Description

1. Traditional Testing Method

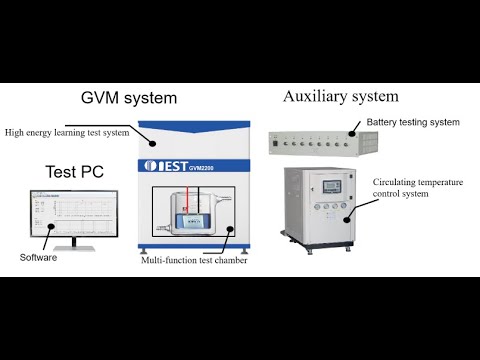

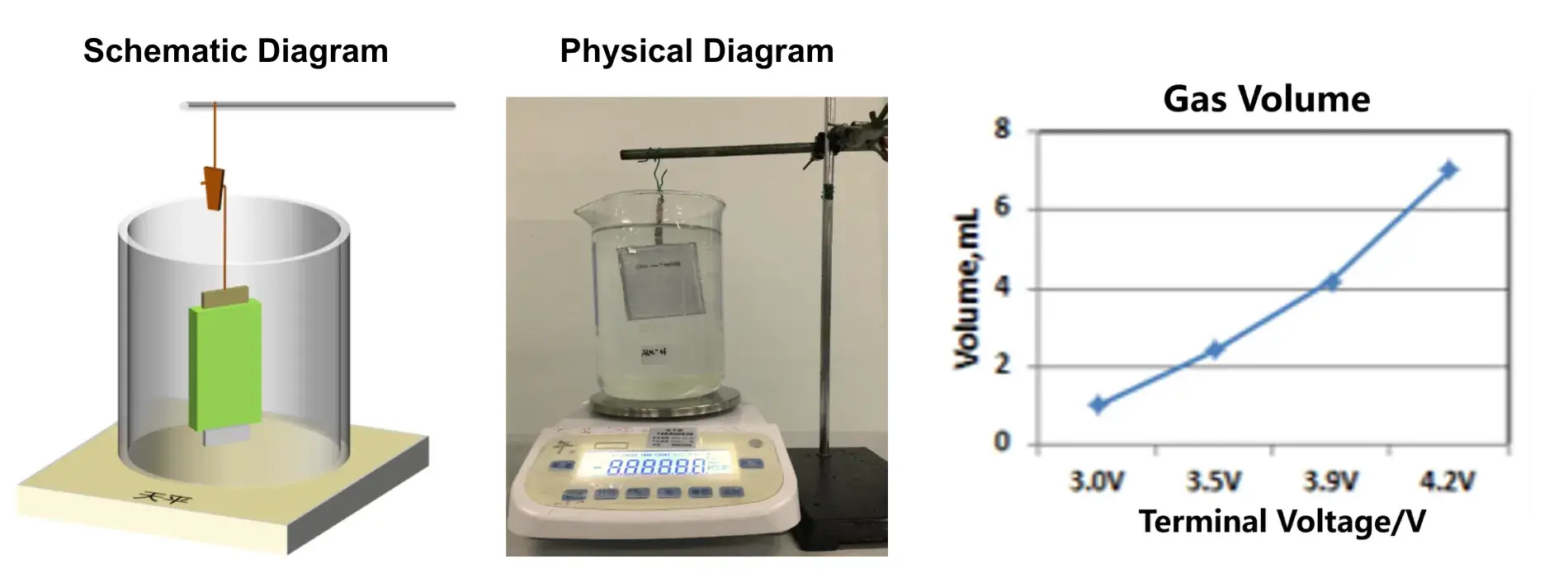

1.1 Single Volume Drainage Method

The Single Volume Drainage Method uses a balance to measure cell volume. It characterizes the volume change of a cell during the entire charging process by taking point-based measurements of the cell volume at different cutoff voltages and fitting the obtained volume data.

Advantages:

-

Low equipment cost

-

Simple structure

-

Easy to operate

Disadvantages:

- Single point-based measurement: Cannot capture the continuous volume change and gas evolution rate variation throughout the entire cell formation process.

-

Ex-situ measurement: The transfer process for measurement is susceptible to external environmental influences.

-

Standard balance weighing: Incapable of long-term, stable, high-precision online measurements.

-

High battery cell consumption: Requires many cells for testing, and cannot eliminate the impact of inconsistencies between cells.

1.2 Simple In-situ Gas Analyzer Device

Self-assembled basic in-situ apparatus

Disadvantages:

- Cannot perform temperature-variable testing at different temperatures;

-

Unable to achieve force-electrical coupling, with significant load cell fluctuations due to external interference;

-

Lacks automated data acquisition software, requiring manual post-processing and merging of data.

