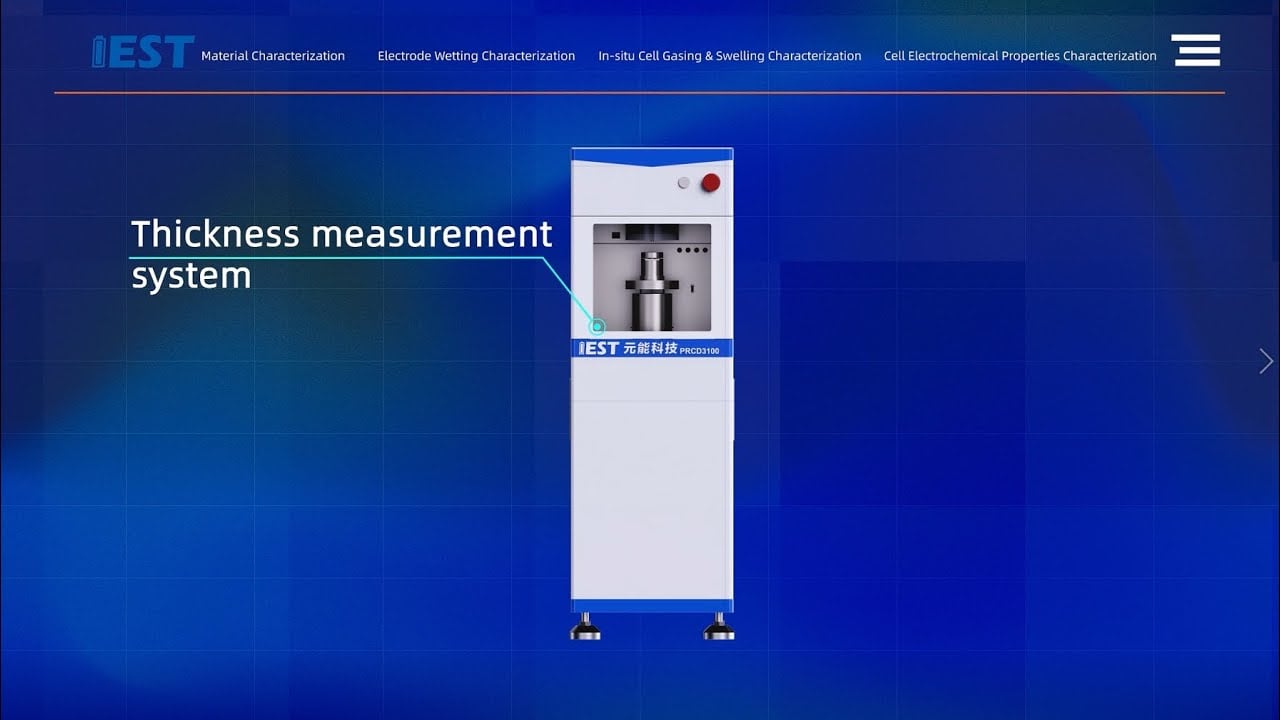

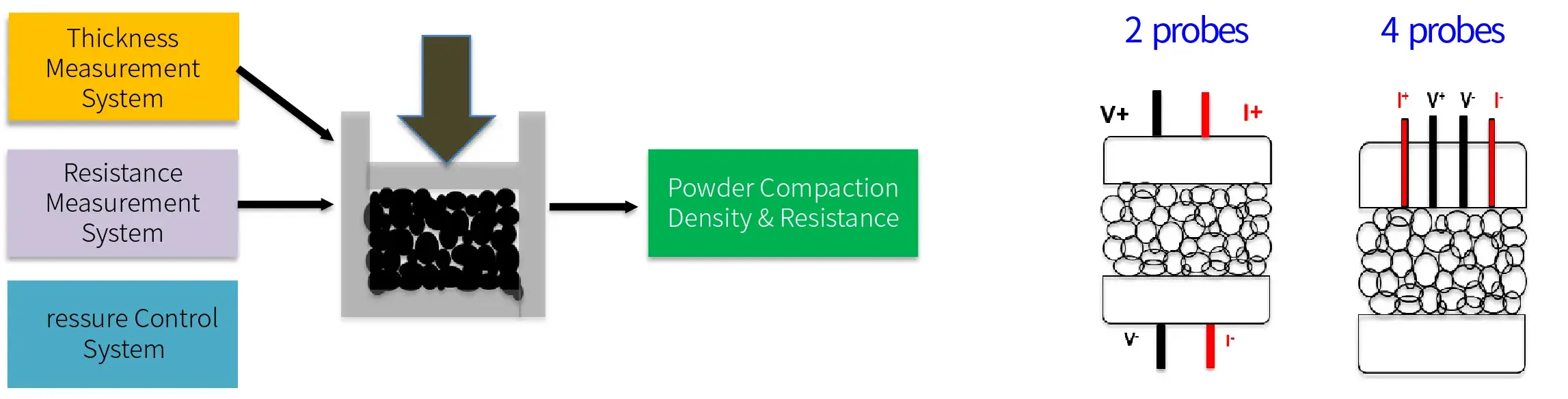

2. Instrument Principles

2.1 Test Methods

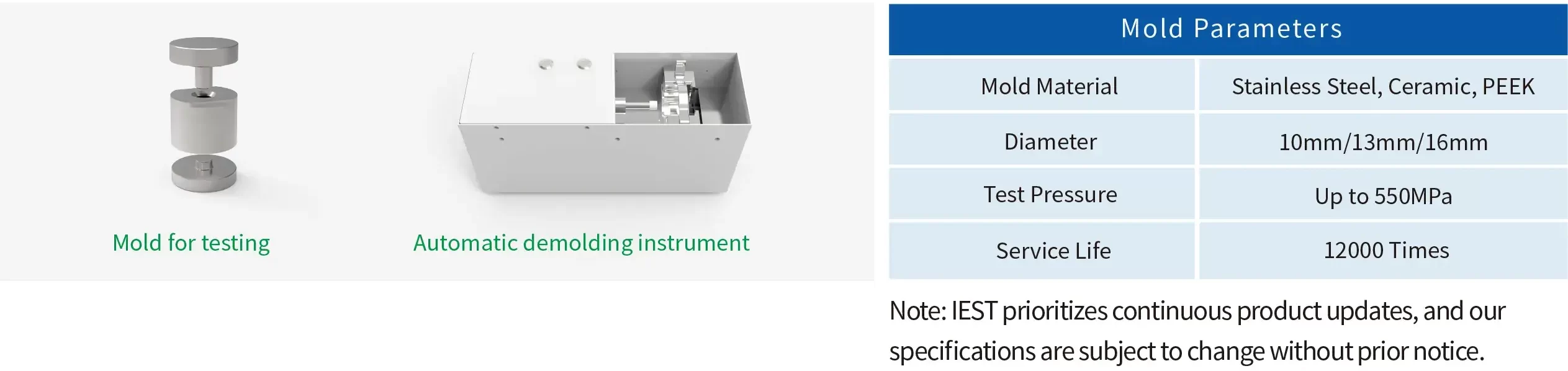

Put a certain amount of powder (1~2g) into the mold and vibrate it, put the mold into the instrument boxset the pressure (<200MPa) and the holding time, and start testing the thickness and resistance changes of the powdeiduring the compression process.

2.2 Test Parameters

Stress, pressure, thickness, resistance, resistivity, conductivity, & compaction density.

2.3 Calculation Formula

Compaction Density(g/cm³):![]()

Resistance(Ω):![]()

Conductivity (S/m):![]()

Resistivity(Ω*cm)-PRCD2100: ![]() (K is the 4 probe point compensation coefficient)

(K is the 4 probe point compensation coefficient)

