-

iestinstrument

A Comprehensive Guide to Silicon-Based Anode Challenges and Solutions

1. Introduction

The rapid growth of the new energy sector is driving demand for lithium-ion batteries with higher energy density and longer cycle life. Conventional graphite anodes, with a theoretical specific capacity of only 372 mAh/g, are increasingly insufficient for future energy density requirements. Silicon-based anodes have emerged as a promising next-generation alternative due to their high theoretical capacity, natural abundance, and suitable lithium intercalation potential. However, several technical challenges impede their large-scale commercialization. This article summarizes the main pain points encountered during production and use of silicon anodes, and outlines practical solutions — including testing and diagnostic tools offered by IEST Instrument — to help R&D and manufacturing teams accelerate deployment

2. Silicon Anode Challenges 1: Significant Volume Expansion

The lithium storage mechanism in silicon involves alloying/dealloying, distinct from the intercalation mechanism in graphite. This process induces massive volume changes; silicon particles can expand by up to 300% when forming the Li15Si4 phase[1]. Silicon oxide (SiOₓ) anodes exhibit lower expansion, around 120%, due to the presence of oxygen, yet this remains far greater than the 10-12% expansion typical of graphite. This severe swelling leads to particle pulverization, degrading electrical contact with conductive agents. Furthermore, it causes continuous cracking and reformation of the Solid Electrolyte Interphase (SEI), consuming active lithium and electrolyte, which accelerates capacity fade and battery aging.

2.1 Nanoscale Engineering and Carbon Coating

Nano-coating with carbon coated is one of the effective methods to solve the expansion of silicon anode. Studies have shown that as long as the silicon particles are reduced to less than 150nm, the expansion rate will drop significantly from 300% to about 30%, and then the outer layer will be coated with carbon, which can act as a buffer layer, thereby further reducing the volume expansion of the silicon-carbon anode Generally, silicon-carbon materials can be prepared by methods such as chemical vapor deposition, high-energy ball milling, and pulsed laser deposition, the main coating structures are divided into the following four types: (1) directly wrapping the carbon shell on the nano-silicon particles, similar to glutinous rice balls; (2) leaving a layer of space while wrapping the nano-silicon particles, like eggs; (3) Use two pieces of carbon materials to clamp nano-silicon particles to make a structure similar to a hamburger; (4) Similar to a watermelon, in which the watermelon seeds are nano-silicon particles, the watermelon flesh is loose graphite, and the watermelon rind is carbon deposition.

2.2 Porous Structure Design

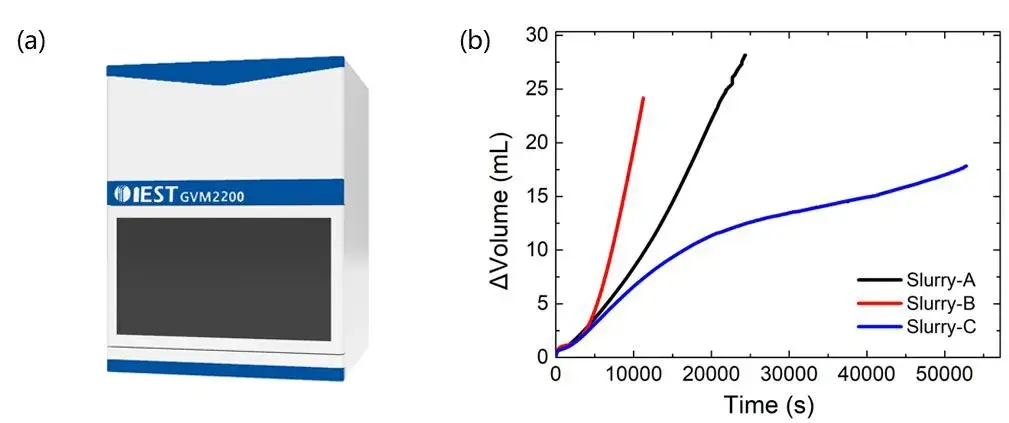

Creating porous structures accommodates volume expansion by providing internal void space, preventing macroscopic electrode deformation. Methods include fabricating hollow Si/C core-shell materials, yolk-shell Si/C composites, and silicon sponge architectures. To facilitate rapid evaluation, IEST offers the Silicon-based Anode In-situ Rapid Swelling Screening System (RSS1400). This system uses model coin cells for in-situ electrode-level expansion testing, streamlining the process, reducing costs, and cutting the evaluation cycle from weeks down to 1-2 days. Figure 1(a) shows the RSS1400, while Figure 1(b) compares expansion for three different Si/C structures.

Figure 1. (a) Silicon-based anodes expansion in-situ rapid screening system (RSS1400, IEST); (b) Comparison of expansion of silicon carbon anode materials with three different structural designs.