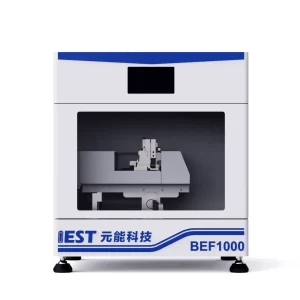

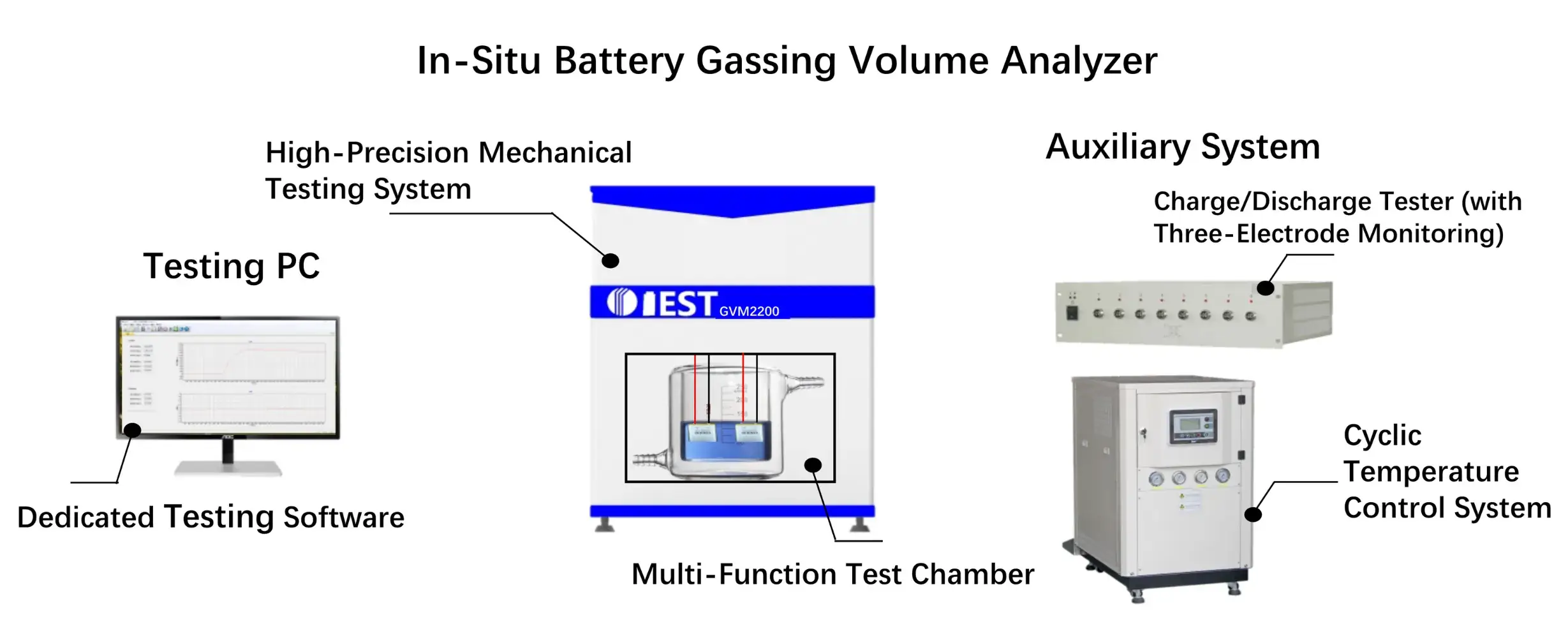

2. IEST Creative Solutions

- Simultaneous Mechanical-Electrochemical Testing System: In-situ long-term monitoring with 1 μL resolution

-

Temperature-controlled environments: 20°C to 85°C

-

Dedicated software: Real-time data acquisition from mechanical test systems with automated plotting of volumetric expansion curves and electrochemical profiles

- Auxiliary System: Special structure design, convenient to intervene in supporting auxiliary system, realize test temperature adjustment control