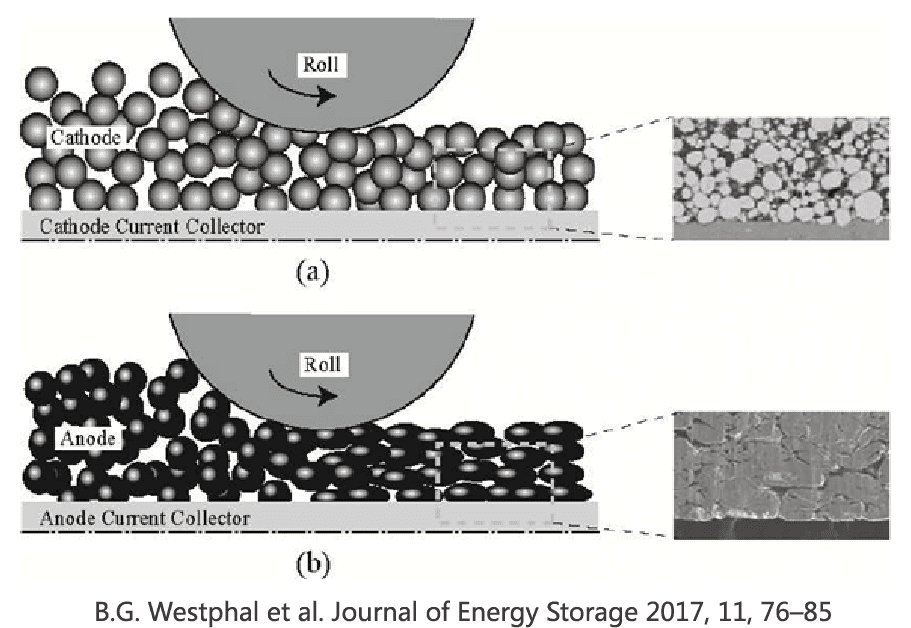

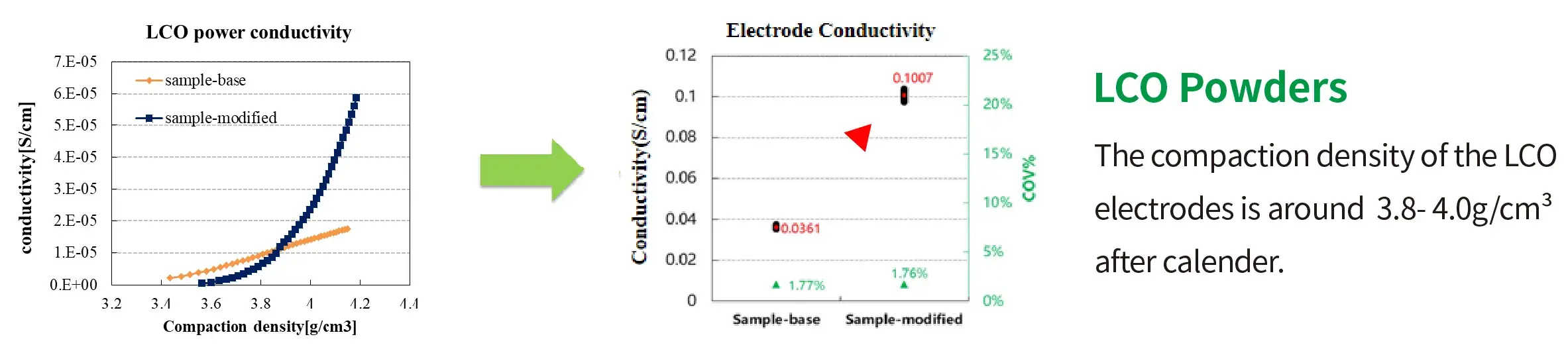

3. Why Compaction Density instead of Tapped Density?

Result analysis

Using LCO powder as an example, when the compaction density ofthe modified powder sample is less thar3.87g/cm’ (pressure <75MPa), its conductivity is lower than that of the unmodified powder sample.However, when the compaction density exceeds 3.87g/cm’ (pressure>75MPa),the conductivity ofthe modified powder beeinsto surpass that of the unmodified powder, and the conductivity improves significantly as the compaction increases

Conclusion: When testing the conductivity of powder, the compaction density should be close to the actual compaction oithe powder in the electrode.

4. Features

- High accuracy pressure system : Driven by servo motor.

- High accuracy displacement sensor : Precisely measure the variation of thickness.

- Specific clamp for resistivity & Compact density test of powder samples : Simplify the process of the powder loading and cleaning.

- Multi-functions : One-stop data collection of key parameters of pressure, resistance, thickness, temperature and humidity with high reliability, to provide a complete traceability for each result.

- Automatic measurement : Providing flexible measurement modes for different kinds of samples, and all the process parameter setting are integrated into a simple software control interface, with one-button to start a measurement

- Integrated design :Integration of control and measurement systems for pressure, resistivity and thickness control and measurement systems.

5. PRCD Software:

- Pressure can be set willfully within the extent of max pressure.

- The resistivity under different pressure can be measured in succession with controllable rate and interval of pressure scan.

- Different data analysis curves can be generated, including resistivity-pressure curve, resistivity-thickness curve, Compact density-pressure curve, and pressure-thickness curve.

- Two resistance data collection modes: interval time mode or automatic steady state condition determine mode.

- Data statistical analysis functions.

- Automatic generation of reports with the value of resistivity (or conductivity) and Compact density.

6. Applictions

Applications

1. High-Nickel Cathode Materials

Powder resistivity measurements serve as a critical analytical tool for elucidating the mechanisms underlying electrode performance enhancement. By quantitatively characterizing the improvement of conductive networks through surface coating, they explicitly demonstrate how material modifications promote electron transport.

(a) Powder resistivity of W-0 and W-0.5 samples; (b) Electronic conductivity; (c) Single-particle compression test; (d) Optical images of W-0 particle before and after mechanical testing; (e) Optical images of W-0.5 particle before and after mechanical testing; (f) CV curves of W-0 at 0.1-0.7 mV s⁻¹; (g) CV curves of W-0.5 at 0.1-0.7 mV s⁻¹; (h) Relationship between scan rate and peak current; (i) PITT measurement of W-0; (j) PITT measurement of W-0.5; (k) Corresponding Li⁺ diffusion coefficients

