-

iestinstrument

How to Efficiently Screen Silicon-Based Anode Materials Using Expansion Thickness Measurement

1. The Challenge: Managing Volume Expansion in High-Energy Anodes

In the race for higher energy density, silicon based anode materials are unparalleled due to their significantly higher theoretical capacity compared to graphite. However, this “star” material has a well-known Achilles’ heel: severe volume expansion. During cycling, silicon can undergo volume changes exceeding 300%. This expansion causes electrode structural damage, active material detachment, rapid capacity fade, and safety concerns. Effectively managing this expansion is therefore the central challenge in developing viable silicon based anode technologies for long-life batteries.

This case study describes an expedited screening workflow that correlates expansion thickness measurements with cell electrochemical performance. Using a small, model full-cell fixture and the IEST In-Situ Silicon Based Anode Swelling Rapid Screening System(RSS1400), engineers can triage candidate silicon materials earlier in development and reduce the need for long, resource-intensive full-cell cycling campaigns.

2. The Limitation of Traditional Screening Methods

Traditional methods for evaluating silicon-carbon anodes are slow and resource-intensive. The conventional process involves:

-

Preparing electrodes with different compaction densities.

-

Assembling full coin or pouch cells.

-

Conducting hundreds of charge-discharge cycles.

-

Analyzing capacity retention and impedance growth to infer the optimal design.

This cycle can take weeks or even months, severely hampering R&D progress and incurring high material and time costs.

3. A Proactive Screening Solution: In-situ Expansion Thickness Analysis

Is there a way to predict an electrode’s performance before committing to lengthy full-cell cycling tests? The answer lies in its expansion behavior. The core principle is straightforward: the expansion thickness of a silicon-carbon electrode during cycling is directly correlated with its structural stability. Under identical test conditions, an electrode exhibiting lower expansion and stable electrochemical performance likely possesses a microstructure better equipped to accommodate silicon’s volume changes, promising longer cycle life in a full cell.

We present an efficient, early-stage screening method using IEST RSS1400 in-situ expansion analyzer and a specialized model coin cell fixture. This approach acts as a “diagnostic tool,” providing critical insights into material performance.

Figure 1. The IEST In-situ Silicon Based Anode Swelling Rapid Screening System(RSS1400) and the specialized model coin cell fixture.

4. How the Method Works

- Simulating Real Conditions: The silicon-carbon electrode is paired with a matching NCM cathode in a model coin cell fixture, creating a functional miniaturized full cell that simulates realistic lithiation/delithiation processes.

-

Precise In-situ Measurement: The assembled fixture is placed in the RSS1400 analyzer. A thickness sensor with 1 µm resolution monitors the electrode’s expansion thickness in real-time under a constant 1 kg applied pressure during low-rate cycling (e.g., 0.1C for 2-3 cycles).

-

Key Evaluation Metrics: The primary data includes the expansion thickness(difference between charged/discharged states) and fundamental electrochemical parameters like first-cycle Coulombic efficiency (CE) and capacity. This combined dataset offers a rapid, multi-faceted performance assessment.

5. Cell preparation and cycling protocol

The test cells are assembled to closely simulate practical electrode behavior while keeping material usage and test time low. Key procedural parameters:

-

Positive electrode: NCM523.

-

Negative electrode: candidate silicon based anode materials (examples labeled SiC-A#, SiC-B#, SiC-1#, 2#, 3# in the dataset).

-

Electrolyte: 1.0 M LiPF₆ in EC:DEC = 1:1 by volume, with 5.0% FEC (vol%) additive.

- Separator: PP microporous separator.

- N/P ratio: matched appropriately for the small full cell to simulate realistic lithiation range.

- Cycling: 0.1C charge/discharge cycling for 2–3 weeks, after which thickness is recorded in the fully charged (or fully discharged) state to compute expansion thickness relative to the initial baseline.

This protocol balances realistic electrochemical stress with throughput: each test run provides actionable data in weeks rather than months.

6. Case Studies: Data-Driven Insights

6.1 Case 1: Comparing Compaction Densities (SiC-A# vs. SiC-B#)

Using NCM523 cathodes and a standard electrolyte, we tested two silicon-carbon materials with different compaction densities.

The results showed(Figure 2 and Figure 3) that material B# exhibited both lower expansion thickness and a higher first-cycle CE compared to material A#. This performance divergence likely stems from differences in their internal microstructure, mechanical integrity, and stress distribution, directly influenced by the compaction process.