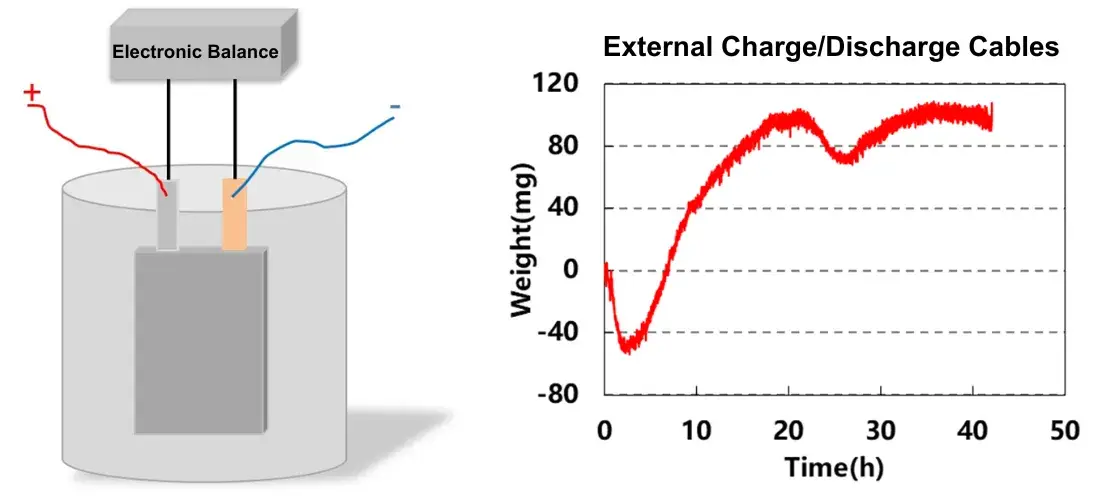

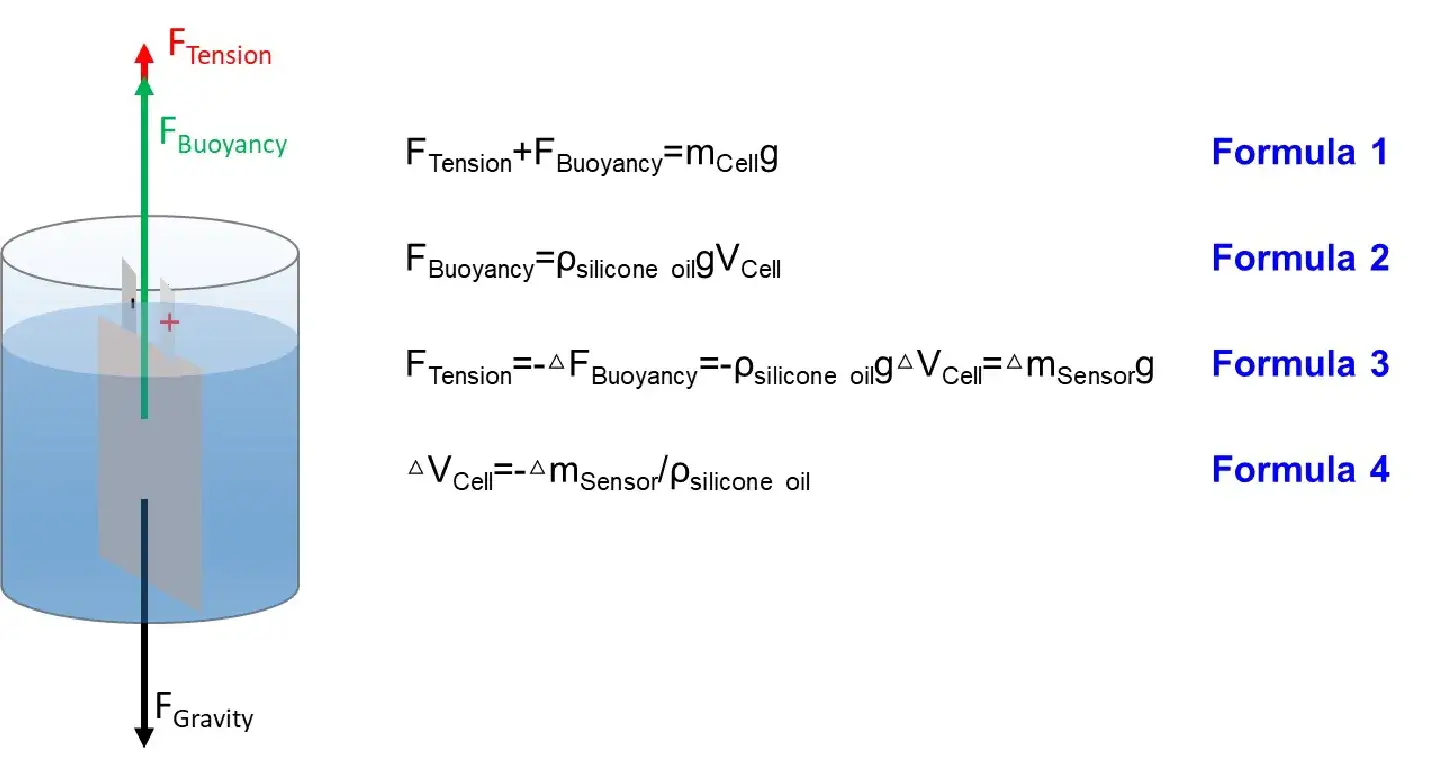

3. Instrument Principles

By combining Newton’s law (formula 1) and Archimedes’ buoyancy principle (formula 2), specialized sensors are used to measure the real-time mass changes of the cell during the charge & discharge process, and then the cell’s volume changes can be further calculated(formula 3 and 4).

4. Product Features

- Multi-Level Gassing Testing: Material Gassing → Single-Layer Stacked Cell Gassing → Small Pouch Cell Gassing → Cylindrical & Prismatic Cell Gassing

- Multi-Channel Gassing Testing: Single channel → 2-channel → 8-channels Testing

- Multiple Temperature Settings: Room Temperature Testing → High and Low Temperature Testing (RT to 85℃ with Water Bath Control)

- Comprehensive Gassing Analysis: Gassing Volume → Gassing Pressure → Gassing Composition Analysis