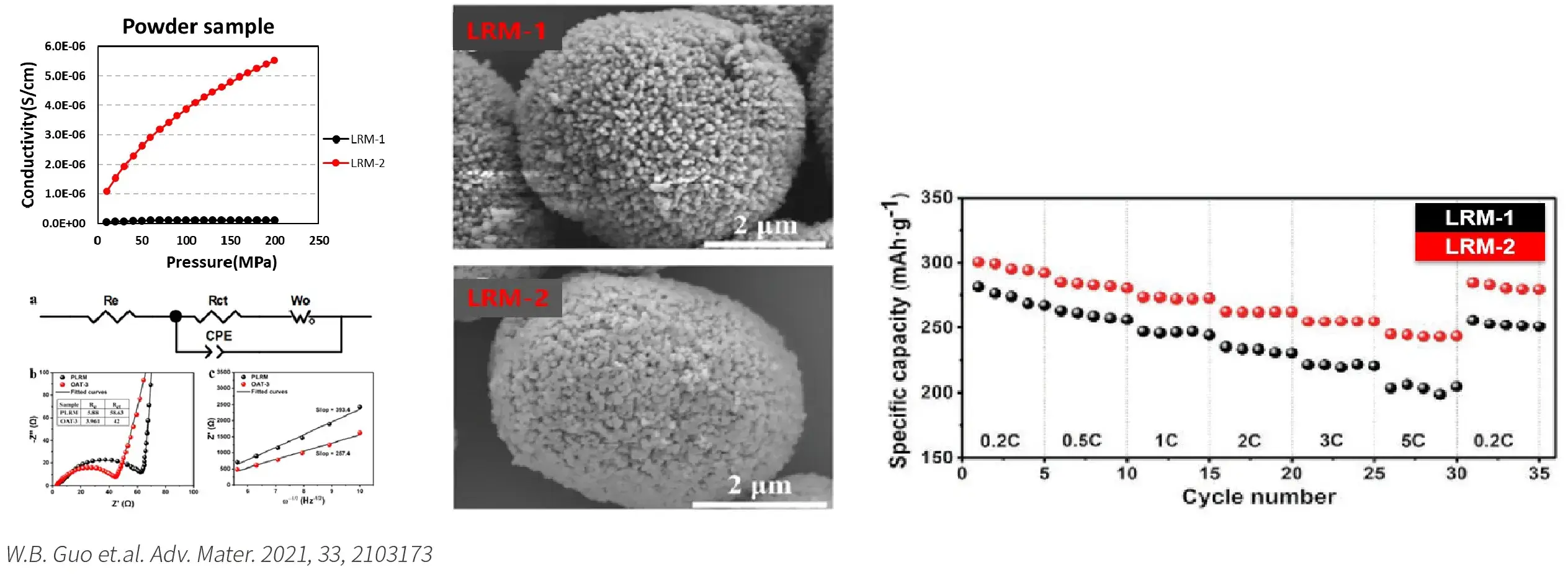

2. Lithium-rich Materials Under Variable Pressure Mode

-

Analysis of the merits and Limitations of modification approaches for lithium-rich materials

- The resistivity of lithium-rich materials can be reduced by regulating the surface structure!

3. Silicon-based materials

The analysis of differences in materials under different mixing ratios and modification process conditions provides a new approach and direction for material modification and differential analysis evaluation.