2.3 Advanced Binders for Silicon Anodes

Specialized binders can effectively restrain silicon particle expansion and suppress pulverization, enhancing cycle stability. Traditional PVDF binders, relying on weak van der Waals forces, are inadequate for large volume changes[2]. Aqueous binders like Carboxymethyl Cellulose (CMC) and Polyacrylic Acid (PAA) are more suitable. SBR/CMC offers good viscoelasticity and dispersion, while PAA’s simpler structure aids synthesis. Research by S. Komaba et al.[3] indicates PAA can form a protective, SEI-like layer on silicon, effectively suppressing electrolyte decomposition. IEST’s In-situ Swelling Analysis System(SWE2110) quantitatively evaluates the swelling suppression efficacy of different binders, as demonstrated for four binders in Figure 2. Other binders like sodium alginate, carboxymethyl chitosan, and polyacrylonitrile can also be assessed using the SWE2110.

Figure 2. In-situ expansion analysis system (SWE2110, IEST) and the comparison of the expansion thickness of silicon carbon anodes under the action of four different binders

3. Silicon Anode Challenges 2: Gas Generation During Slurry Mixing

Surface modification and element doping can reduce expansion but may introduce instability. Factors like surface alkalinity or incomplete coating can expose nano-silicon, leading to reactions with hydroxyl ions and gas generation during slurry preparation. Pre-lithiation or pre-magnesiation of SiOₓ improves initial Coulombic efficiency but can cause processing issues like gas generation and coating adhesion problems.

IEST’s In-situ Gassing Volume Monitor (GVM2200) can monitor the gas production behavior of the silicon-based anodes slurry in real time and quantitatively (as shown in Figure 3(a)). It is equipped with high-precision sensors that can effectively monitor small changes in gas production (with a resolution of up to 1μL), assisting R&D personnel to reveal the mechanism of slurry gas production and formulate effective suppression measures. Figure 3(b) shows the variation of gas production of three different SiC slurries with homogenization time when homogenized in aqueous solvent. From the point of view of slope, slurry B produced gas most rapidly; and from the point of view of gas production, slurry A produced most gas. This result can assist researchers to adjust the modification process of silicon-based materials and accelerate the development of high-performance silicon-based anodes materials.

Figure 3. (a) GVM2200 system; (b) Gas production of three different Si/C slurries during mixing in aqueous solvent

4. Silicon Anode Challenges 3: Poor Electrical Conductivity

The electronic conductivity of active material particles critically impacts battery performance, especially rate capability. Compared to carbon, silicon’s conductivity is nearly 100 million times lower, and SiOₓ is even more resistive. Poor conductive agent dispersion or weak electrical contact with active particles increases polarization and accelerates aging.

4.1 Carbon Coating and Conductive Agents

Carbon coating combined with appropriate conductive agents significantly enhances the electronic conductivity of silicon-based materials. Common carbon sources include phenolic resin, glucose, graphene oxide, and carbon nanotubes (CNTs). CNTs, particularly single-walled CNTs (SWCNTs), are crucial conductive agents for silicon anodes. Their flexibility and strong van der Waals forces contribute to cycling stability and provide a buffer against silicon expansion. In evaluating the electrical conductivity of silicon materials, IEST Powder Resistivity & Compaction Density Measurement System (PRCD3100) can be used for testing. featuring both two-probe and four-probe methods (Figure 4) at the same time, and can evaluate and compare the conductivity of different carbon-coated silicon-based materials. In addition, the equipment can also carry out a variable pressure test of up to 200MPa to provide users with the change of resistance and compaction density of silicon-based powder under different pressures, so as to guide calendaring processes of silicon-based anodes.

Figure 4. The physical picture and test principle of the powder resistance meter (PRCD3100, IEST) and the comparative evaluation of the electrical conductivity of different carbon-coated silicon-based anode materials.

5. Silicon Anode Challenges 4: Low Initial Coulombic Efficiency (ICE)

The formation process, which creates the SEI on silicon particles, consumes active lithium from the electrolyte or cathode. Due to the high surface area of nano-silicon, this consumption is substantial, leading to significant irreversible capacity loss in the first cycle (ICE as low as 70-90%). SiOₓ anodes typically exhibit even lower ICE, a major barrier to their commercialization.

5.1 Prelithiation Techniques

Prelithiation is an effective strategy to improve ICE, particularly for SiOₓ. The main approaches are anode prelithiation and cathode lithium supplementation.

Anode Prelithiation, noted for its high capacity compensation, includes methods like lithium foil and stabilized lithium metal powder (SLMP). Lithium foil prelithiation uses a potential difference to drive Li⁺ into the anode but can be difficult to control precisely. SLMP, developed by FMC, involves lithium powder coated with a thin Li₂CO₃ layer, which can be sprayed onto the dry anode or added during slurry mixing.