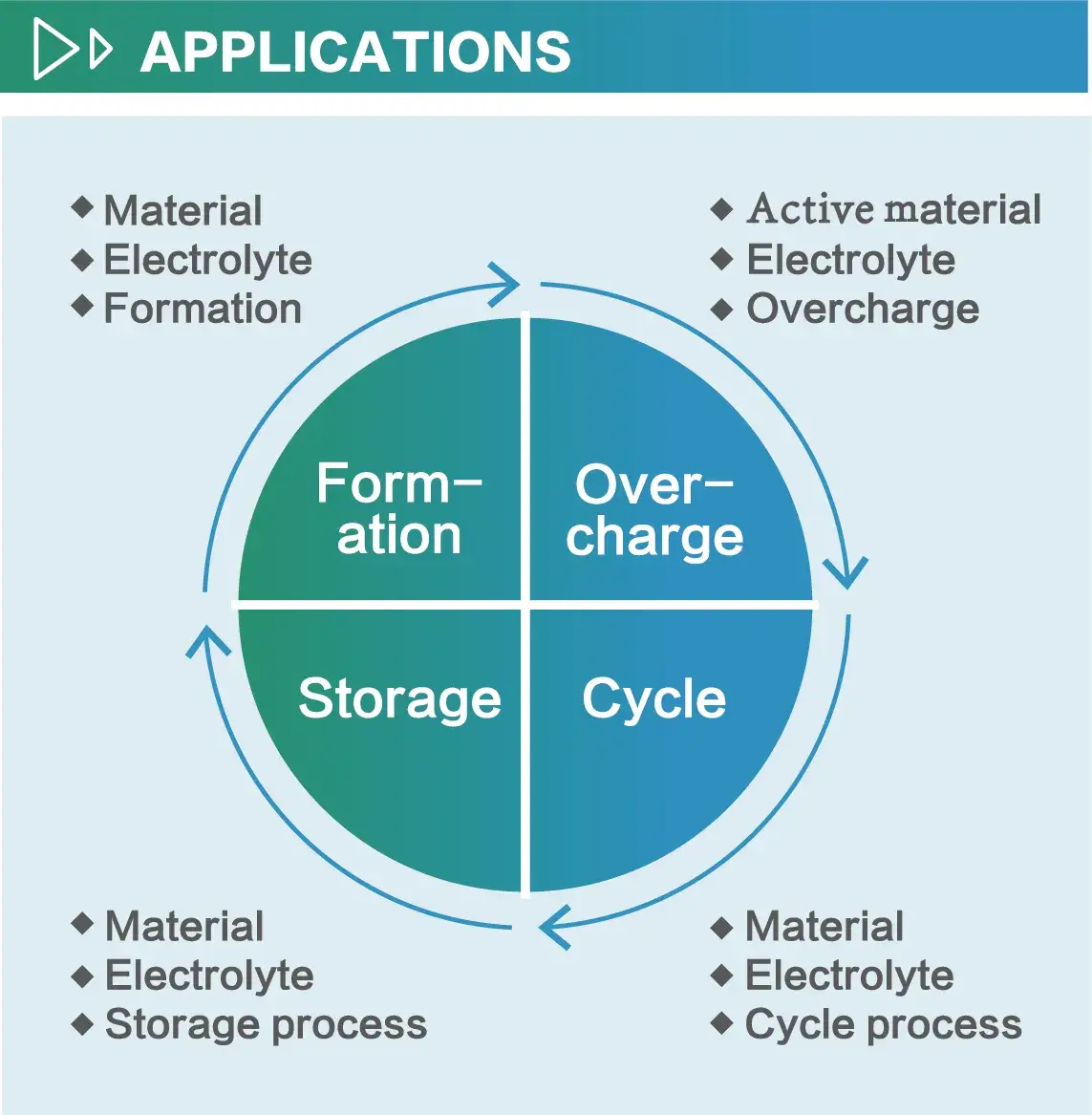

5. Applications

- Overcharge Gassing

- Cycle Gassing

- Storage Gassing

- Formation Gassing

Applications

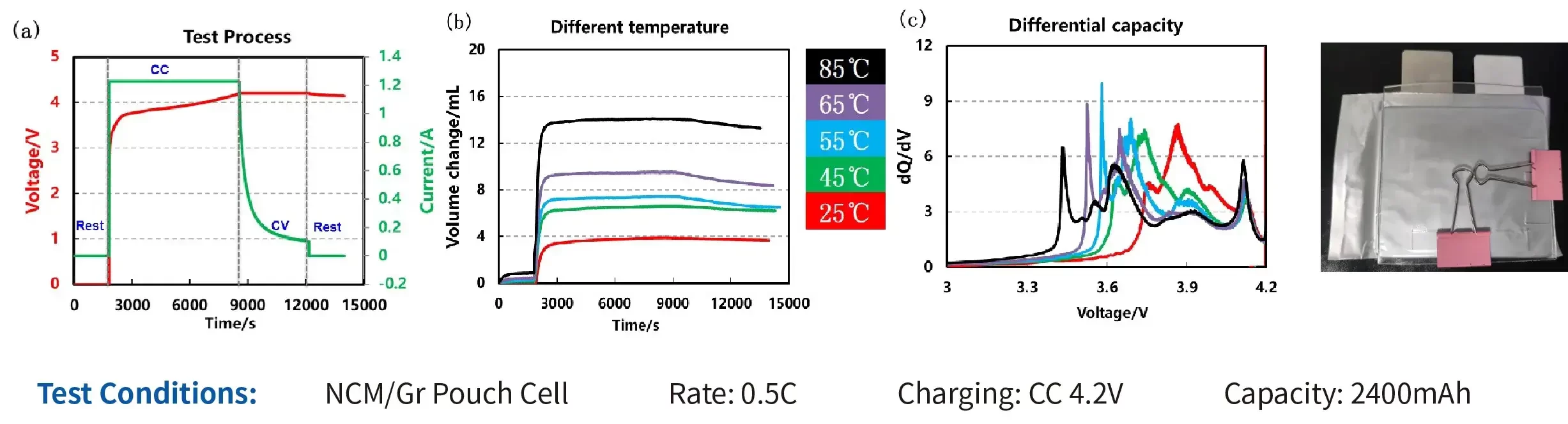

1. Application Case: Formation Gassing

1.1 Formation at different temperatures

Conclusion:

- Gas production increases progressively with elevated formation temperatures.

- From the perspective of differential capacity curves, higher formation temperatures reduce the polarization of each phase transition. However, when the temperature exceeds 55°C, the first phase transition peak becomes sharper, which may be related to the more vigorous SEI film formation reaction at elevated temperatures.

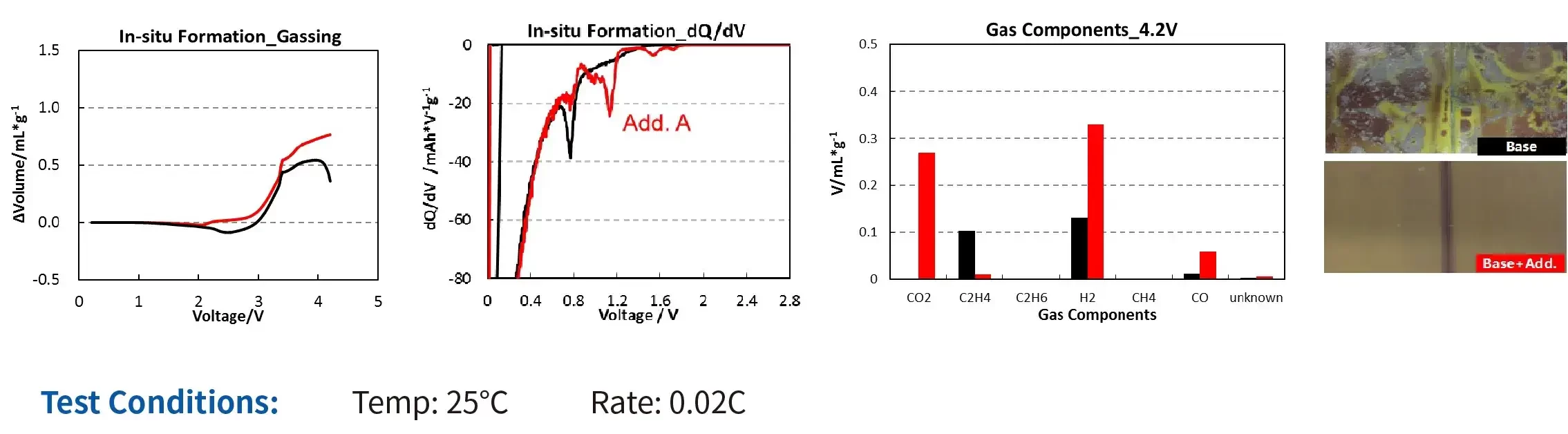

1.2 Formation with different electrolyte additives

Conclusion:

- In the same electrolyte, the gas generation volume and gas generation rate of the cell formed with electrolyte B, which contains a certain additive, are both higher than those of the electrolyte A without the additive. This additive helps the cell’s film formation reaction to be more complete.

- Comparative analysis of gas evolution volume/rate dynamics across electrolytes with varying additives enables rapid assessment of additive impacts on formation processes. Combined with three-electrode formation data, this approach facilitates targeted electrolyte formulation optimization.