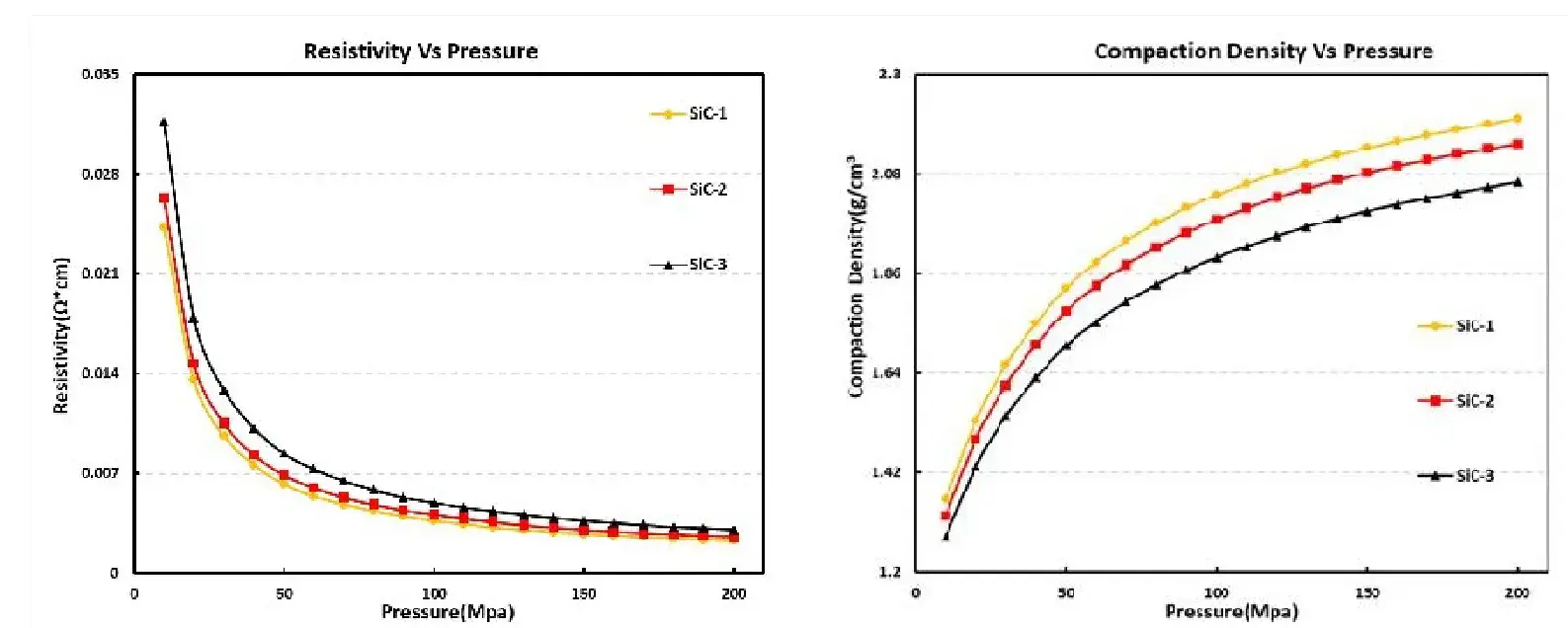

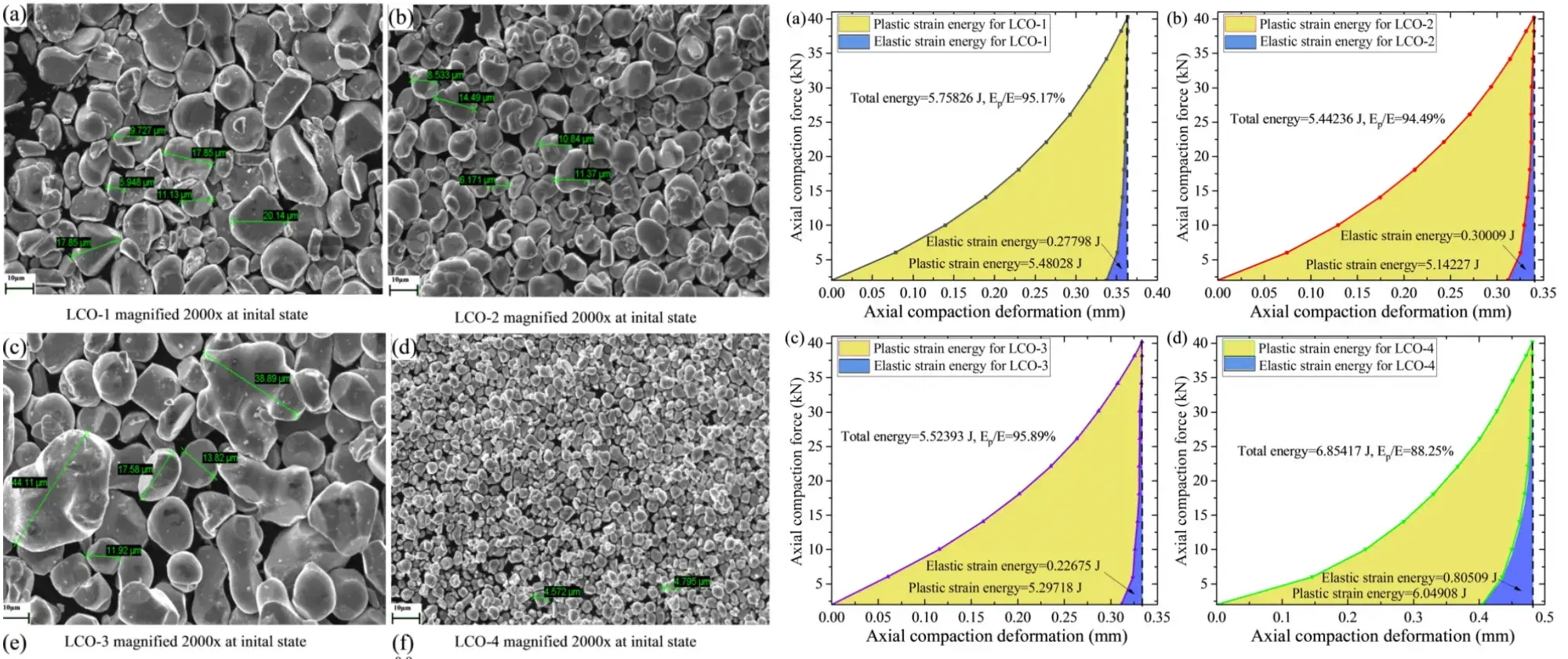

Test Condition: Si content: 3%, 6% and 10%(SiC-1/Sic-2/sic-3)