Cathode Lithium Supplementation offers better compatibility with existing battery manufacturing processes, being safer, more stable, and cost-effective, making it a highly promising technology. Generally speaking, positive electrode lithium supplements can be mainly divided into the following three categories: one is to use binary lithium-containing compounds to supplement lithium, such as Li2O,Li2O2 and Li3N. This type of substance has a high specific capacity, and only a small amount of addition can achieve the lithium supplement effect, but the disadvantage is that it has poor stability, and it is easy to decompose and generate gas during the actual homogenization and lithium supplement process. Theas production can also be monitored in real time by using the IEST in-situ gas production volume monitor (GVM2200, IEST). The specific experimental process is shown in Figure 5. The second is to use lithium-rich compounds to replenish lithium, such as Li5FeO4 and Li2NiO2; the third is to use lithium compounds to replenish lithium, such as Li2S/Co,LiF/Co and Li2O/Co. These types of substances have their own advantages and disadvantages. Therefore, in the future, positive electrode lithium supplement materials need to be developed in the direction of high chemical stability, low decomposition potential, no gas production, and high lithium delithiation capacity.

![]()

Figure 5. Flowchart of measuring Si content in silicon carbon materials using in-situ gas volume monitor (GVM2200, IEST)

6. Silicon Anode Challenges 5: Monitoring Material Composition and Ratios

Rapidly determining the Si/C ratio, Si/O ratio, or nano-silicon content is crucial for assessing process stability and estimating specific capacity, thereby enhancing R&D efficiency.

Analytical Techniques

-

High-Frequency Infrared Carbon-Sulfur Analyzer: Measures carbon content. A sample (~0.05g) is mixed with flux and combusted in oxygen.

-

Inert Gas Fusion Infrared Absorption (ONH Analyzer): Determines oxygen content in SiOₓ anodes. A sample (~0.03g) is melted in a pulse furnace under inert gas.

-

Silicon Molybdenum Blue Spectrophotometry: Detects silicon content. This method involves fusion with strong alkali, pH adjustment, addition of ammonium molybdate, and spectrophotometric detection of SiO₂ concentration. However, it cannot distinguish between Si and SiO₂ and requires careful, error-prone procedures with specialized containers.

-

X-ray Diffraction (XRD): A semi-quantitative, non-destructive method offering speed, good reproducibility, and clear differentiation between phases without chemical processing.

7. Practical Recommendations for R&D and Scale-up

-

Combine nanosized Si (<150 nm) with a robust carbon shell and consider yolk–shell or hollow architectures for best cycle life.

-

Use PAA or SBR/CMC binders for improved adhesion and elastic accommodation of volume change.

-

Integrate real-time gas monitoring (GVM2200) into process development to identify problematic chemistries early.

-

Employ powder resistivity and compression testing (PRCD3100) to optimize conductive networks and calendering pressures.

- Adopt controlled pre-lithiation strategies (SLMP or compatible cathode additives) while monitoring gas and decomposition behavior.

8. Summary

Silicon-based andoes materials have become the most commercially promising next-generation anode materials, and their technical routes are mainly divided into silicon carbon and silicon oxygen. The more mature commercial products at this stage are mainly silicon-oxygen materials, but in the future they will gradually move closer to silicon carbon anode materials. This article summarizes some industry pain points in the production and use of silicon-based anodes material, such asvolume expansion, slurry gas generation, poor conductivity, and low ICE. In order to solve these problems, it is not only necessary for upstream materials companies and downstream cell companies to integrate advantageous resources to accelerate the development of micro-mechanisms and preparation processes, but also for testing equipment companies to develop convenient, fast and effective testing instruments. As a comprehensive solution provider in the lithium battery testing industry, IEST is committed to providing the most professional solutions for the research and development of silicon-based anodes materials in terms of expansion, gas production, and electrical performance testing, and to help the large-scale commercialization of silicon-based anodes materials!

9. References

[1] M. Ashuri, Q.R. He and L.L. Shaw, Silicon as a potential anode material for Li-ion batteries: where size, geometry and structure matter. Nanoscale 8 (2016) 74–103.

[2] Z.H. Chen, L. Christensen, and J.R. Dahn, Large-volume-change electrodes for Li-ion batteries of amorphous alloy particles held by elastomeric tethers. Electrochem. Commun. 5 (2003) 919-923.

[3] S. Komaba, K. Shimomura, N. Yabuuchi, T. Ozeki, H. Yui and K. Konno, Study on polymer binders for high-capacity SiO negative electrode of Li-ion batteries. J. Phys. Chem. C 115 (2011) 13487-13495.

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.