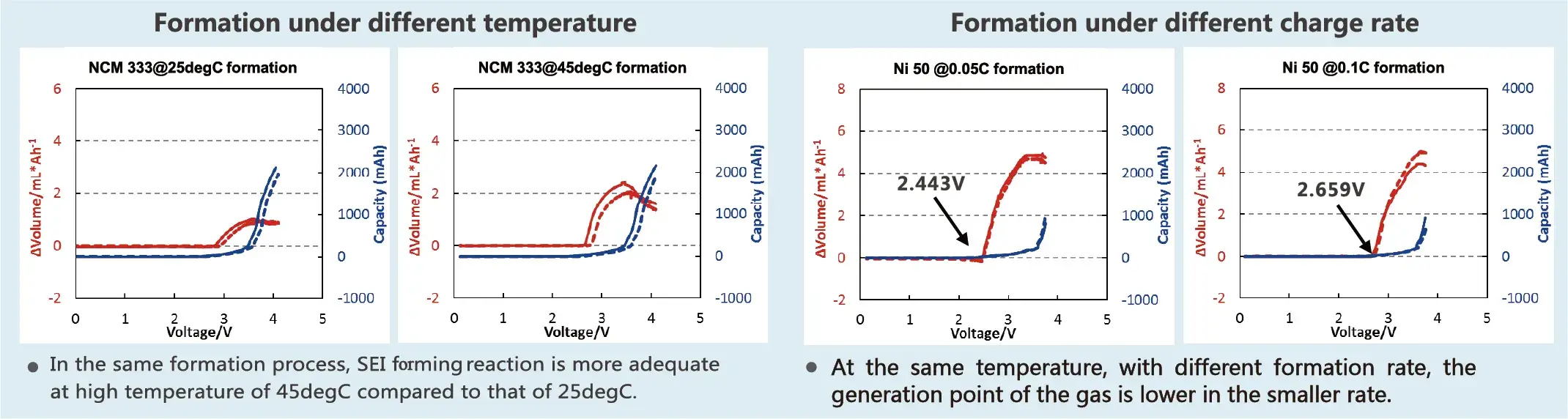

1.3 Different temperature and rate of formation conditions

- By setting different formation conditions, it can quantitatively obtain the starting voltage of the gas production under different formation conditions, as well as the gassing quantity and the gassing rate of different stage of the formation process, which can help to guide the improvement ofthe formationprocess and the technology of LIBs and raise the production efficiency of the enterprise.

2. Application Case: Overcharge Gassing

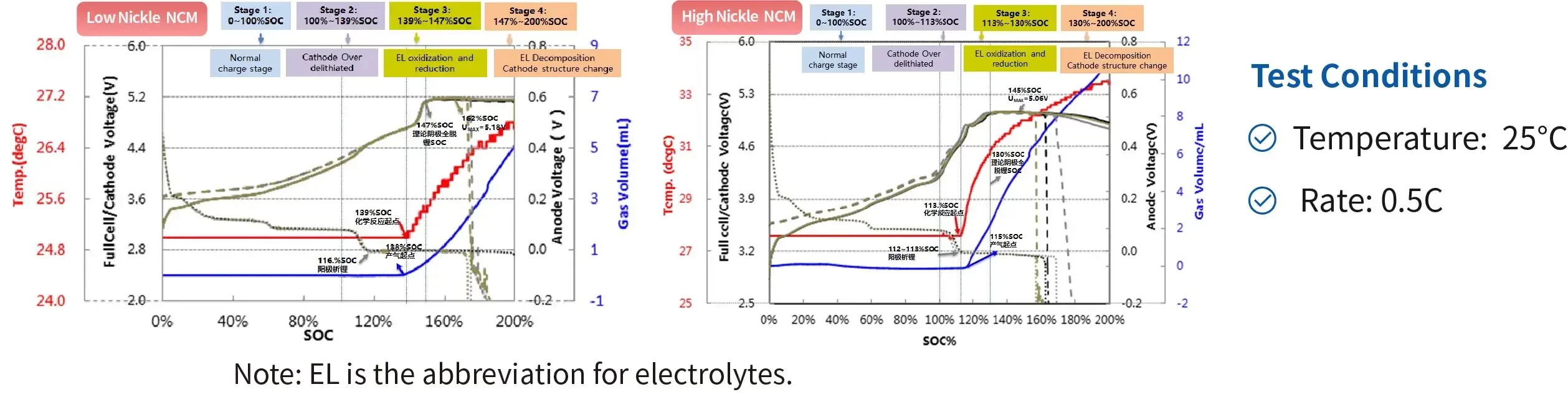

2.1 NCM cells with different Ni contents

Conclusion:

- When overcharged to a certain voltage, the slope of the volume change curve suddenly increases, the surface temperature of the cell sharply rises, and gas generation begins instantaneously.

- For ternary materials, as the nickel content increases, the gas generation initiation point corresponds to a State of Charge (SOC) that shifts from 138% to 115%.

- By monitoring the normal charging process and overcharge volume and temperature changes of the cell, and correlating them with the three-electrode curve, the voltage and reaction rate at which side reactions occur in large quantities, as well as the overcharge lithium plating voltage, can be accurately obtained. This quantitative data helps in analyzing and studying the overcharge performance of materials, allowing targeted improvements to be made, thereby enhancing R&D efficiency.