Conclusion:

- Resistivity: Sic-1< Sic-2< SiC-3

- Compaction density: Sic-1>SiC-2> Sic-3

Test condition: Sintering temperature of SiO

Materials: Si0-1< Si0-2<Si0-3<Si0-4

Conclusion:

- Resistivity: Sio-1>Si0-2>Si0-3> Si0-4

- Compaction density: Sio-1>Si0-2>Si0-3>Si0-4

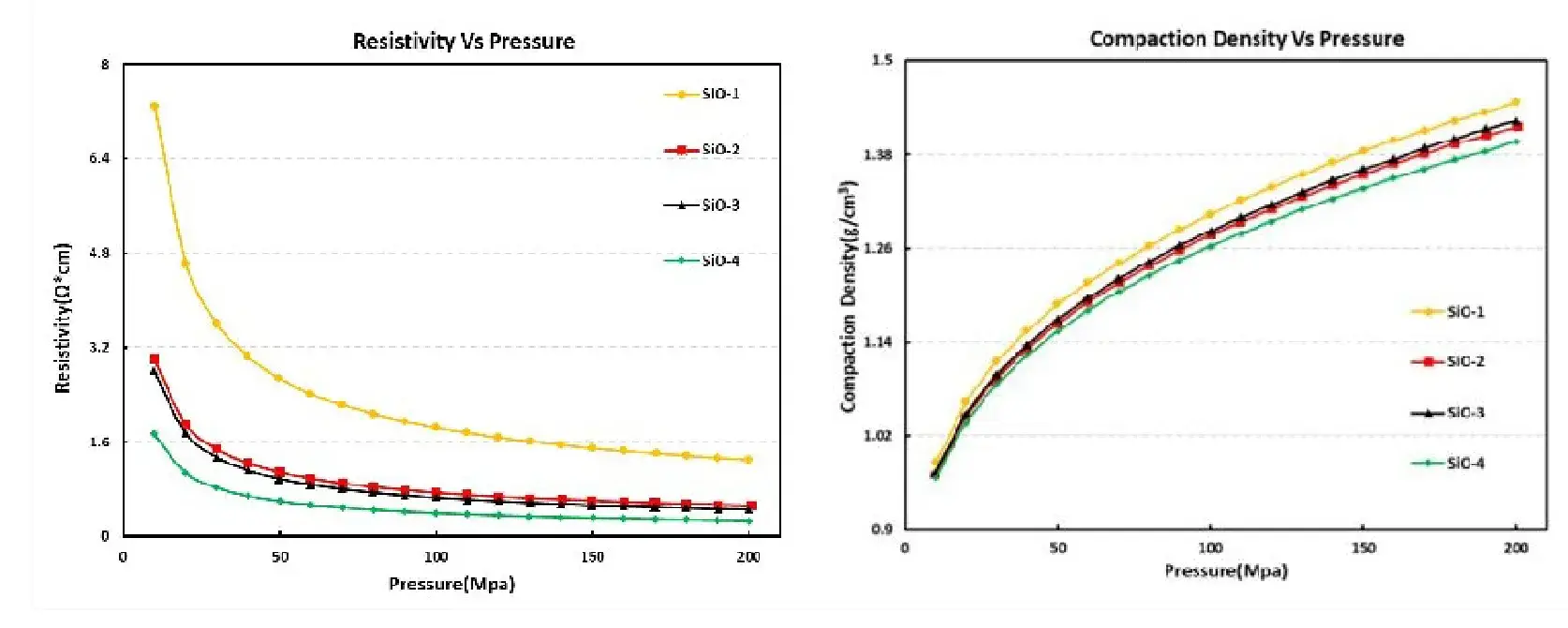

4. Anode Materials and Conductive Agents

- Powder Resistivity & Compaction Density of Common Anode Materials & Conductive Additives: Statistically significant differentiation exists in both powder resistivity and compaction density across various types of anode materials and conductive additives.