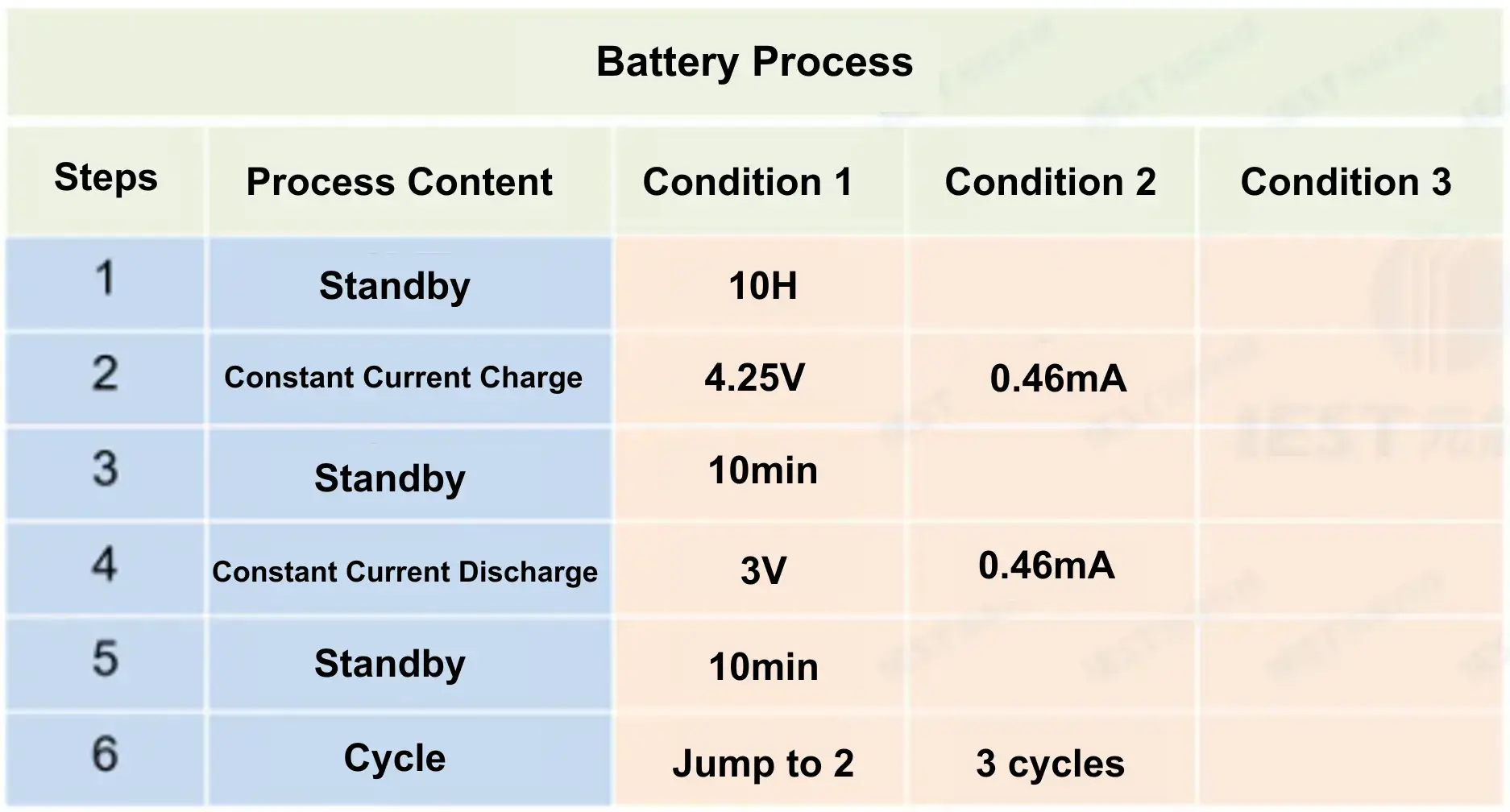

Table 1. Charge and discharge process

![]()

Figure 2. Comparison of expansion thickness for two silicon based anode materials with different compaction densities (SiC-A# and SiC-B#).

![]()

Figure 3. Comparison of and electrochemical performance for two silicon based anode materials with different compaction densities (SiC-A# and SiC-B#).