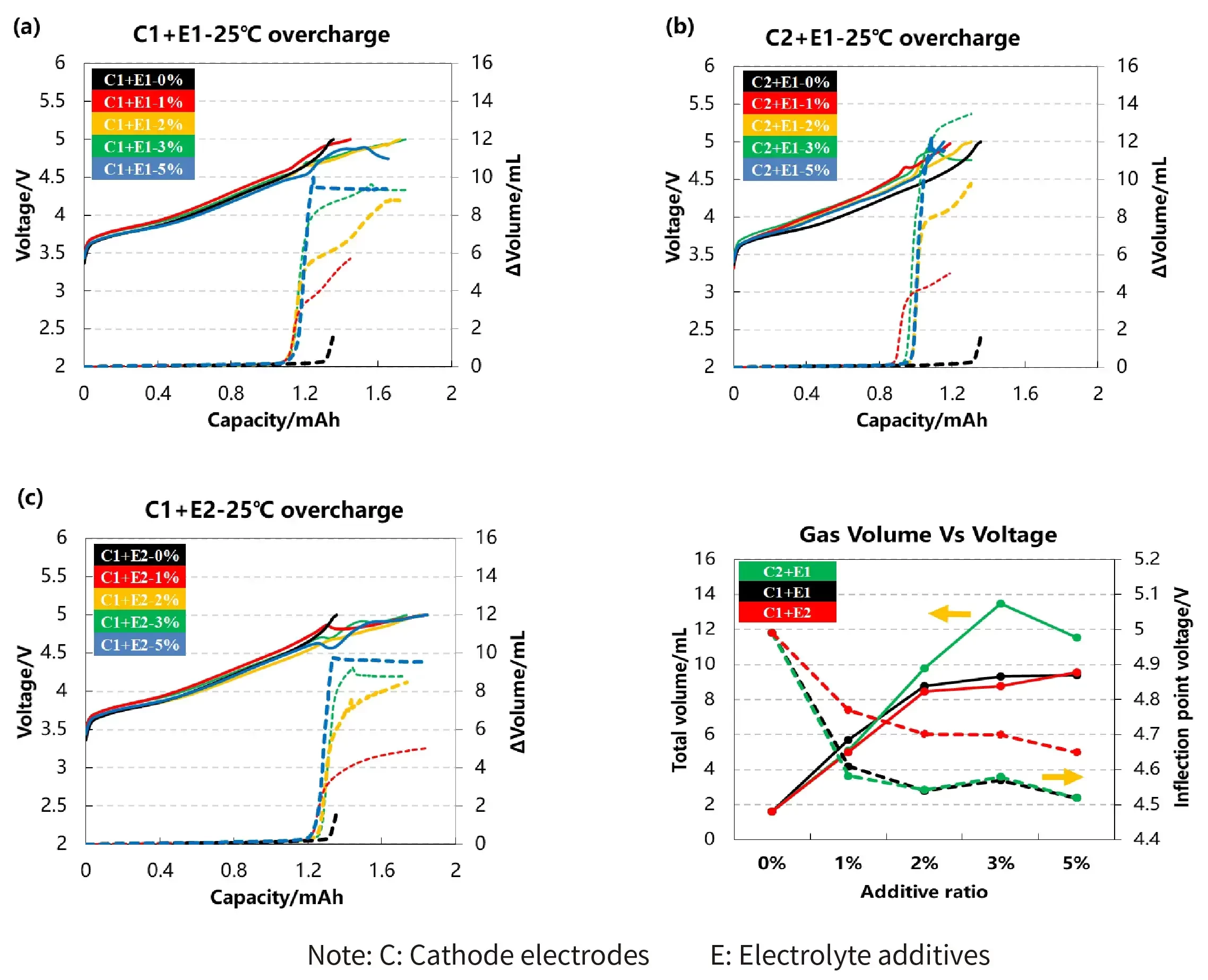

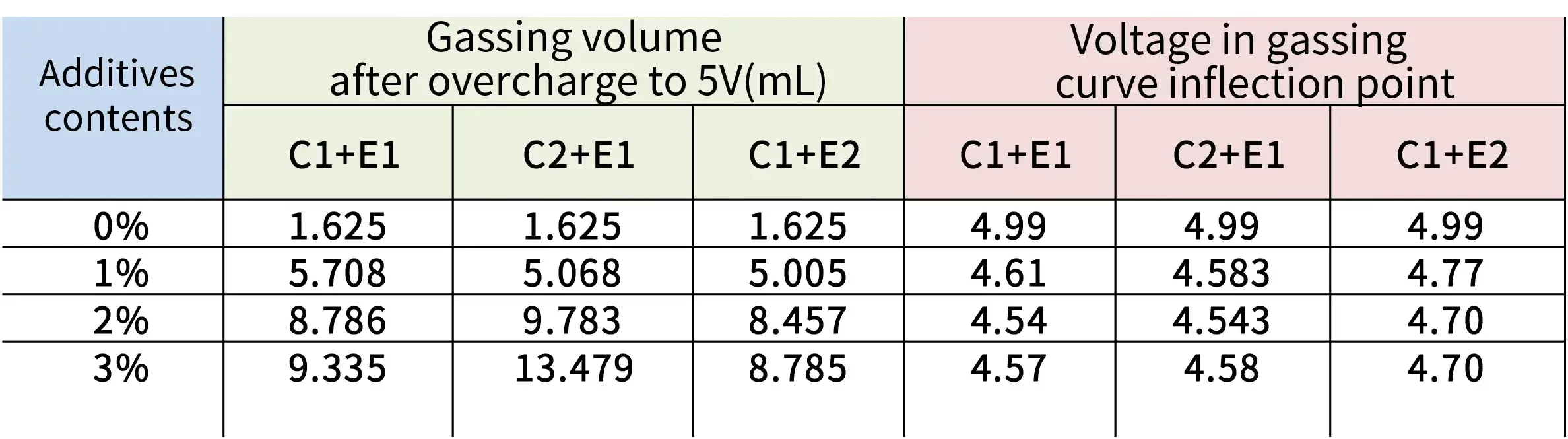

2.2 Cells with different cathodes and contents of electrolyte additives

Conclusion:

Conclusion:

- Both cathode material types and electrolyte additive concentrations significantly influence total gas generation in cells, while the additive type dictates the gas evolution potential.

- Consequently, strategic selection of cathode materials, electrolyte additive types, and their concentrations enables modulation of overcharge-induced gassing behavior.