5. Elastic Modulus

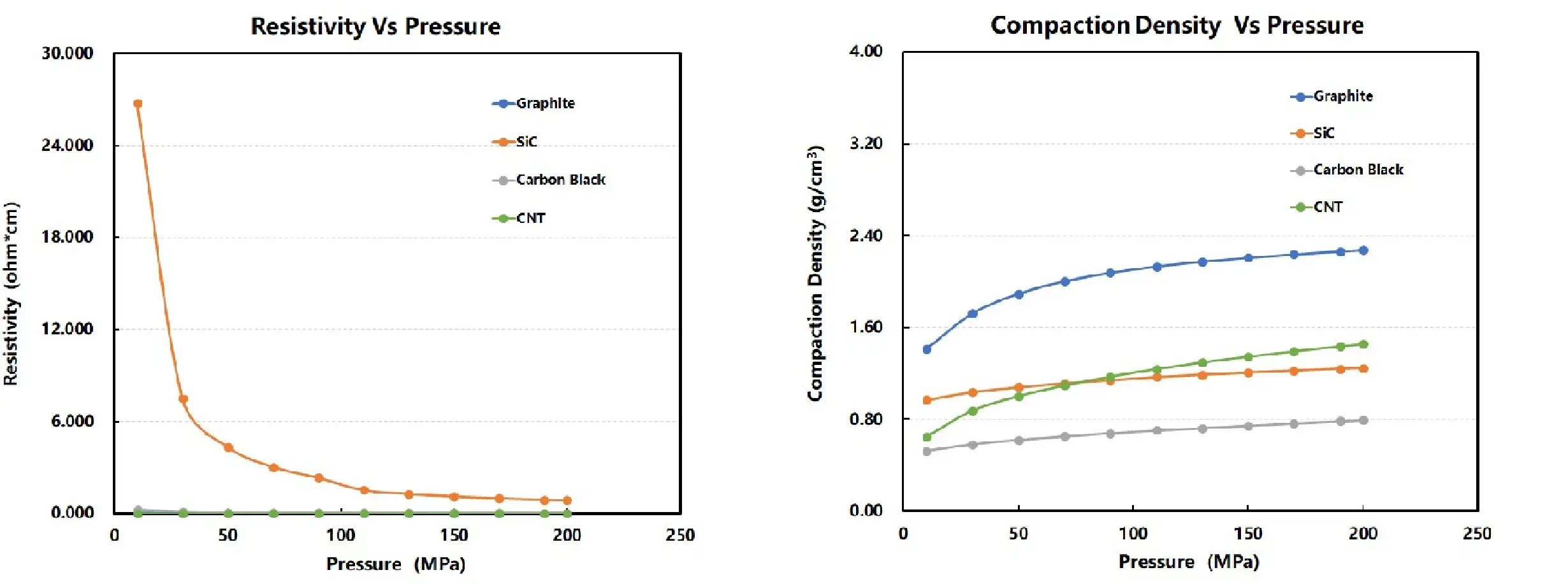

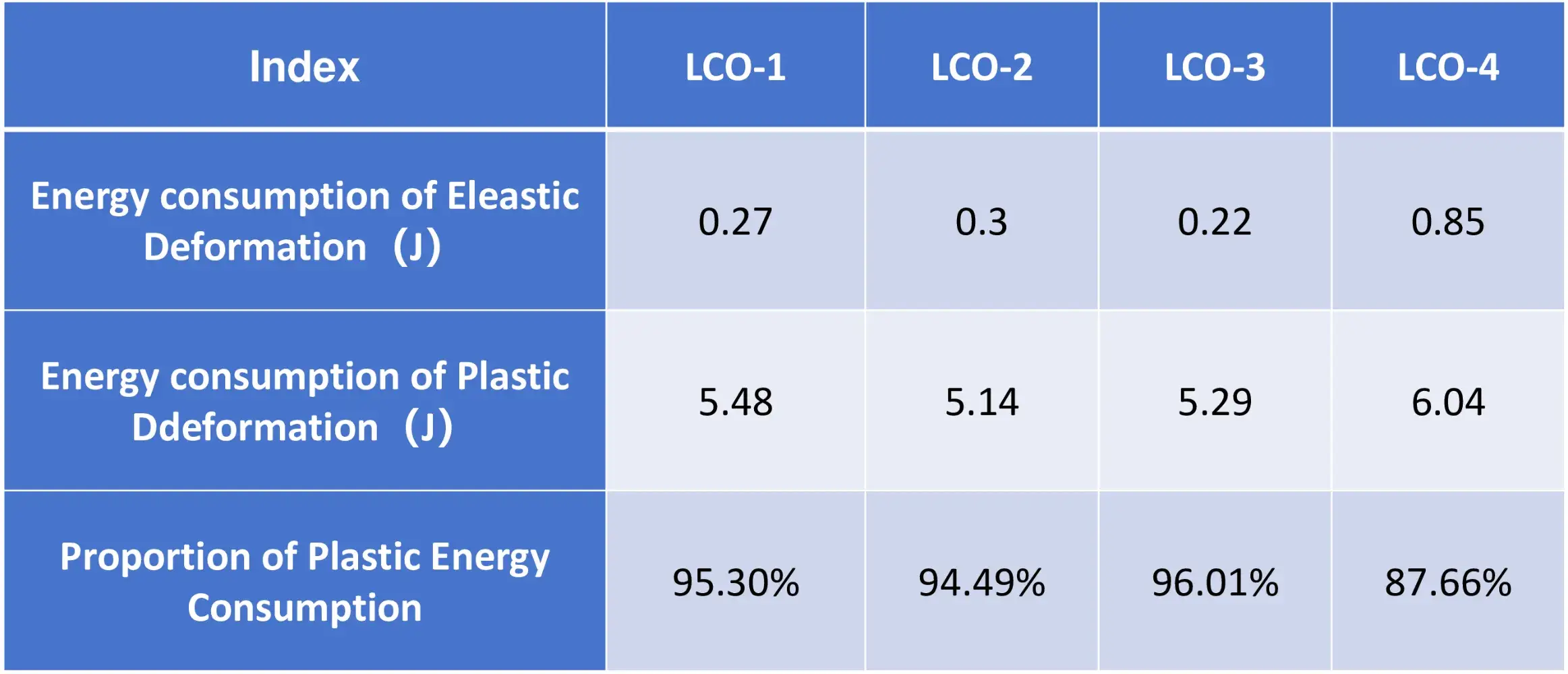

5.1 LCO under Steady-state Mode

LCO Particle Size:

- LCO-1: 5μm-30μm

- LCO-2: 5μm-15μm

- LCO-3: 10μm-45μm

- LCO-4: 5μm

Conclusion:

- During the compaction, plastic deformation typically accounts for approximately 90% of the total deformation.