6.2 Case 2: Screening Different Silicon-Based Materials (SiC-1#, 2#, 3#)

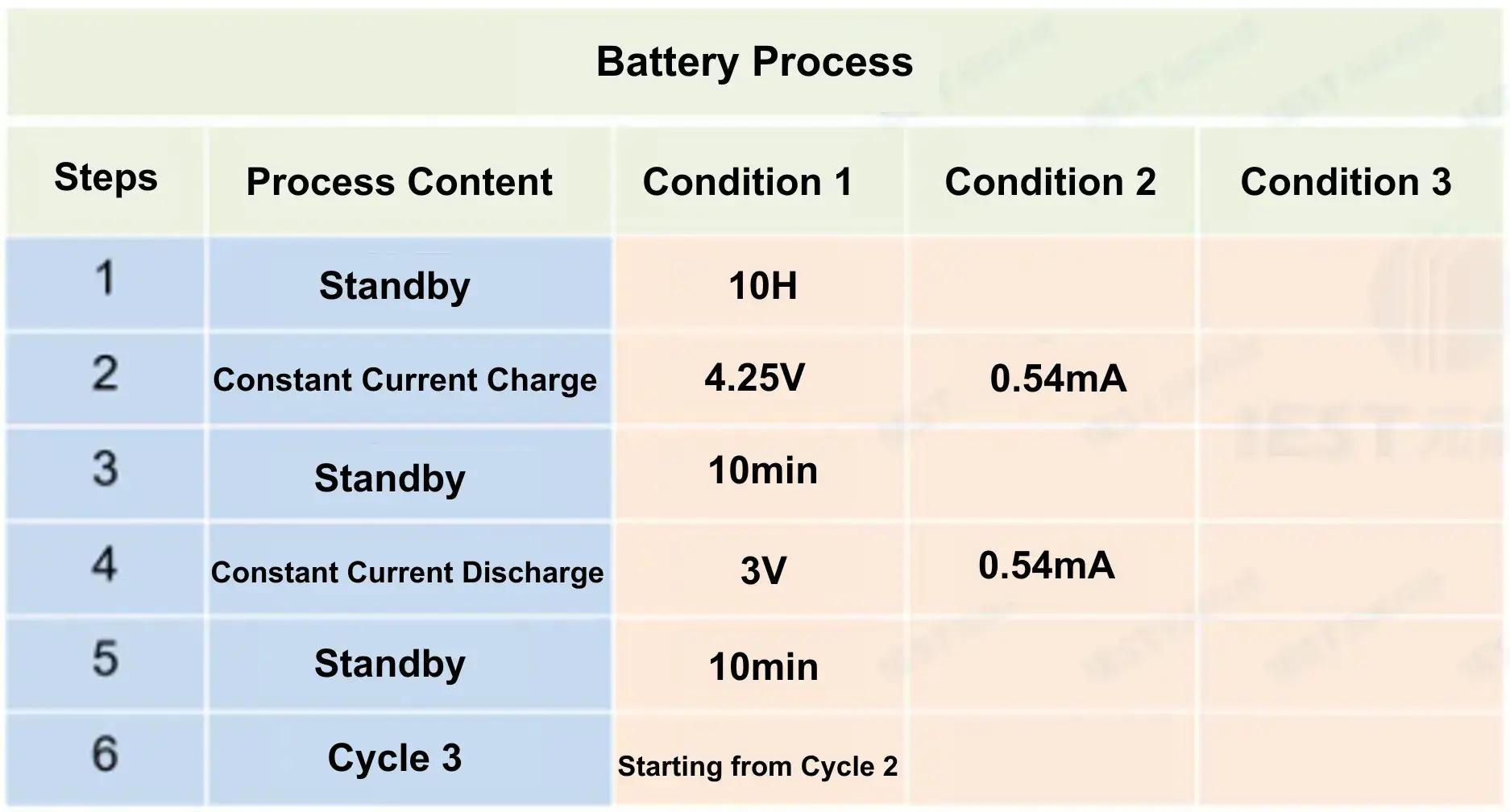

Table 2. Charge and discharge process

A test comparing three distinct silicon based anode materials under the same conditions revealed clear differences. Material 1# showed the largest expansion and the lowest first-cycle CE. While materials 2# and 3# had similar initial efficiency, material 2# displayed greater expansion. This data suggests that variations in material composition, particle size, and porosity significantly impact both expansion behavior and electrochemical efficiency.

![]()

Figure 4. Screening results of three different silicon-based materials (SiC-1#, 2#, and 3#) based on expansion thickness.

![]()

Figure 5. Screening results of three different silicon-based materials (SiC-1#, 2#, and 3#) based on charge-discharge performance.

7. Practical Applications and Advantages of the In-situ Expansion Thickness Analysis

Based on this data, researchers can intuitively understand the performance and expansion thickness of different silicon-based anodes. It is as if they are equipped with a “stethoscope,” “X-ray,” and “physical examination report” for the battery, enabling them to deeply diagnose its internal state, reveal its performance limits and degradation mechanisms, and guide the optimization of next-generation battery designs:

-

Electrolyte Formulation Optimization: A formulation that results in smaller expansion, higher efficiency, and more stable charge-discharge curves indicates better compatibility with the electrode material and the ability to form a more stable solid-electrolyte interphase (SEI) layer.

-

Electrode Material and Additive Screening: When evaluating a new silicon-carbon anode material, close attention must be paid to the rate of change in its expansion thickness. Simultaneously, observing whether its charge-discharge curves are stable and whether its efficiency remains steady at a high level serves as the core criterion for judging its commercial viability.

-

Manufacturing Process Verification (e.g., Compaction Density, Electrolyte Volume): Optimized processes yield lower internal resistance (manifested as a smaller voltage difference between charge/discharge plateaus), higher efficiency, and reduced irreversible expansion.

8. Conclusion: Accelerating Development with Proactive Diagnostics

The path to next-generation, high-energy-density batteries inevitably leads through silicon based anode materials, with managing volume expansion as the critical gate. Measuring expansion thickness with a high-resolution RSS1400 and a reproducible model cell fixture provides a rapid, physically grounded screen for silicon based anode candidates. The method reduces development lead time by enabling early triage of materials that balance energy density and mechanical stability. When combined with simple electrochemical metrics—first-cycle Coulombic efficiency and initial charge/discharge profiles—this approach helps teams find the most promising silicon formulations before committing to prolonged full-cell validation.

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.