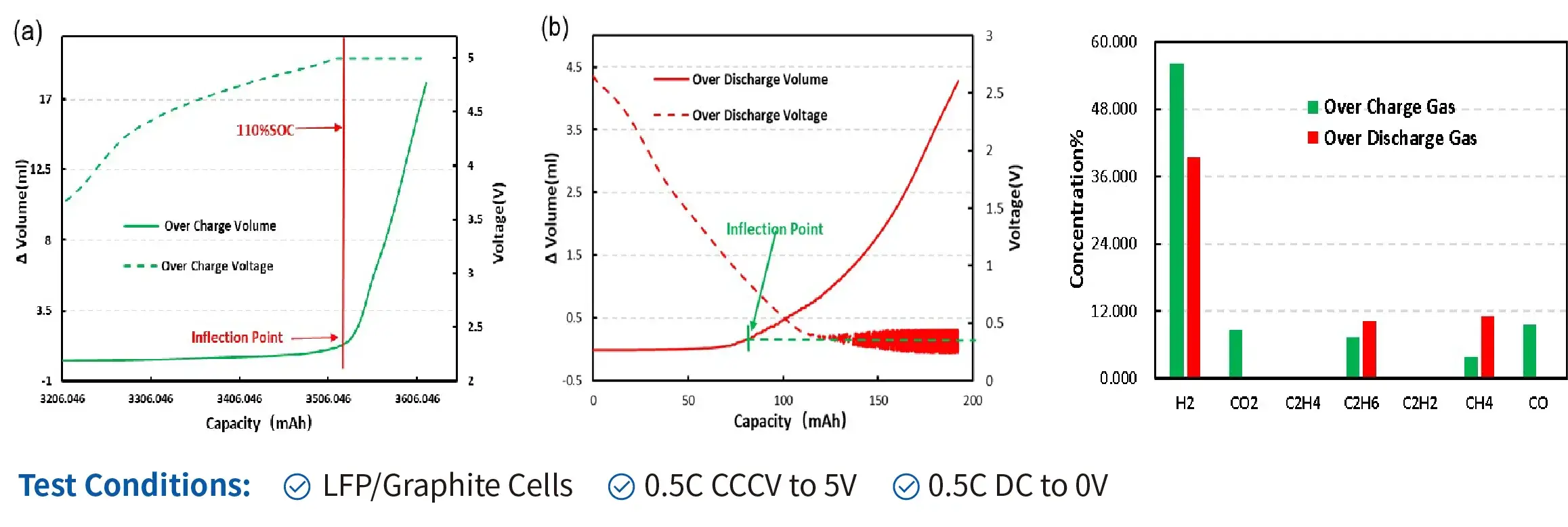

2.3 Overcharge and overdischarge of LFP batteries

Conclusion:

- As the cell is overcharged or overdischarged, the starting point of gas production can be detected in real time;

- Gas chromatography analyzes the gas composition under these two working conditions. in addition to the same gas type as the over-discharge cell, a relatively high content of CO and CO2 gas is also detected

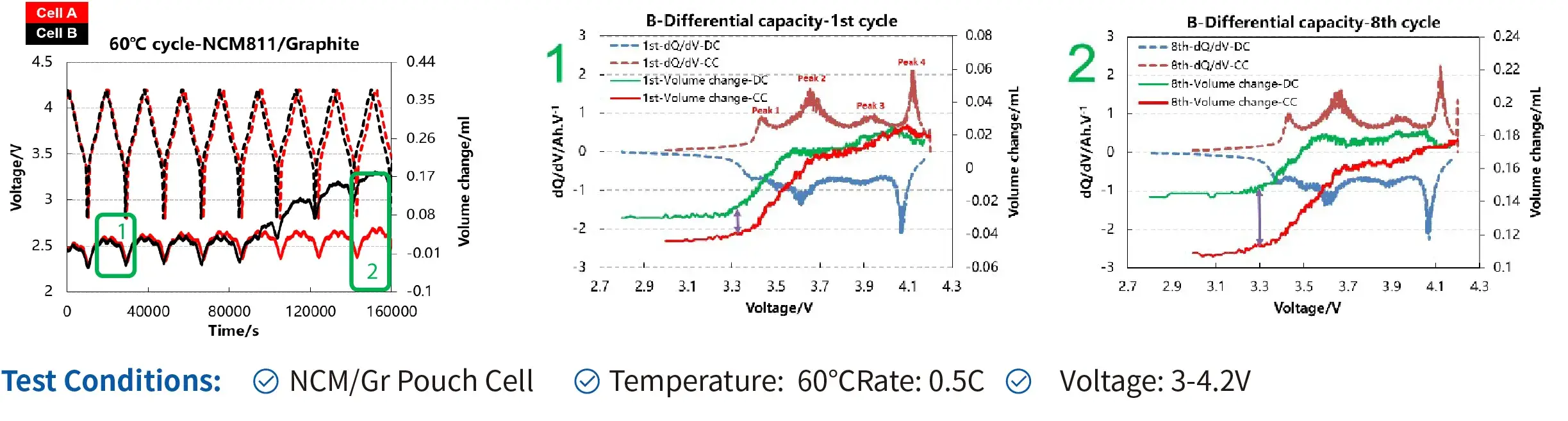

3. Application Case: Cycling Gassing

3.1 Cycle performance ofdifferent NCM cells

Conclusion:

- Cell-A and Cell B are made by diferent NCM matemals. The volume change of Cell-B is larger than that of Cell-A during the long-term cycling and the irreversible volume change also increase from 0.01 mL to 0.04 mL.

- It can help to quantitatively analyze the cycling performance of diferent materials, modify the materials in a targeted manner, and improve the R&D efficiency.

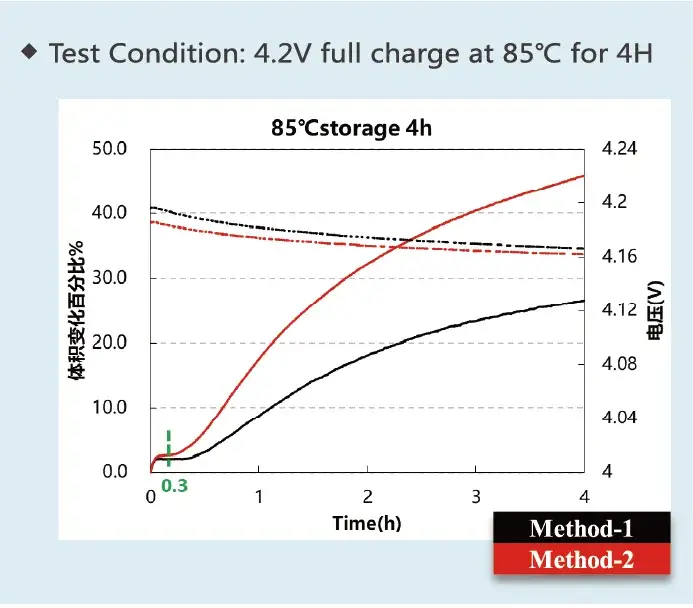

4. Application Case: Storage Gassing

4.1 Comparing NCM811 modified conditions

- At 85°C, both the voltage drop and the gas production of NCM811 modified by Method-1 arelarger than that of NCM811 modified by Method.

- It can used to compare the advantages of different modification methods of materials by using this in-situ method to continuously monitor the gas production during storage, which can help toimprove the efficiency of R&D.