- Powders of smaller particle size(LCO-4) exhibit a more noticeable reboundness, and its proportion of Plastic energy consumption is relatively lower as well.

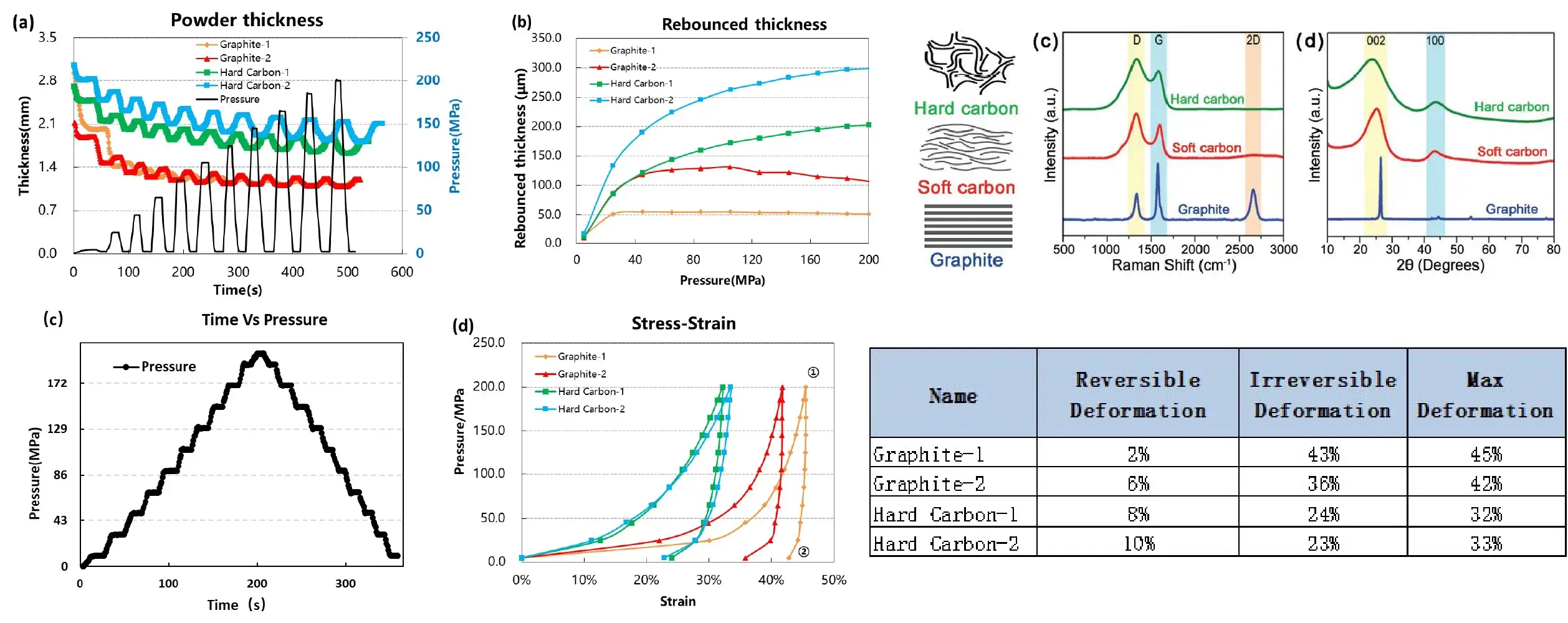

5.2 Compressive Properties of Carbon Materials

- Analysis of Material Springback: Graphite exhibits greater compressive resilience at the particle level compared to hard carbon, primarily attributed to differences in their microstructural architecture.

Video

Specifications