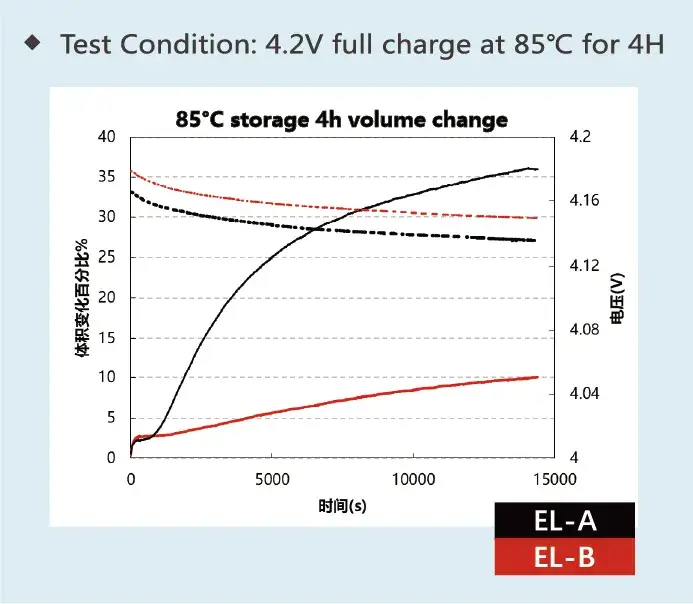

4.2 Comparing different type of electrode

- Cell-A and Cell-B are made by different electrolyte systems. From the volume change curves during the full-charge storage, it can be found that Cell-A produce more gas than Cell-B, indicating that the electrolyte of EL-A is much easier to produce the gas under high temperatre and high voltage.

- Help to quantitatively analyze the gas production performance of different electrolytes, modify the electrolytes in a targeted manner, and improve the R&D efficiency.

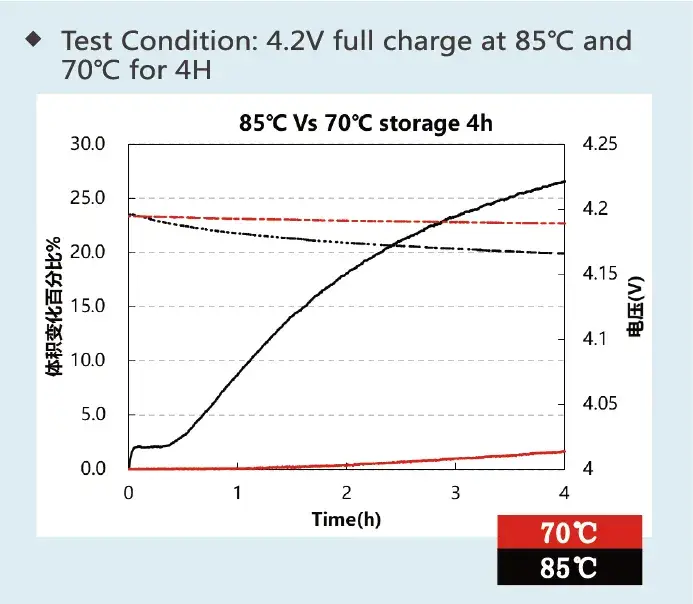

4.3 Comparing different storage temperature

- This cell has better storage performance at 70°C, while it produce more gas at 85°C

- By using in-situ method to continuously monitor the gas production during, the storage point and maximum point of gas production can be obtained, which is helpful for researchers to carry out the next step of R&D work in a targeted manner.

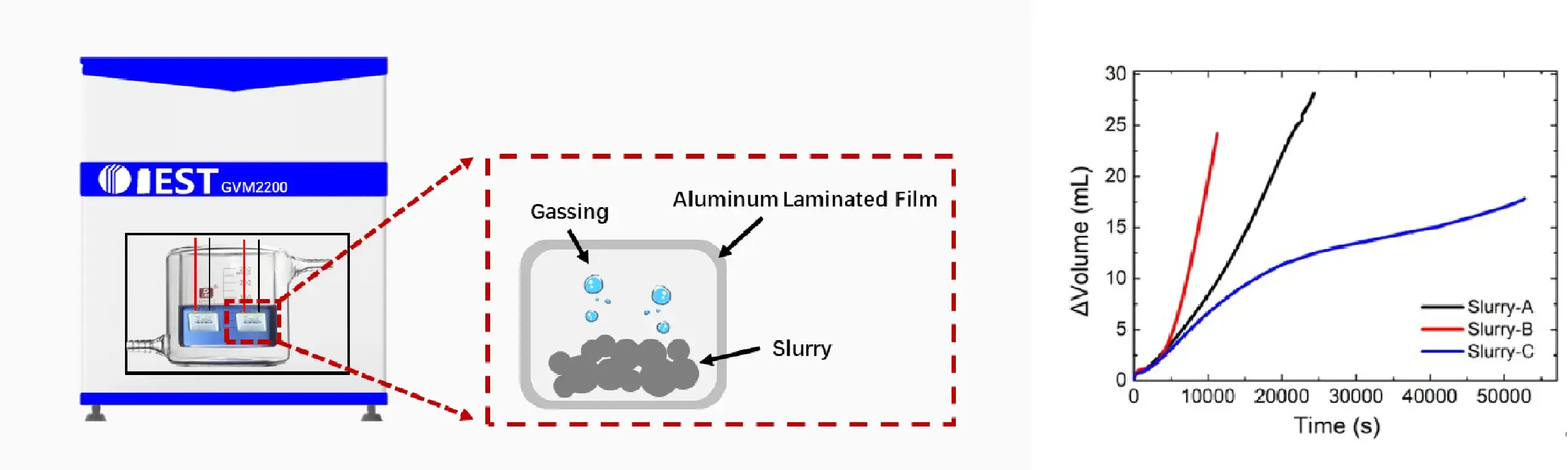

5. Application Case: Gassing from silicon-based slurries

Conclusion:

- Pre-magnesium or pre-lithiation treatment of silicon monoxide results in gas generation in the slurry.

- Lithium compensation additives in the cathode tend to decompose and generate gas during the actual slurry and lithium compensation process.

- IEST in-situ gas analyzers (GVM2200) can be used to characterize slurry gas production in real time;

Video